A kind of vulcanization active agent for blended rubber and preparation method thereof

A vulcanization activator and rubber technology, which is applied in the field of vulcanization activator for blended rubber and its preparation, can solve the problems of reducing the mechanical properties of blended rubber, inconsistent zinc oxide dispersion, affecting the vulcanization performance of blended rubber, etc., to prevent Agglomeration, good reinforcement effect, small particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

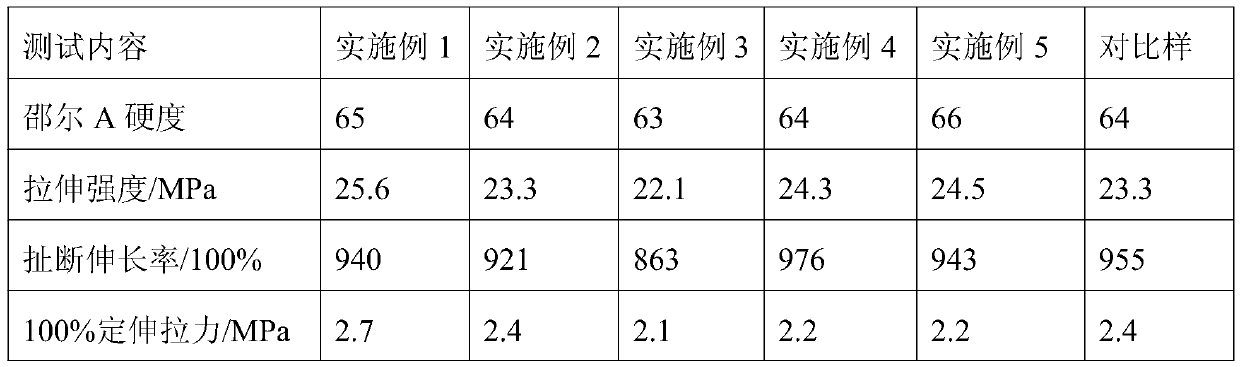

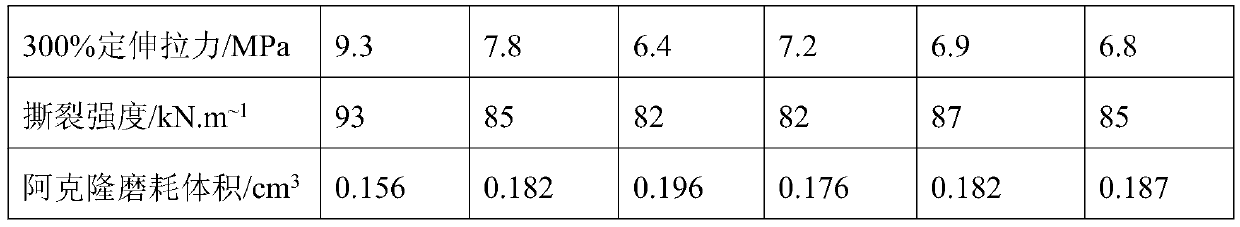

Examples

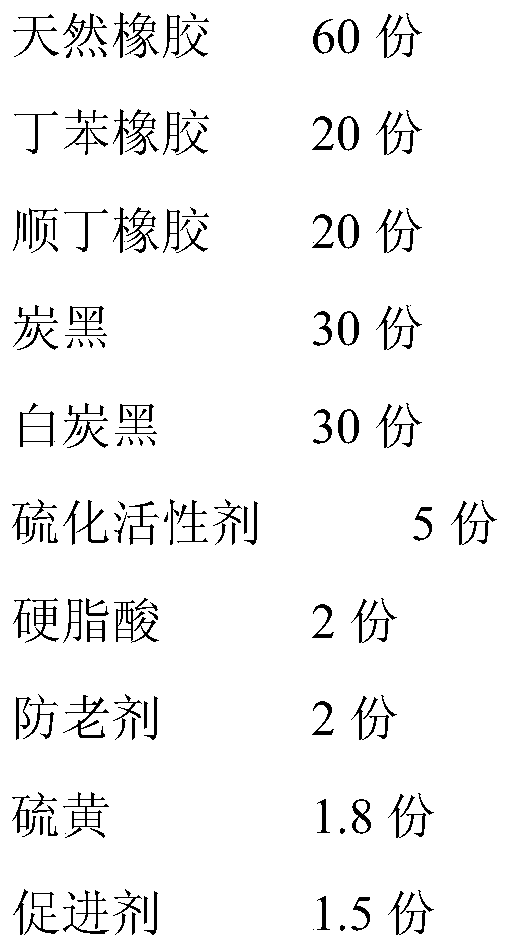

Embodiment 1

[0021] This embodiment provides a vulcanization activator for blended rubber, its raw material includes the following components by weight: 60 parts of nano-zinc oxide, 40 parts of zinc methacrylate, 2 parts of oligoester, 1 part of silane coupling agent, 1 part of dispersant; wherein, the oligomer is a mixture of oligomer 12-I and methacrylic oligomer in a weight ratio of 8:1, the dispersant is a carboxylate dispersant, and the silane The coupling agent is KH-550, and nano zinc oxide and zinc methacrylate are prepared by chemical deposition.

[0022] This embodiment also provides a method for preparing a vulcanization activator for blended rubber, comprising the following steps:

[0023] Step 1, 11.8g sodium hydroxide is mixed with 15% solution; 20g zinc chloride is made into 20% solution, under stirring condition, zinc chloride solution is slowly added dropwise in the sodium hydroxide solution, stirring speed is 200r / min, after the addition of the zinc oxide solution, adjus...

Embodiment 2

[0028] This embodiment provides a vulcanization activator for blended rubber, the raw material of which includes the following components by weight: 50 parts of nano-zinc oxide, 50 parts of zinc methacrylate, 2 parts of oligoester, 1 part of silane coupling agent, 1 part of dispersant; wherein, the oligomer is a mixture of oligomer 12-1 and methacrylic oligomer in a weight ratio of 8:1, the dispersant is a silicate dispersant, and the silane The coupling agent is KH-791, and nanometer zinc oxide and zinc methacrylate are prepared by chemical deposition.

[0029] This embodiment also provides a method for preparing a vulcanization activator for blended rubber, comprising the following steps:

[0030] Step 1, 11.8g sodium hydroxide is mixed with 10% solution; 20g zinc chloride is made into 30% solution, under stirring condition, zinc chloride solution is slowly added dropwise in the sodium hydroxide solution, stirring speed is 200r / min, after the addition of the zinc oxide solu...

Embodiment 3

[0035] This embodiment provides a reactive crosslinking agent for blended rubber, its raw materials include the following components by weight: 45 parts of nano-zinc oxide, 55 parts of zinc methacrylate, 2 parts of oligoester, and 1 part of silane coupling agent , 0.5 part of dispersant; Wherein, described oligopolyester is the mixture of oligopolyester 12~I and methacrylic acid oligopolyester with a weight ratio of 8:1, and described dispersant is sodium dodecylsulfonate, The silane coupling agent is KH-580, and the nanometer zinc oxide and zinc methacrylate are prepared by chemical deposition.

[0036] Step 1, 11.8g sodium hydroxide is mixed with 15% solution; 20g zinc chloride is made into 20% solution, under stirring condition, zinc chloride solution is slowly added dropwise in the sodium hydroxide solution, stirring speed is 200r / min, after the addition of the zinc oxide solution, adjust the pH of the solution between 8 and 12, then fully stir the reaction for 0.5 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com