Composite bumper and preparation method thereof

A bumper and composite film technology, applied to bumpers and other directions, can solve problems such as low shrinkage rate, high heat distortion temperature, and complex raw materials, and achieve the effect of improving impact resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

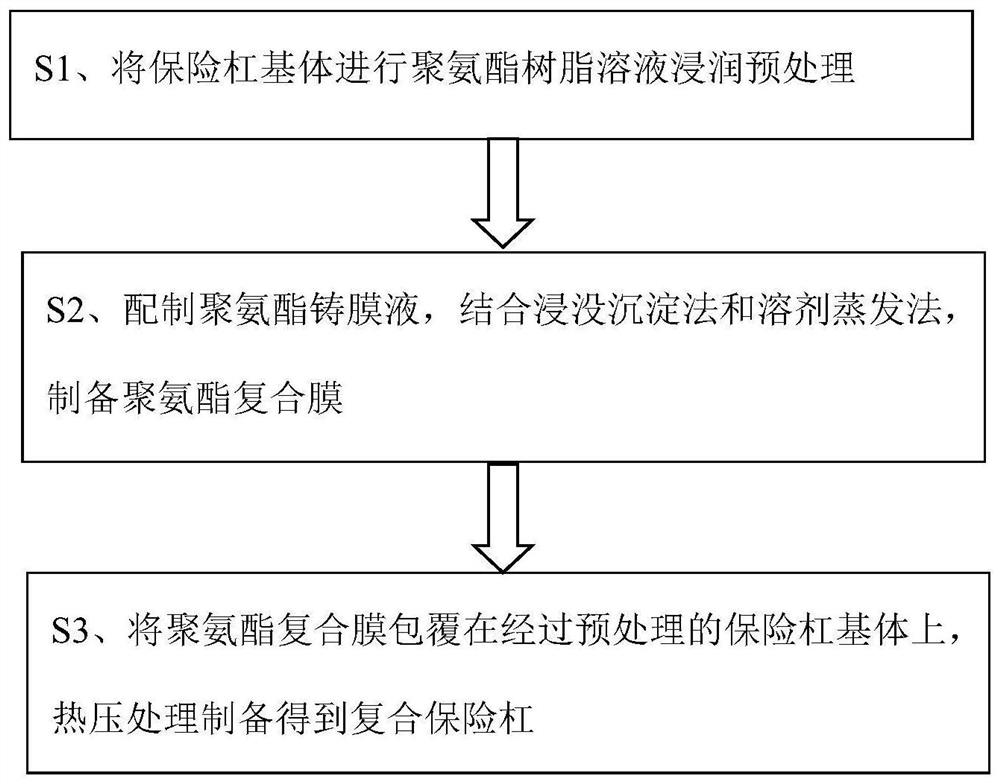

[0032] see figure 1 As shown, the invention provides a kind of preparation method of composite bumper, comprises the steps:

[0033] S1. Pretreatment: immerse the bumper base in the polyurethane resin solution, take it out after fully infiltrating, and then dry and pretreat the bumper base with the polyurethane resin on its surface at 80°C for 10-15s;

[0034] S2, the preparation of polyurethane composite film;

[0035] S3. Coating and hot pressing: Lay a layer of polyurethane composite film described in step S2 on the bumper substrate pretreated in step S1, and heat press at 100-140°C for 5-15 minutes to prepare a composite bumper .

[0036] Wherein, step S2 comprises the following steps:

[0037] S21. Preparation of casting solution: prepare a mixed solution of toluene and N,N-dimethylformamide, then add triphenyl phosphate, inorganic flame retardant, stabilizer and thermoplastic polyurethane particles in sequence and mix evenly, stir until completely dissolved and vacuum ...

Embodiment 1

[0048] Preparation method of composite bumper:

[0049] S1. Pretreatment: immerse the bumper base in the polyurethane resin solution, take it out after fully infiltrating, and then dry the bumper base loaded with the polyurethane resin on the surface for 10s at 80°C; wherein, the polyurethane The resin solution is composed of 30wt% polyurethane resin and 70wt% N,N-dimethylformamide.

[0050] S2, the preparation of polyurethane composite film:

[0051] S21. Preparation of casting solution: Add organic flame retardant triphenyl phosphate (TPP) into toluene solvent to disperse evenly, stir at 300r / min for about 20min; then add N,N-dimethylformamide (DMF) solvent After mixing evenly, add thermoplastic polyurethane particles (TPU), inorganic flame retardant magnesium hydroxide and stabilizer, stir at 600r / min for 4 hours, and the stirring temperature is 25°C. Membrane fluid;

[0052] Wherein, in the casting solution, the mass fraction of the mixed solvent of toluene and N,N-dime...

Embodiment 2-6

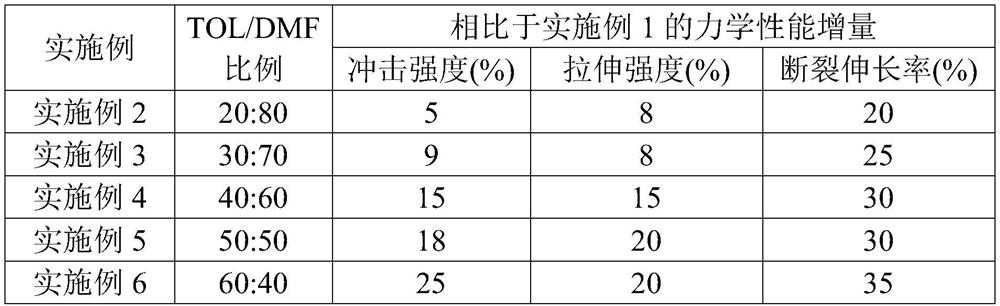

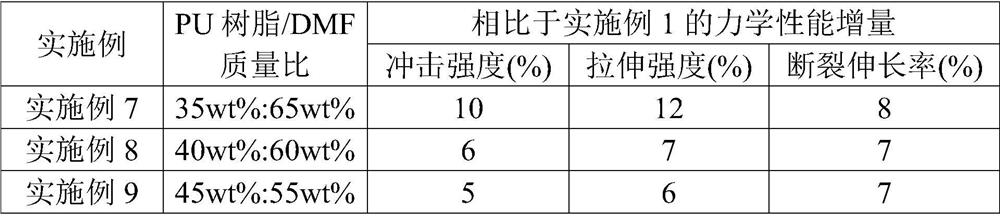

[0067] The difference from Example 1 is that in step S2, the ratio of TOL / DMF in the casting solution is different, and the other steps are basically the same, and will not be repeated here.

[0068] Table 2 is TOL / DMF ratio setting and mechanical performance parameter in embodiment 2-6

[0069]

[0070] Embodiment 1 and embodiment 2-6 are analyzed in conjunction with table 2:

[0071] Along with the increase of toluene ratio, the impact resistance of the composite bumper prepared by the present invention increases, and this is mainly because when adopting the polyurethane composite film that toluene and nitrogen nitrogen dimethylformamide solvent system prepares, immersion in coagulation bath During the precipitation process, the increase in the proportion of hydrophobic toluene can slow down the diffusion rate of the solvent in the polyurethane film casting liquid, so that water cannot diffuse into the polyurethane film, and toluene can only swell the polyurethane, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com