Composite material for vehicle bumper and preparation method thereof

A technology for automobile bumpers and composite materials, which is applied in the field of modified polypropylene composite materials and its preparation, which can solve the problems of poor low-temperature brittleness of PP materials, poor material flow properties, and decreased rigidity and strength, and achieve good molding and processing performance , Good impact resistance, low molding shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

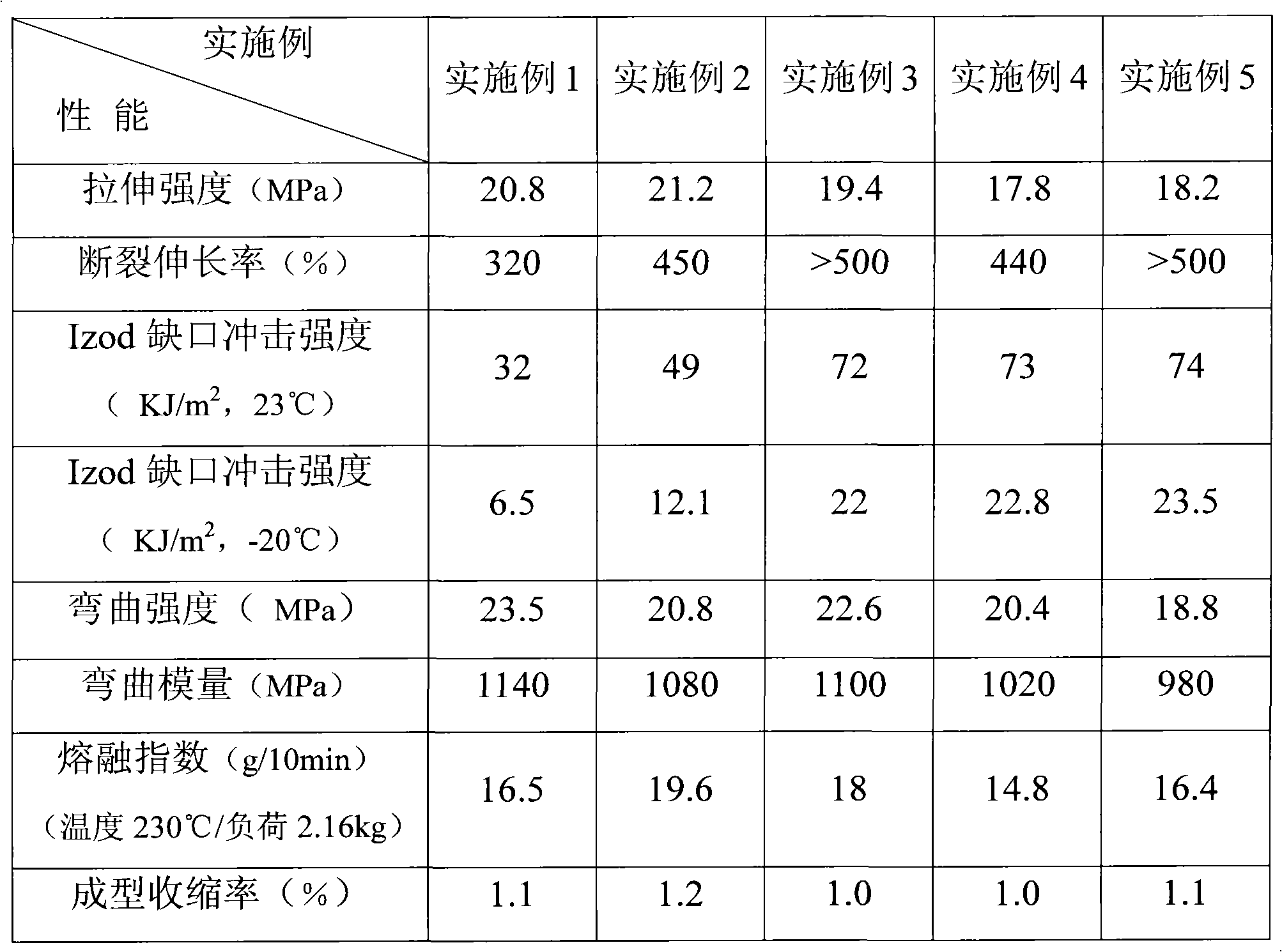

Examples

preparation example Construction

[0025] The specific preparation process is:

[0026] ①Raw materials are evenly mixed: according to the proportion, polypropylene, metallocene ethylene-hexene copolymer, nano-calcium carbonate, antioxidant and lubricant are mixed evenly in the mixer;

[0027] ② Mixing in the twin-screw extruder: Add the mixture obtained in step ① into the twin-screw extruder for mixing. The temperature of the twin-screw extruder is set between 170 and 220°C, and the mixture is The total residence time in the extruder is 3-8min, and the speed of the twin-screw extruder is 300-350r.min -1 ;

[0028] ③The obtained material is extruded, cooled, and pelletized to obtain composite materials for automobile bumpers.

[0029] The metallocene ethylene-hexene copolymer selected in the composite material has low crystallinity. Compared with the traditional elastomer EPDM, there is no double bond in the molecular chain, and it has higher thermal stability and anti-ultraviolet stability. As the polypropyle...

Embodiment 1

[0032] Mix 74 parts of polypropylene, 5 parts of metallocene ethylene-hexene copolymer, 20 parts of nano-calcium carbonate, 0.5 part of antioxidant and 0.5 part of ethylene bis-stearamide in a high-speed mixer, and then feed into the twin-screw Extruder, the blend is mixed in the twin-screw extruder, and the temperature of each section of the twin-screw extruder is set to T 1 =170°C, T 2 =180°C, T 3 =190°C, T 4 =205°C, T 5 =210°C, T 6 =220°C, the total residence time of the mixture in the twin-screw extruder is 3-8min, and the rotational speed of the twin-screw extruder is 330r / min; extruded and granulated, and finally the special material for automobile bumper is obtained.

Embodiment 2

[0034] 80 parts of polypropylene, 9.4 parts of metallocene ethylene-hexene copolymer, 10 parts of nano-calcium carbonate (the particle size of nano-calcium carbonate is less than 100nm, whiteness ≥ 94%, activation rate ≥ 95%), 0.4 part of antioxidant Agent and 0.2 parts of lubricant are mixed evenly in a high-speed mixer, and then fed into a twin-screw extruder, and the blend is mixed in the twin-screw extruder, and the temperature of each section of the twin-screw extruder is set to T 1 =170°C, T 2 =190°C, T 3 =195°C, T 4 =200°C, T 5 =205°C, T 6 = 210°C, the total residence time of the mixture in the twin-screw extruder is 3 to 8 minutes, and the rotational speed of the twin-screw extruder is 300r / min; finally extruded and granulated to finally obtain special materials for automobile bumpers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com