Aggregate surface strengthening method and equipment

A surface strengthening and aggregate technology, applied in the field of aggregate surface strengthening, can solve the problem that porous and macroporous aggregates are not suitable for strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

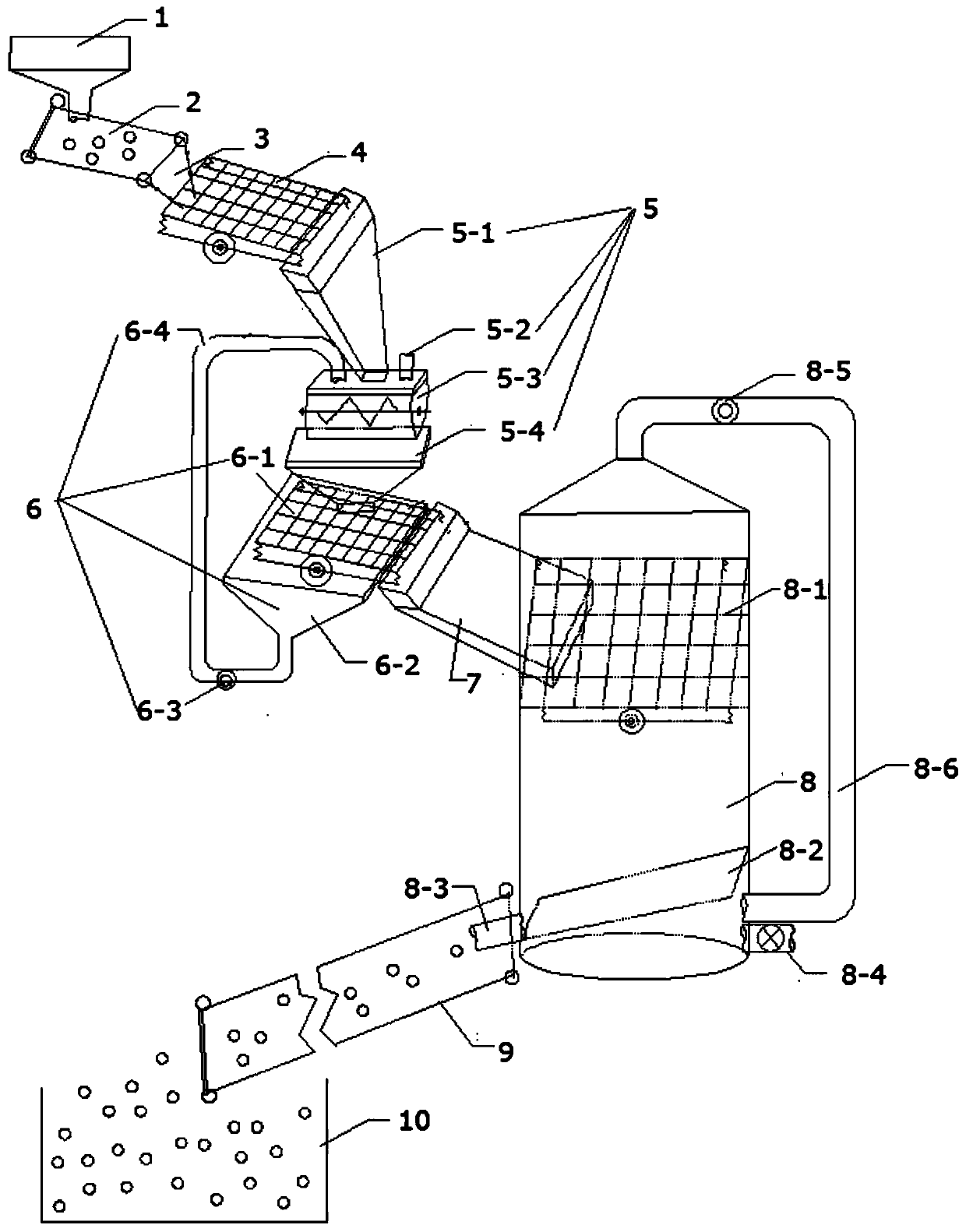

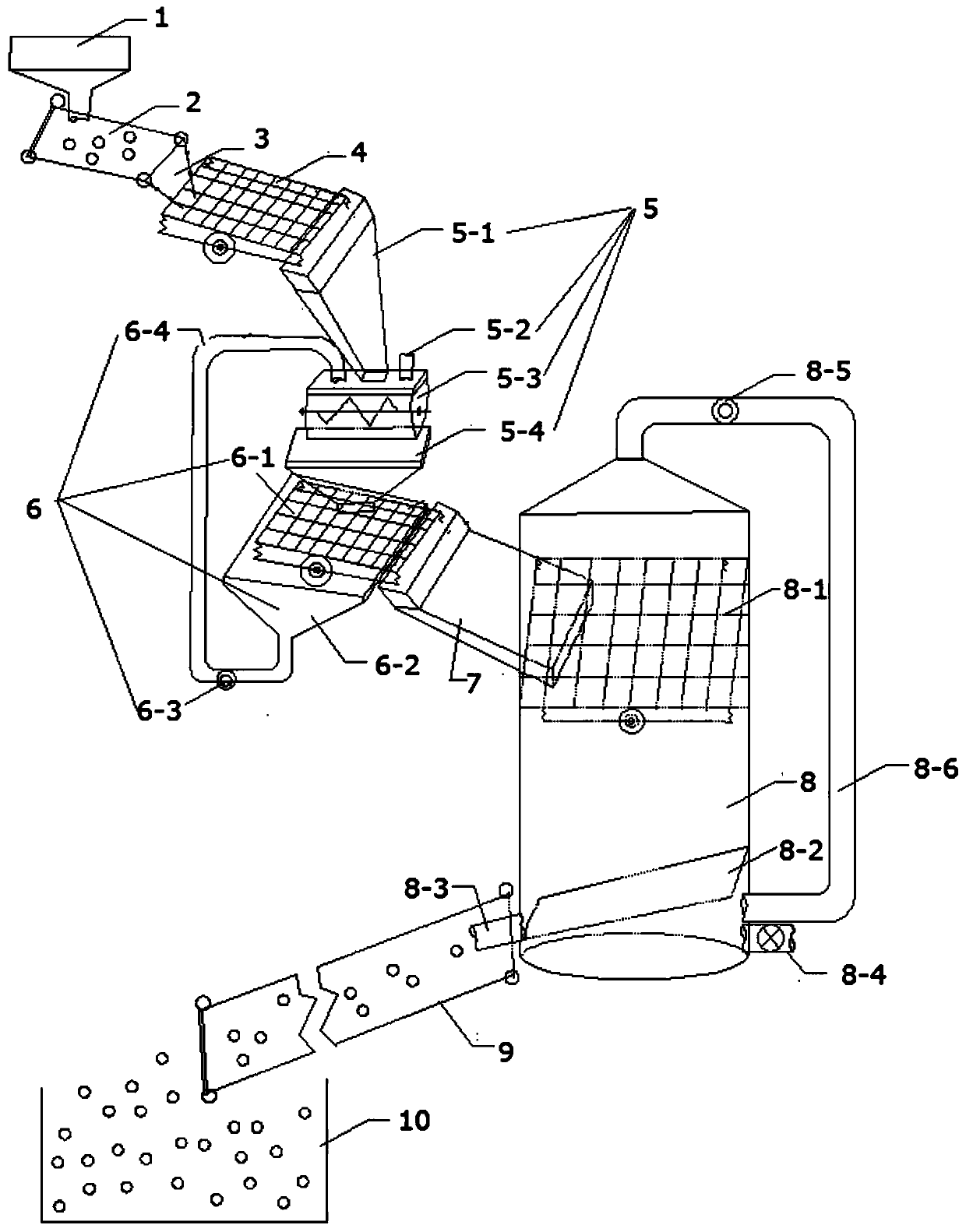

[0081] After autoclaved aerated concrete block aggregates are subjected to self-impact and friction shaping treatment by the aggregate shaping part 1, shaped coarse aggregates close to round or oval are obtained; into the wetting part 3 and sprayed with water mist to obtain a wet aggregate with a moisture content of 18%;

[0082] The wet aggregate falls into the first vibrating sieve 4 for the first sieving treatment, the under-sieve part is wet aggregate with a single particle size, the single particle size wet aggregate particle size is 6mm, and the cylinder compressive strength is 1.6 MPa;

[0083] The single-size wet aggregate falls into the mixer 5-3 through the aggregate batching hopper 5-1 and mixes evenly with the aluminate cement slurry, and falls into the second vibrating screen 6- through the lower hopper 5-4. 1 (the size of the sieve hole is 4mm, and the inclination angle is 25°), the second screening process is carried out, and the excess aluminate cement slurry ...

Embodiment 2

[0087] After autoclaved aerated concrete block aggregates are subjected to self-impact and friction shaping treatment by the aggregate shaping part 1, shaped coarse aggregates close to round or oval are obtained; into the wetting part 3 and sprayed with water mist to obtain a wet aggregate with a moisture content of 10%;

[0088] The wet aggregate falls into the first vibrating sieve 4 for the first sieving treatment, the under-sieve part is a wet aggregate with a single particle size, the particle size of the wet aggregate with a single particle size is 5 mm, and the cylinder compressive strength is 1.0 MPa;

[0089] The single-size wet aggregate falls into the mixer 5-3 through the aggregate batching hopper 5-1 and mixes evenly with the aluminate cement slurry, and falls into the second vibrating screen 6- through the lower hopper 5-4. 1 (the size of the sieve hole is 4mm, and the inclination angle is 20°), the second screening process is carried out, and the excess alumina...

Embodiment 3

[0093] After autoclaved aerated concrete block aggregates are subjected to self-impact and friction shaping treatment by the aggregate shaping part 1, shaped coarse aggregates close to round or oval are obtained; into the wetting part 3 and sprayed with water mist to obtain a wet aggregate with a moisture content of 20%;

[0094] The wetted aggregate falls into the first vibrating screen 4 for the first sieving treatment, the under-sieve part is wetted aggregate with a single particle size, the particle size of the wetted aggregate with a single particle size is 10mm, and the cylinder compressive strength is 0.8 MPa;

[0095] The single-size wet aggregate falls into the mixer 5-3 through the aggregate batching hopper 5-1 and mixes evenly with the aluminate cement slurry, and falls into the second vibrating screen 6- through the lower hopper 5-4. 1 (the size of the sieve hole is 7mm, and the inclination angle is 14°), the second screening process is carried out, and the excess...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com