A kind of repair mortar, its preparation method and construction method

A technology for repairing mortar and sand, which is applied in building maintenance, sustainable waste treatment, solid waste management, etc., can solve problems such as single function, high cost, and small application range, so as to reduce adsorption, reduce delay effect, and improve dispersion effect Effect

Active Publication Date: 2022-06-03

NAT ENG LAB FOR HIGH SPEED RAILWAY CONSTR +1

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The thixotropic cement-based materials obtained in the above patents have the problems of high cost, single function, and small application range

[0006] In summary, there is an urgent need for a repair mortar, its preparation method and construction method to solve the problems of high cost, single function and small application range of thixotropic cement-based materials in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

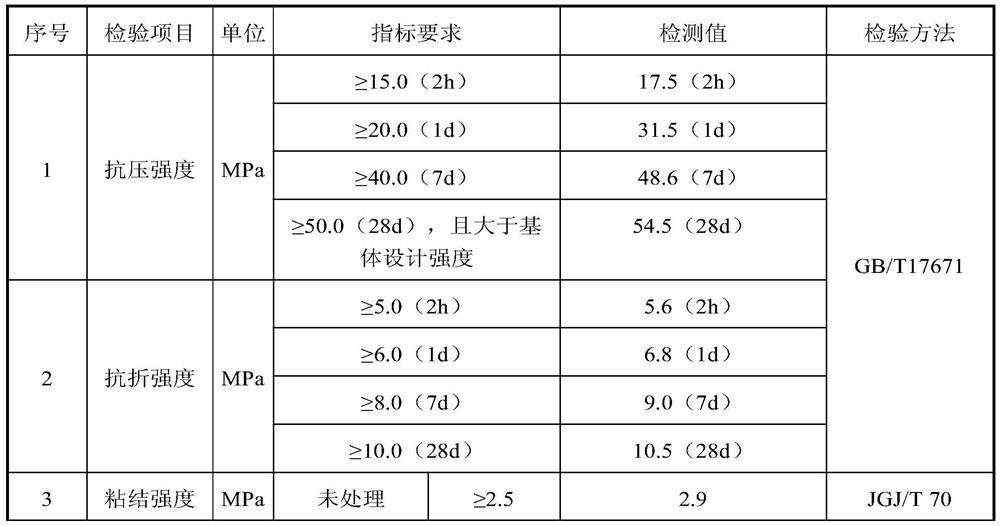

Embodiment 1

[0042] In step S3, the water in the raw material is mixed with mixture A and mixture B to obtain repair mortar.

[0045] Step W2, the repairing mortar obtained in step S3 is directly formed on the pretreated construction surface.

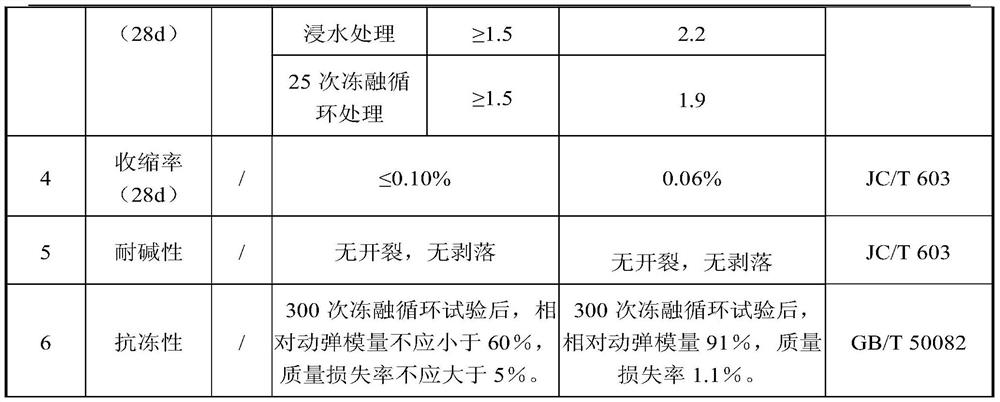

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a repair mortar, its preparation method and construction method. The repair mortar includes raw materials: Portland cement, expansion agent, polymer emulsion, viscosity modifier, water, powder water reducer, composite fiber , super absorbent resin and sand. The preparation method includes step S1, mixing wollastonite needle powder, potassium feldspar powder and polymer emulsion to obtain mixture A; step S2, mixing portland cement, magnesium oxide, viscosity modifier, powder The water reducer, the composite fiber, the superabsorbent resin and the sand are mixed uniformly to prepare a mixture B; in step S3, water is uniformly mixed with the mixtures A and B to prepare a repair mortar. The construction method includes step W1, pretreating the construction surface of the concrete matrix to be repaired; step W2, directly forming the repair mortar prepared in step S3 on the pretreated construction surface. The repair mortar described in the invention has better thixotropy.

Description

A kind of repair mortar, its preparation method and construction method technical field The present invention relates to concrete material technical field, be specifically related to a kind of repair mortar, its preparation method and construction method Law. Background technique Concrete structures are generally faced with serious durability problems, which greatly reduces the durability and service of concrete. life, but also directly promote the development of the concrete repair industry. Concrete repair works are mainly divided into structural repair works. There are two types of repairs and non-structural repairs. Among them, the concrete problem addressed by non-structural repairs is generally the occurrence of tortoises on the entire exposed surface. cracks, peeling, etc., or cracks and defects of non-main stress-bearing parts. For non-structural repairs, mainly using repair materials material to replace problematic parts of concrete structures. However...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B28/18E04G23/02C04B111/72

CPCE04G23/0218C04B28/18C04B2111/72C04B7/02C04B14/045C04B22/066C04B24/2676C04B24/383C04B22/002C04B2103/302C04B14/068C04B14/42C04B16/0633C04B14/4643C04B24/2641Y02W30/91

Inventor 元强左胜浩余志武黄庭杰

Owner NAT ENG LAB FOR HIGH SPEED RAILWAY CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com