Repair mortar, and preparation method and construction method thereof

A technology for repairing mortar and sand, which is applied in building maintenance, sustainable waste treatment, solid waste management, etc., can solve problems such as single function, high cost, and small application range, so as to reduce adsorption, reduce delay effect, and improve dispersion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

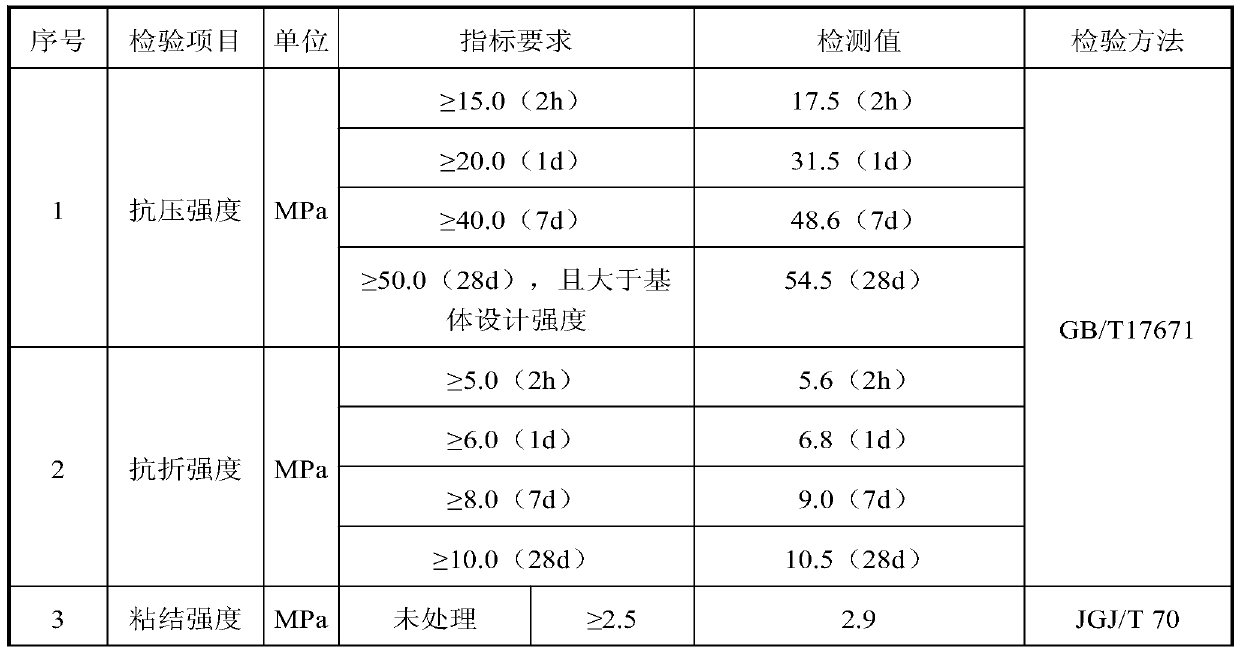

Examples

Embodiment 1

[0032] A kind of repair mortar, including the following raw materials in mass percentage: Portland cement 25%, expansion agent 4%, polymer emulsion 5%, viscosity modifier 0.2%, water 8%, powder water reducing agent 0.4%, composite fiber 0.3%, 0.08% of superabsorbent resin and the rest of sand, the expansion agent includes wollastonite needle powder, potassium feldspar powder and magnesium oxide, and the magnesium oxide has been calcined.

[0033] The expansion agent is composed of wollastonite acicular powder, potassium feldspar powder and magnesium oxide, wherein the mass ratio of the wollastonite acicular powder to the repair mortar is 0.5%, and the mass ratio of the potassium feldspar powder to the repair mortar is 0.5%, the mass ratio of magnesium oxide to repair mortar is 3%.

[0034] The fineness of the wollastonite acicular powder is 1000 mesh, and the aspect ratio of the particles is 10:1; the fineness of the potassium feldspar powder is 400 mesh; the calcination tempe...

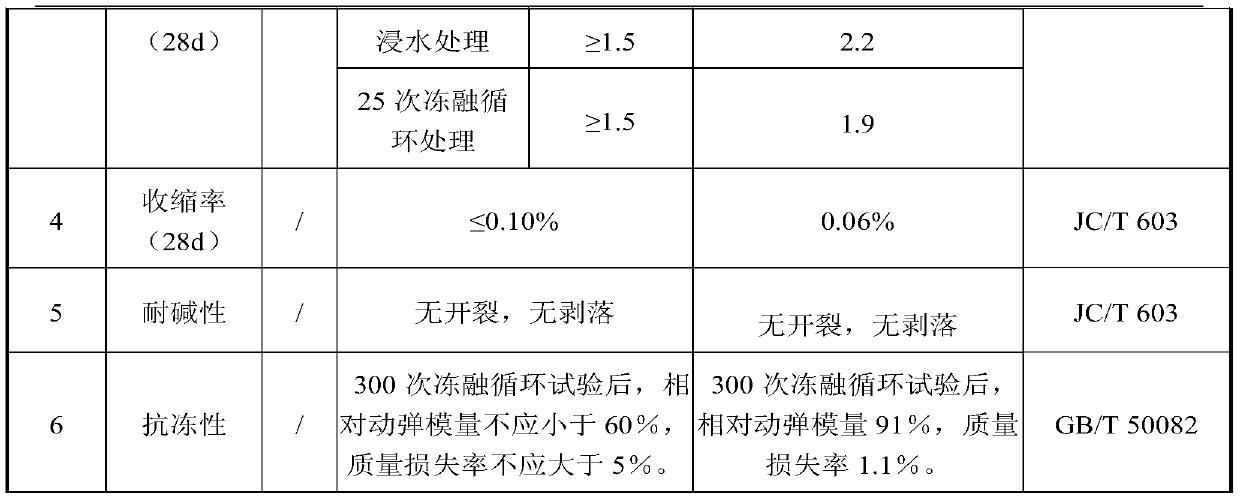

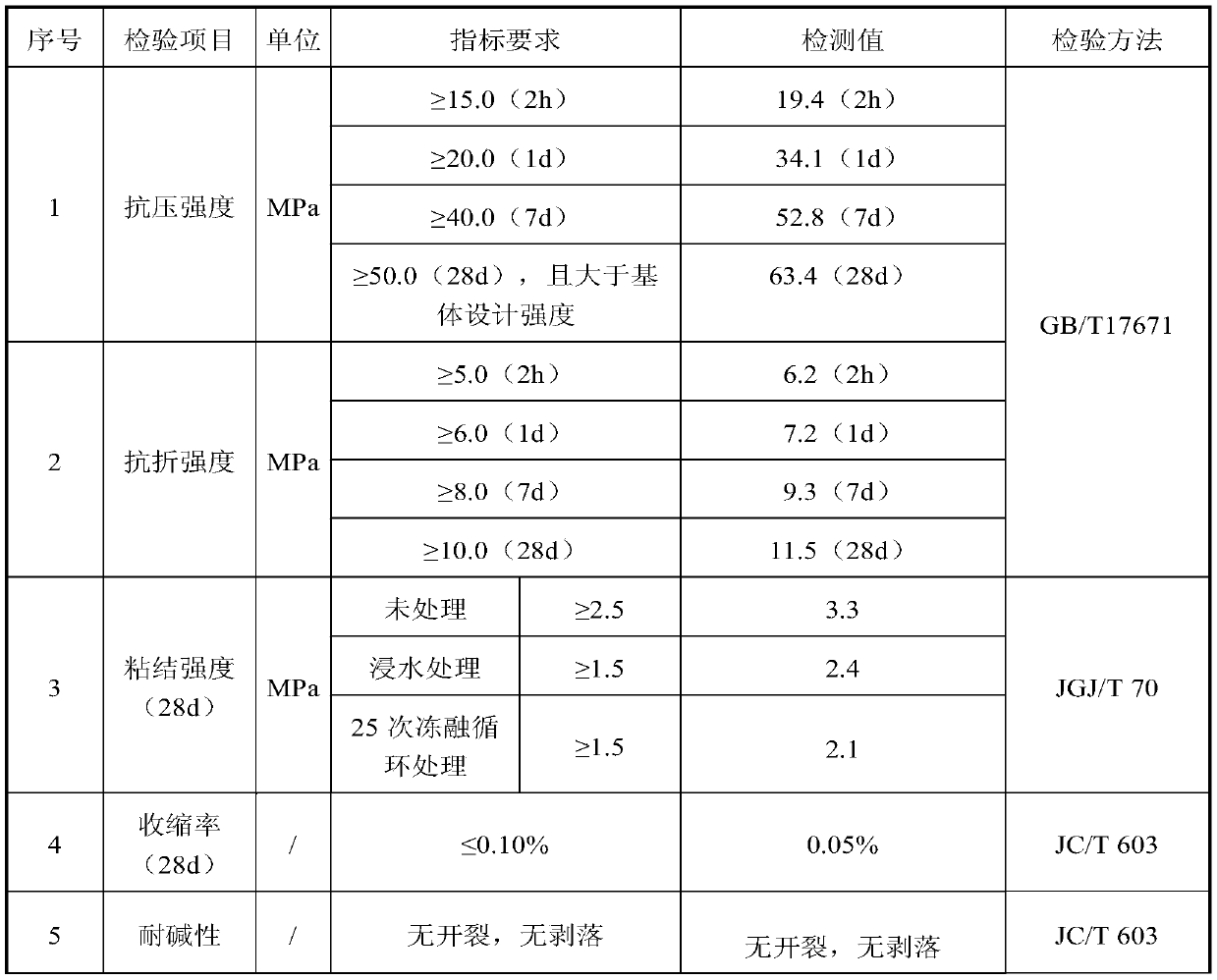

Embodiment 2

[0048] The difference from Example 1 is that the repair mortar contains 30% of Portland cement, 6% of polymer emulsion, 0.1% of viscosity modifier, 10% of water, 0.6% of powder water reducer, 0.5% of composite fiber and high Water absorbent resin 0.1%. Other conditions are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com