Double-component epoxy adhesive for bonding ceramics, preparation method and using method thereof

An epoxy adhesive, a two-component technology, applied in the direction of adhesives, epoxy resin adhesives, carboxyl rubber adhesives, etc., can solve the problems of large difference in linear expansion coefficient and large interface stress, etc., to achieve a good bonding interface and reduce Effect of internal stress, apparent mechanical fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

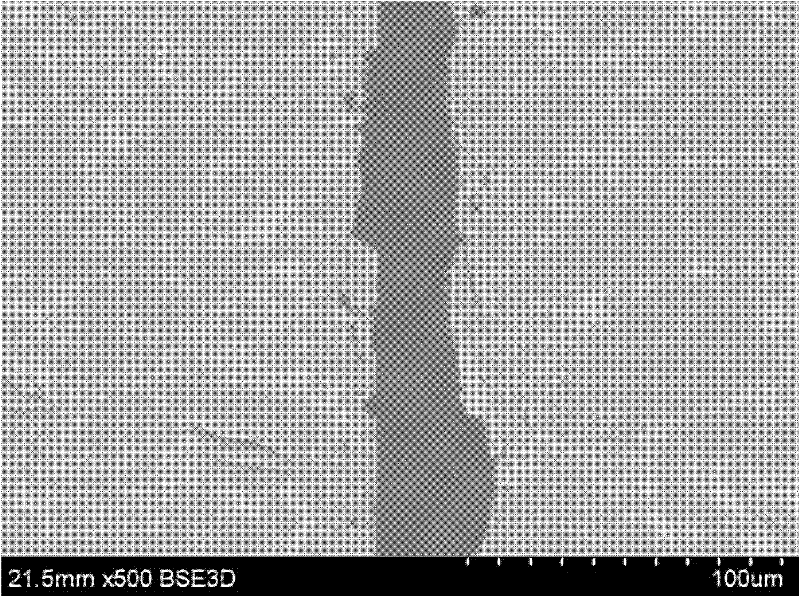

Image

Examples

specific Embodiment approach 1

[0012] Embodiment 1: The two-component epoxy adhesive for bonding ceramics in this embodiment is composed of component A and component B, wherein component A is composed of 60 to 100 parts of E-44 epoxy resin, 60-100 parts of E-51 epoxy resin, 15-35 parts of liquid carboxyl-terminated nitrile rubber (toughening agent), 40-60 parts of quartz powder, 1-10 parts of carbon fiber (reinforcing agent), 0.1-0.2 parts of carbon nano Tube, 1-10 parts of SiC whisker (filler) and 0.1-1 part of ultraviolet absorber UV-531 (anti-aging agent), component B is composed of 20-50 parts of 3-diethylaminopropylamine according to the ratio of parts by mass (DEAPA, as a curing agent), 1~3 parts of silane coupling agent KH-550, 0.5~1.5 parts of accelerator DMP-30 and 10~20 parts of quartz powder (filler), mix A component and B component According to the mass ratio of 100:20~25, mix evenly under heating conditions and then sizing.

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the first component is composed of 70-90 parts of E-44 epoxy resin, 70-80 parts of E-51 epoxy resin, 20-30 parts of liquid-terminated carboxylated nitrile rubber, 45-55 parts of quartz powder, 2-8 parts of carbon fiber, 0.12-0.18 parts of carbon nanotubes, 4-7 parts of SiC whiskers and 0.4-0.8 parts of ultraviolet absorber UV-531 production. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the first component is composed of 80 parts of E-44 epoxy resin, 75 parts of E-51 epoxy resin, 25 parts of liquid end Carboxylated nitrile rubber, 50 parts of quartz powder, 5 parts of carbon fiber, 0.15 parts of carbon nanotubes, 5 parts of SiC whiskers and 0.6 parts of ultraviolet absorber UV-531. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com