Wear-resistant and slip-resistant rubber and preparation method thereof

A rubber and anti-slip technology, which is applied in the field of rubber, can solve the problems of being unable to meet the demand for anti-slip and the inability to use the outsole of shoes, etc., and achieve the effect of good wear-resistant and anti-slip performance, strong wear-resistant and anti-slip performance, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0035] The formula in Table 1 is adopted to prepare the wear-resistant anti-slip rubber of the present invention, and the preparation process is as follows:

[0036] (1) Preparation of modified short fibers

[0037] Spray vinyl triethoxysilane to pretreat basalt (diameter 10-100μm, length 1-10mm), the amount of coupling agent is 1% of the mass of basalt, store and dry to make uniform modification short fibre.

[0038] (2) Mixing

[0039] 1) First mix some (50%) rough billets (natural rubber, butadiene rubber, nitrile rubber and pretreated short fibers) at a temperature of 100±5°C, and spread them on the tray after completion. 90s;

[0040] 2) Add magnesium oxide, silane, stearic acid, sulfur and ZnO to another part of rough billets (natural rubber, butadiene rubber, nitrile rubber and pretreated short fibers), add sulfur and ZnO in sequence, and then add The temperature of mixing in the material in step 1) is 125±5°C, and the time is 120s:

[0041] During the mixing proce...

Embodiment 1

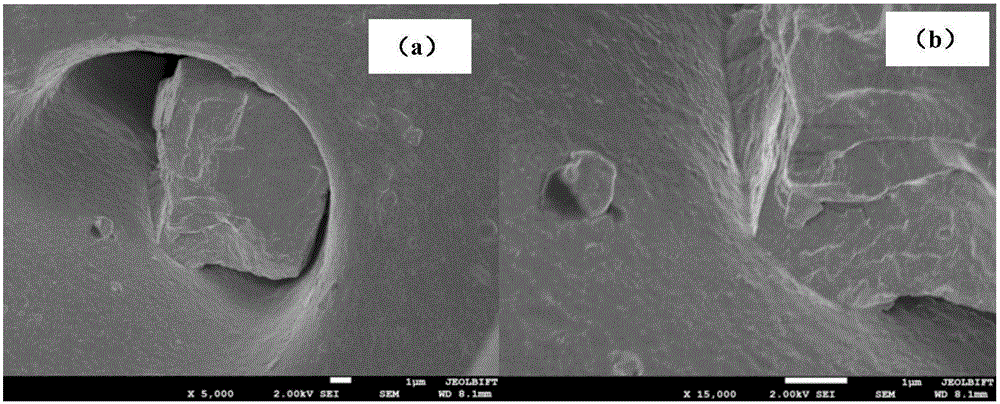

[0054] The electron micrograph of the rubber that embodiment 1 prepares is as figure 1 , figure 2 , image 3 with Figure 4 shown, where figure 1 The magnification of (a) is 5000, figure 1 The magnification of (b) is 15000, by figure 1 It can be seen that there are still gaps between the basalt fiber and the rubber, which belong to incomplete bonding, and the bonding form is mosaic.

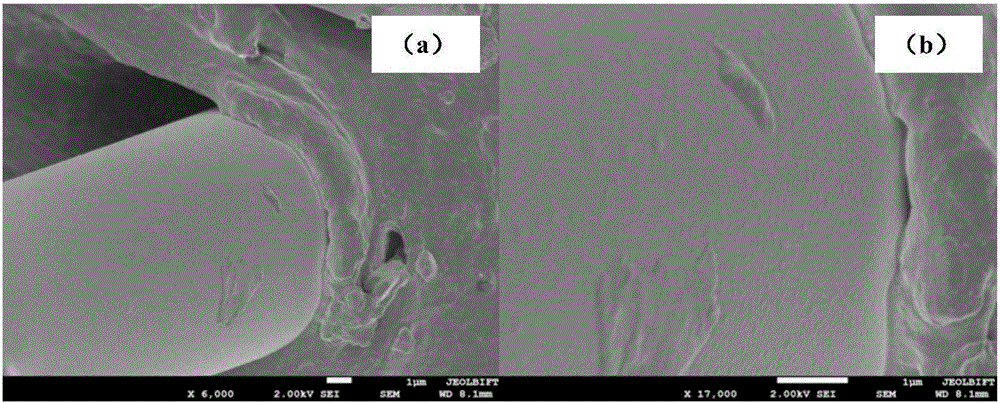

[0055] in figure 2 The magnification of (a) is 6000, figure 2 The magnification of (b) is 17000, by figure 2 It can be seen that there are still gaps between the basalt fiber and the rubber, which belong to incomplete bonding, and the bonding form is electric welding.

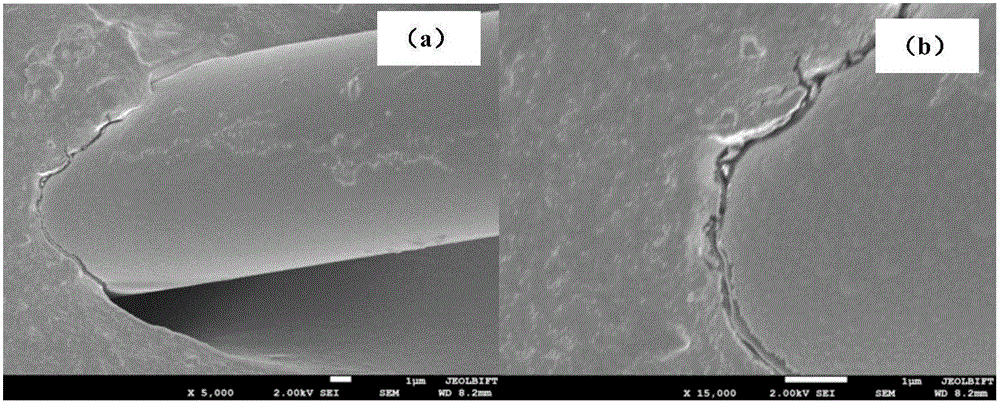

[0056] figure 2 The electron micrograph of the welded bonded edge of basalt fiber and rubber is shown as image 3 shown, where image 3 The magnification of (a) is 5000, image 3 The magnification of (b) is 15000.

[0057] Figure 4 (a) with a magnification of 100, Figure 4 (b) with a magnification of 1000, Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com