Method for lowering edge drop of tin plate

A technology of tinplate and edge drop, applied in the field of steel rolling, can solve the problems of difficult control of edge waves and poor edge drop control ability of tin-plated strip steel, and achieves the effect of uniform thickness distribution and improved edge drop control ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

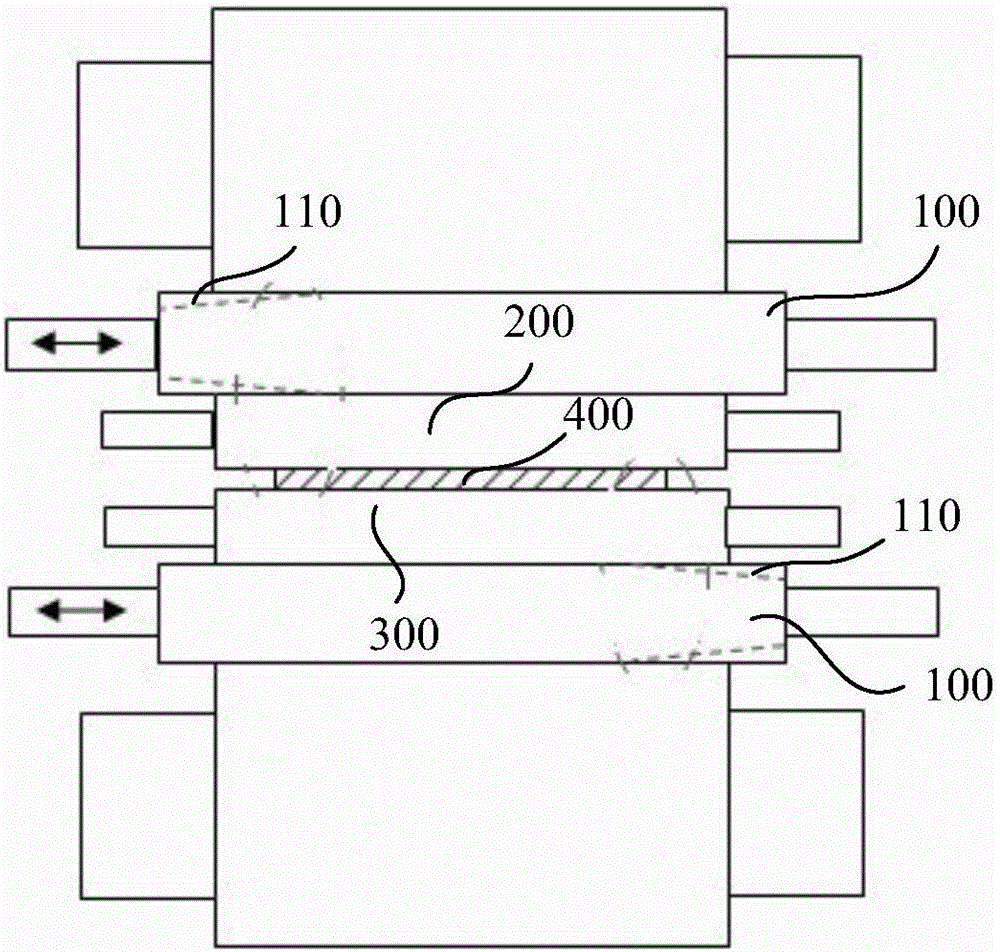

[0062] Rolling mill 1420 cold rolling group S1~S3 stands were tested, aiming at the roll shape parameters of the middle roll of this group, it was used to produce tinplate with a width of 874mm~1062mm.

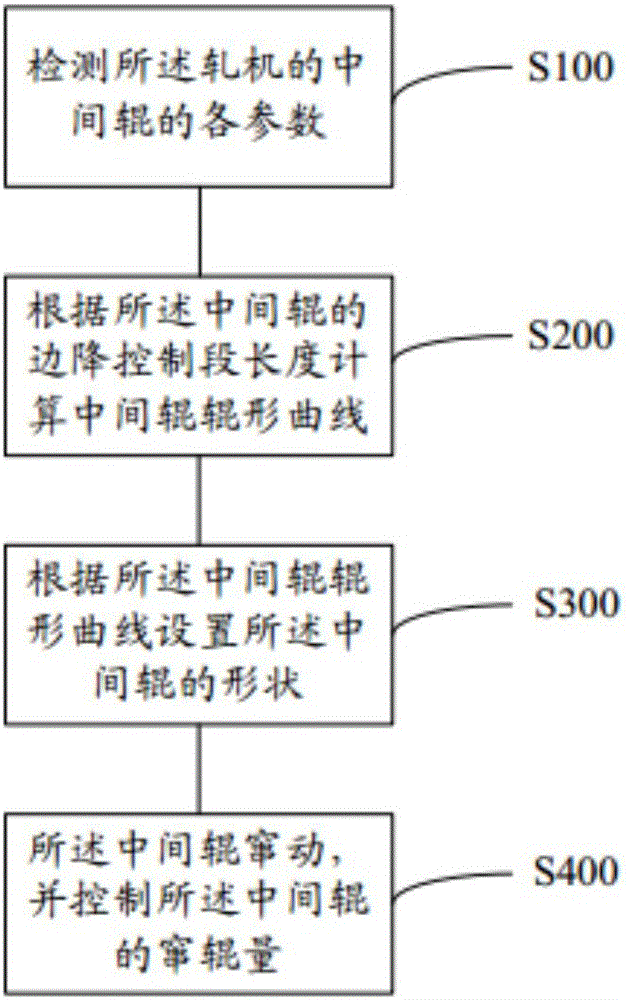

[0063] (1) detect each parameter of the intermediate roll of described rolling mill;

[0064] Among them, it is detected that L in the rolling mill IEDC 200mm, L IMR It is 1420mm.

[0065] (2) calculate the roll shape curve of the middle roll according to the edge drop control section length of the middle roll;

[0066] choose a 1 2.38780e -3 , a 2 is -3.85635e -6 , a 3 2.42966e -9 ; put a 1 、a 2 、a 3 , L IEDC , L IMR Substitute into the formula g(x) LMR =a 1 x 2 +a 2 x 4 +a 3 x 6 Among them, the roll shape curve function of the middle roll is obtained.

[0067] (3) setting the shape of the intermediate roll according to the roll shape curve of the intermediate roll;

[0068] (4) The intermediate roll is shifted, and the amount S of the intermediate roll ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com