Ramp bridge scaffold support with overlapped arc-shaped steel plates

A technology of arc-shaped steel plate and scaffolding, which is applied in bridges, bridge construction, building structure support, etc., and can solve problems such as uneven stress on components under the support and unfavorable support stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

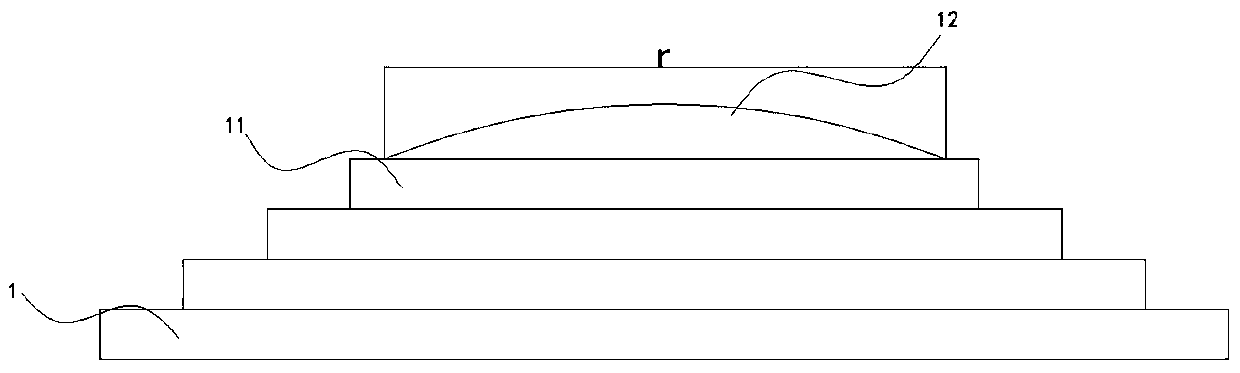

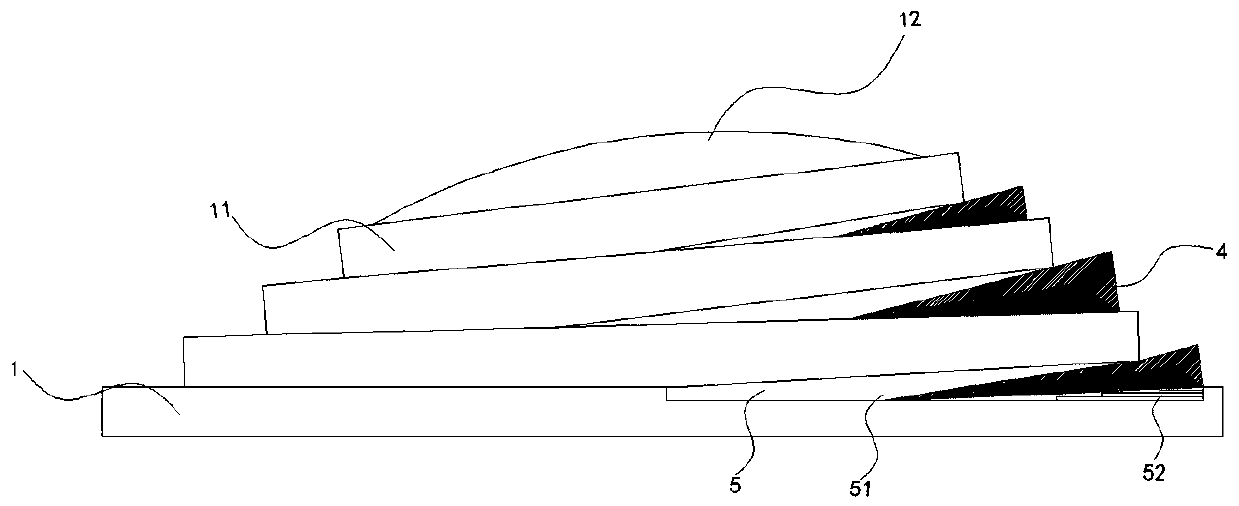

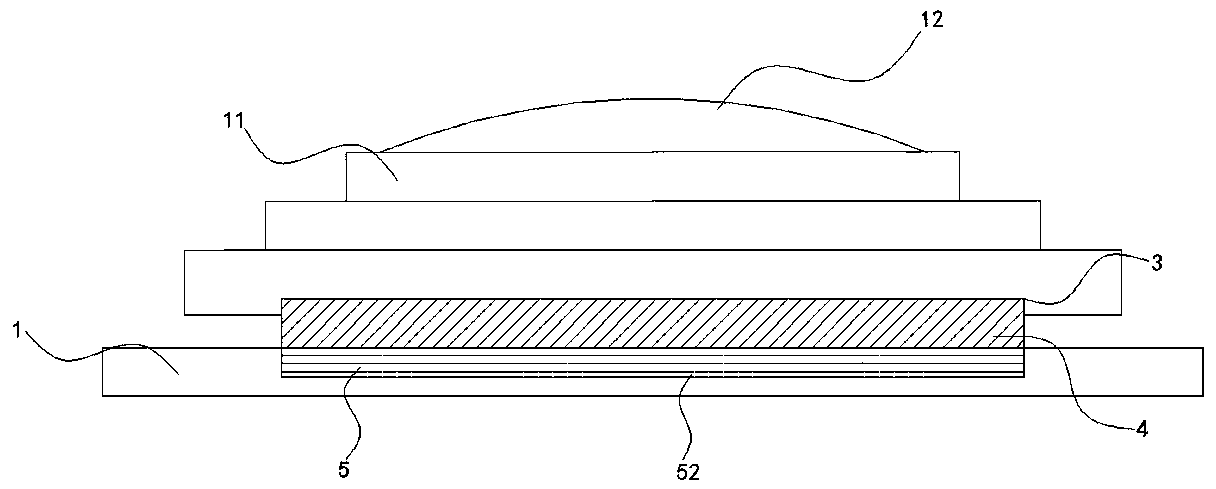

[0026] Embodiment one, such as figure 1 The shown arc-shaped steel plate superimposed support for slope bridge scaffolding includes several horizontally stacked steel plate layers 1, the steel plate layer 1 has a top layer 11, and the surface of the top layer 11 has an upward arc surface 12, and the arc surface 12 has a 30° The angle r. The horizontal area of the steel plate layer 1 is arranged from large to small from bottom to top, and the horizontal area of the steel plate layer 1 is 1:3 / 4:1 / 2:1 / 4 from bottom to top. Freely placed between steel plate layers 1. The top layer 11 adopts high-strength wear-resistant steel materials such as No. 45 steel, and the steel plate layer 1 other than the top layer 11 is made of common Q235 steel plates. This device is used in the construction of cast-in-place tie girder scaffolding. The bridge is located on the vertical curve. This device solves the problem of uneven force on the support of the beam bottom and the resulting stabil...

Embodiment 2

[0027] Embodiment two, such as figure 1 The shown arc-shaped steel plate superimposed support for slope bridge scaffolding includes several horizontally stacked steel plate layers 1, the steel plate layer 1 has a top layer 11, and the surface of the top layer 11 has an upward arc surface 12, and the arc surface 12 has a 45° The angle r. The horizontal area of the steel plate layer 1 is arranged from large to small from bottom to top, and the horizontal area of the steel plate layer 1 is 1:3 / 4:1 / 2:1 / 4 from bottom to top. Freely placed between steel plate layers 1. The top layer 11 adopts high-strength wear-resistant steel materials such as No. 45 steel, and the steel plate layer 1 other than the top layer 11 is made of common Q235 steel plates.

Embodiment 3

[0028] Embodiment three, such as figure 1 The shown arc-shaped steel plate superimposed support for slope bridge scaffolding includes several horizontally stacked steel plate layers 1, the steel plate layer 1 has a top layer 11, and the surface of the top layer 11 has an upward arc surface 12, and the arc surface 12 has a 60° The angle r. The horizontal area of the steel plate layer 1 is arranged from large to small from bottom to top, and the horizontal area of the steel plate layer 1 is 1:3 / 4:1 / 2:1 / 4 from bottom to top. Freely placed between steel plate layers 1. The top layer 11 adopts high-strength wear-resistant steel materials such as No. 45 steel, and the steel plate layer 1 other than the top layer 11 is made of common Q235 steel plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com