Display device, and method for producing array substrate for display device

A technology of a display device and a manufacturing method, applied in the directions of identification devices, optics, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

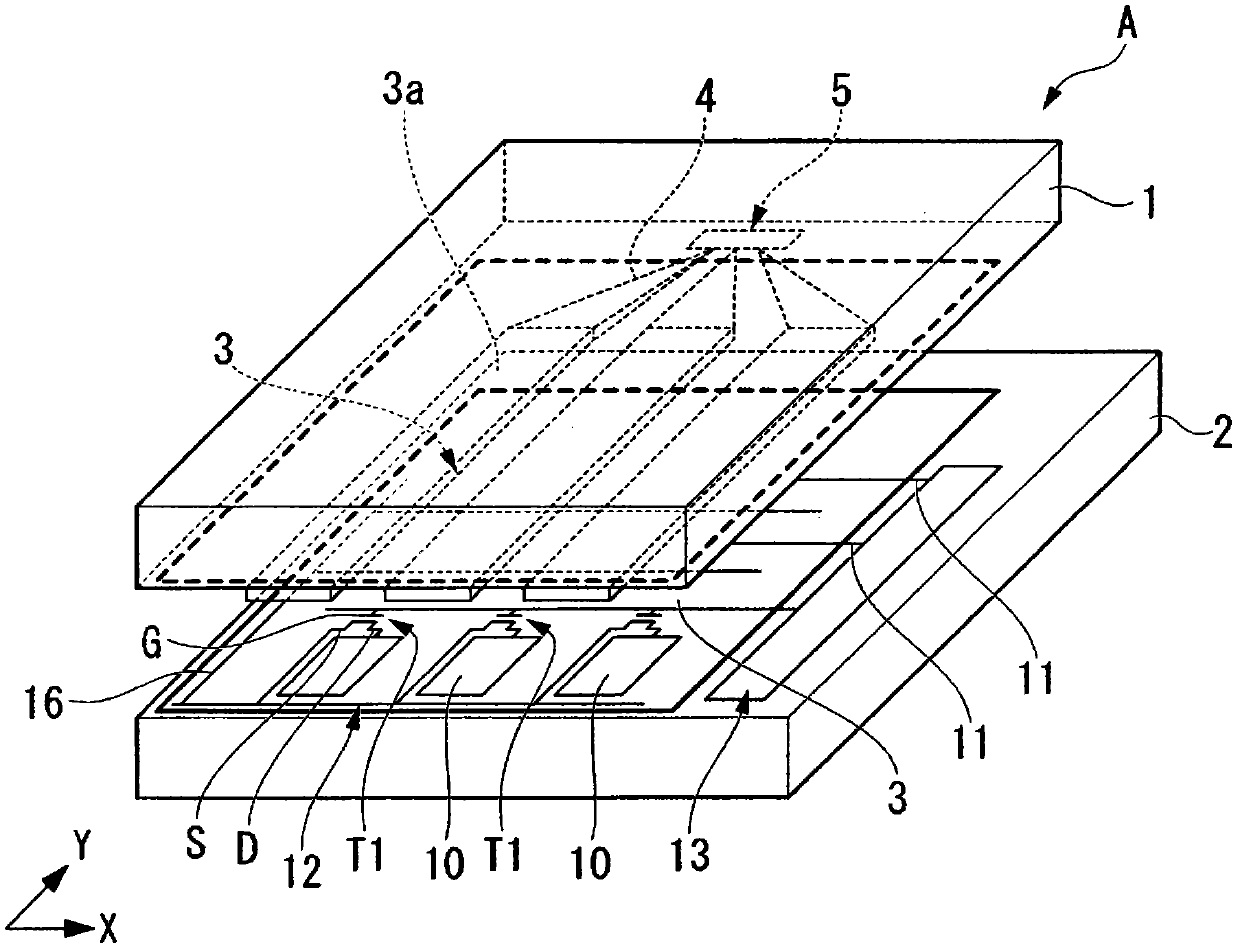

[0225] Below, while referring to the attached Figure 1 One embodiment of the display device of the present invention will be described.

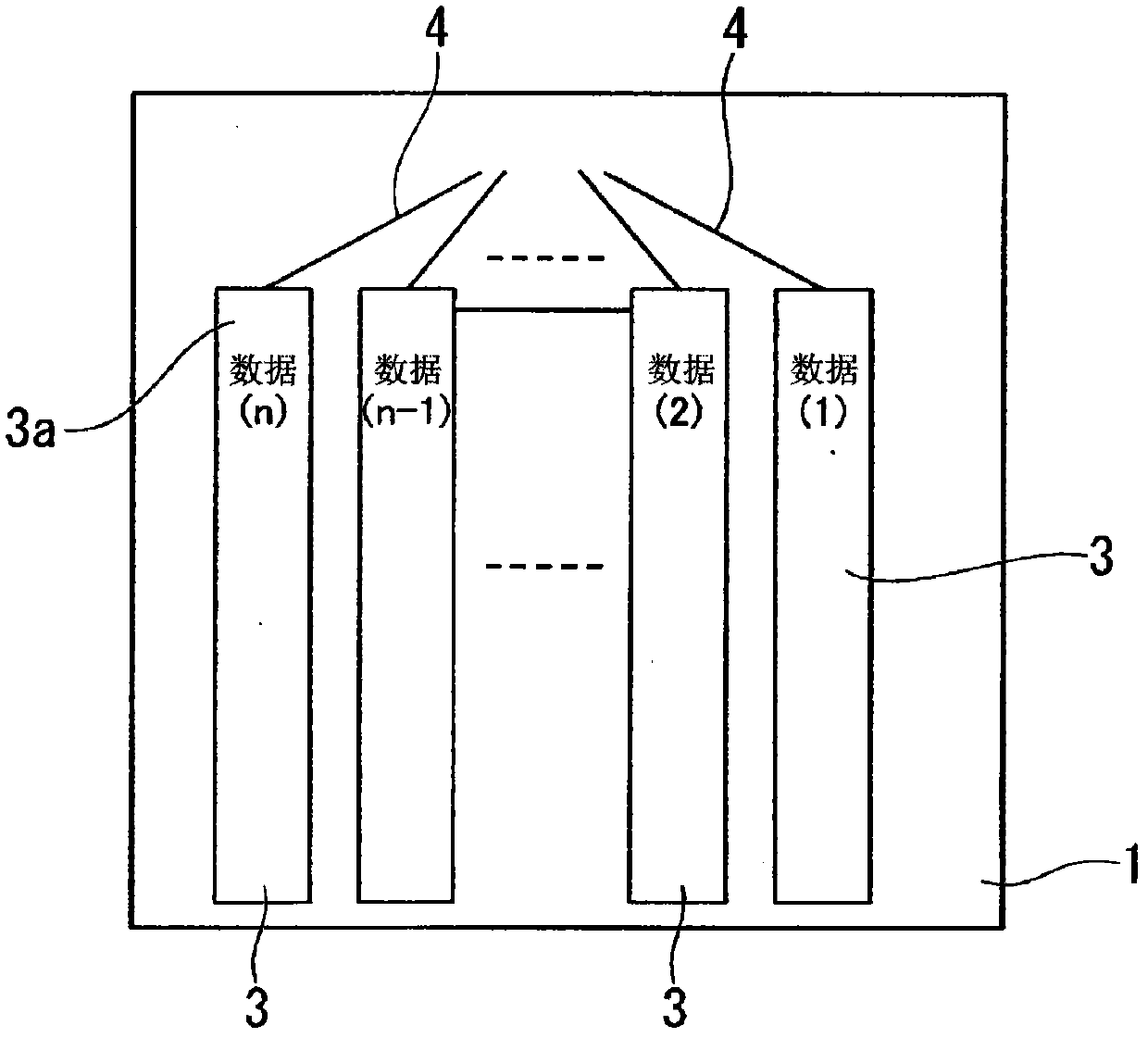

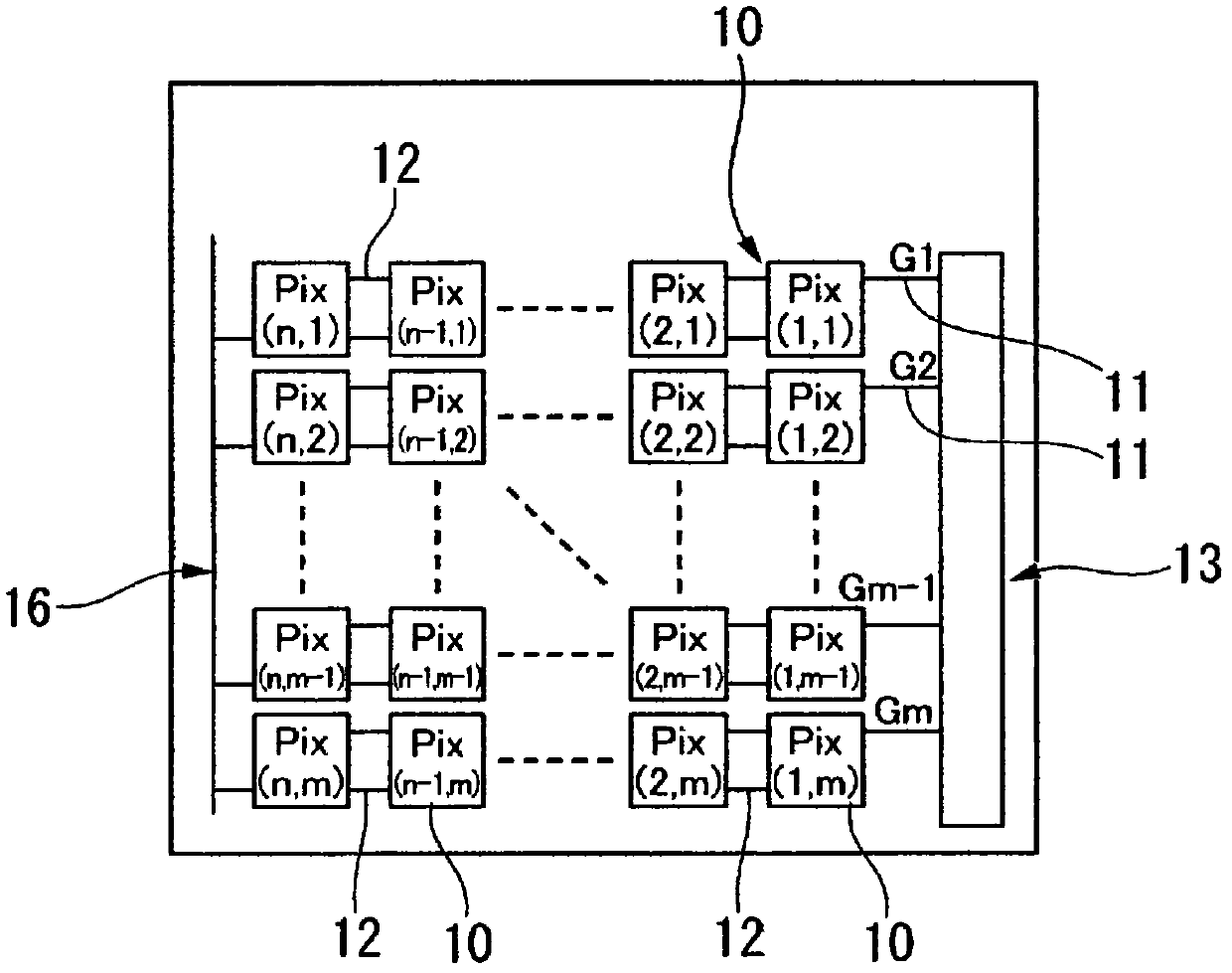

[0226] The display device of the present embodiment is applied to a relative data supply type display device in which a display medium layer such as a liquid crystal layer is sandwiched between a pair of substrates. figure 1 It is a figure which shows the outline|summary of both board|substrates and the wiring formed on both board|substrates in the state which made both board|substrates face each other. figure 2 It is a diagram showing the wiring of the opposite substrate. image 3 It is a diagram showing the wiring of the element-side substrate. Figure 4 It is a diagram showing a wiring structure around a pixel electrode. Figure 5 It is a schematic diagram showing an overall circuit of a display device in which both substrates are combined. Figure 6A and Figure 6B It is a configuration diagram showing an example of a thin film t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com