Wafer level vacuum packaging method of MEMS (Micro-electromechanical System) component

A vacuum packaging, wafer-level technology, applied in decorative arts, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of manufacturing process pollution, complex processing technology of MEMS devices, etc., to reduce pollution, improve process compatibility, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

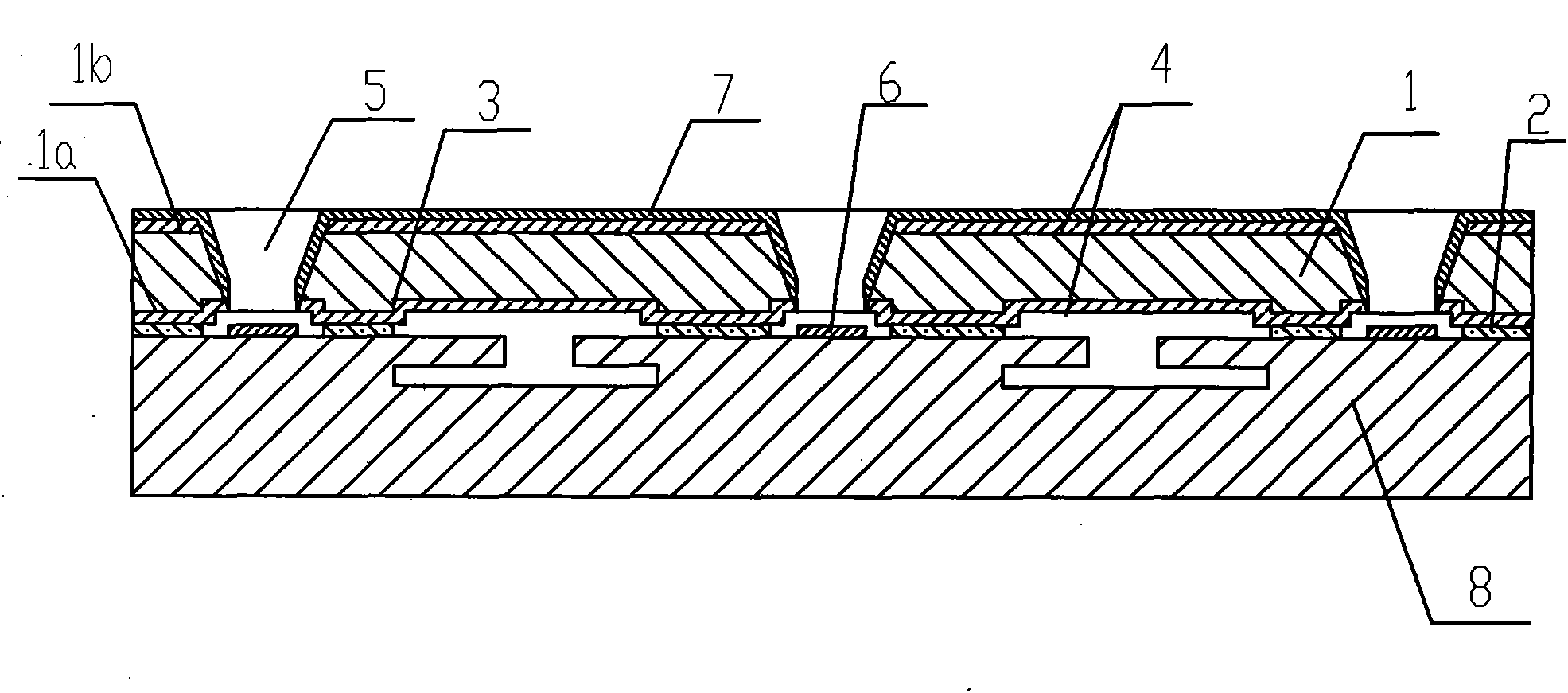

[0014] figure 1 It is a schematic diagram of the package structure of a MEMS device unit. From top to bottom, there are package cover plate 1 and MEMS device 8 in sequence. The package cover plate 1 and MEMS device 8 are bonded together by gold-silicon eutectic bonding.

[0015] Combine below Figure 2-1 to Figure 2-12 Specific embodiments of the present invention will be described.

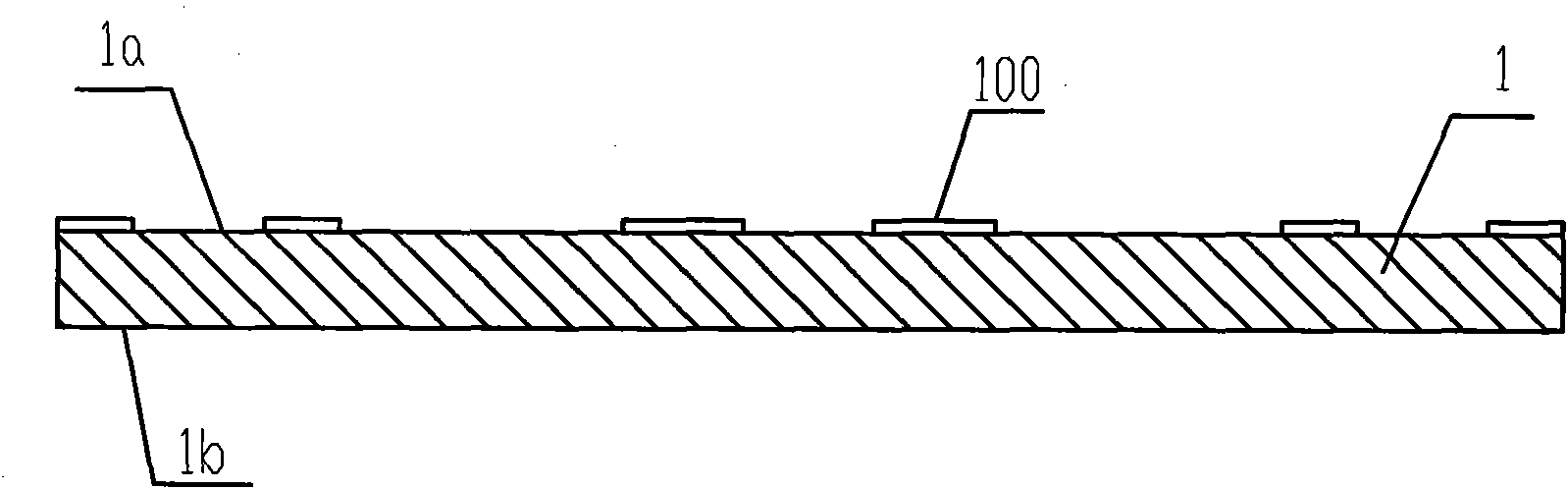

[0016] A MEMS device wafer-level vacuum packaging method, the steps of the method include: 1) depositing a metal film 2 for gold-silicon bonding on the MEMS device, 2) polishing the packaging cover plate 1 on both sides, 3) depositing the packaging cover plate 1 on both sides insulating dielectric 4, 4) etching the electrode lead-out via hole 5, 5) using gold-silicon eutectic bonding technology to bond and package the package cover plate 1 and MEMS device 8, 6) through deposition, photolithography, etching Prepare the lead-out electrode of the MEMS device on the surface of the MEMS device corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com