Liquid crystal display panel and liquid crystal display device

A technology for liquid crystal display panels and substrates, which is used in static indicators, nonlinear optics, instruments, etc., can solve the problems of low contrast, high cost, and complicated process of liquid crystal display panels, and achieves the improvement of contrast, simplification of the process, and increased contrast. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

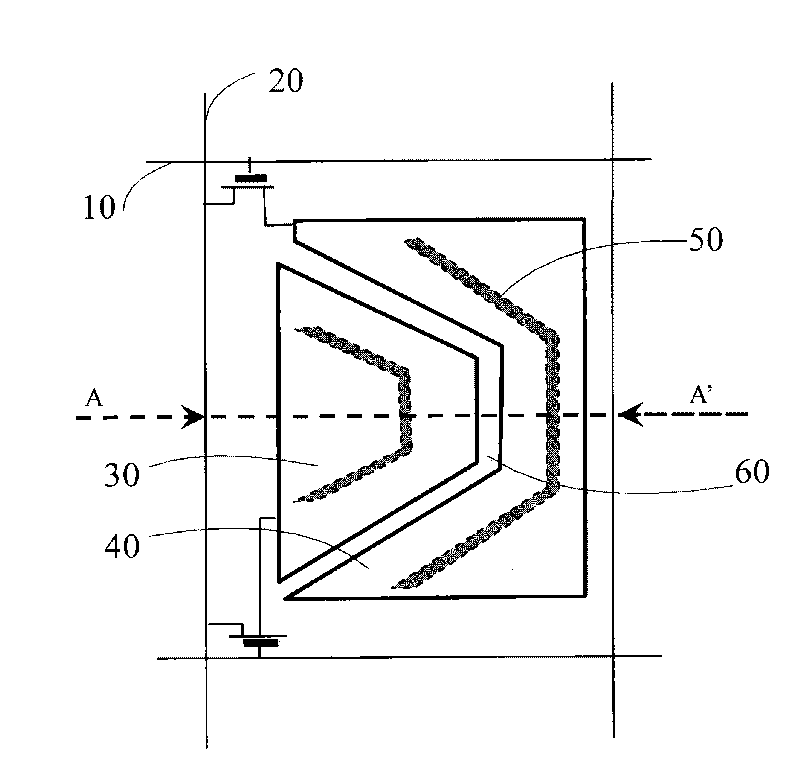

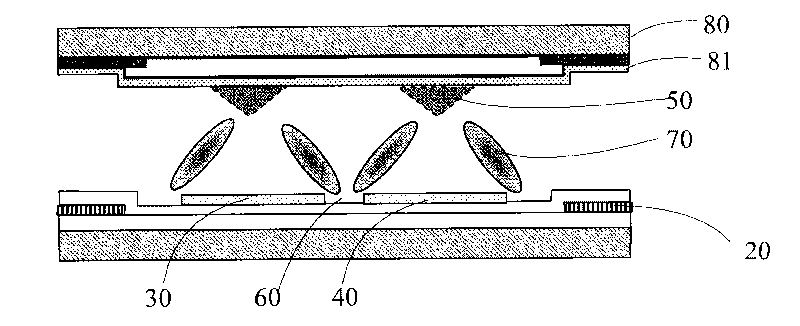

[0037] Figure 3 to Figure 5 Shown is a liquid crystal display panel according to a first embodiment of the present invention. image 3 It is a schematic structural diagram of a single pixel of the liquid crystal display panel of the first embodiment, Figure 4 is along image 3 The sectional view of the line B-B' in the middle, Figure 5 It is a partial structure diagram of the liquid crystal display panel of the first embodiment of the present invention. For highlighting the invention point of the present invention, image 3 Only a single pixel area is shown in , which should actually include such as Figure 5 An array of multiple pixel regions is shown in .

[0038] The liquid crystal display panel in this embodiment is a novel multi-region vertical alignment type liquid crystal display panel, which includes: a first substrate 10, a second substrate 20 opposite to the first substrate 10, and a substrate sandwiched between the first substrate 10 and the liquid crystal ...

no. 2 example

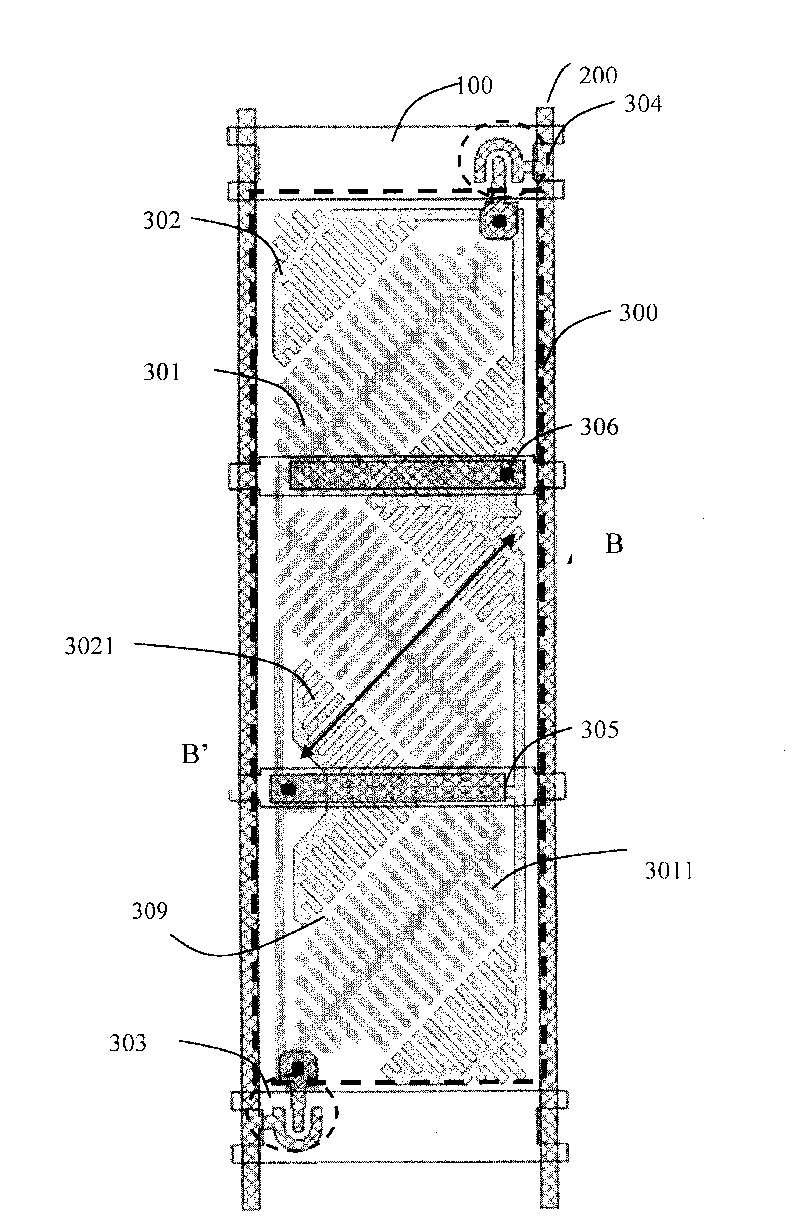

[0061] Image 6 It is a partial structural schematic diagram of the liquid crystal display panel according to the second embodiment of the present invention.

[0062] Similarly, the pixel area of the liquid crystal display panel according to the second embodiment of the present invention also has the first sub-pixel electrode 301 and the second sub-pixel electrode 302 respectively in the shape of fishbone, and the first sub-pixel electrode 301 and the second sub-pixel The electrodes 302 have a nested structure, wherein the first sub-pixel electrode 301 has at least one nesting region 3011 extending into the second sub-pixel electrode 302, and the second sub-pixel electrode 302 has at least one nesting region 3011 extending into the first sub-pixel Nesting region 3021 within electrode 301 . In addition, when the liquid crystal display panel is working, since the first sub-pixel electrode 301 and the second sub-pixel electrode 302 nested therein have opposite polarities, the ...

no. 3 example

[0066] Figure 7 It is a partial structural schematic diagram of the liquid crystal display panel according to the third embodiment of the present invention.

[0067] Similarly, the pixel area of the liquid crystal display panel in the third embodiment of the present invention also has the first sub-pixel electrode 301 and the second sub-pixel electrode 302 respectively in the shape of fishbone, and the first sub-pixel electrode 301 and the second sub-pixel The electrodes 302 have a nested structure, wherein the first sub-pixel electrode 301 has at least one nesting region 3011 extending into the second sub-pixel electrode 302, and the second sub-pixel electrode 302 has at least one nesting region 3011 extending into the first sub-pixel Nesting region 3021 within electrode 301 . In addition, when the liquid crystal display panel is working, since the first sub-pixel electrode 301 and the second sub-pixel electrode 302 nested therein have opposite polarities, the first sub-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com