Lateral composite grating DFB laser structure and application

A technology of DFB lasers and composite gratings, which is applied to lasers, laser components, semiconductor lasers, etc., can solve the problems of difficult simultaneous realization of high-power lasers, instability of single-mode characteristics, lateral leakage of carriers, etc., and achieve narrow Effects of linewidth and high-power laser output, avoiding secondary epitaxy steps, and improving slope efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

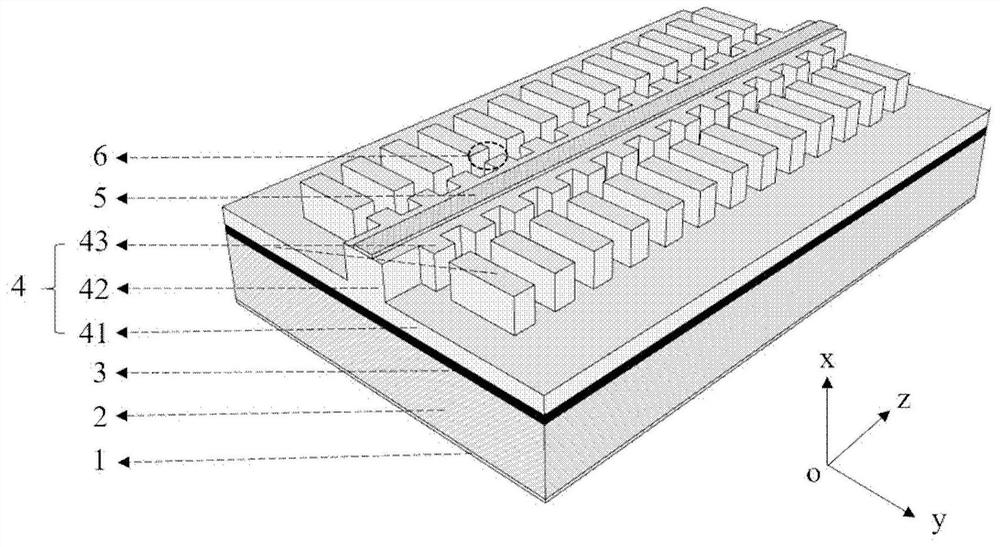

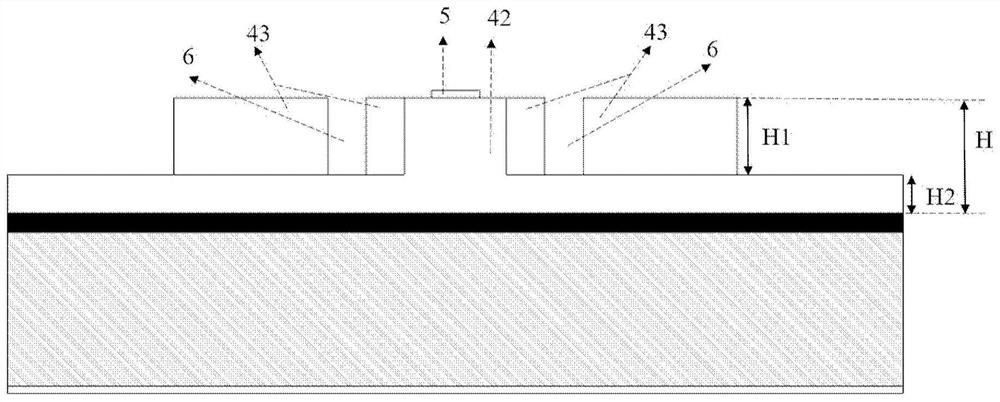

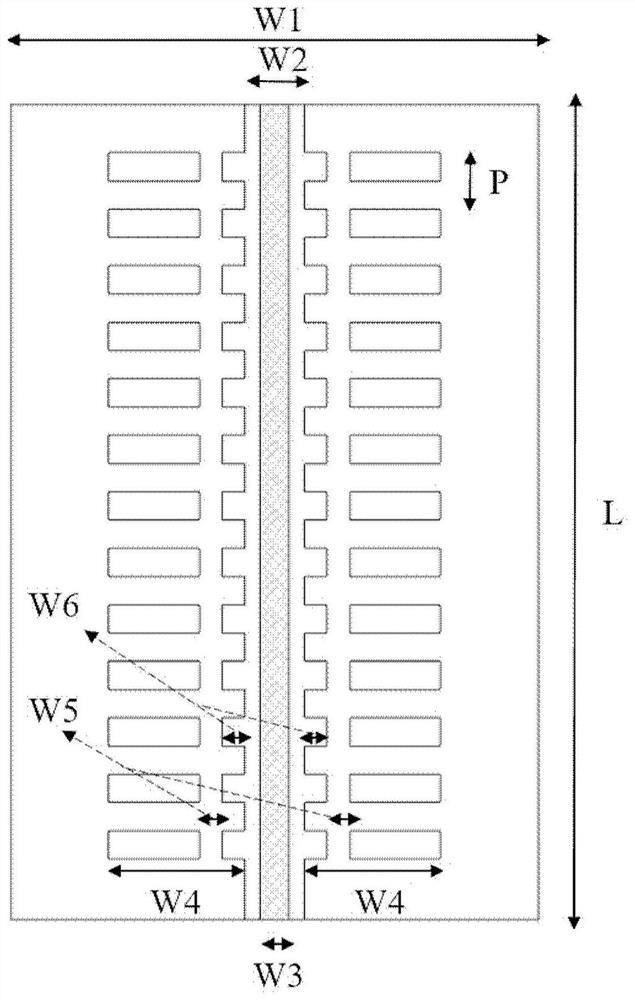

[0035] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and embodiments, in order to assist those skilled in the art to fully understand the objects, features and effects of the present invention. Exemplary embodiments of the present invention are shown in the drawings, but it should be understood that the present application can also be implemented in various other forms and should not be limited by the embodiments described here. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention. In addition, the various embodiments provided below in the present invention and the technical features in the embodiments can be combined with each other in any manner.

[0036] The terminology used herein is for the purpose of describing particular embodiments only, and is not intended to be limiting of the invention. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com