Patents

Literature

38results about How to "Reduced Auger Recombination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet method etching process

InactiveCN102569502APromote absorptionIncrease IscFinal product manufactureSemiconductor devicesSilicon alloyLight energy

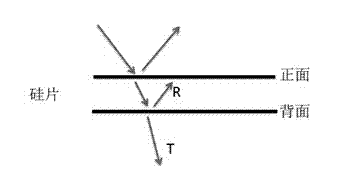

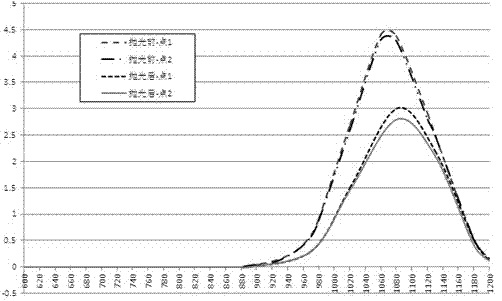

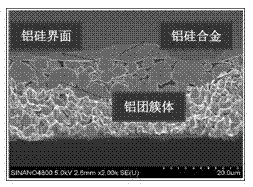

The invention discloses a wet method etching process for crystal silicon wafers, which mainly comprises a back side polishing process. After etching and edge removing, the polishing process performed to the back sides of the crystal silicon wafers through a polishing solution is added, the temperature of the polishing solution in polishing is 5-30 DEG C, the polishing time is 10 seconds to 10 minutes, and the polishing solution contains, by mass, 0.5%-10% of HF, 35%-55% of HNO, 45%-55% of H2SO4 and 5%-30% of acetic acid. By adding the back side polishing process, the back sides of the silicon wafers can be smooth, back reflection of the silicon wafers is strengthened, and absorption of long-wave band spectrums in sunlight is enhanced, thereby improving light energy conversion and short-circuit current (Isc) of a battery and finally improving the conversion efficiency of the battery. In addition, the back of the smooth battery further facilitates combination of follow-up aluminum-silicon alloy and a silicon body, improves ohmic contact, strengthens the light reflection effect of an interface, improves variable output circuit (Voc), and finally improves the conversion efficiency of the battery.

Owner:HEFEI & SOLAR TECH

Oxide-metal multilayer film back contact crystalline silicon solar cell and preparation method thereof

ActiveCN105789342ALow costThe process steps are simpleFinal product manufacturePhotovoltaic energy generationMetal electrodesCrystalline silicon

The invention discloses an oxide-metal multilayer film back contact crystalline silicon solar cell, which comprises a crystalline silicon wafer, wherein passivation layers are arranged on the front surface and the back surface of the crystalline silicon wafer; the passivation layer on the back surface is provided with an emitter, an emitter metal electrode and a base metal electrode; the emitter comprises a first oxide thin film, a metal film and a second oxide thin film; the first oxide thin film or the second oxide thin film is a WO3 thin film, an NiO thin film or a V2O5 thin film; and the metal thin film is an Ag thin film, an Au thin film, a Pd thin film, a Cu thin film, an Ni thin film, an Mo thin film, a W thin film or an Al thin film. The surface of the cell is not shielded by a metal grid line; the raw materials do not include inflammable, explosive or toxic materials and are friendly to environment; expensive devices of a photoetching device, a laser device and the like and a complicated technological process are not needed in the overall preparation process; and the crystalline silicon solar cell disclosed by the invention is free of a high temperature, simple in processing step and suitable for large-scale production, does not need to use a transparent conductive thin film, is low in cost and has a wide application prospect.

Owner:江苏润阳悦达光伏科技有限公司

Nitride light emitting diode and manufacturing method thereof

InactiveCN103647009AReduce entryReduce refluxPolycrystalline material growthFrom chemically reactive gasesQuantum wellPhysical chemistry

The invention discloses a nitride light emitting diode and a manufacturing method thereof. The structure at least comprises a substrate, an n type nitride layer, an active area and a p type nitride layer. The active area comprises M pairs of AlxIn1-x-yGayN / GaN quantum wells and N pairs of InGaN / GaN quantum wells. Electronic reflux and a polarization effect are improved. Composite efficiency of a quantum well area and a density of two-dimension electron gas at an interface are increased. Photoelectric conversion efficiency of the light emitting diode is increased too. Simultaneously, an endurance capacity of the LED to static electricity is enhanced and an electrical property of the LED is improved.

Owner:TIANJIN SANAN OPTOELECTRONICS

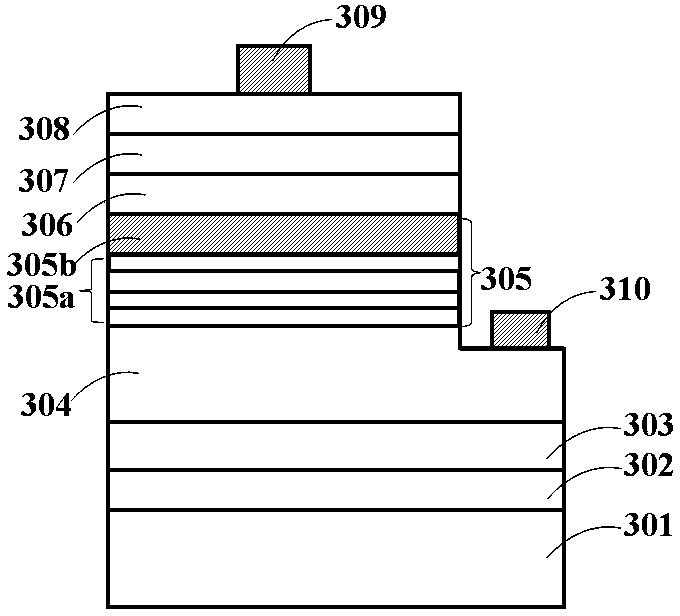

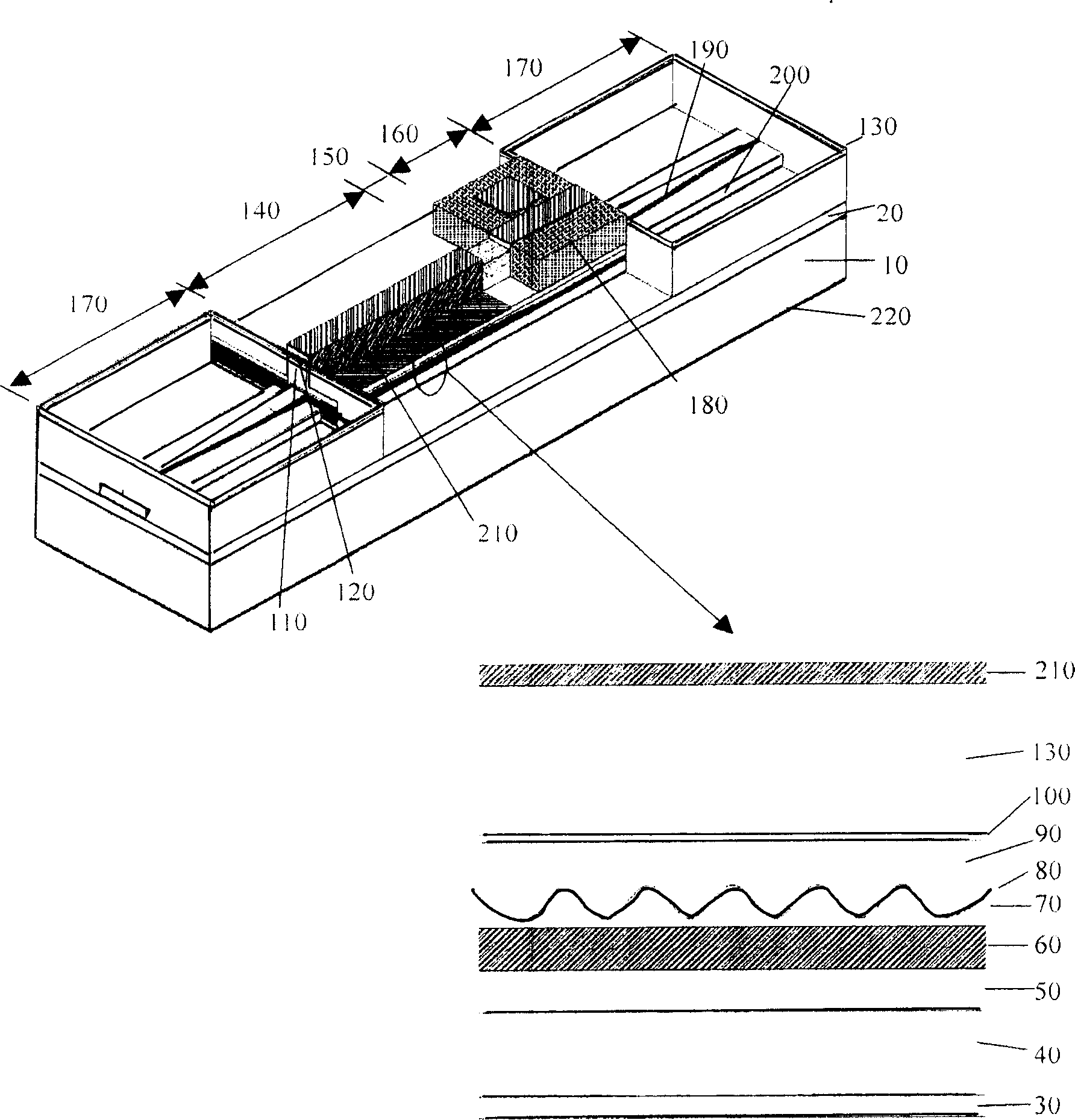

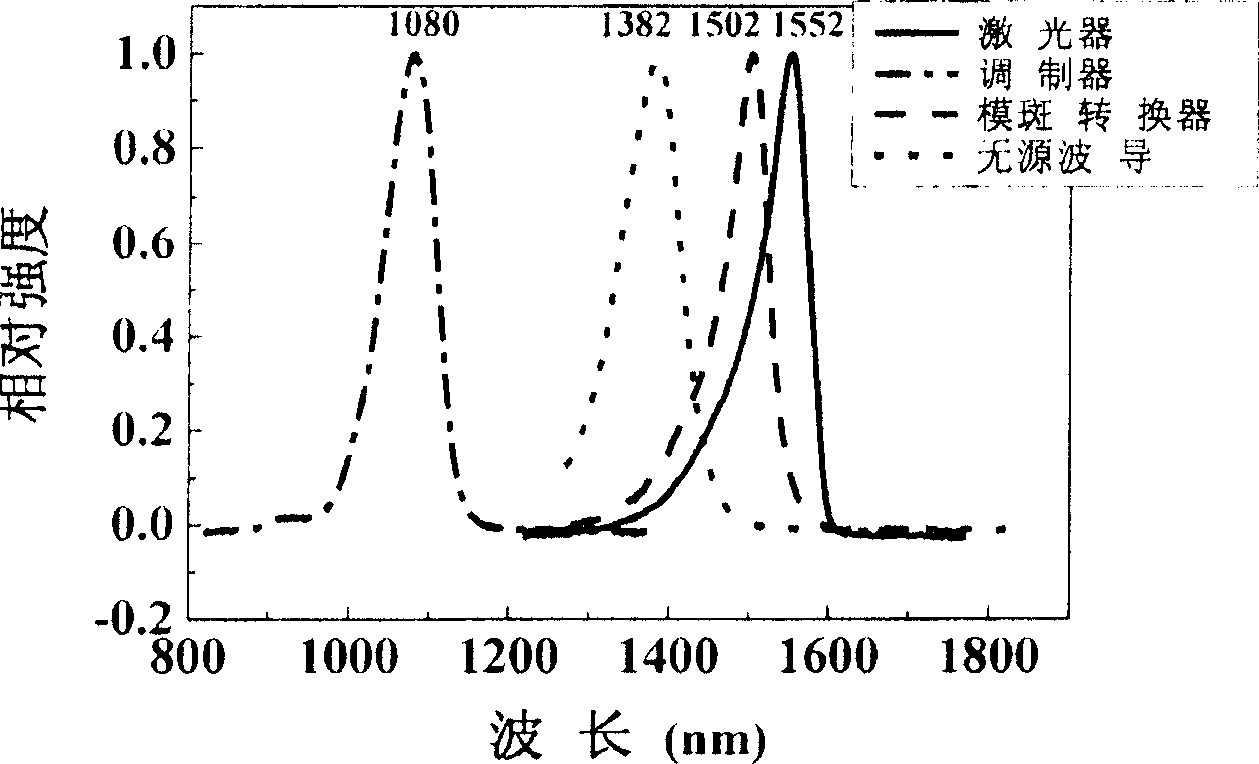

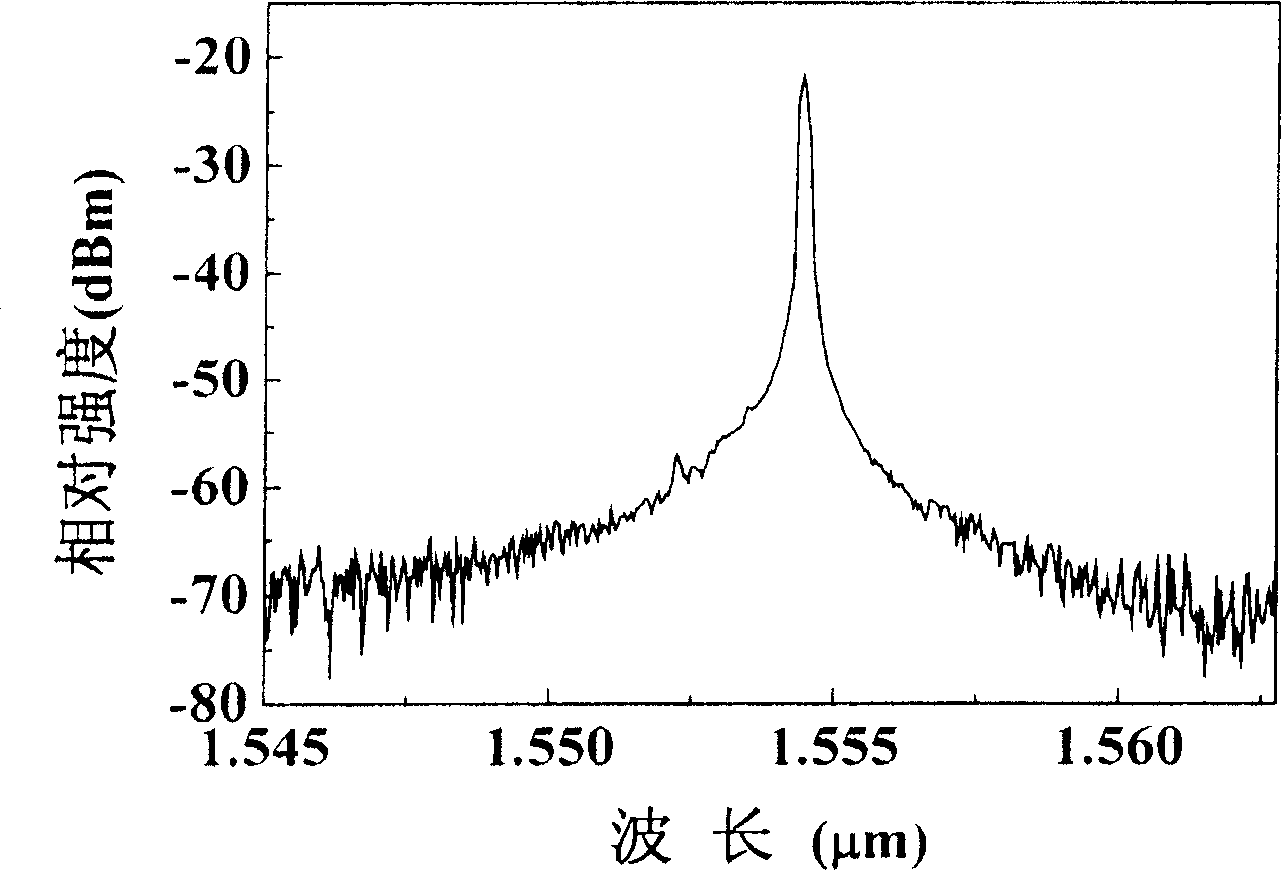

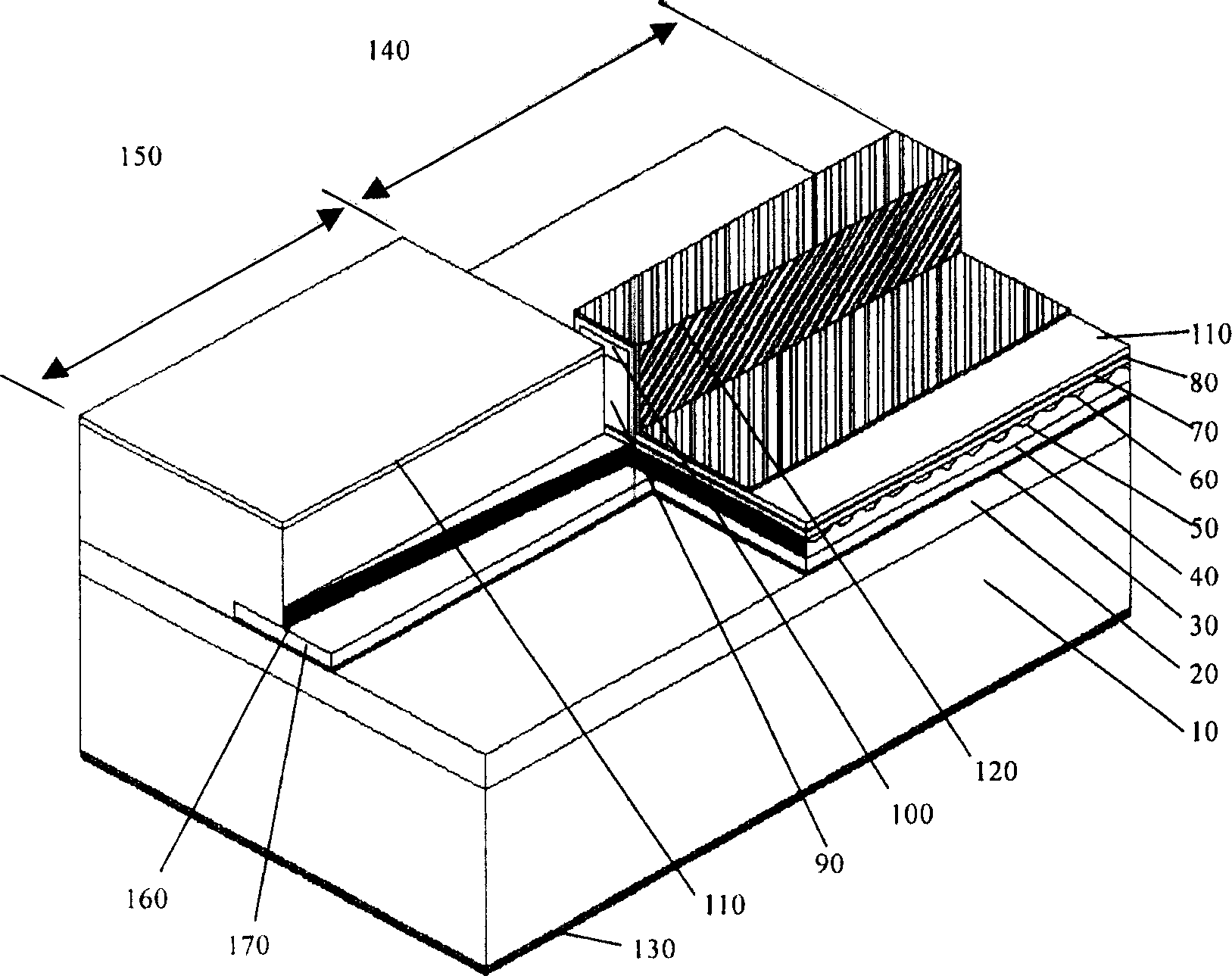

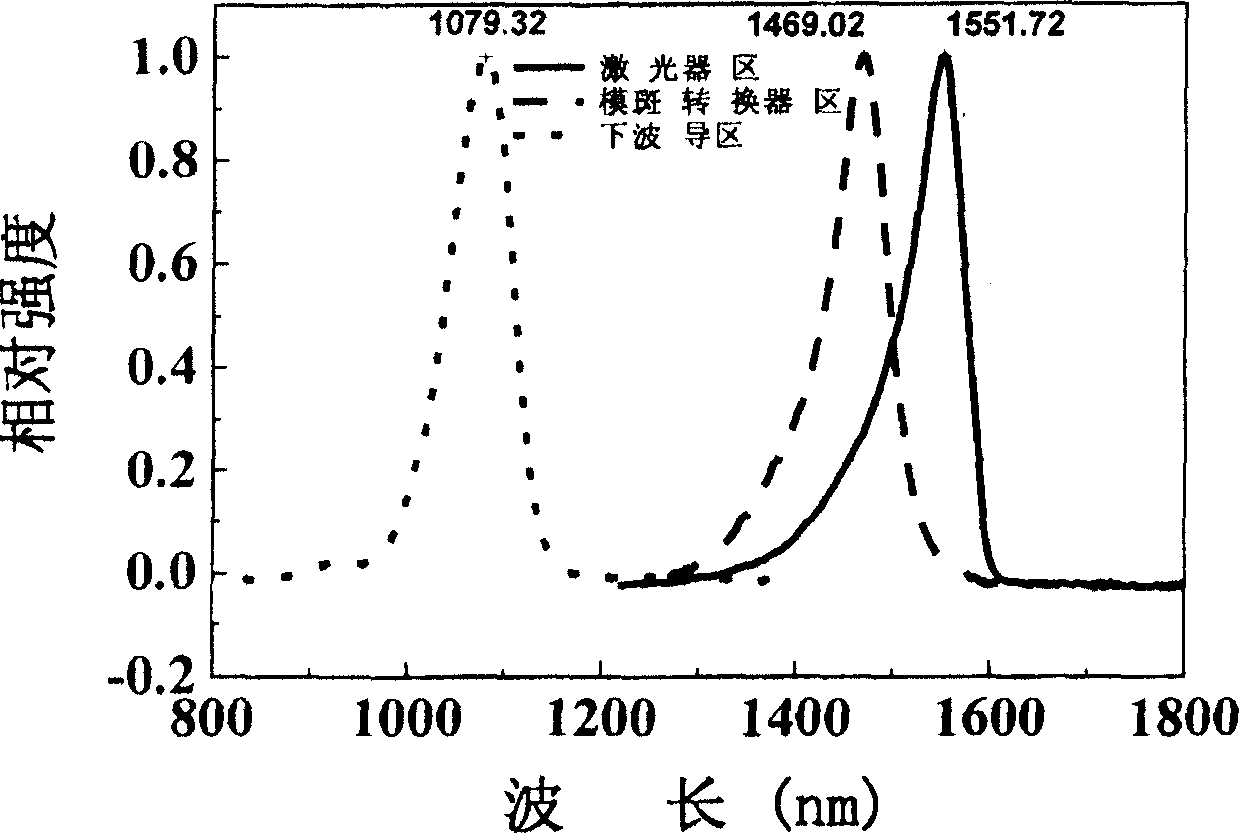

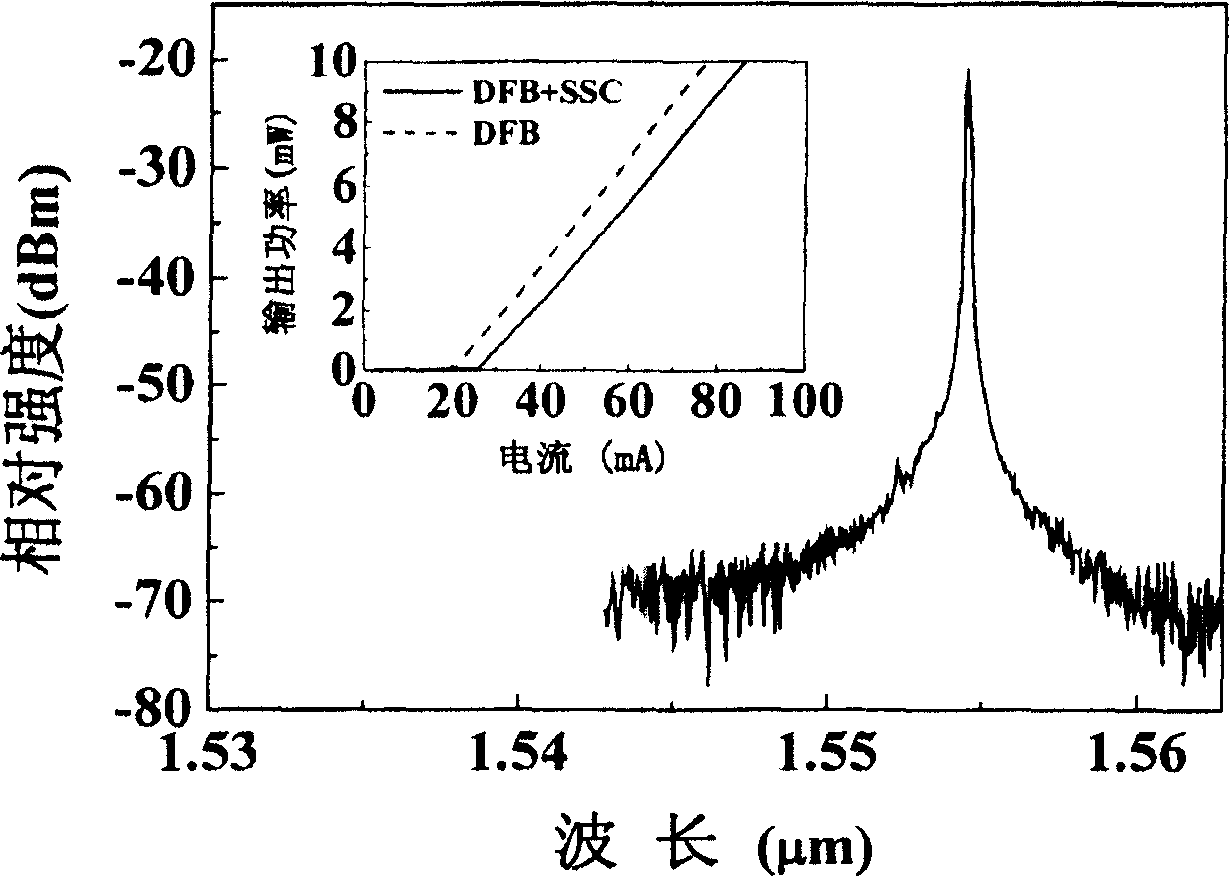

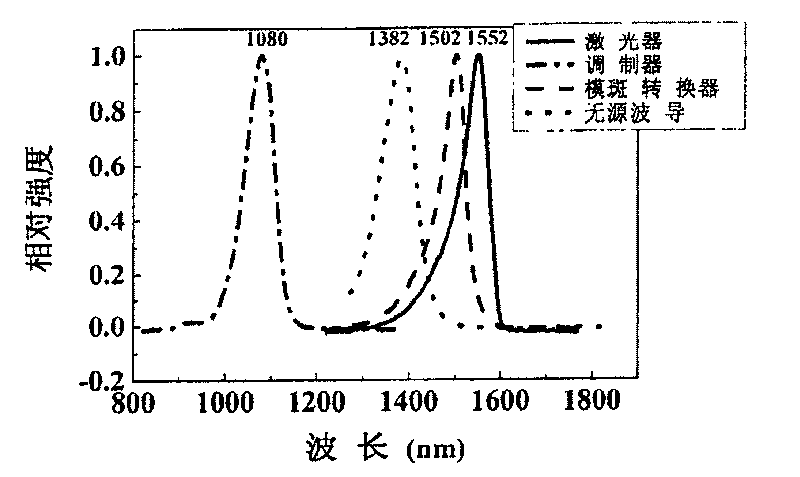

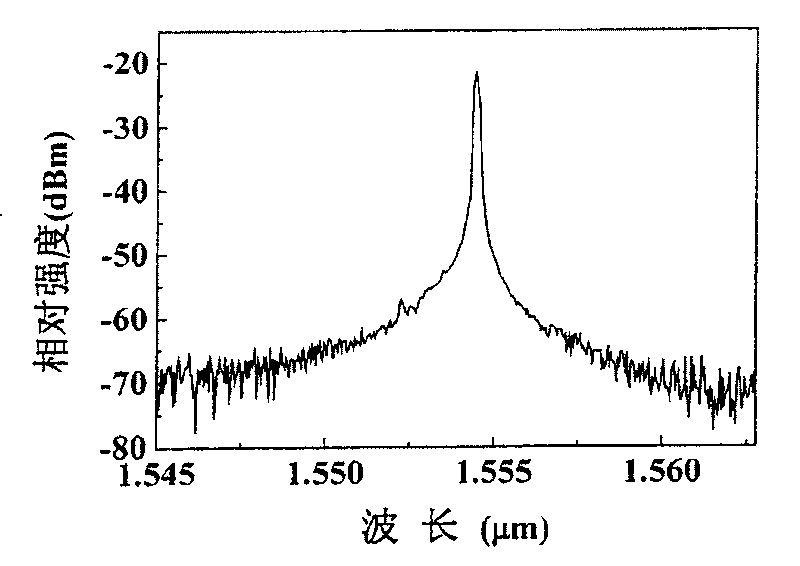

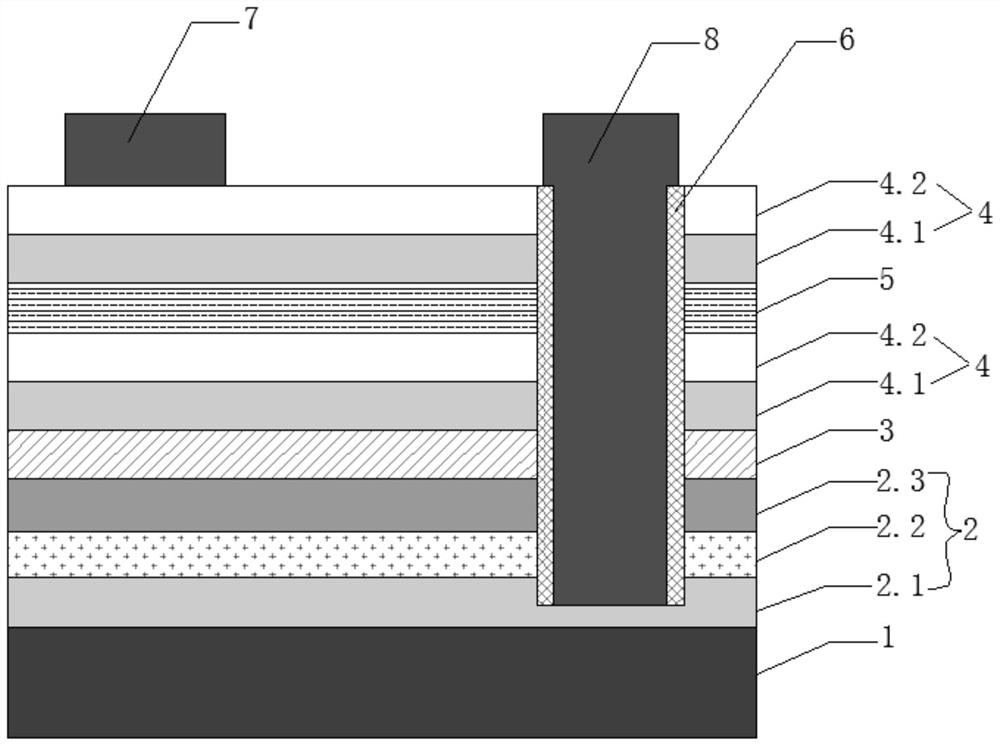

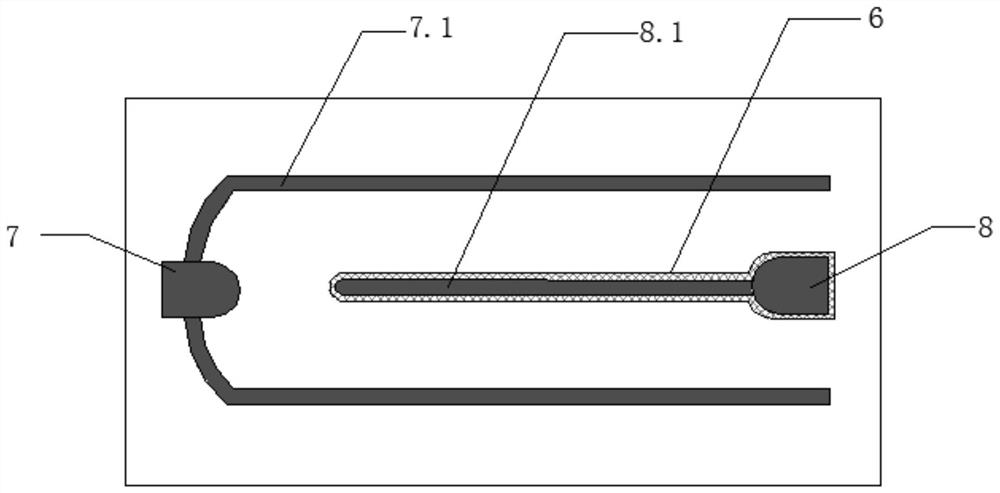

Integration method for electric absorption modulation laser and modular spot converter

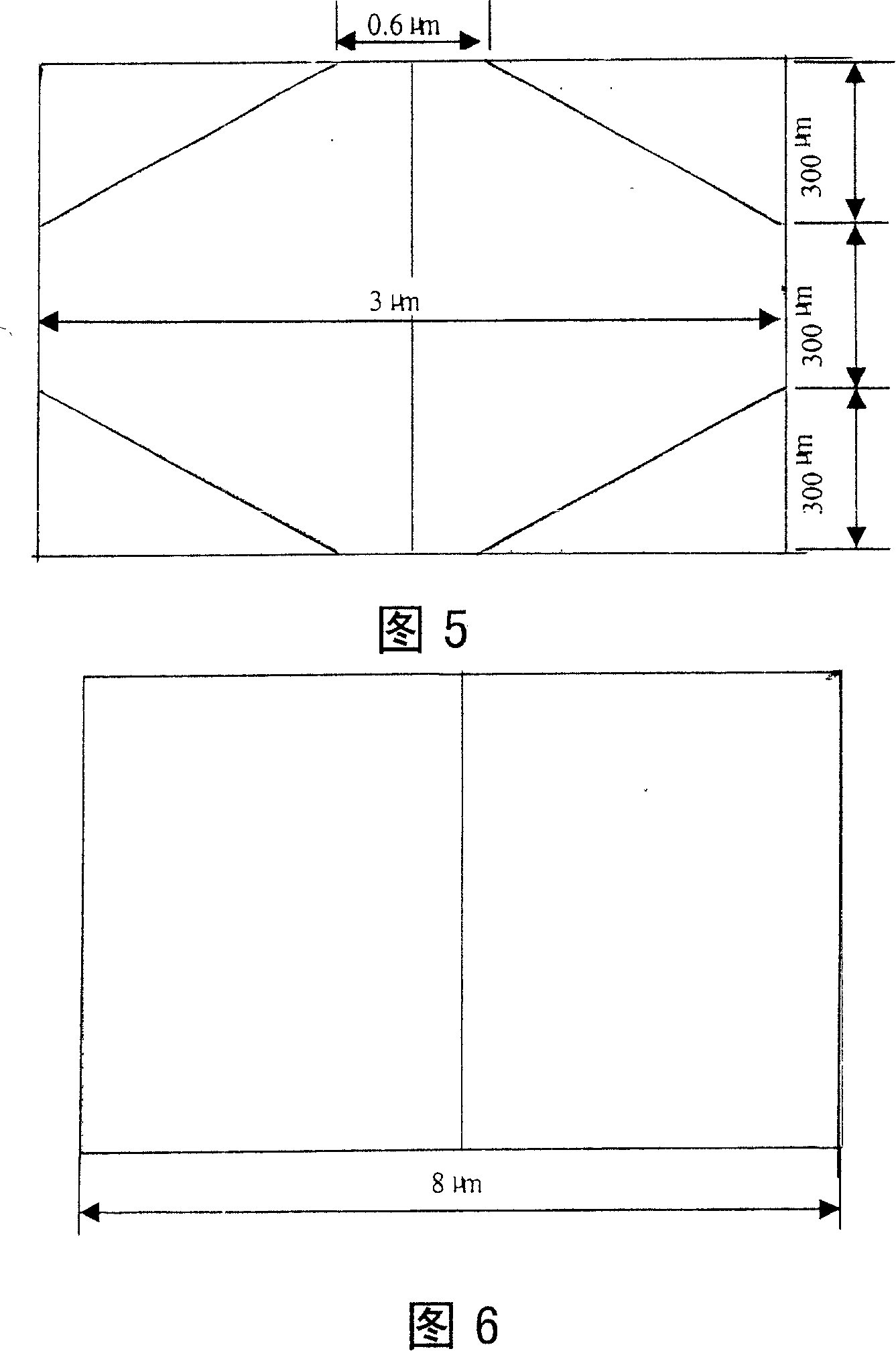

InactiveCN1909309AReduce the number of growthHas an effectLaser detailsSemiconductor lasersPhosphate ionSilicon dioxide

The invention relates to an integration method of electric adsorption modulation laser and mode speckle converter, which comprises: growing n-type indium phosphate buffer layer on the substrate; corroding the upper 1.1Q layer on the chip, to grow buffer layer; growing silica dioxide protective layer on the whole chip, and corroding the silica dioxide protective layer at two ends of mode speckle converter; pouring low-energy phosphate ion; growing the silica dioxide protective layer again; heating, keeping warm, anneal on the chip; corroding silica dioxide protective layer; using relative light etching plate to mask the laser and modulator, to form the upper ridge and lower ridge on the converter; growing p-type indium phosphate and indium gallium arsenic phosphate etching stop layer; etching ridge pilot structure; depositing medlin at two sides of laser and modulator; opening the electrode windows of laser and modulator; etching the electrode images on the laser and modulator to splash the P electrode and remove the P electrode; extending the substrate, and splashing n electrode; slicing the sample to form tubular chip.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

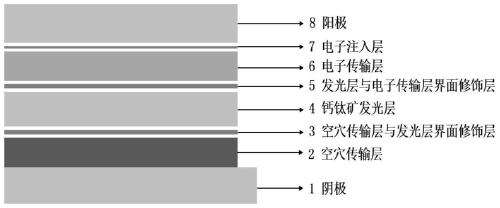

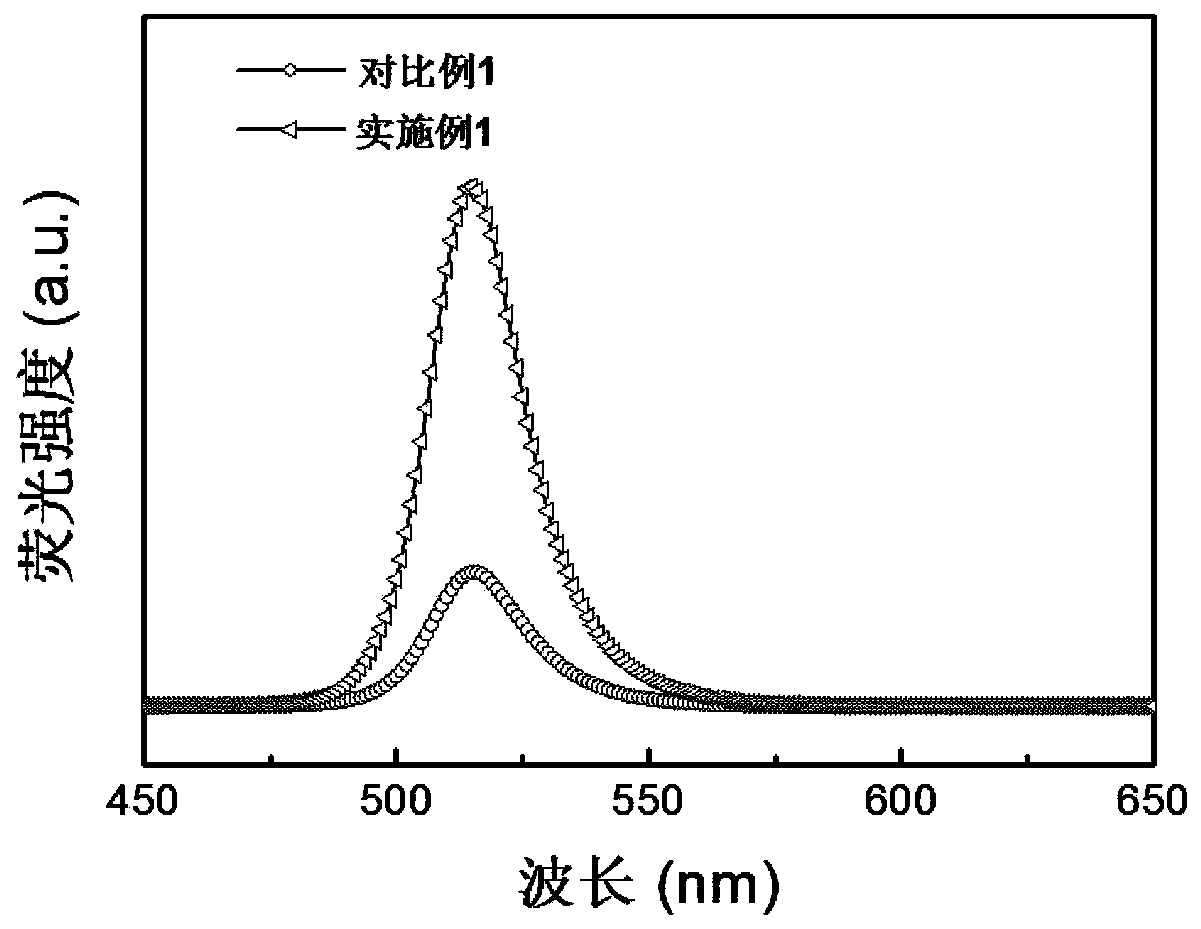

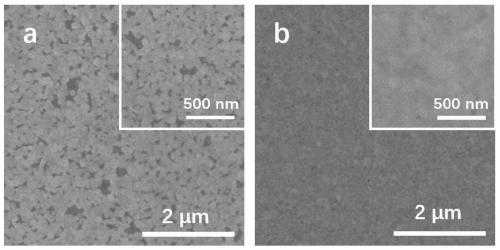

Low-roll-off quasi-two-dimensional perovskite light emitting diode and preparation method thereof

ActiveCN111192971ASolve the problem of serious efficiency roll-offImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectron holeElectron transporting layer

The invention discloses a low-roll-off quasi-two-dimensional perovskite light-emitting diode and a preparation method thereof. The low-roll-off quasi-two-dimensional perovskite light-emitting diode issequentially provided with a cathode, a hole transport layer, a hole transport layer and light-emitting layer interface modification layer, a perovskite light-emitting layer, a light-emitting layer and electron transport interface modification layer, an electron transport layer, an electron injection layer and an anode from bottom to top. By modifying the interface of the hole transport layer andthe perovskite light-emitting layer, the hole injection barrier between the hole layer and the light-emitting layer is reduced, the hole injection efficiency is improved, the hole layer can be prevented from quenching the perovskite layer, and the light-emitting efficiency of the perovskite layer is improved. The interface of the perovskite light-emitting layer and the electron transport layer isalso modified, so that the defect state of the perovskite surface can be passivated, the film quality of the light-emitting layer is improved, non-radiative recombination is inhibited, and the light-emitting efficiency of the device is further improved.

Owner:SHANGHAI UNIV

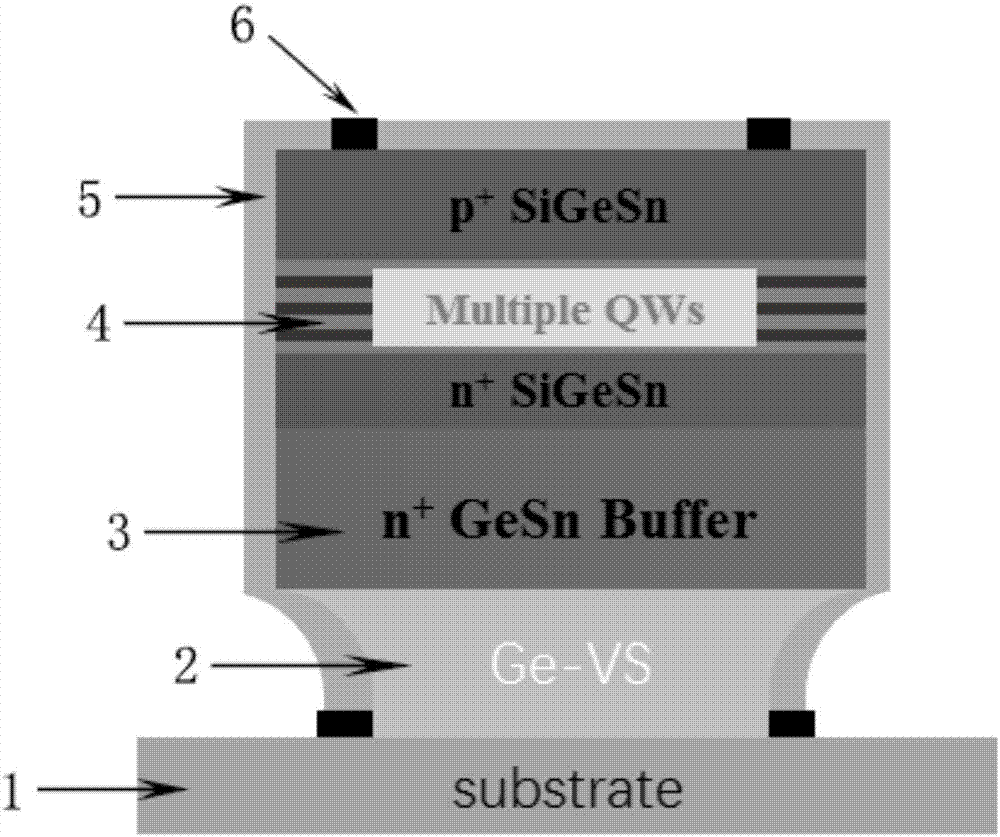

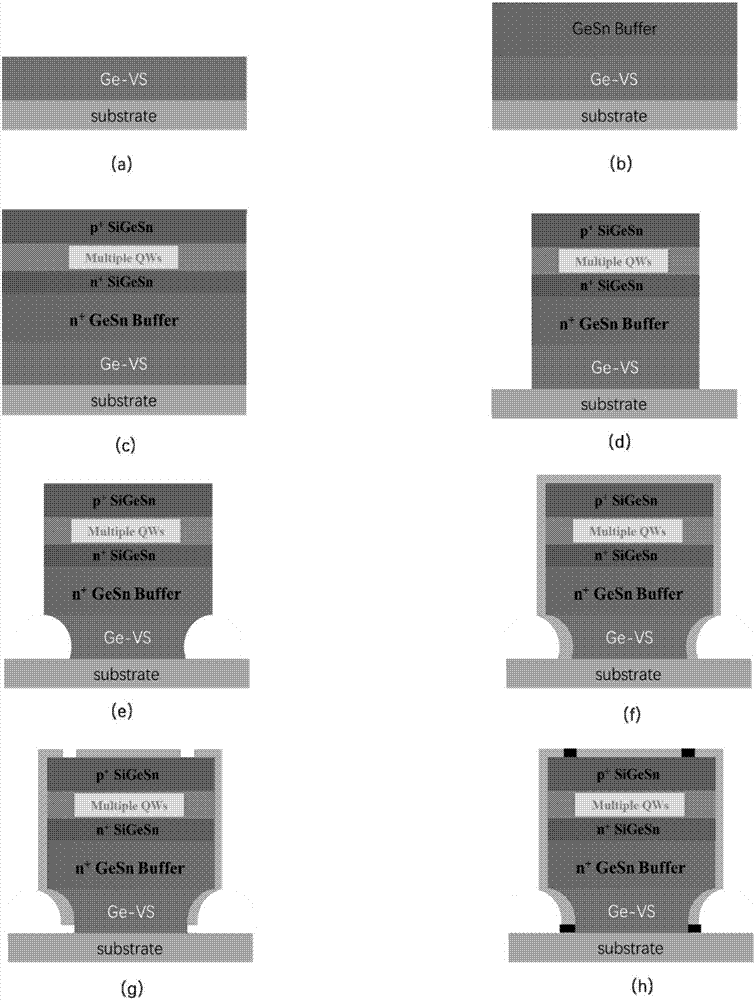

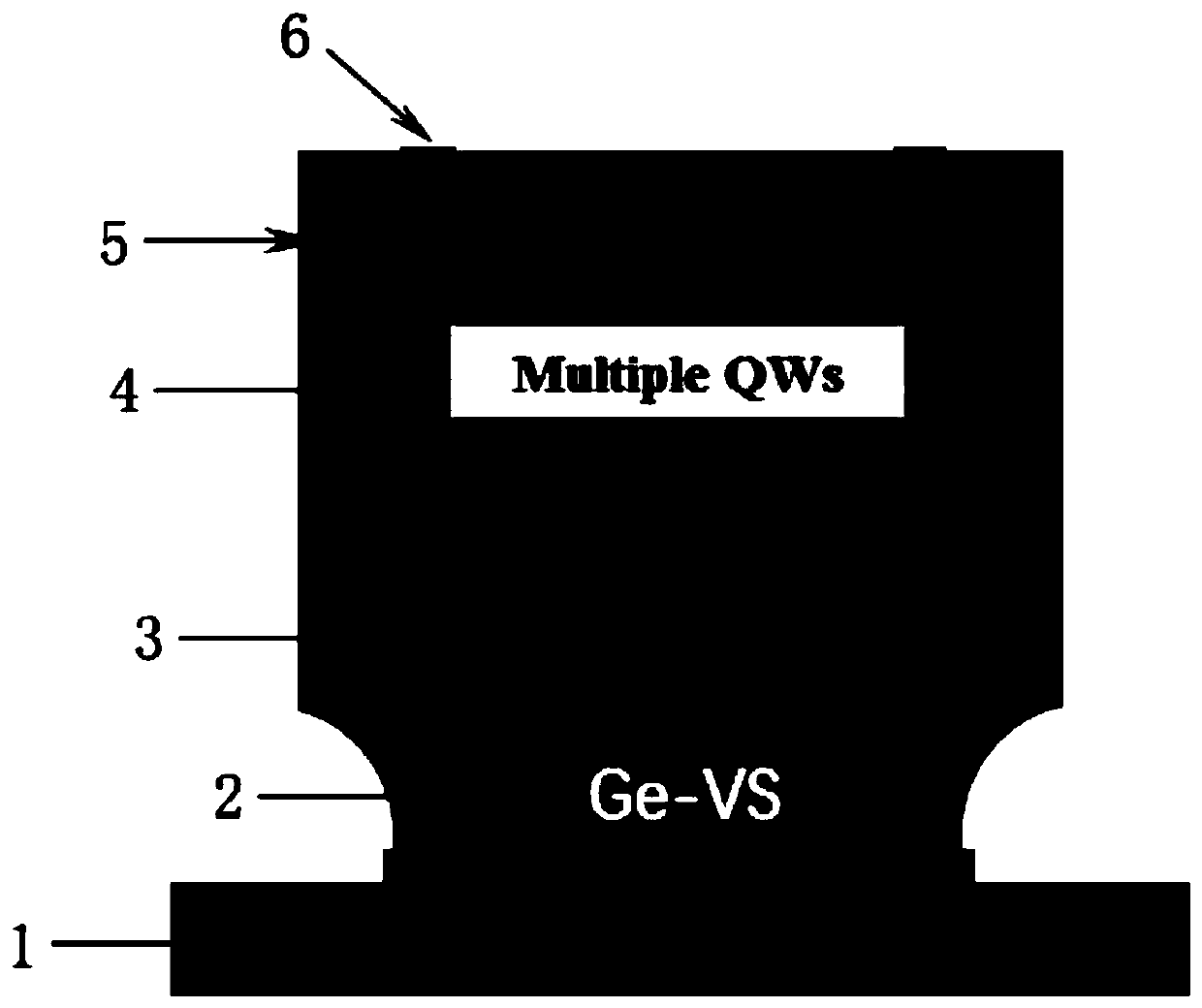

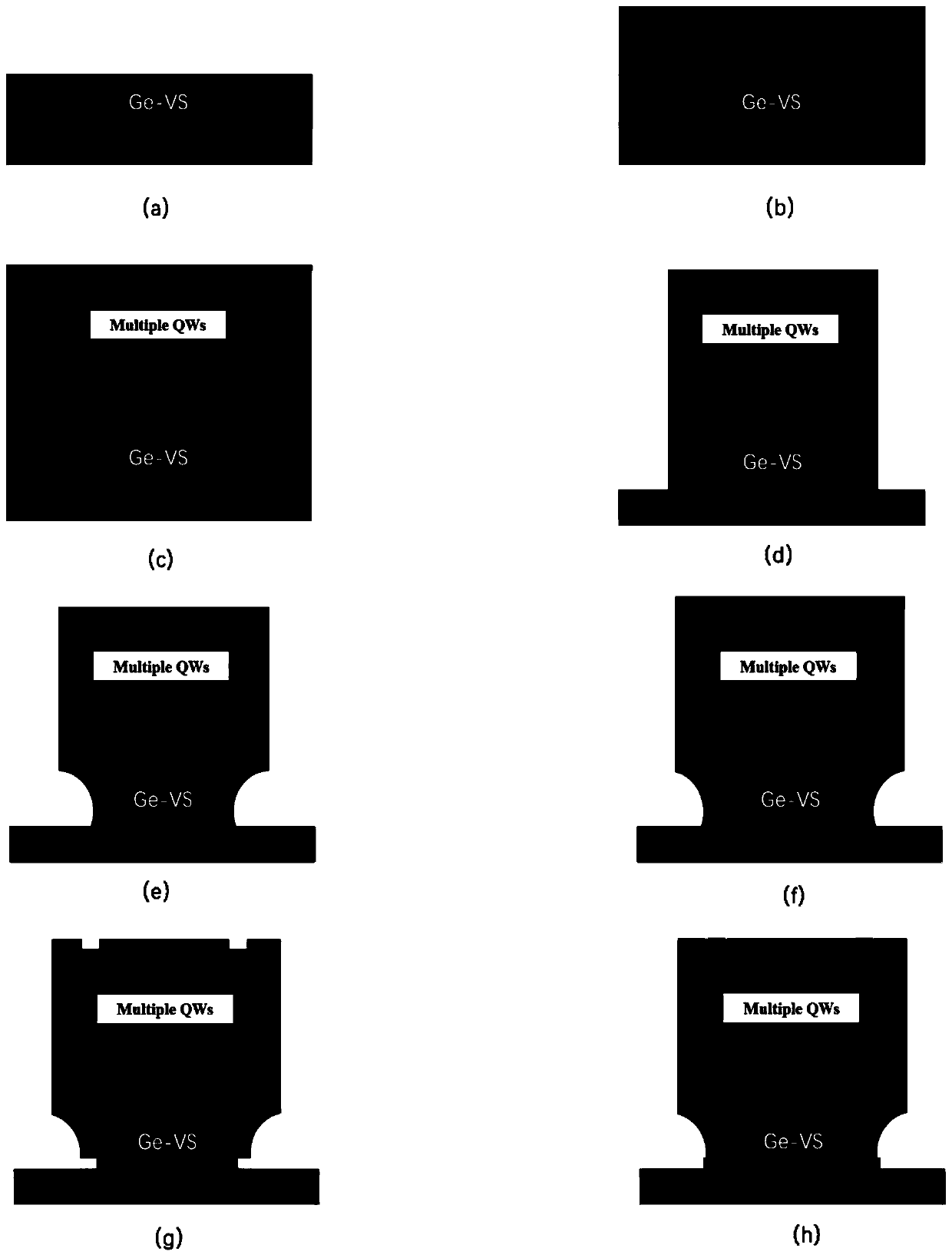

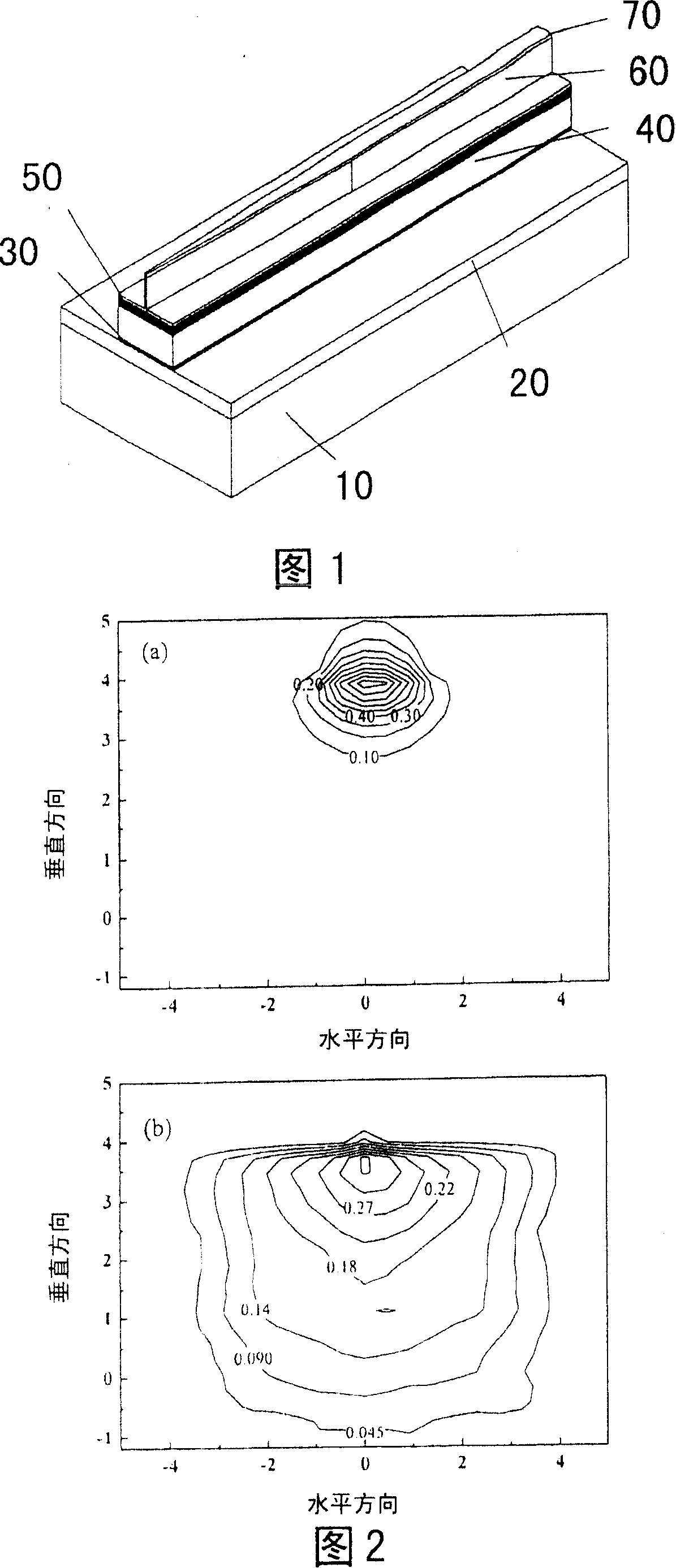

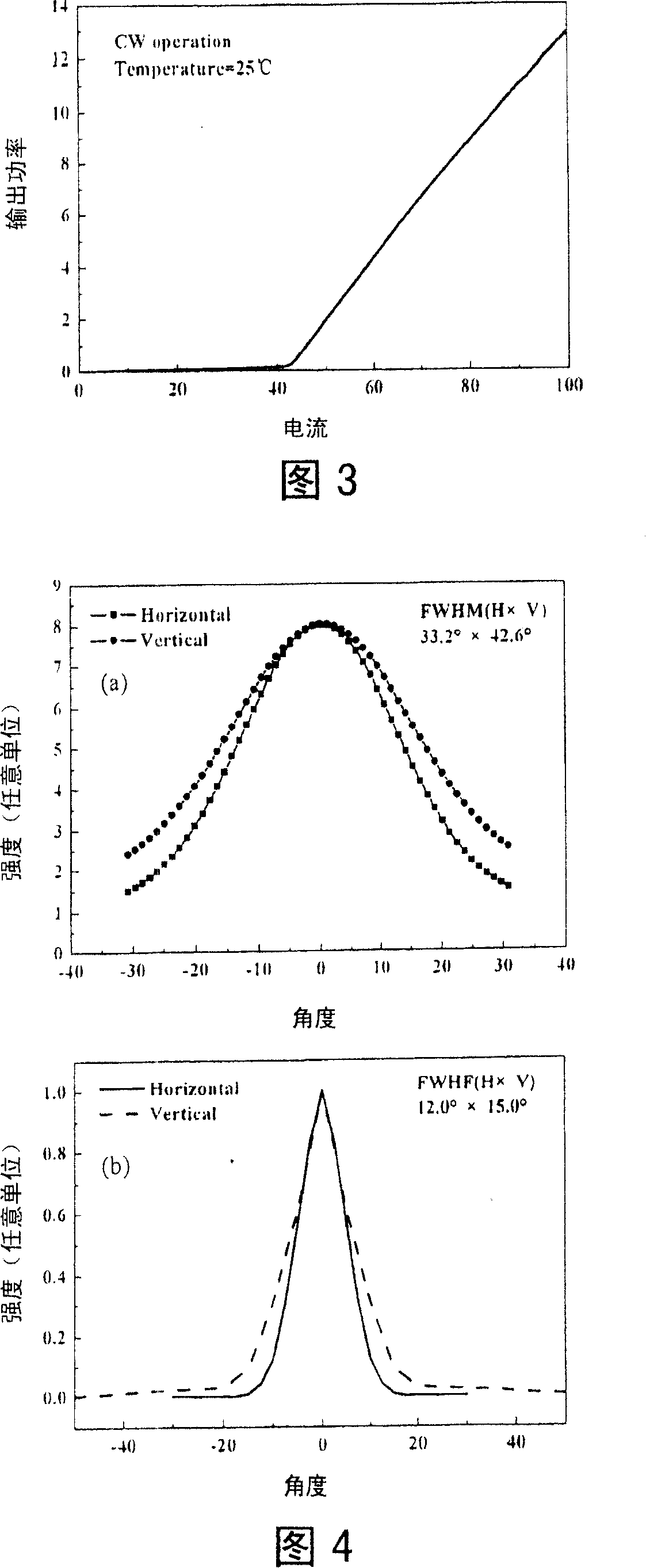

Strain multiple quantum well laser device based on GeSn/SiGeSn material and manufacturing method thereof

ActiveCN107342535ALower bandgapRedshift working wavelengthLaser active region structureManufacturing technologyPhysical chemistry

The invention discloses a strain multiple quantum well laser device based on GeSn / SiGeSn material and a manufacturing method thereof. A barrier layer adopts a GeSiSn material; and the barrier layer adopts a GeSn material. A pseudo substrate (Ge), a buffer layer (GeSn) and an active area (GeSn / GeSiSn) are vertically distributed on a substrate (Si) from bottom to top in sequence, and an Si3N4 tensile stress film is wrapped around the pseudo substrate, the buffer layer and the active area. The manufacturing method of the laser device disclosed by the invention comprises the following steps: (1) adopting a low-temperature solid-source molecular beam epitaxy growth technology to grow the GeSn and GeSiSn materials; and (2) adopting a standard laser device manufacturing technology to process the device. Through a multiple quantum well structure and the tensile strain introduced by the additionally added Si3N4 stress film, red shift occurs for the laser wavelength of the laser device, the optical gain of the laser device is obviously improved, and the threshold value is greatly reduced.

Owner:XIDIAN UNIV

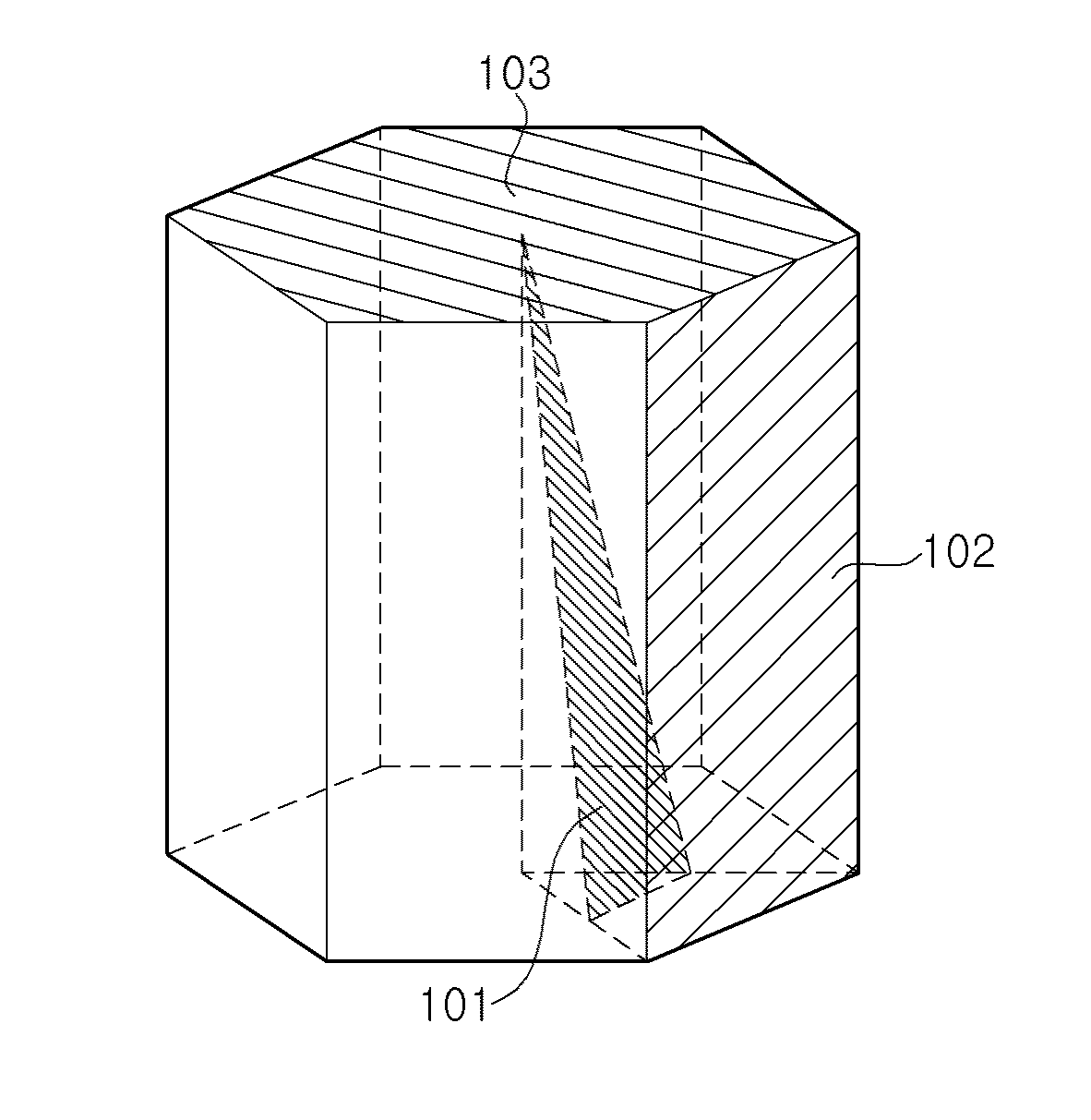

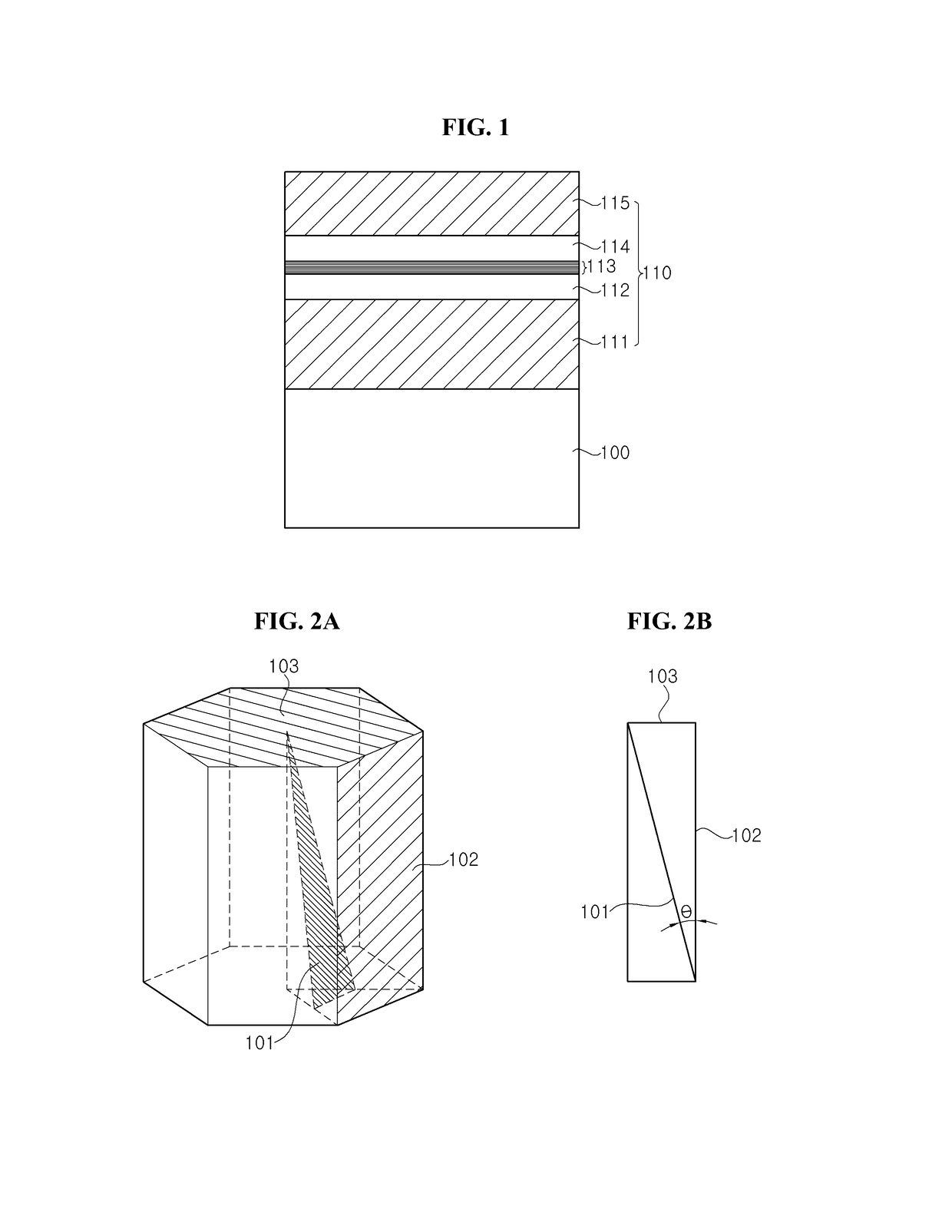

Light emitting device with high efficiency

ActiveUS20170069790A1Increasing thicknessReduced Auger RecombinationSemiconductor devicesGallium nitrideNitride semiconductors

A light emitting device includes a substrate including gallium nitride, and a semiconductor layer disposed on the substrate, the semiconductor layer including an n-type nitride semiconductor layer, an active layer disposed on the n-type nitride semiconductor layer, and a p-type nitride semiconductor layer disposed on the active layer, in which an angle defined between a crystal growth plane of the substrate and an m-plane thereof is in a range of 3.5° to 6.

Owner:SEOUL VIOSYS CO LTD

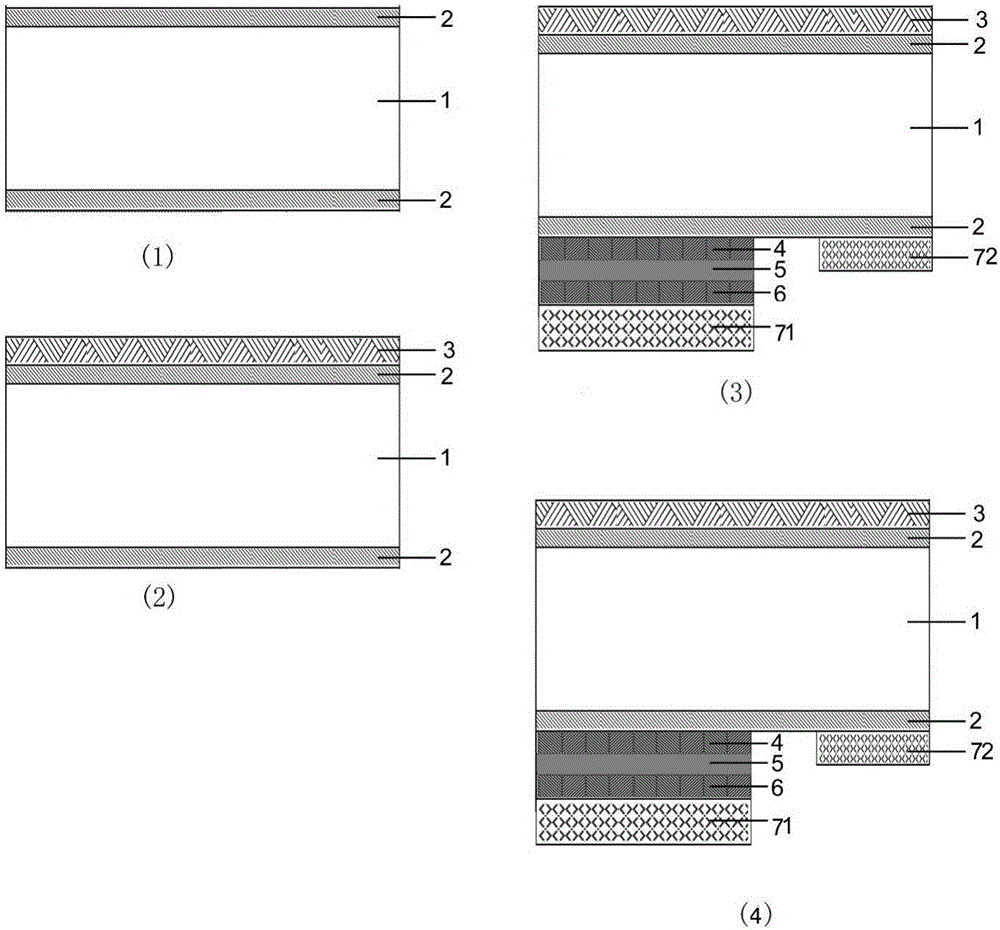

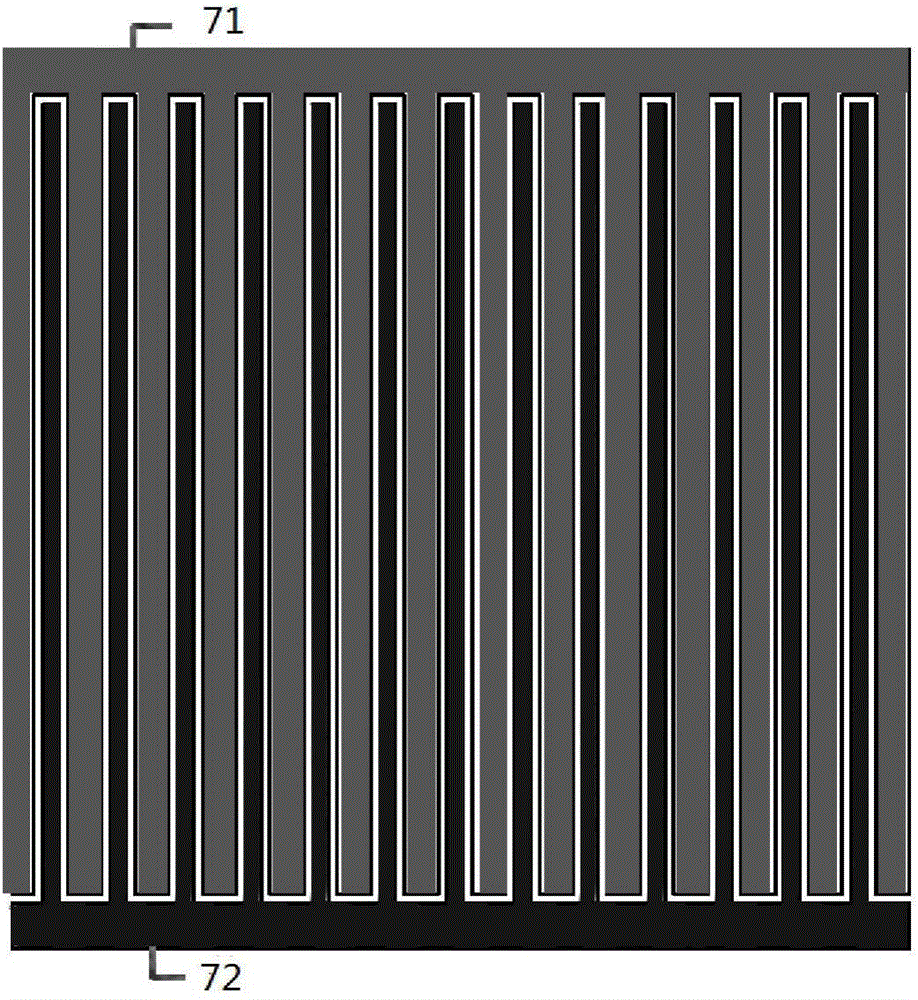

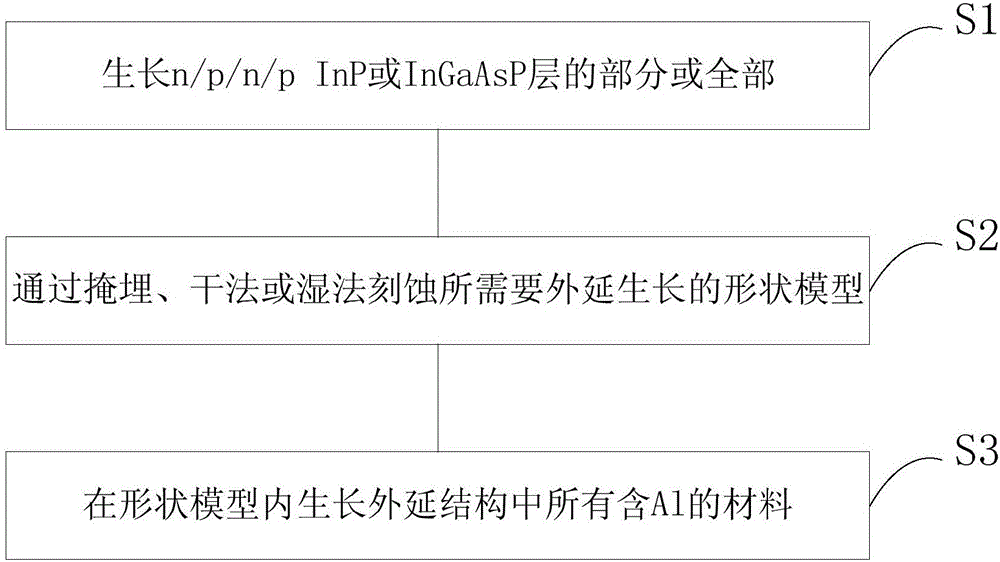

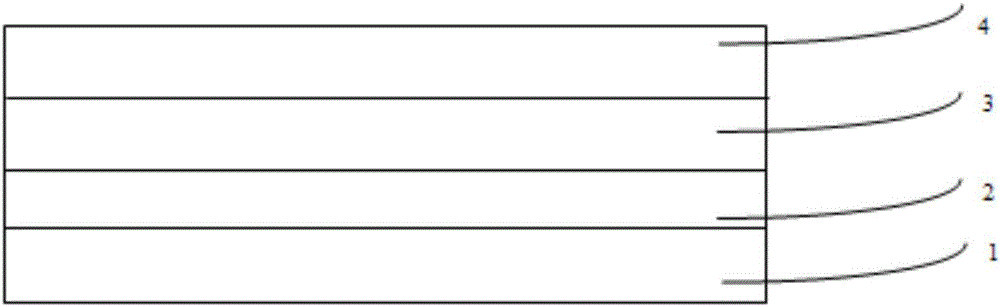

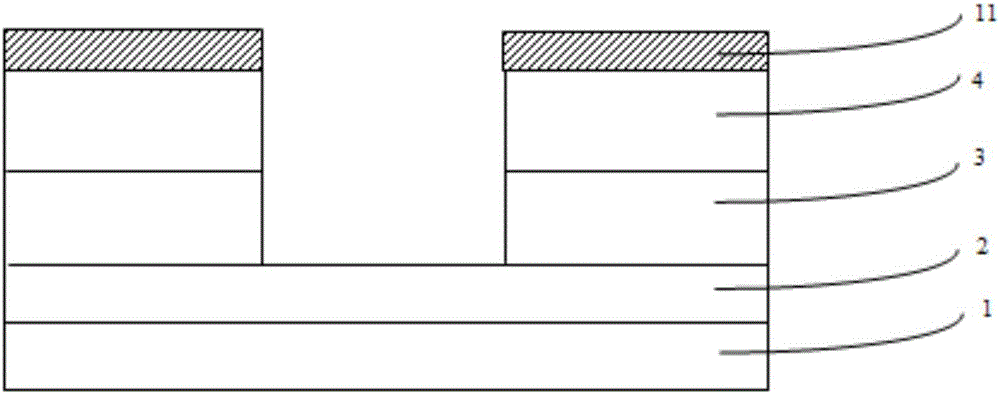

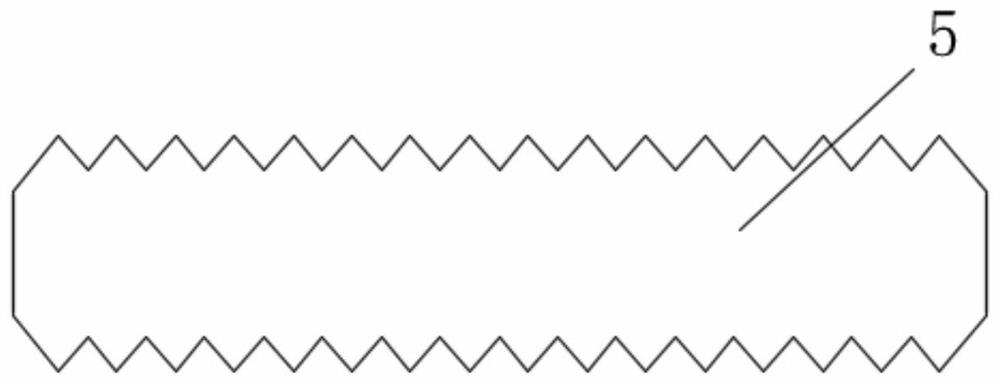

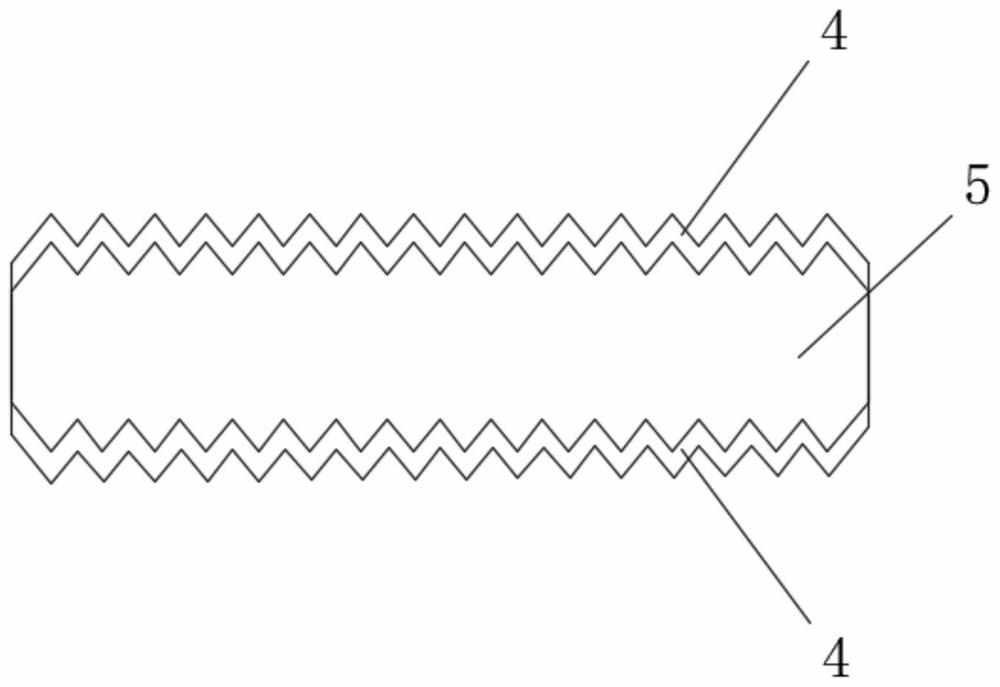

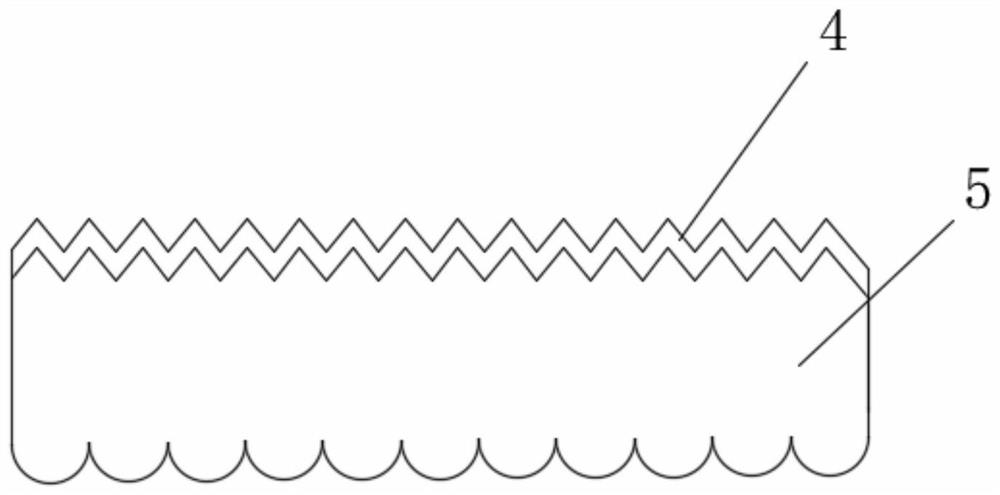

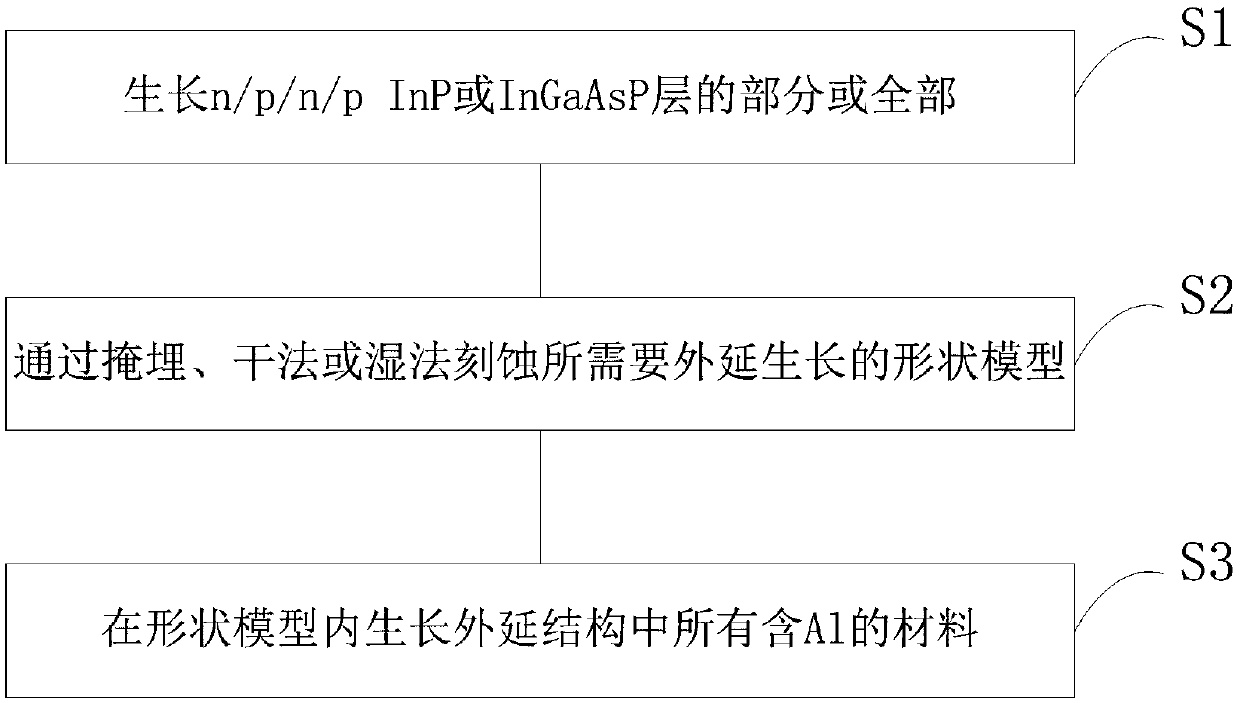

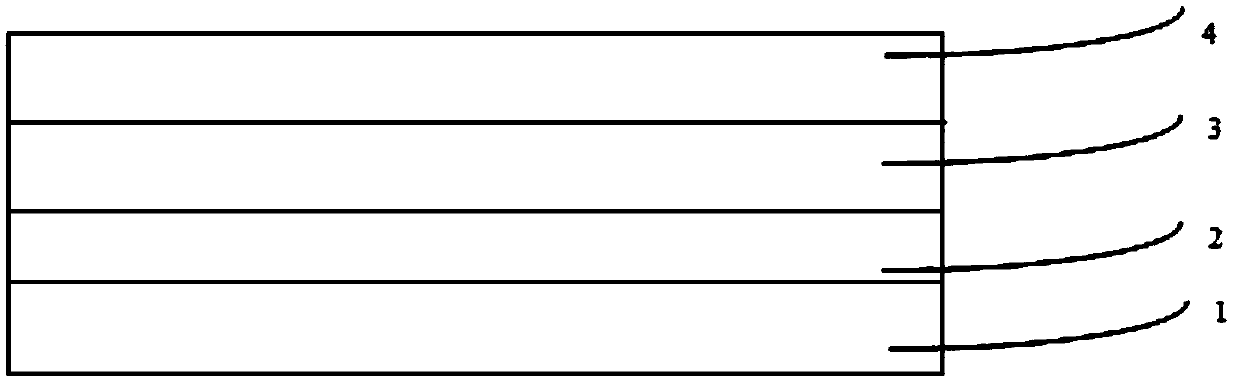

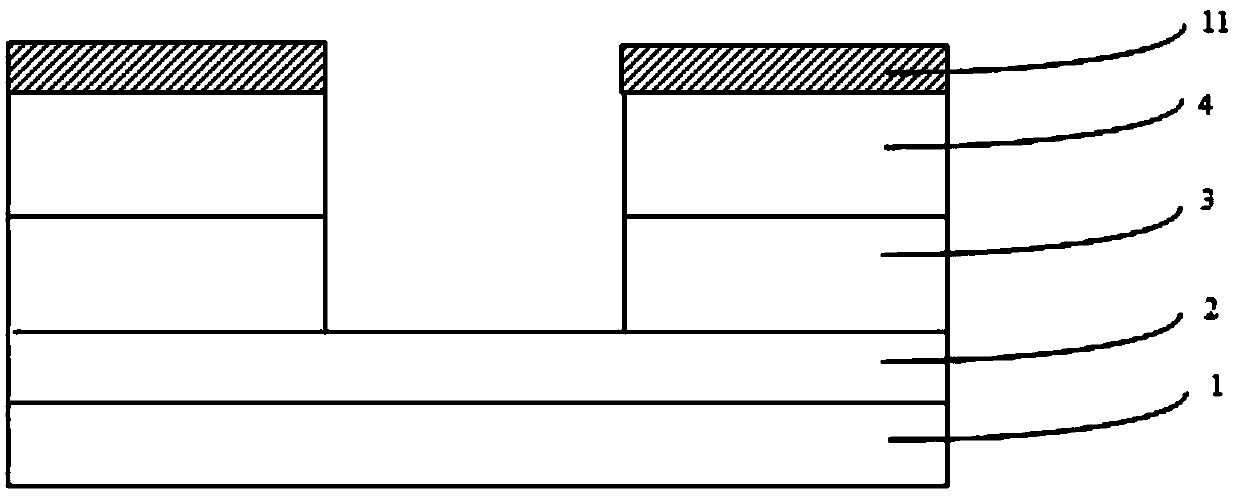

Epitaxial growth method and epitaxial layer with heterostructure buried

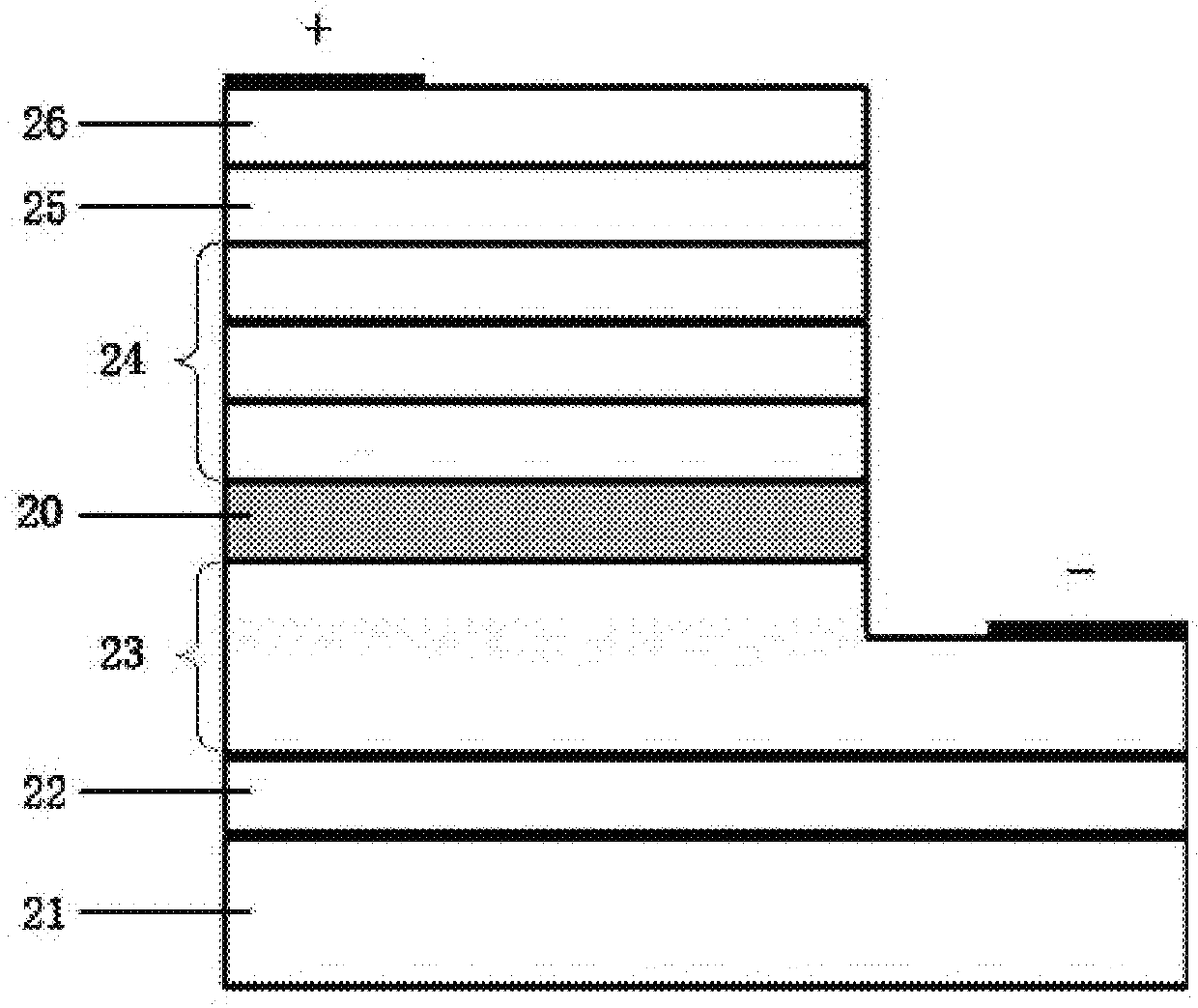

ActiveCN106300013ALower threshold current densityImprove high temperature characteristicsLaser detailsSemiconductor/solid-state device manufacturingQuantum efficiencyQuantum well

The invention relates to an epitaxial growth method and an epitaxial layer with a heterostructure buried. The epitaxial growth method includes following steps: S1, growing part of or all of an n / p / n / p InP or InGaAsP layer; S2, etching a shape model needing epitaxial growth through burying, a dry method or a wet method; S3, growing all material containing Al in an epitaxial structure in the shape model. Part of or all of an n / p / n / p structure is formed, the shape of the epitaxial layer needing growth is etched, and the epitaxial layer is grown in the shape. By utilizing the method, the advantages of AlGaInAs / InP materials and BH technology can be combined effectively to grow an efficient laser device epitaxial structure, effects of avoiding Al oxidation, lowering auger recombination and interband adsorption and improving high-temperature characteristics of devices are realized, threshold current density of a laser device is reduced, and feature temperature of an active layer material and external quantum efficiency, internal quantum efficiency and conversion efficiency of an active area quantum well are increased.

Owner:WUHAN HUAGONG GENUINE OPTICS TECH

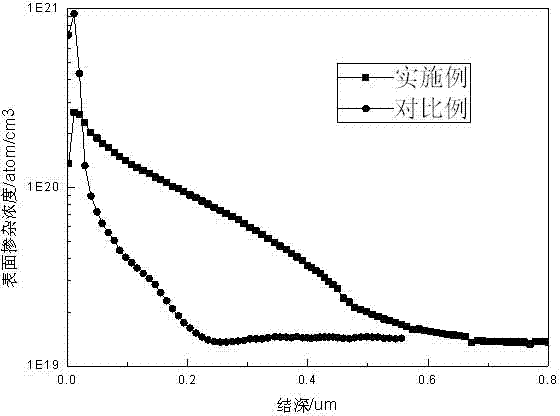

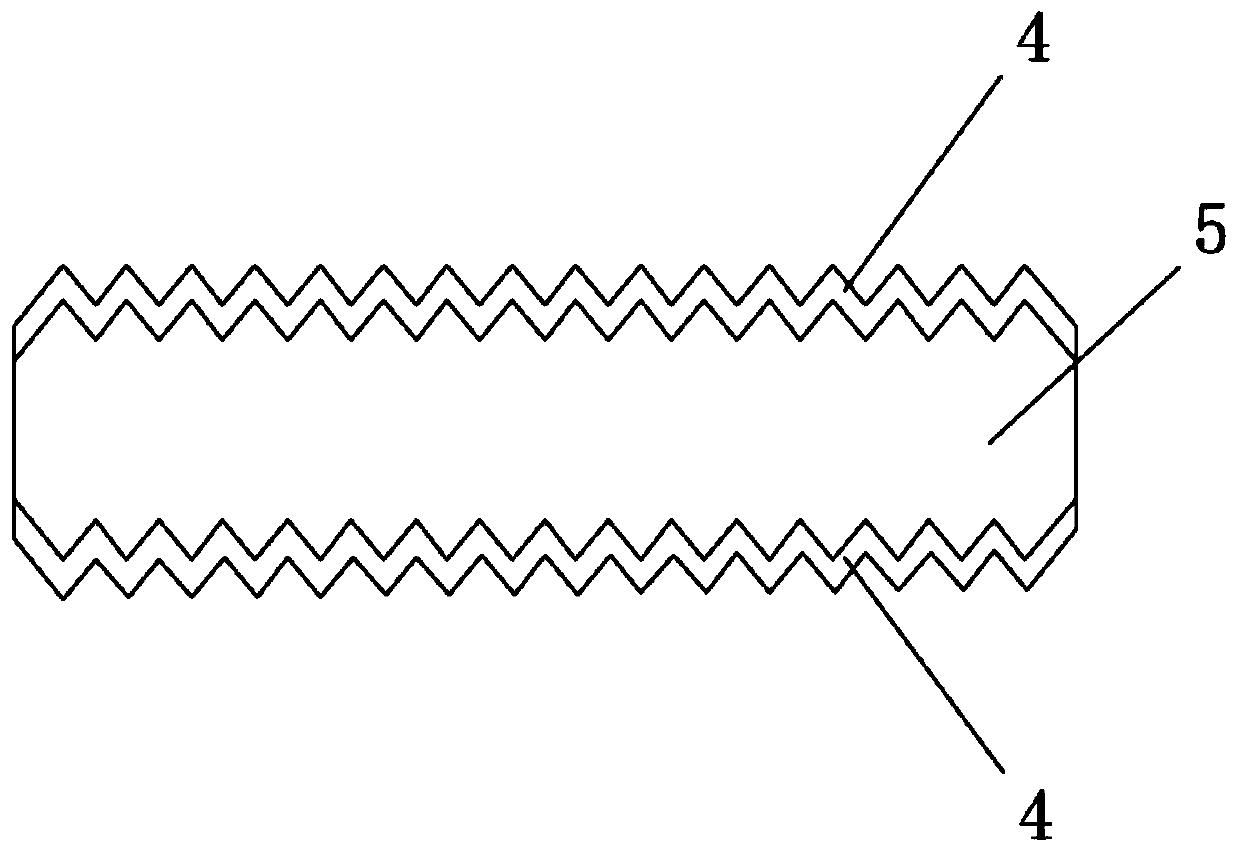

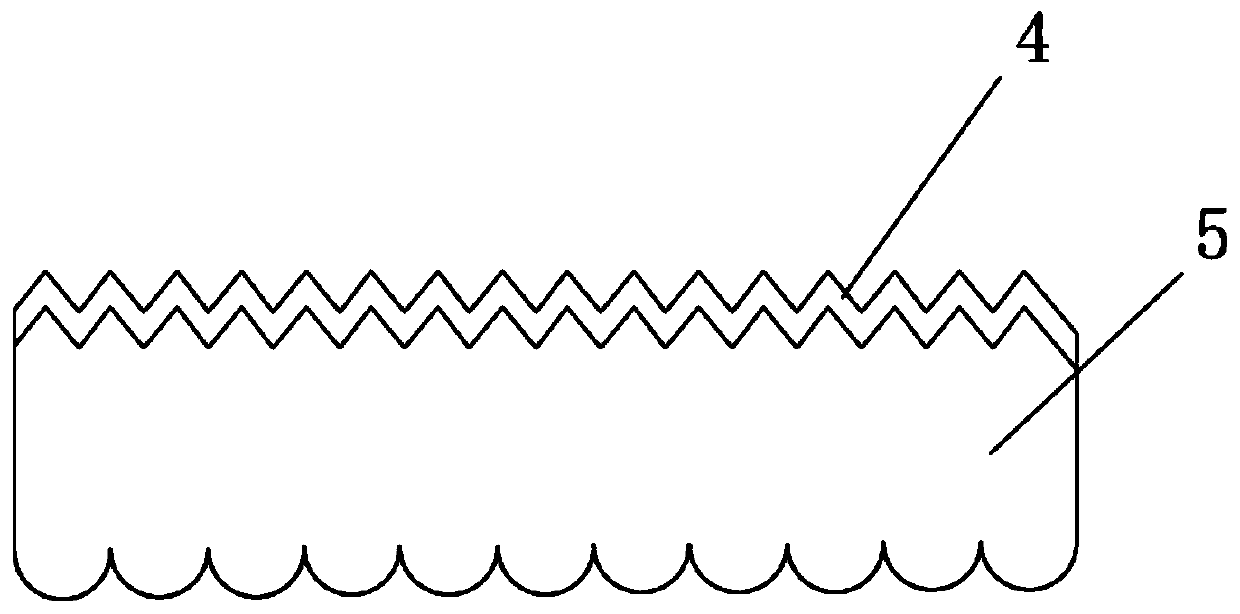

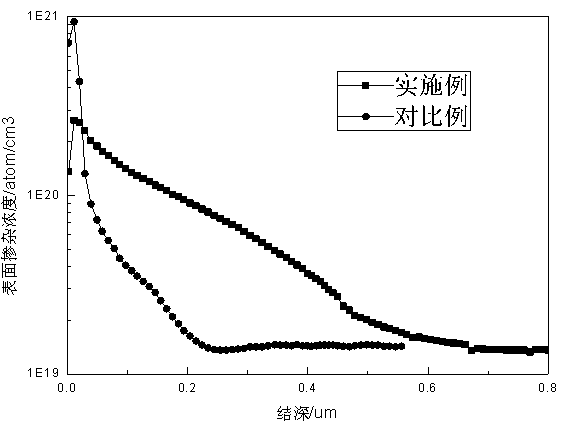

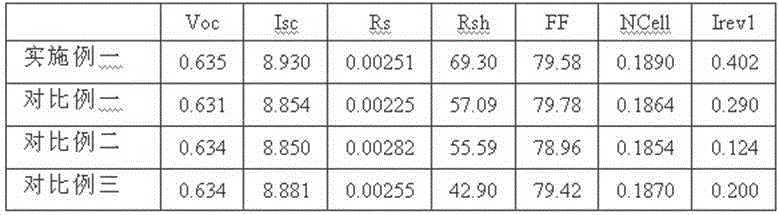

Crystal wafer and diffusion method thereof

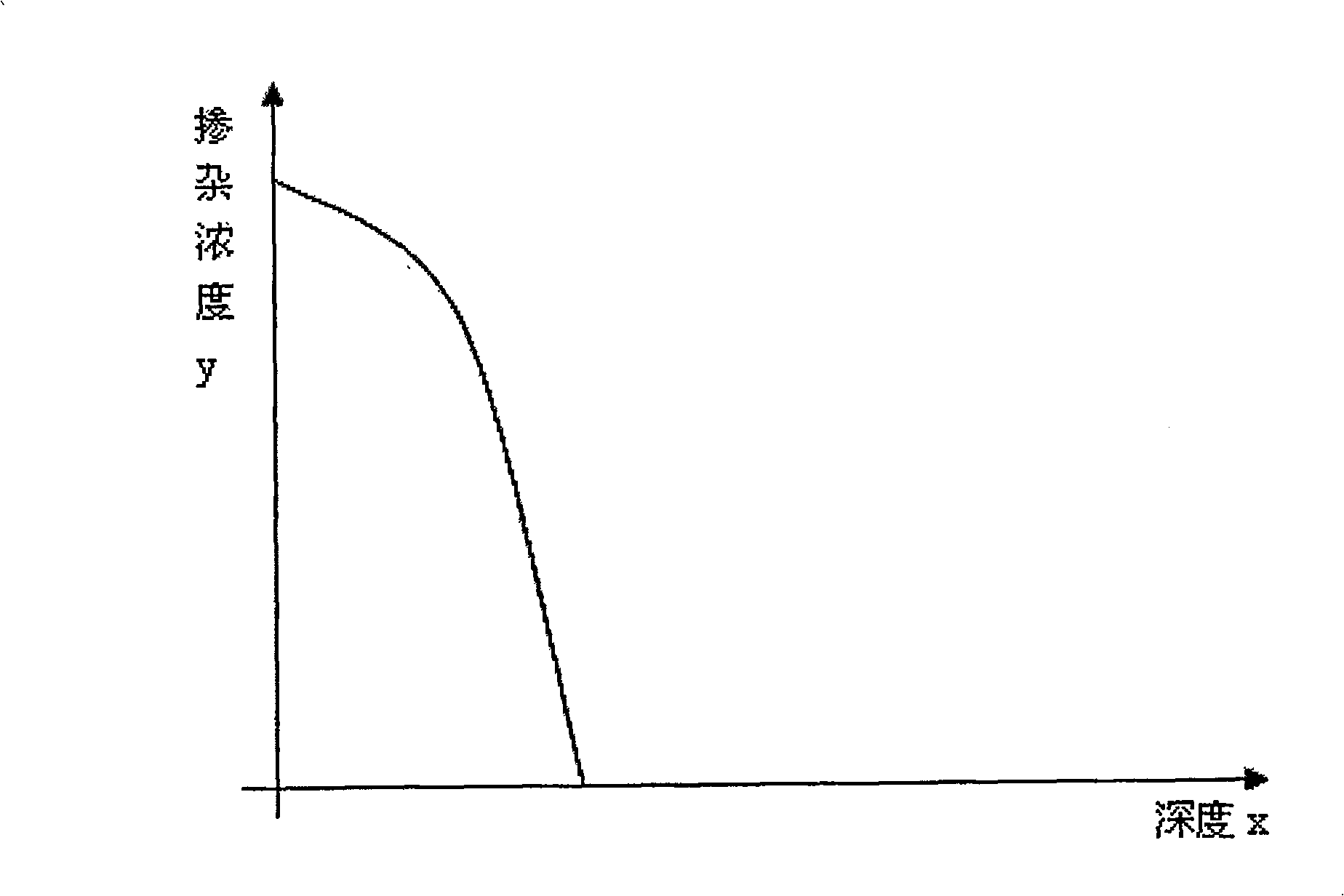

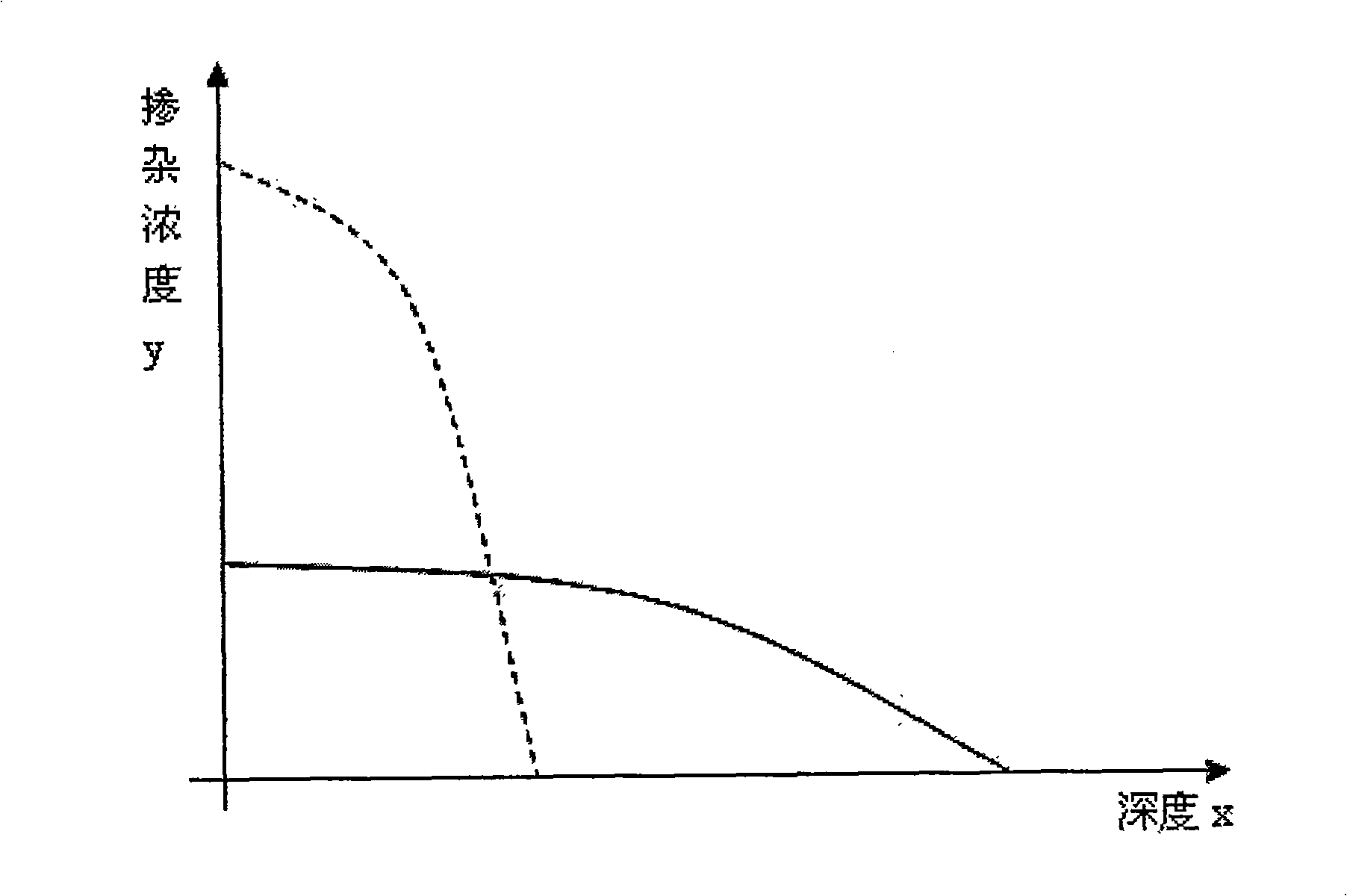

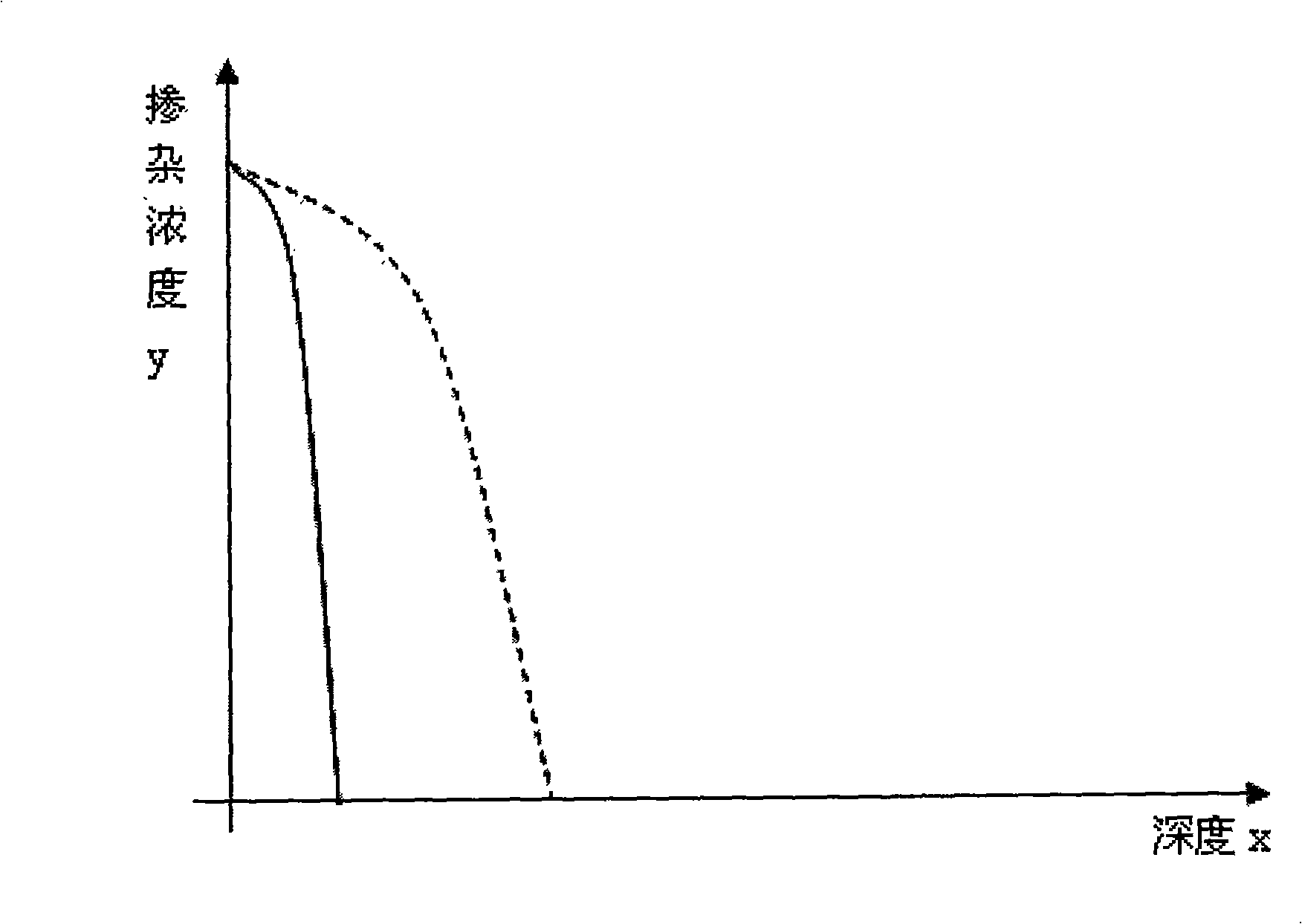

ActiveCN102737964AReduced Auger RecombinationExtend your lifeSemiconductor/solid-state device manufacturingSemiconductor devicesDiffusion methodsHigh surface

The invention discloses a diffusion method of a crystal wafer, which comprises the following steps that (1) the crystal wafer is made into wool and cleaned; (2) constant source diffusion is carried out, the atmosphere in a furnace comprises nitrogen, oxygen and pure nitrogen which carry diffusion sources, and the flow of the nitrogen, the oxygen and the pure nitrogen which carry the diffusion sources remains unchanged during a diffusion process; (3) impurity glass is removed, and cleaning is carried out; (4) limited source diffusion is carried out, only the nitrogen and the oxygen are fed in during the diffusion process, and the flow of the nitrogen and the oxygen remains unchanged; (5) diffusion is over, and the wafer is taken out; the surface doping concentration of the wafer is 1*1020atom / cm<3> to 5*1020atom / cm<3>; and the depth of a PN junction is 0.5mum to 1mum. According to the diffusion method, the 'dead-layer' effect caused by high surface doping concentration is effectively reduced, the auger recombination of surface photon-generated carrier is reduced, and the minority carrier lifetime is prolonged.

Owner:CSI CELLS CO LTD +1

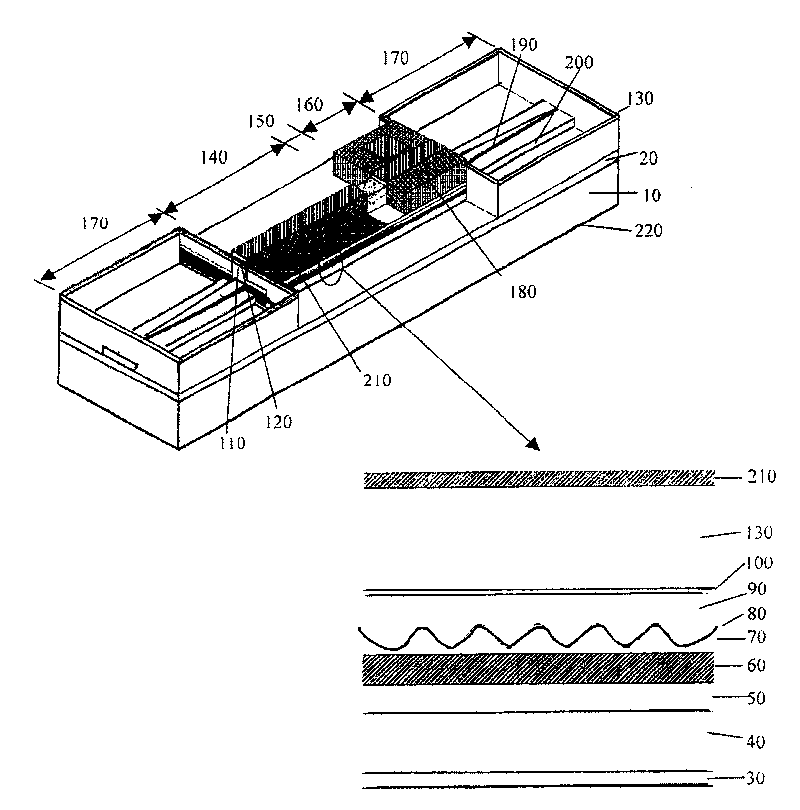

Method for making modular spot converting distributed-feedback Prague laser by using quantum trap confounding

InactiveCN1909310AReduce the number of growthHas an effectOptical wave guidanceLaser detailsGratingPhosphate

The invention relates to a method for using quantum well mixing to produce mode speckle conversion distributed feedback Bragg lasers, which comprises: growing n-type indium phosphate buffer layer on the substrate; using silica dioxide to mask the distributed feedback Bragg lasers, and generating point corrosion on the characteristic indium phosphate pour buffer layer at the mode speckle converter; corroding the silica dioxide protective layer; heating chip, keeping warm and annealing; corroding the protective layer; grating the whole chip; corroding the characteristic indium phosphate pour buffer layer; etching the upper and lower ridge pilot structures on the converter; cleaning the chip; growing p-type indium phosphate layer, indium gallium arsenic phosphate etching stopping layer, p-type indium phosphate package and high-doping p-type indium gallium arsenic ohm electrode contact layer; growing silica dioxide insulated layer on the whose chip; opening electrode window at the laser, and splashing p electrode; extending the substrate; boiling n electrode at the back; slicing the sample into tubular core.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

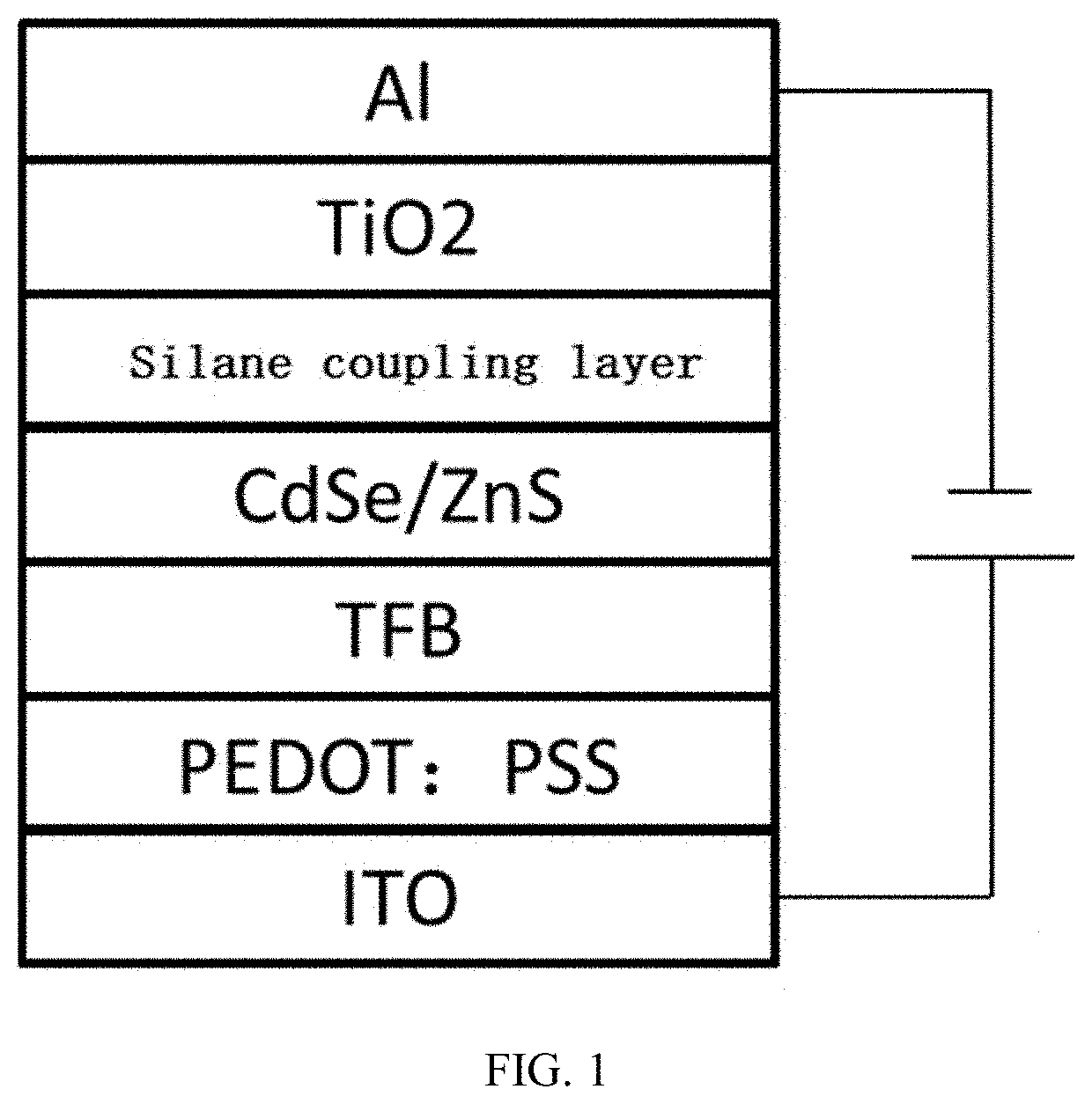

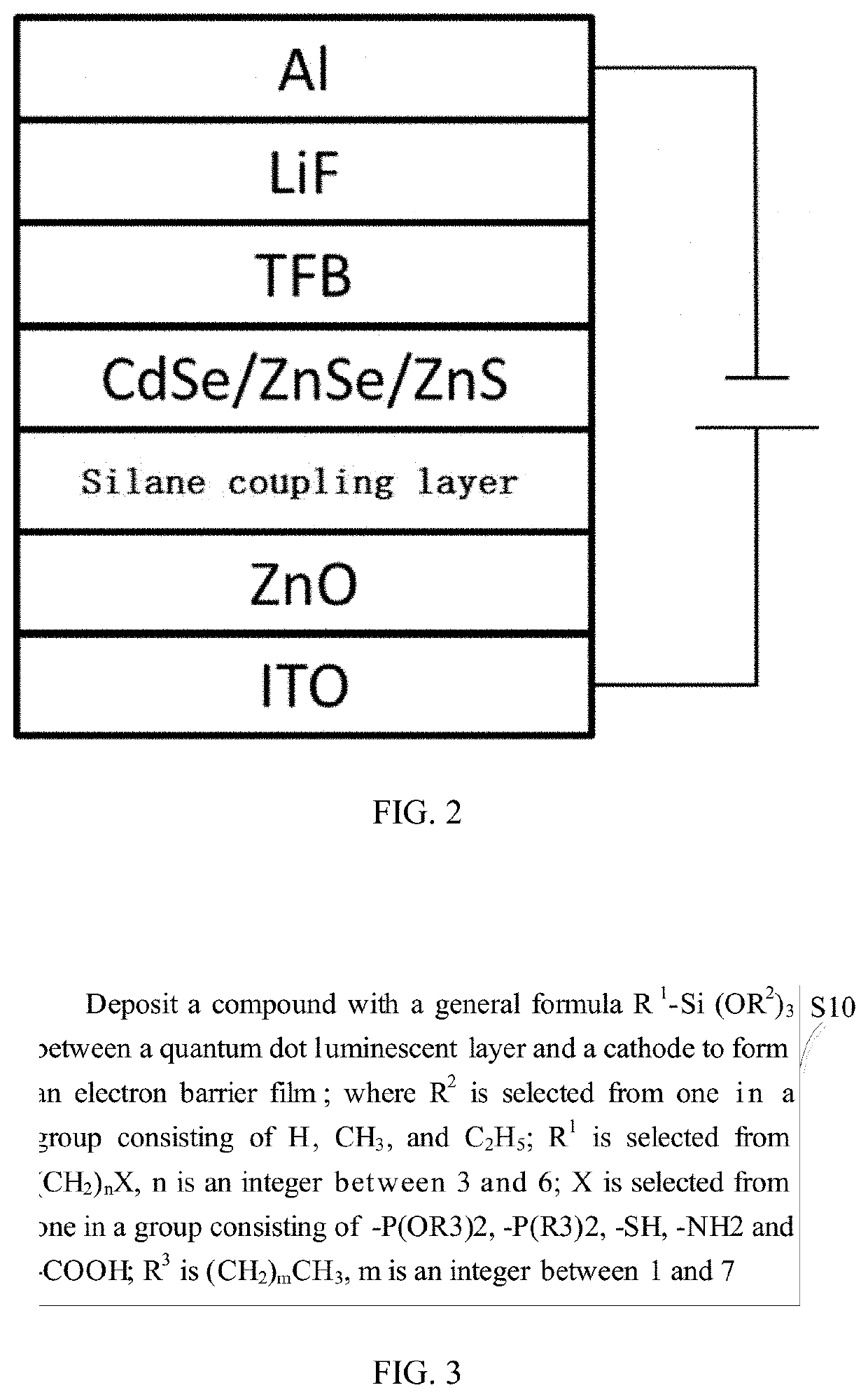

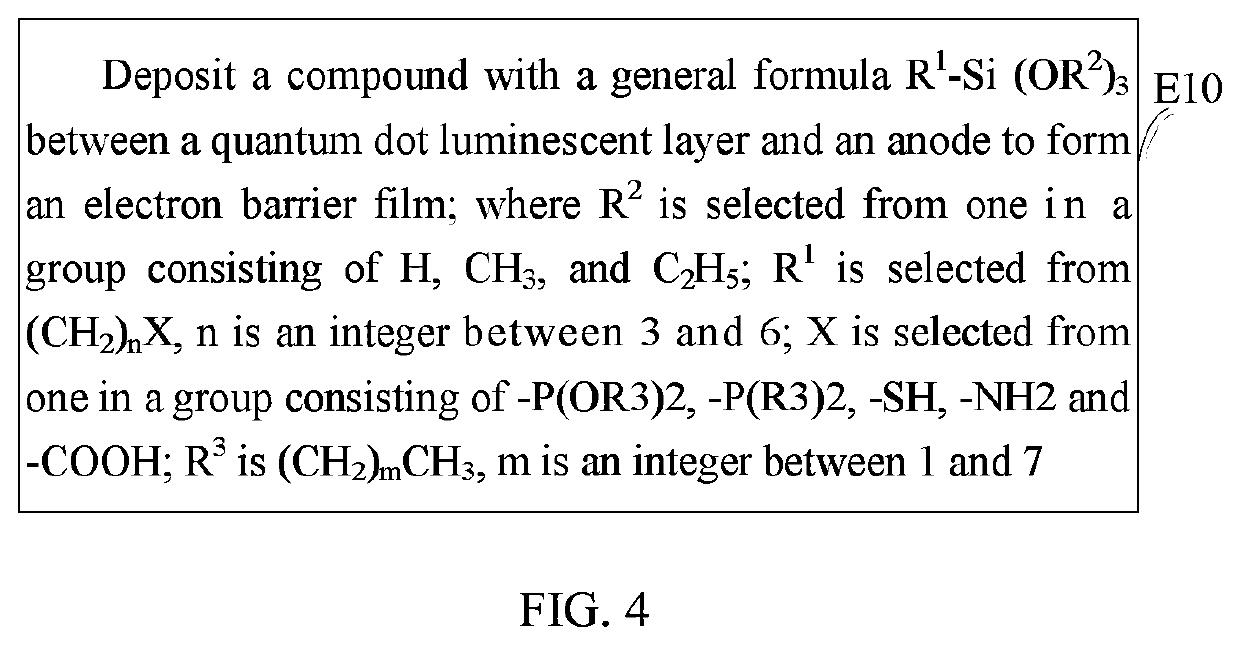

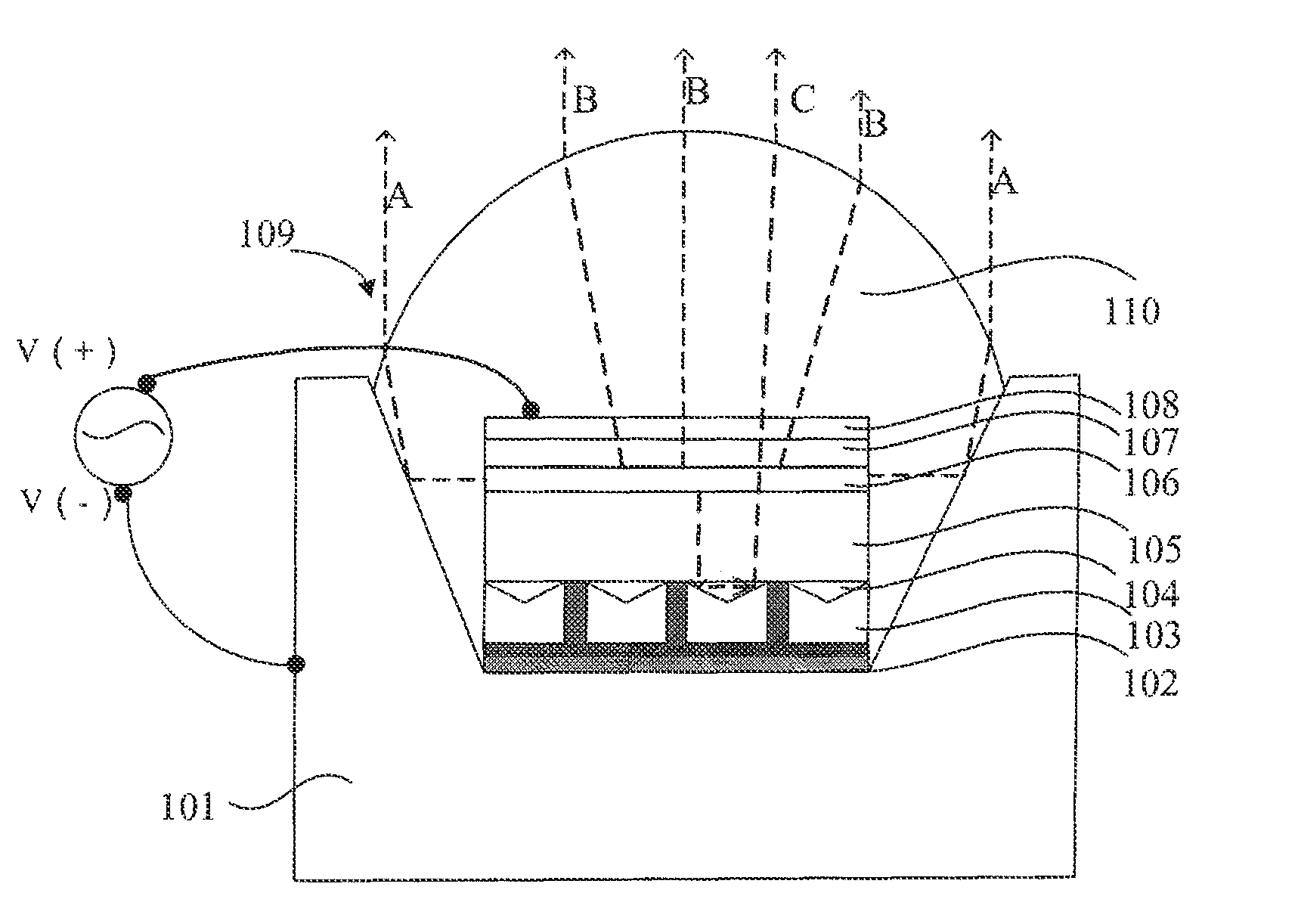

Electron barrier film, quantum dot light-emitting diode and preparation method thereof

PendingUS20220328776A1Improve recombination efficiencyReduce surface roughnessSolid-state devicesSemiconductor/solid-state device manufacturingElectron holeQuantum dot

An electron barrier film for a quantum dot light-emitting diode, the electron barrier film includes: a compound with a general formula R1—Si(OR2)3; or a raw material for forming the electron barrier film includes a compound with the general formula R1—Si(OR2)3 one in a group. Not only can a rate of injecting electrons into the luminescent layer be adjusted, so that the number of electron holes in the quantum dot luminescent layer can be equal to the number of electrons in the quantum dot luminescent layer, and a recombination efficiency of the electrons and the electron holes in the luminescent layer is improved, a better interface modification effect can also be achieved, and a surface roughness of the quantum dot luminescent layer is reduced, so that an overall performance of the quantum dot light-emitting diode is more stable.

Owner:TCL CORPORATION

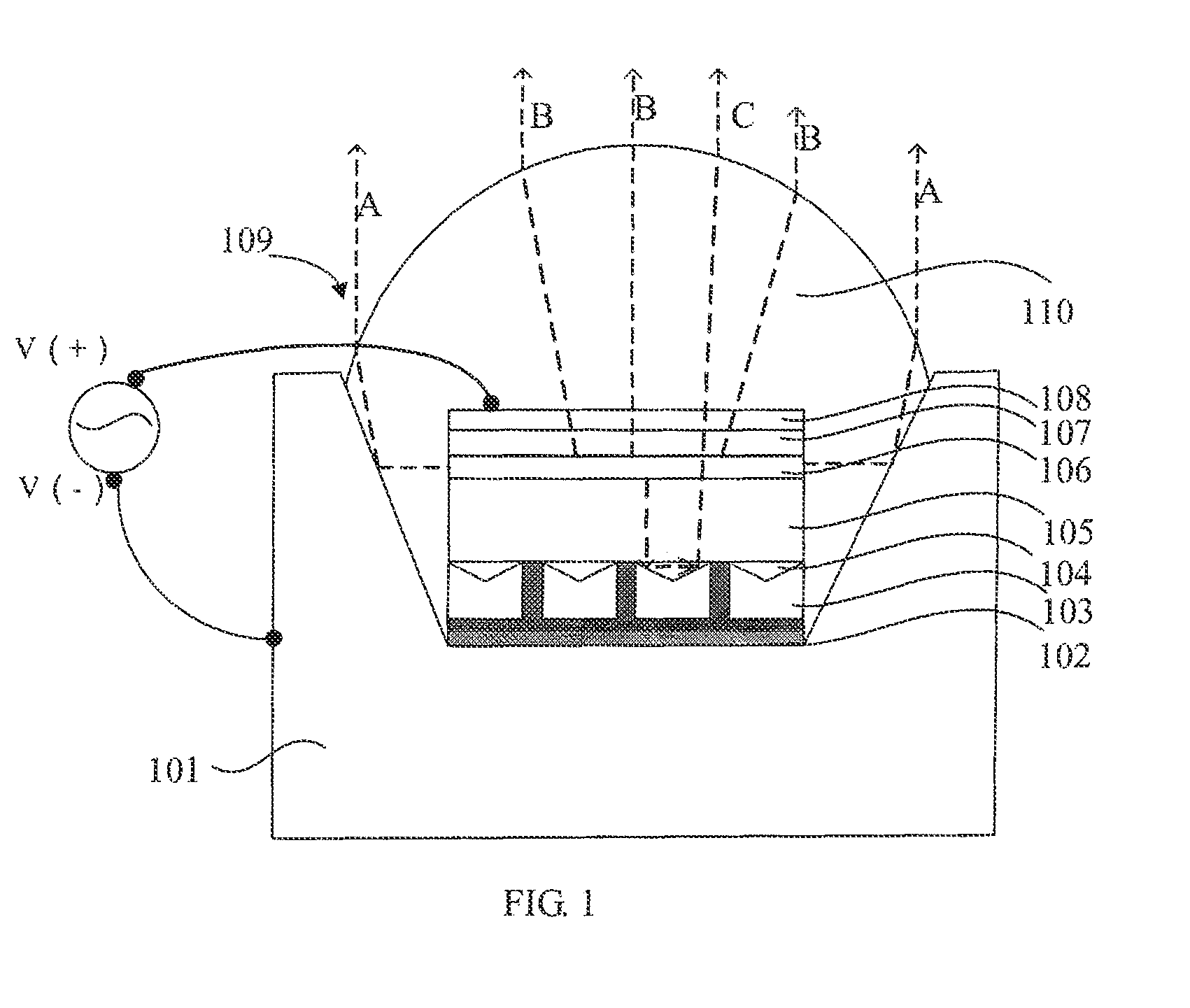

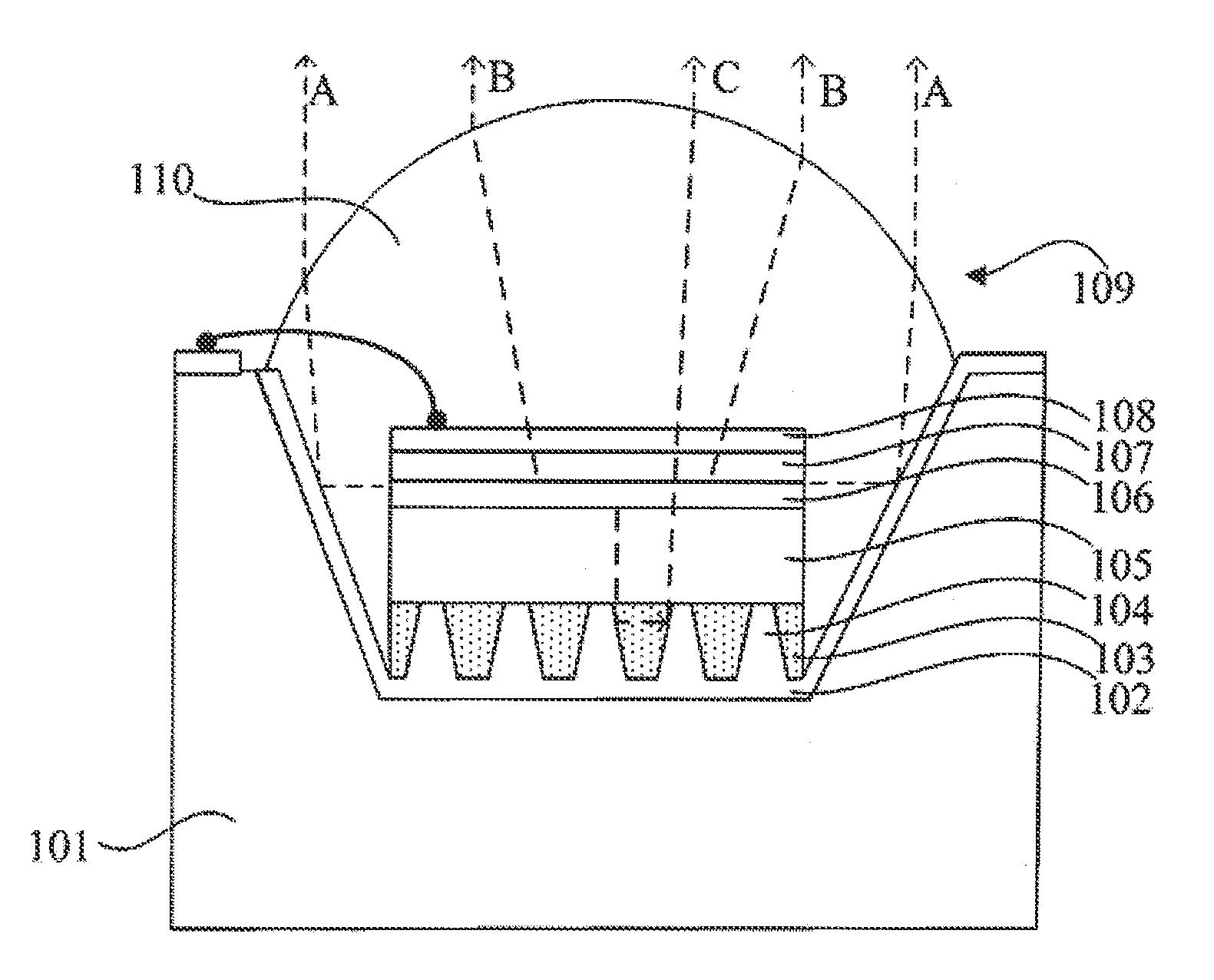

Light emitting diode and light emitting device

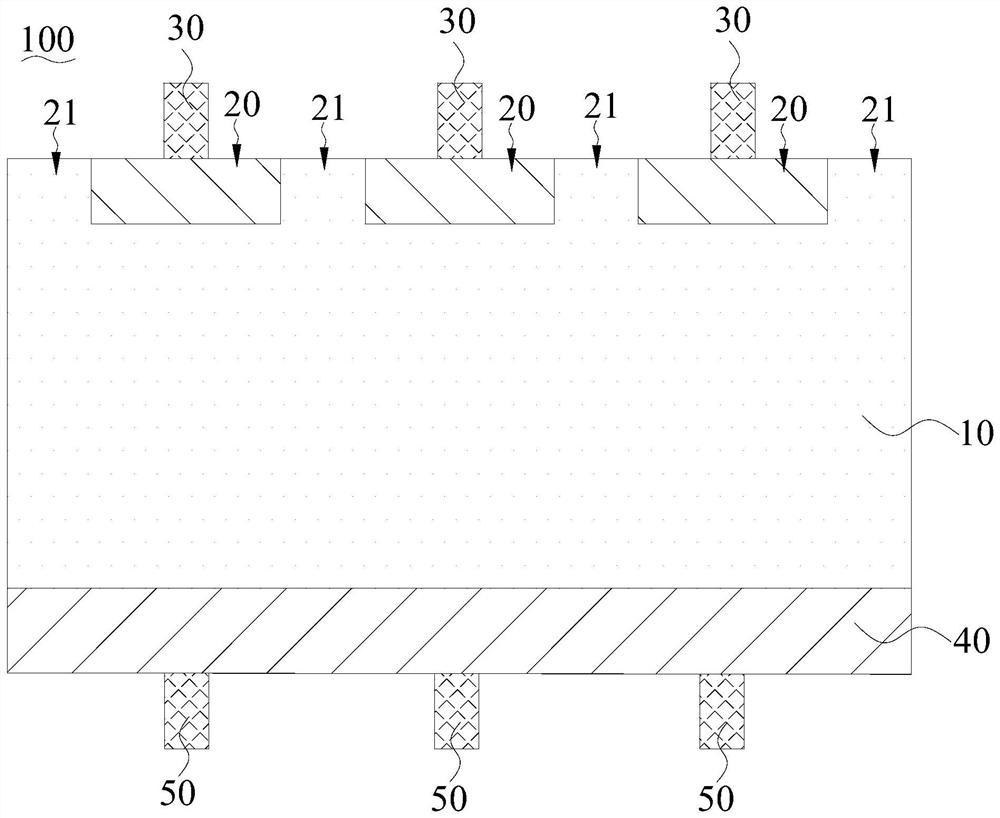

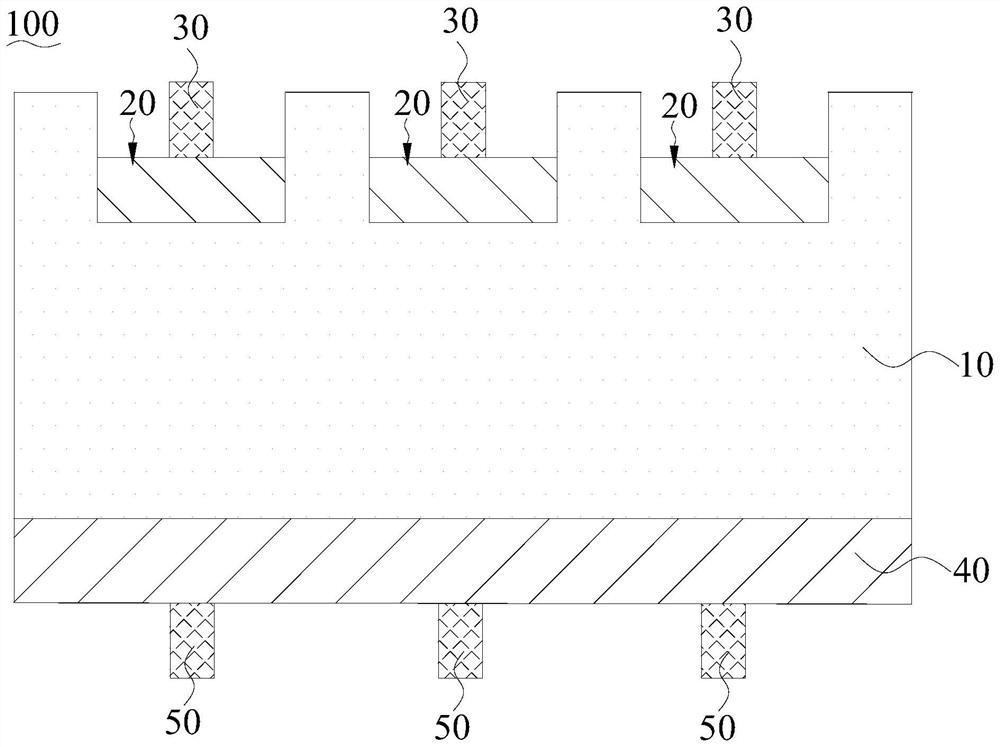

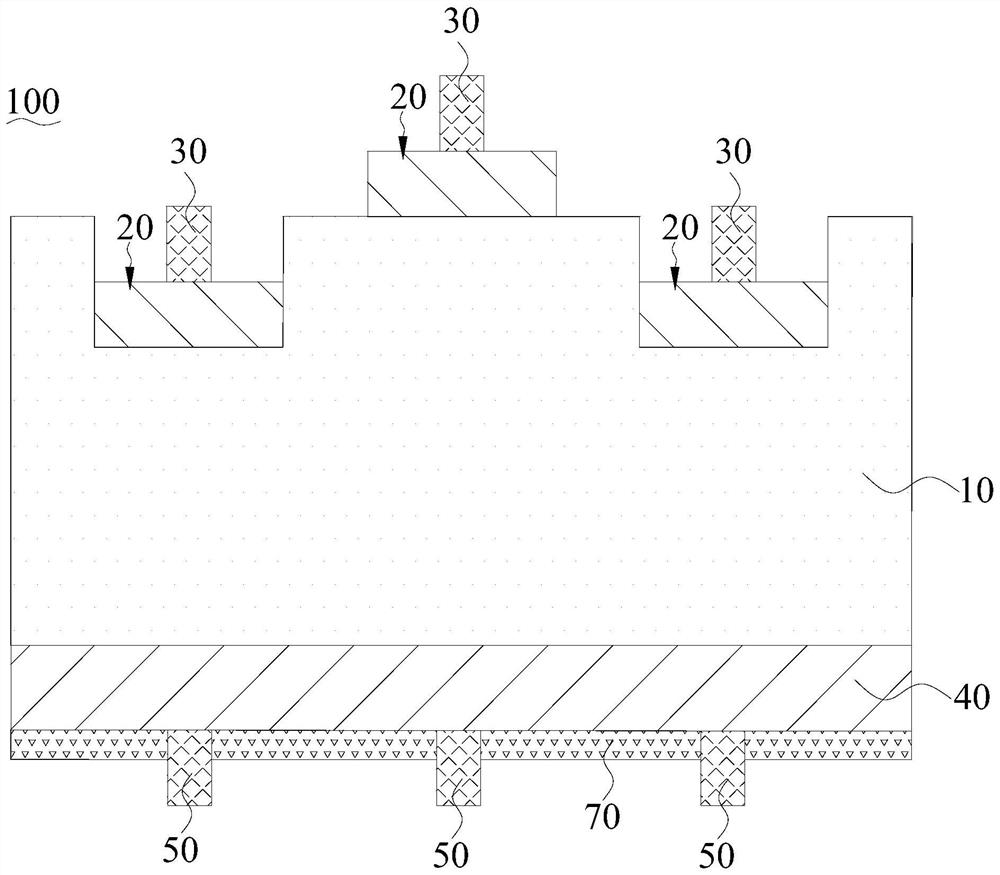

InactiveUS8809874B2High luminous efficiencyImprove internal quantum efficiencySolid-state devicesSemiconductor/solid-state device manufacturingLight emitting deviceLight-emitting diode

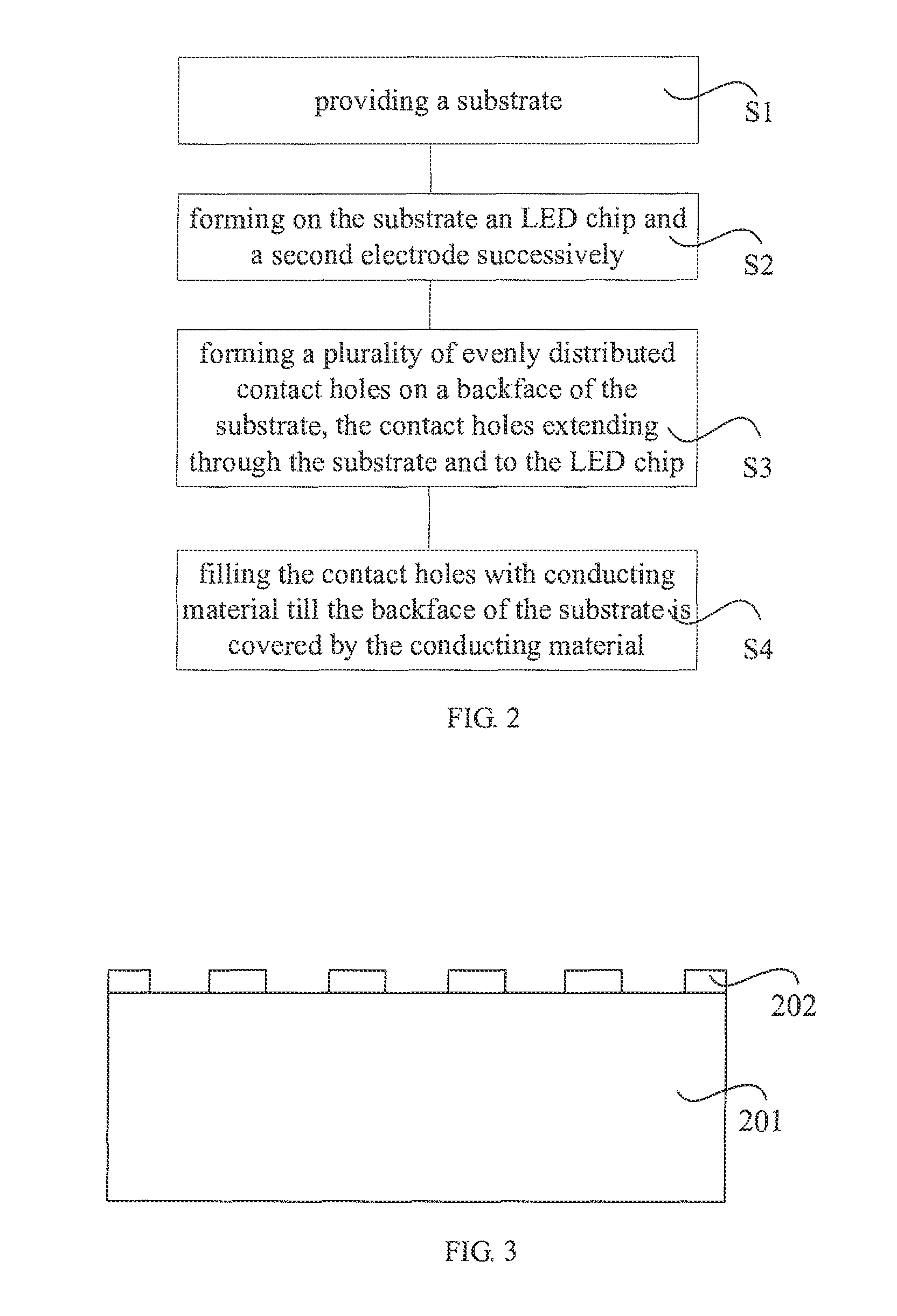

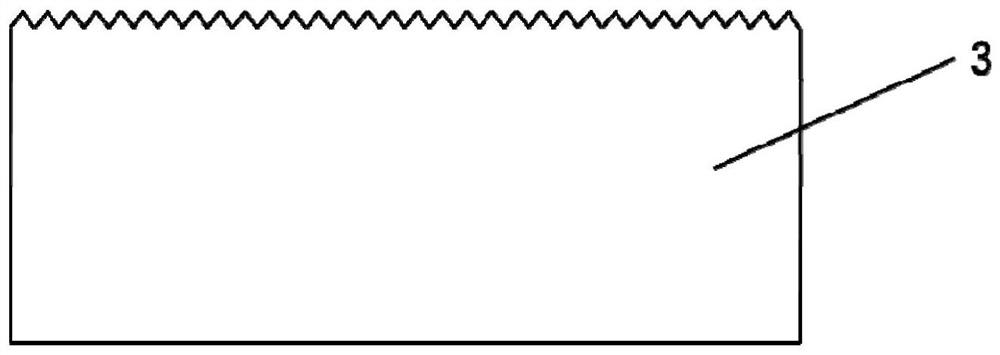

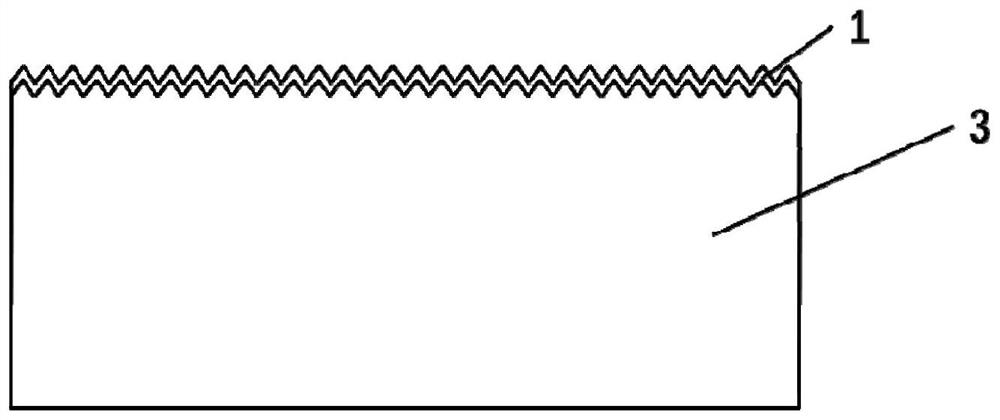

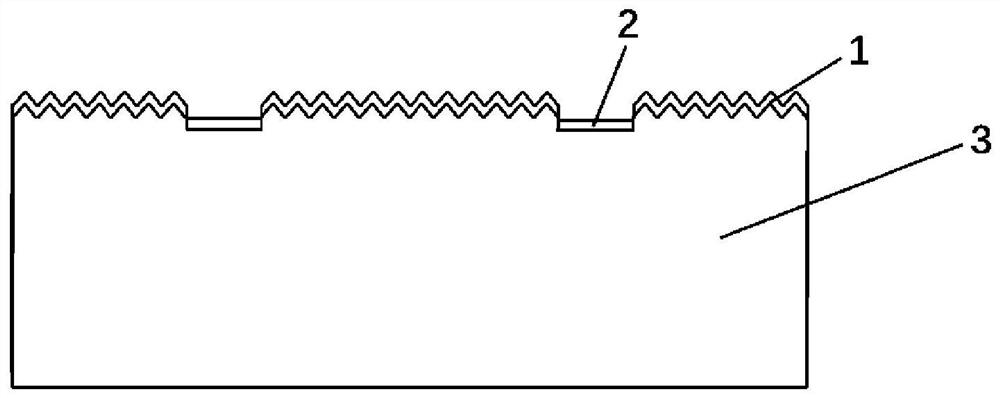

The present invention provides an LED and the manufacturing method thereof, and a light emitting device. The LED includes a first electrode, for connecting the LED to a negative terminal of a power supply; a substrate, located on the first electrode; and an LED chip, located on the substrate; in which a plurality of contact holes are formed through the substrate, the contact holes are evenly distributed and filled with electrode plugs connecting the first electrode to the LED chip. The light emitting device includes the LED, and further includes a base and an LED mounted on the base. The manufacturing method includes: providing a substrate; forming on the substrate an LED chip and a second electrode successively; forming a plurality of evenly distributed contact holes on a backface of the substrate, the contact holes extending through the substrate and to the LED chip; and filling the contact holes with conducting material till the backface of the substrate is covered by the conducting material. The LED has a high luminous efficiency and the manufacturing method is easy to implement.

Owner:ENRAYTEK OPTOELECTRONICS

Preparation method of selective doping structure of solar cell

PendingCN112701192AReduced series resistanceImprove fill factorFinal product manufacturePhotovoltaic energy generationLaser processingPhysical chemistry

The invention belongs to the technical field of solar cells, and relates to a preparation method of a selective doping structure of a solar cell; the method comprises the following steps: step 1, pretreating the surface of a silicon wafer, and depositing a poly layer containing a doping source on the surface of the pretreated silicon wafer; step 2, carrying out laser processing on a part of the surface of the poly layer to form a heavily doped region; step 3, annealing the silicon wafer to form a lightly doped region in a non-laser-treated region on the surface of the poly layer, and introducing O2-containing gas in the annealing treatment process to oxidize the poly layer into a BSG / PSG layer; and step 4, cleaning the silicon wafer to remove the BSG / PSG layer so as to obtain the selective doping structure of the solar cell. According to the preparation method, the doping amounts of the lightly doped region and the heavily doped region of the selective doping structure can be accurately controlled, the preparation process and structure can be simplified, and the preparation efficiency is improved.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

A diffusion technique applied on silicon solar battery

InactiveCN100530704CLateral resistance does not increaseImprove lateral resistanceFinal product manufactureSemiconductor/solid-state device manufacturingDiffusionNitrogen

The invention relates to a diffusion process which is applied in a silicon solar cell, the diffusion steps can be mainly divided into two steps, which specifically include: (1) a first diffusion is carried out: a silicon wafer is placed in a diffusion furnace, big nitrogen, small nitrogen and oxygen are introduced simultaneously, the diffusion temperature is at 800 to 860 DEG C and the time is 15 to 30 minutes; (2) the temperature of the diffusion furnace is increased to 870 to 920 DEG C, the silicon wafer is stably placed for 10 to 30 minutes and then is distributed; (3) a second diffusion is carried out: the diffusion temperature is at 870 to 920 DEG C, the time is 1 to 10 minutes; (4) the diffusion process is finished, the temperature of the diffusion furnace is decreased and the silicon wafer is taken out. The invention can obtain more optimized doping curve in an emission region based on the method, thereby reducing the Auger recombination which is caused by high doping in the emission region and improving the short-circuit current of the cell by 0.5 to 1mA / cm<2>. A sheet resistance in the emission region and a contact resistance between the emission region and a grid line can not be increased by using the method; furthermore, all the diffusion steps are continuously carried out in a furnace tube, and the complexity of the technique is not increased.

Owner:BEIJING SOLAR ENERGY INST

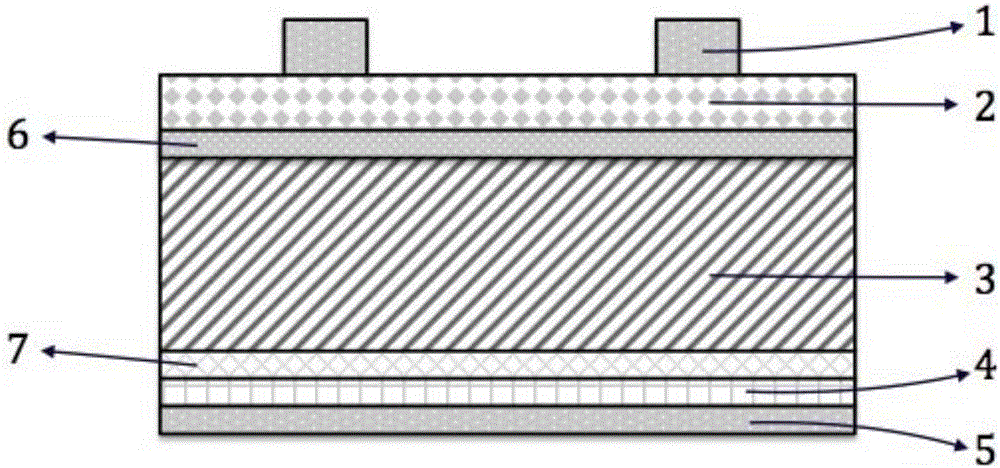

High-efficiency crystal silicon solar cell and fabrication method thereof

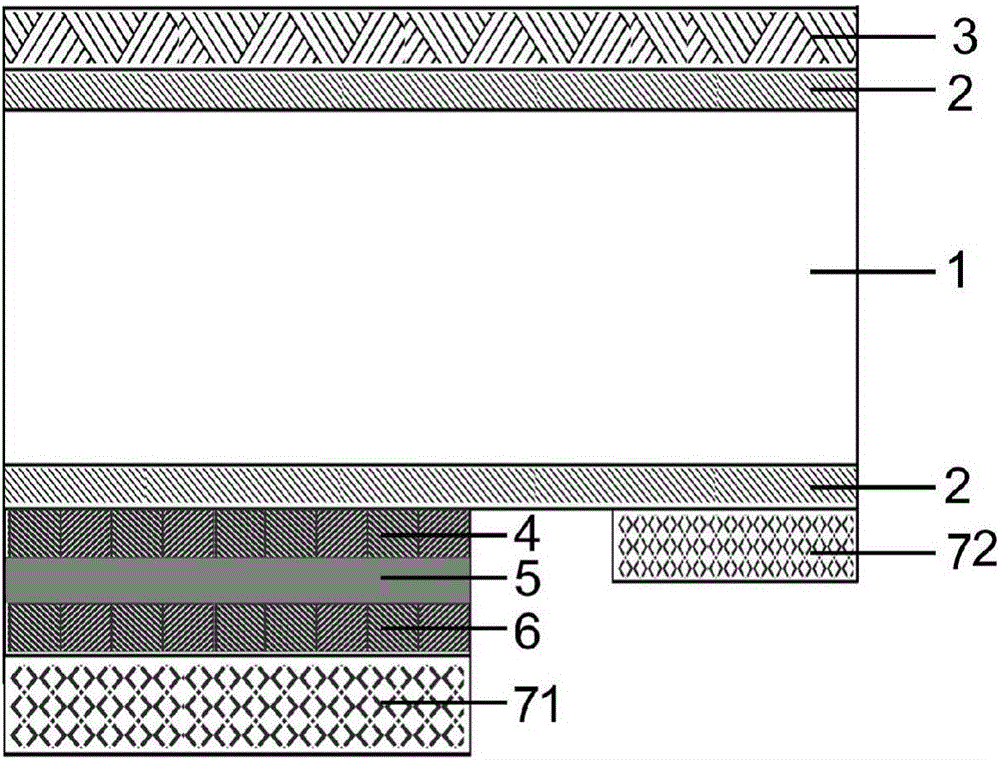

ActiveCN106098811AImprove conversion efficiencyAct as field passivationFinal product manufacturePhotovoltaic energy generationProduction lineCell fabrication

The invention provides a high-efficiency crystal silicon solar cell and a fabrication method thereof. The high-efficiency crystal silicon solar cell comprises an upper electrode, a passivation anti-reflection SiN layer, a phosphorus diffusion layer, a substrate crystal silicon wafer, an aluminum diffusion layer, an adjustment layer and a lower electrode which are sequentially laminated, wherein the adjustment layer comprises a dielectric material and / or a conductive film material or a quantum well material. The invention also discloses the fabrication method of the high-efficiency crystal silicon solar cell. The high-efficiency crystal silicon solar cell is simple in structure and low in fabrication cost, and the high-efficiency crystal silicon solar cell can be simply upgraded by means of a traditional solar cell production line to complete cell fabrication.

Owner:锦州阳光能源有限公司

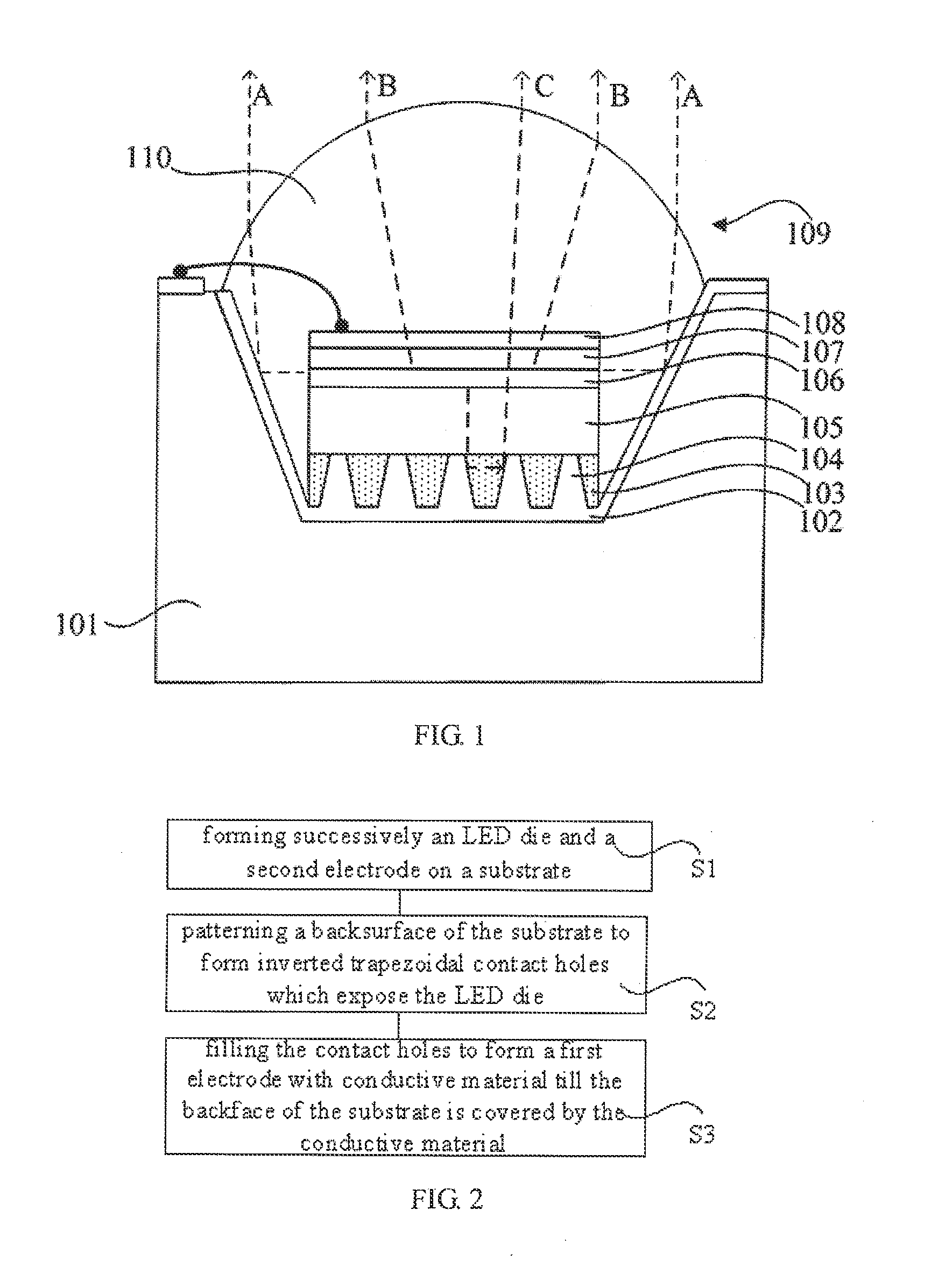

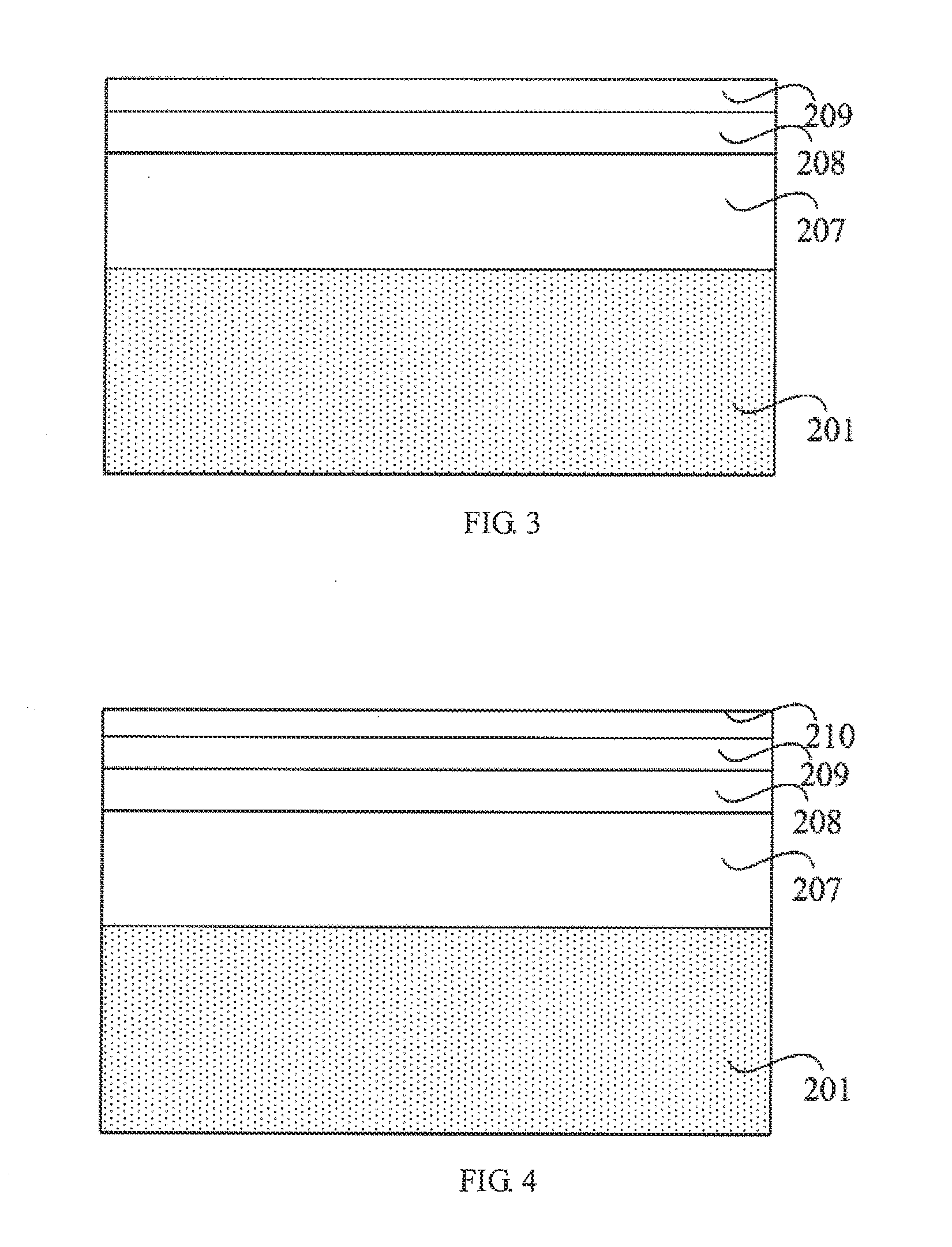

Light emitting diode and a manufacturing method thereof, a light emitting device

InactiveUS20130221387A1Solve low luminous efficiencyHigh luminous efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesSusceptorConductive materials

The present invention provides an LED and the manufacturing method thereof, and a light emitting device. The LED includes a first electrode, for connecting the LED to a negative electrode of a power supply; a substrate, located on the first electrode; and an LED die, located on the substrate; in which a plurality of contact holes are formed extending through the substrate, the diameter of upper parts of the contact holes is less than the diameter of lower parts of the contact holes, and the contact holes are filled with electrode plugs connecting the first electrode to the LED die. The light emitting device includes the LED, and further includes a susceptor and an LED mounted on the susceptor. The manufacturing method includes: forming successively an LED die and a second electrode on a substrate; patterning a backsurface of the substrate to form inverted trapezoidal contact holes which expose the LED die; and filling the contact holes with conductive material till the backface of the substrate is covered by the conductive material. The LED has a high luminous efficiency and the manufacturing method is easy to implement.

Owner:ENRAYTEK OPTOELECTRONICS

Method for preparing passivation contact structure based on low pressure chemical vapor deposition (LPCVD) secondary ion injection

ActiveCN110983289AIncrease surface ion concentrationImprove fill factorPolycrystalline material growthAfter-treatment detailsChemical vapor depositionElectronic conductivity

The invention provides a method for preparing a passivation contact structure based on low pressure chemical vapor deposition (LPCVD) secondary ion injection. The problem encountered when a heavily-doped polysilicon layer is prepared through a tubular LPCVD ion injection method can be well solved, namely, the problem that the number of ions diffused to penetrate through a tunneling oxide layer isincreased when the surface ion concentration is improved at the same time can be solved, the surface ion concentration of polysilicon can be improved, the electrical conductivity is improved, and thecontact resistance is reduced, so that cell fill factors are improved; the number of the ions diffused to penetrate through the tunneling oxide layer is reduced, the auger recombination is reduced, apassivation effect of the structure is improved, and the open-circuit voltage and the short-circuit current are improved; and the technological process is mature and can be accomplished by adopting anexisting equipment secondary process.

Owner:江苏杰太光电技术有限公司

Crystal wafer and diffusion method thereof

ActiveCN102737964BReduced Auger RecombinationExtend your lifeSemiconductor/solid-state device manufacturingSemiconductor devicesChemical physicsPhysical chemistry

The invention discloses a diffusion method of a crystal wafer, which comprises the following steps that (1) the crystal wafer is made into wool and cleaned; (2) constant source diffusion is carried out, the atmosphere in a furnace comprises nitrogen, oxygen and pure nitrogen which carry diffusion sources, and the flow of the nitrogen, the oxygen and the pure nitrogen which carry the diffusion sources remains unchanged during a diffusion process; (3) impurity glass is removed, and cleaning is carried out; (4) limited source diffusion is carried out, only the nitrogen and the oxygen are fed in during the diffusion process, and the flow of the nitrogen and the oxygen remains unchanged; (5) diffusion is over, and the wafer is taken out; the surface doping concentration of the wafer is 1*1020atom / cm<3> to 5*1020atom / cm<3>; and the depth of a PN junction is 0.5mum to 1mum. According to the diffusion method, the 'dead-layer' effect caused by high surface doping concentration is effectively reduced, the auger recombination of surface photon-generated carrier is reduced, and the minority carrier lifetime is prolonged.

Owner:CSI CELLS CO LTD +1

A preparation method of low surface concentration shallow diffusion junction solar cell

ActiveCN103078002BReduce compoundingIncrease the diffusion lengthFinal product manufactureSemiconductor devicesSurface concentrationSolar battery

The invention discloses a manufacturing method for a low-surface concentration shallow diffused junction solar battery. The manufacturing method comprises the following steps of: firstly, depositing a barrier layer on a light-sensitive surface of a flocked silicon chip, wherein the barrier layer is a microcrystal silicon layer; secondly, feeding the deposited silicon chip into a diffusion furnace for diffusing; thirdly, removing the barrier layer by cleaning; and fourthly, producing a back electrode back field and a printing positive electrode and sintering to obtain the low-surface concentration shallow diffused junction solar battery. According to the manufacturing method disclosed by the invention, the manufacture of the low-surface concentration shallow diffused junction solar battery is realized by using traditional equipment and conditions, so that the diffusion length of a minority carrier is increased, the service life of the minority carrier is prolonged and the photoelectric conversion efficiency of a battery piece is finally increased.

Owner:CSI CELLS CO LTD

Solar cell and cell module

PendingCN114068740AReduced Auger RecombinationReduce parasitic absorptionPhotovoltaic energy generationSemiconductor devicesPhysicsBody region

The invention is suitable for the technical field of solar cells, and provides a solar cell and a cell module, and the solar cell comprises a silicon substrate, a first doped region and a first conductive layer which are sequentially disposed on the front surface of the silicon substrate, and a back passivation contact structure and a second conductive layer which are sequentially disposed on the back surface of the silicon substrate. Multiple first doped regions are mutually spaced, the doping polarity of the first doped regions is the same with the polarity of the silicon substrate, the first conductive layer is in electric contact with the first doped regions, and the second conductive layer is in electric contact with the back passivation contact structure. Thus, due to the fact that the first doped regions with the same polarity as the silicon substrate are locally designed, most carriers can be transmitted to the first doped regions through the body region of the silicon substrate, the first doped regions do not need to make contact with the whole surface of the silicon substrate, and auger recombination or parasitic absorption can be reduced. Meanwhile, the body region of the silicon substrate can transport carriers more sufficiently.

Owner:ZHEJIANG AIKO SOLAR ENERGY TECH CO LTD +3

Strained multiple quantum well laser based on gesn/sigesn material and its fabrication method

ActiveCN107342535BLower bandgapRedshift working wavelengthLaser active region structureTensile strainManufacturing technology

The invention discloses a strain multiple quantum well laser device based on GeSn / SiGeSn material and a manufacturing method thereof. A barrier layer adopts a GeSiSn material; and the barrier layer adopts a GeSn material. A pseudo substrate (Ge), a buffer layer (GeSn) and an active area (GeSn / GeSiSn) are vertically distributed on a substrate (Si) from bottom to top in sequence, and an Si3N4 tensile stress film is wrapped around the pseudo substrate, the buffer layer and the active area. The manufacturing method of the laser device disclosed by the invention comprises the following steps: (1) adopting a low-temperature solid-source molecular beam epitaxy growth technology to grow the GeSn and GeSiSn materials; and (2) adopting a standard laser device manufacturing technology to process the device. Through a multiple quantum well structure and the tensile strain introduced by the additionally added Si3N4 stress film, red shift occurs for the laser wavelength of the laser device, the optical gain of the laser device is obviously improved, and the threshold value is greatly reduced.

Owner:XIDIAN UNIV

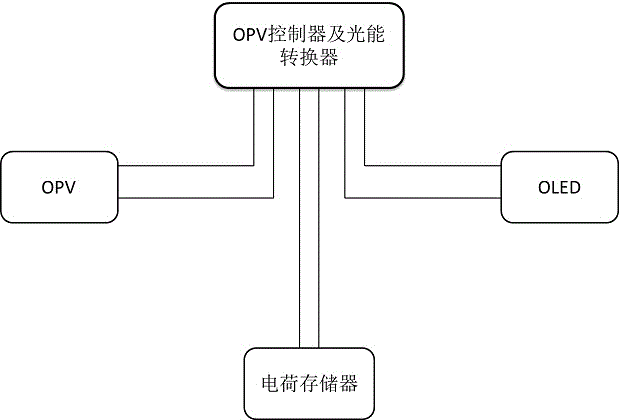

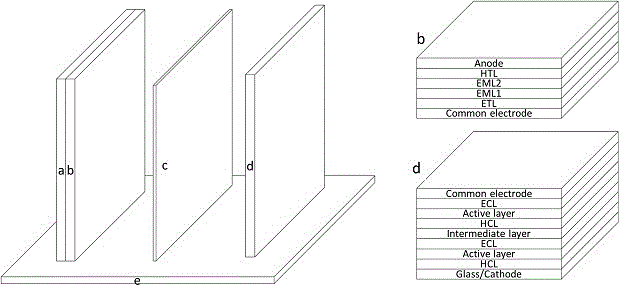

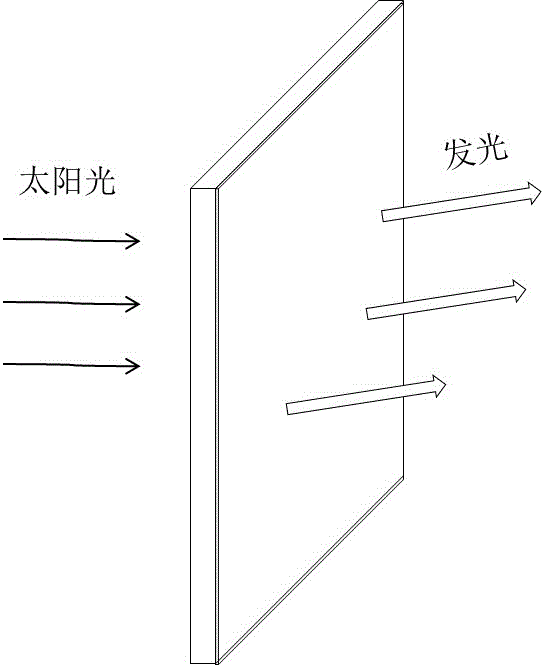

OLED light source driven by opv and preparation method thereof

ActiveCN105307304BReduce feverReduced Auger RecombinationElectrical apparatusElectroluminescent light sourcesMolecular materialsActive layer

The invention discloses an OPV-driven OLED light source and a preparation method thereof. The OPV collects sunlight and stores it in an energy storage and a controller. The energy storage and the controller are made of organic materials. The energy storage and the controller, the OPV and the OLED After assembly, OPV, energy storage and OLED are all transparent or translucent devices. A plate-shaped integrated system is formed through stacked assembly and embedded assembly. The energy storage and the controller control the energy storage to automatically supply power to the OLED, thereby realizing the OPV-driven OLED. The light source emits light. The active layer of OPV has a double-layer structure. The active layer is made of materials with narrow bandgap width. The dual emission layer of OLED is formed by doping the guest material in the host molecular material at a low concentration. The integrated system of the present invention uses all organic materials to make a translucent integrated system, which has low preparation cost, is environmentally friendly and simple in process, provides a new idea for the future lighting industry, and has a wide range of uses for the finished product.

Owner:SHANGHAI UNIV

A high-efficiency crystalline silicon solar cell

ActiveCN106098811BImprove conversion efficiencyAct as field passivationFinal product manufacturePhotovoltaic energy generationCell fabricationQuantum well

The invention provides a high-efficiency crystal silicon solar cell and a fabrication method thereof. The high-efficiency crystal silicon solar cell comprises an upper electrode, a passivation anti-reflection SiN layer, a phosphorus diffusion layer, a substrate crystal silicon wafer, an aluminum diffusion layer, an adjustment layer and a lower electrode which are sequentially laminated, wherein the adjustment layer comprises a dielectric material and / or a conductive film material or a quantum well material. The invention also discloses the fabrication method of the high-efficiency crystal silicon solar cell. The high-efficiency crystal silicon solar cell is simple in structure and low in fabrication cost, and the high-efficiency crystal silicon solar cell can be simply upgraded by means of a traditional solar cell production line to complete cell fabrication.

Owner:锦州阳光能源有限公司

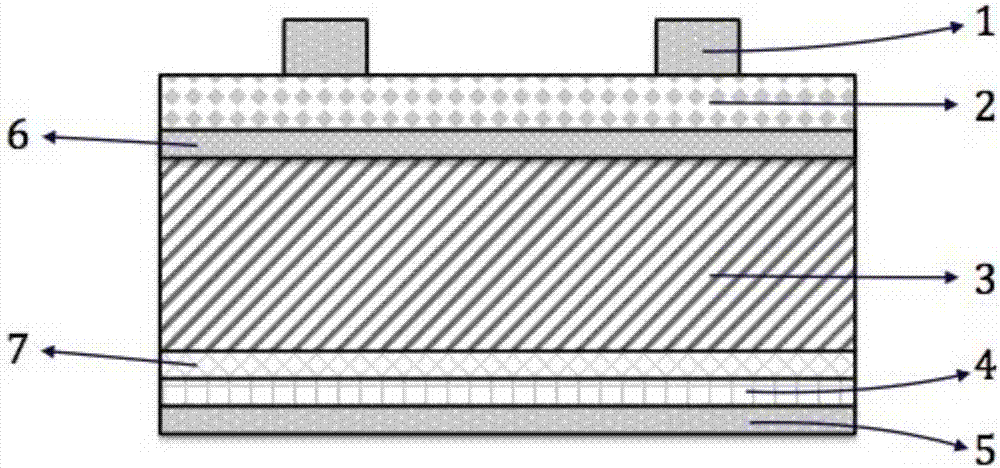

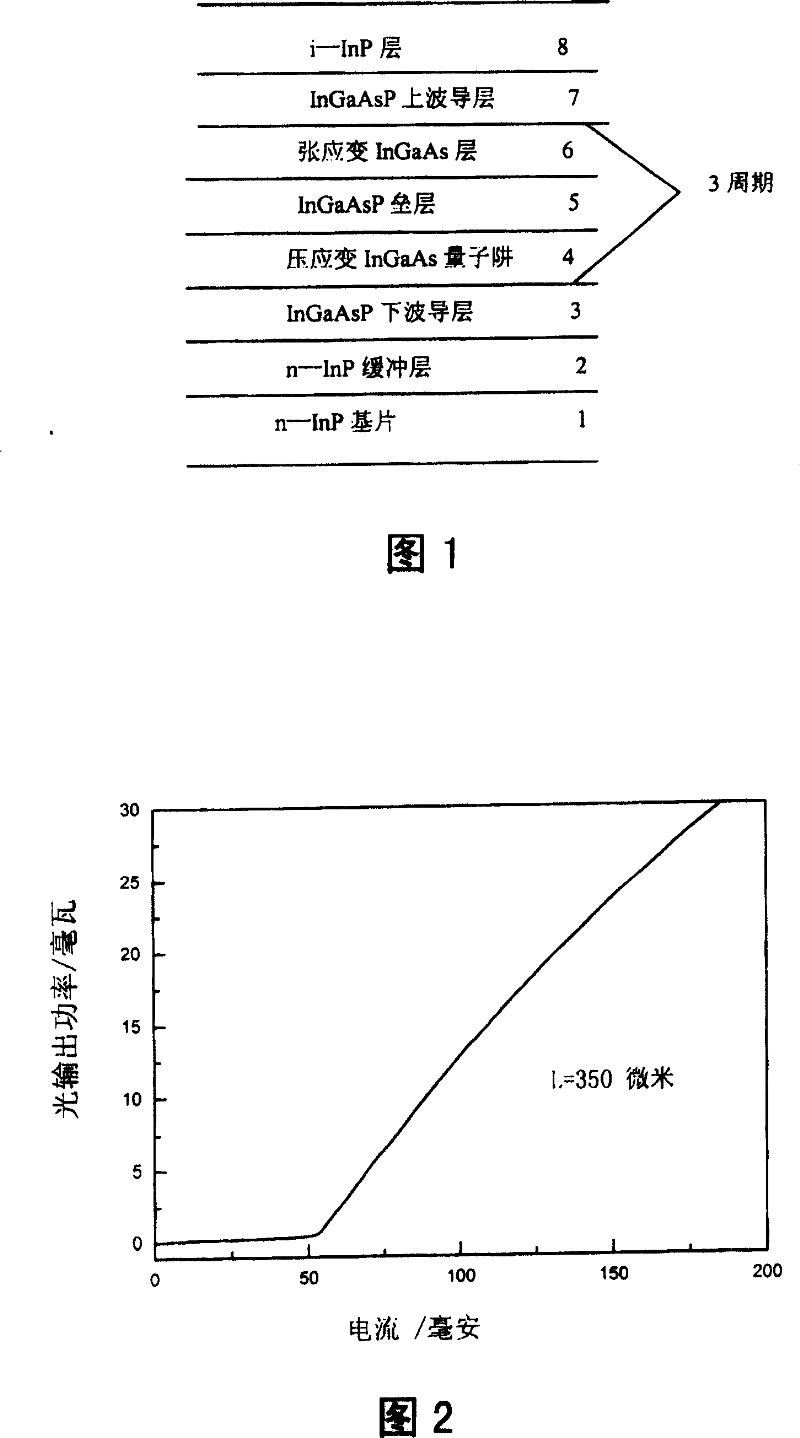

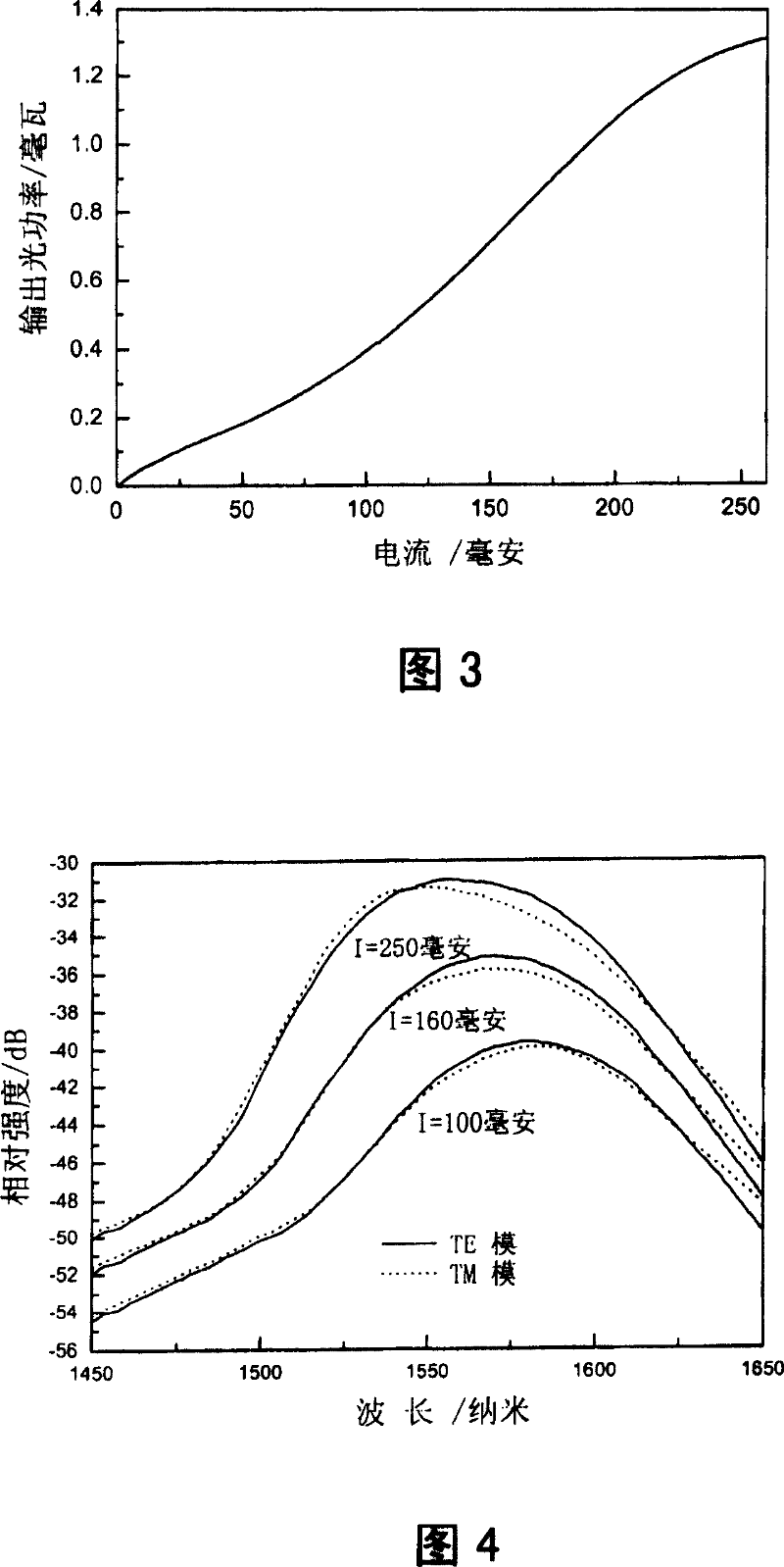

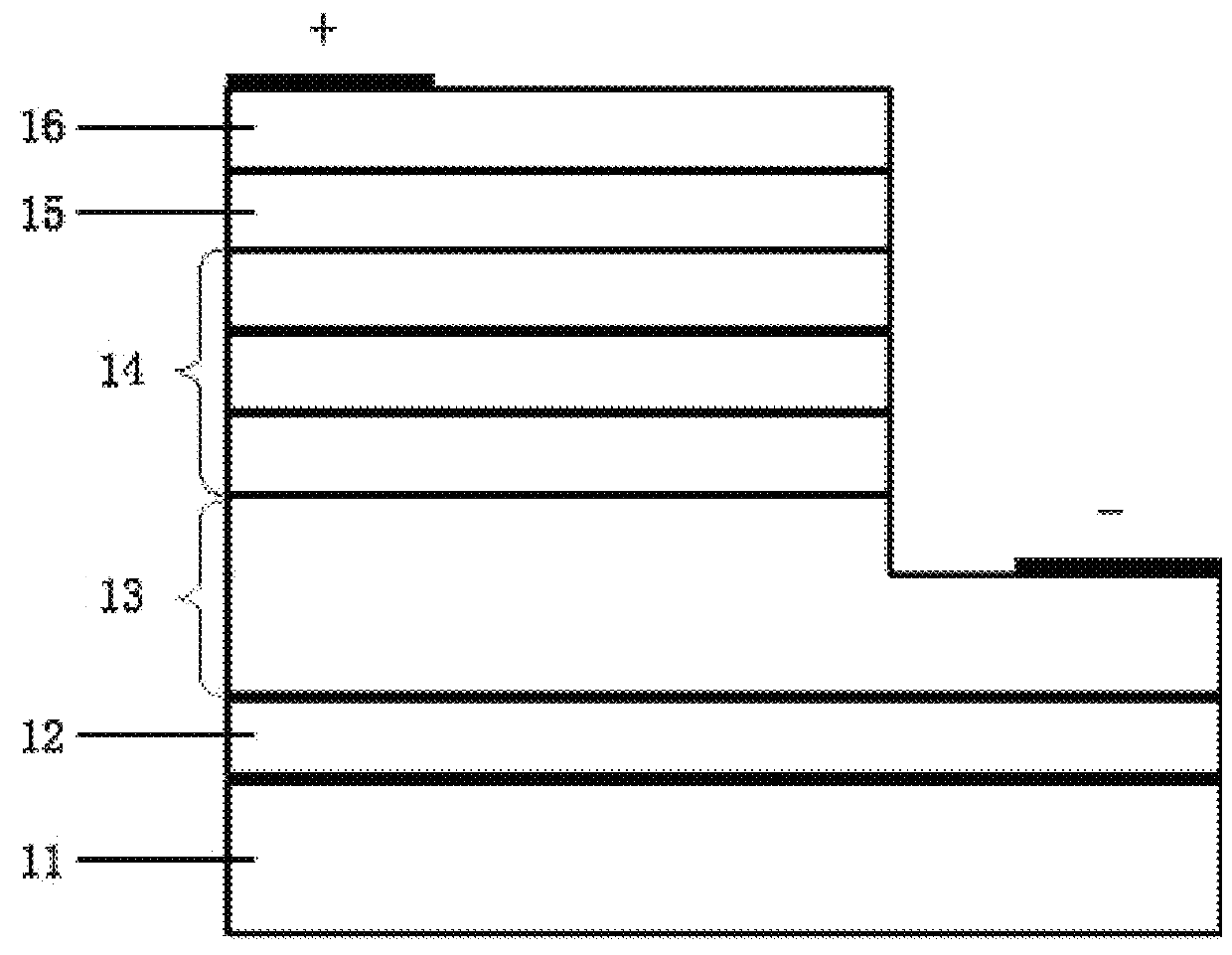

Manufacturing method of polarizing non sensitive semiconductor optical multiplier

InactiveCN100354701CImprove internal quantum efficiencyRaise differential gainNon-linear opticsQuantum wellEngineering

The present invention relates to a method for preparing semiconductor optical amplifier with insensitive polarization. Said method is characterized by that on N-type indium phosphide substrate said method adopts three epitaxial process, photoetching process, electrode-making process, cleavage process and anti-reflective film plating process to implement said device preparation.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Integration method for electric absorption modulation laser and modular spot converter

InactiveCN1909309BReduce the number of growthHas an effectLaser detailsSemiconductor lasersPhosphate ionSilicon dioxide

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

A method for preparing passivation contact structure based on lpcvd secondary ion implantation

ActiveCN110983289BIncrease surface ion concentrationImprove fill factorPolycrystalline material growthAfter-treatment detailsEngineeringIon implantation

A method for preparing a passivation contact structure based on LPCVD secondary ion implantation provided by the present invention can well solve the problem encountered in preparing a heavily doped polysilicon layer by tubular LPCVD ion implantation, that is, while increasing the surface ion concentration The problem of increasing the number of ions that inevitably diffuse through the tunnel oxide layer can increase the surface ion concentration of polysilicon, increase the electrical conductivity, reduce the contact resistance, and thereby improve the battery fill factor; reduce the diffusion through the tunnel oxide layer. ions, reducing Auger recombination, improving the passivation effect of the structure, increasing the open circuit voltage and short circuit current; the process is mature and can be completed by using the existing equipment for secondary processing.

Owner:江苏杰太光电技术有限公司

A kind of epitaxial growth method and the epitaxial layer of buried heterostructure

ActiveCN106300013BLower threshold current densityImprove high temperature characteristicsLaser detailsSemiconductor/solid-state device manufacturingQuantum efficiencyQuantum well

The invention relates to an epitaxial growth method and an epitaxial layer for burying a heterostructure, comprising the following steps: S1, growing part or all of an n / p / n / p InP or InGaAsP layer; S2, by burying, dry method or wet method Etch the shape model of the epitaxial growth required; S3, grow all Al-containing materials in the epitaxial structure in the shape model. In the present invention, part or all of the n / p / n / p structure is formed first, and then the shape of the epitaxial layer to be grown is etched, and then the epitaxial layer is grown therein. The method of the invention can effectively combine the advantages of AlGaInAs / InP material and BH technology to grow a high-efficiency laser epitaxial structure, so as to avoid Al oxidation, reduce Auger recombination, inter-band absorption, and improve the high temperature characteristics of the device. The threshold current density of the laser is reduced, the characteristic temperature of the active layer material and the external quantum efficiency, internal quantum efficiency and conversion efficiency of the quantum well in the active region are improved.

Owner:WUHAN HUAGONG GENUINE OPTICS TECH

A kind of large size LED chip and its manufacturing method

ActiveCN112652686BStable structureGuaranteed current extension effectSemiconductor devicesOhmic contactEpitaxial material

The present invention provides a large-size LED chip and a manufacturing method thereof. Tunneling junctions and several current spreading composite layers are arranged on the surface of the epitaxial stack facing away from the substrate, wherein the current spreading composite layers Layers are stacked on the surface of one side of the tunnel junction away from the epitaxial stack, and each of the current spreading composite layers includes a second N-type semiconductor layer and an ohmic contact layer stacked in sequence along the first direction; the current spreading The composite layer has a first through hole, the first through hole penetrates from the ohmic contact layer of the top layer to part of the first N-type semiconductor layer, and exposes part of the surface of the first N-type semiconductor layer; the P A tunneling effect is formed between the N-type semiconductor layer and the bottommost second N-type semiconductor layer. In this way, the transparent conductive layer of the traditional structure is replaced by the epitaxial material layer (that is, the N-type semiconductor layer), and a stable and reliable chip structure can be better realized while ensuring its current spreading effect.

Owner:XIAMEN CHANGELIGHT CO LTD

Method for forming semiconductor laser and spot-size converter by once epitaxy

InactiveCN100375348CReduce pollutionLow costLaser detailsSemiconductor lasersTime extensionSemiconductor package

Disclosed a method for one time extension forming the semiconductor laser and mode spot switch comprises following steps: (1), on the N type indium phosphide substrate, extending growing the N type indium phosphide breaker, a lower waveguide layer, a 2.4 mu m indium phosphide space layer, a lower light-limited layer of active region, a compression strain quanta active region, a upper light-limited layer, a P type indium phosphide envelope, and a high doping P type indium gallium arsenide ohmic electrode contract layer; (2), utilizing the wet corrosion process to etch the upper carinate shape of laser and mode spot switch; (3) utilizing the auto-alignment process to etch the lower carinate shape; (4), growing the SiO2 insulating layer and opening a electrode window; (5) decreasing the substrate of extended plate to 100 mu m, and manufacturing P / N electrodes to be scribed into the tube core of 250X600mu m.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

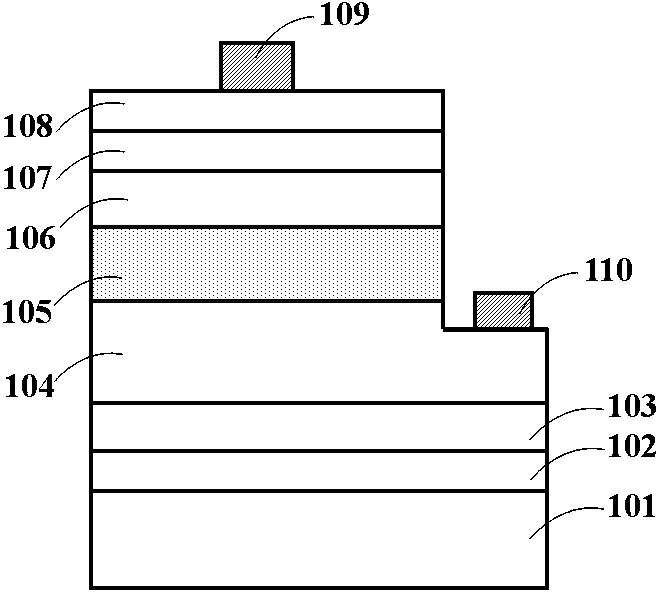

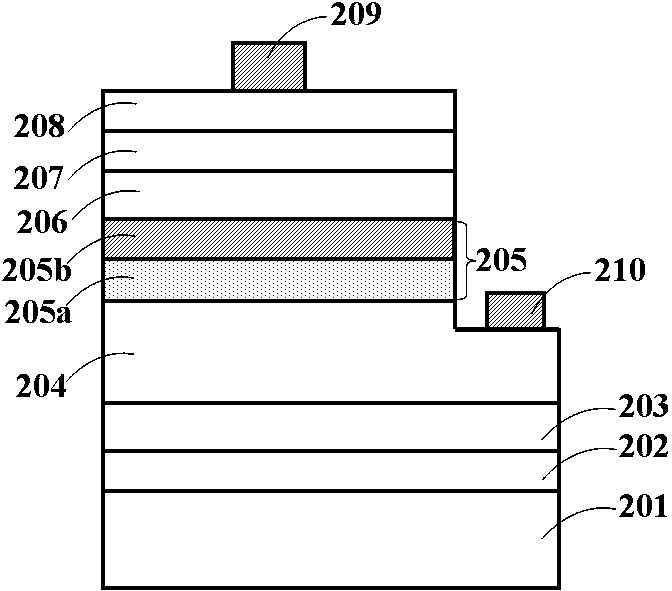

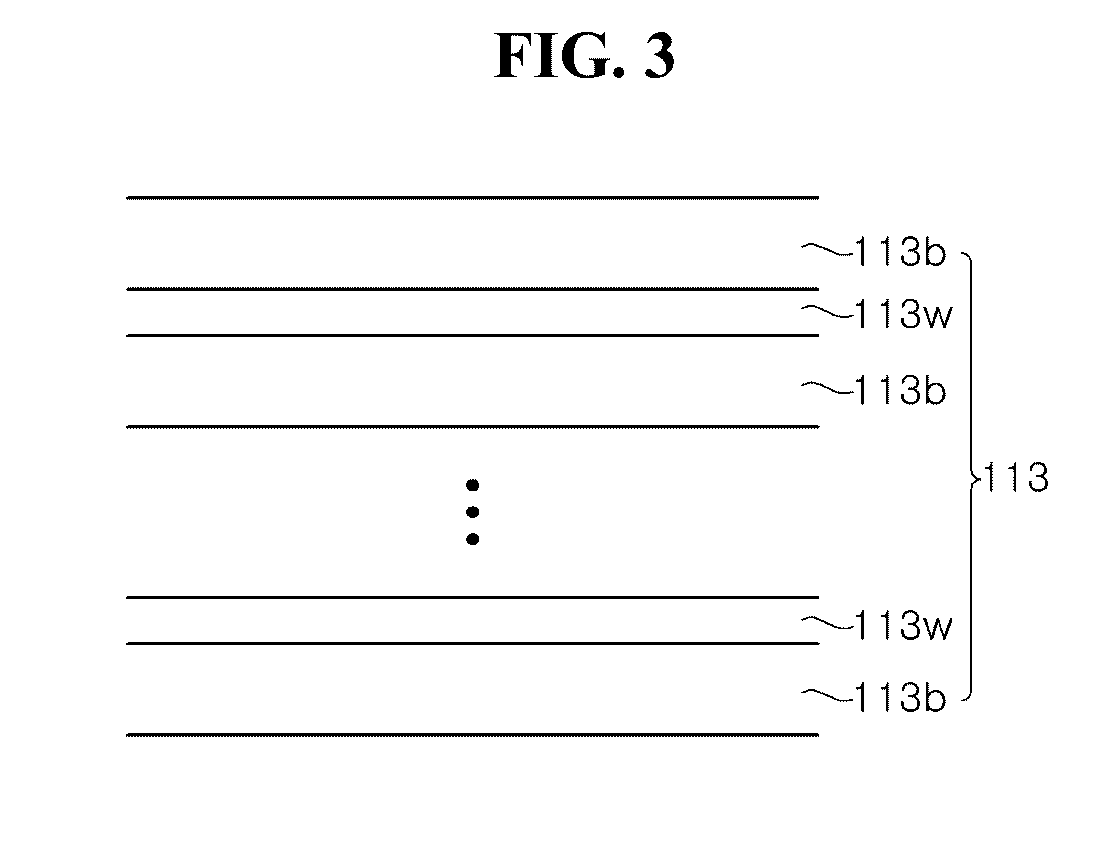

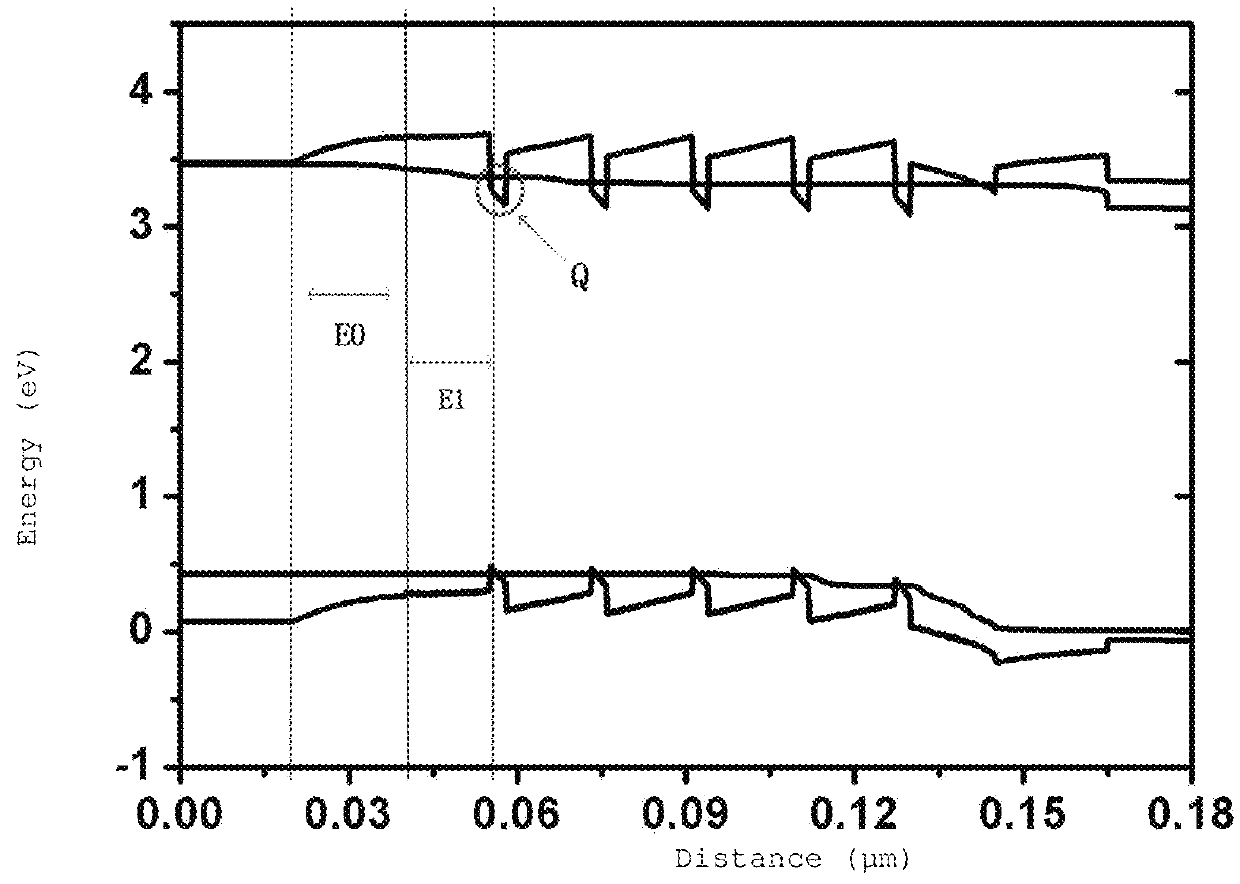

Semiconductor epitaxial structure and light-emitting device thereof

InactiveUS9385269B2Improve internal quantum efficiencyReduced Auger RecombinationLaser detailsSemiconductor lasersEffective potentialQuantum efficiency

The present invention discloses an epitaxial structure for semiconductor light-emitting device, comprising an electron injection region, a hole injection region, a multi-quantum well active region, a potential barrier layer for blocking carriers, and one or more band edge shaping layers. The doping type and / or doping concentration of said band edge shaping layers are different from those of the adjacent layers. It may trim the band edge shape of the semiconductor energy band through the local built-in electric field formed as a result of adjusting the doping type, doping concentration and / or layer thickness thereof, such that the carriers in the multi-quantum well active region are distributed uniformly, the overall Auger recombination is decreased, and the effective potential barrier height of the potential barrier layer for blocking carriers is increased to reduce the drain current formed by carriers overflowing out of the multi-quantum well active region, thereby improving internal quantum efficiency. The present invention further discloses a semiconductor light-emitting device that employs said epitaxial structure, which similarly achieves the effects of reduced Auger recombination and / or decreased drain current through the trimming of the band edge shape of the energy band structure by the local built-in electric field, thereby improving internal quantum efficiency of the device.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com