Oxide-metal multilayer film back contact crystalline silicon solar cell and preparation method thereof

A technology for solar cells and oxide films, applied in the field of solar cells, can solve the problems of raw material silane being inflammable and explosive, reducing the photo-generated current of cells, low filling factor, etc., and achieving the effects of low cost, reduced compounding, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

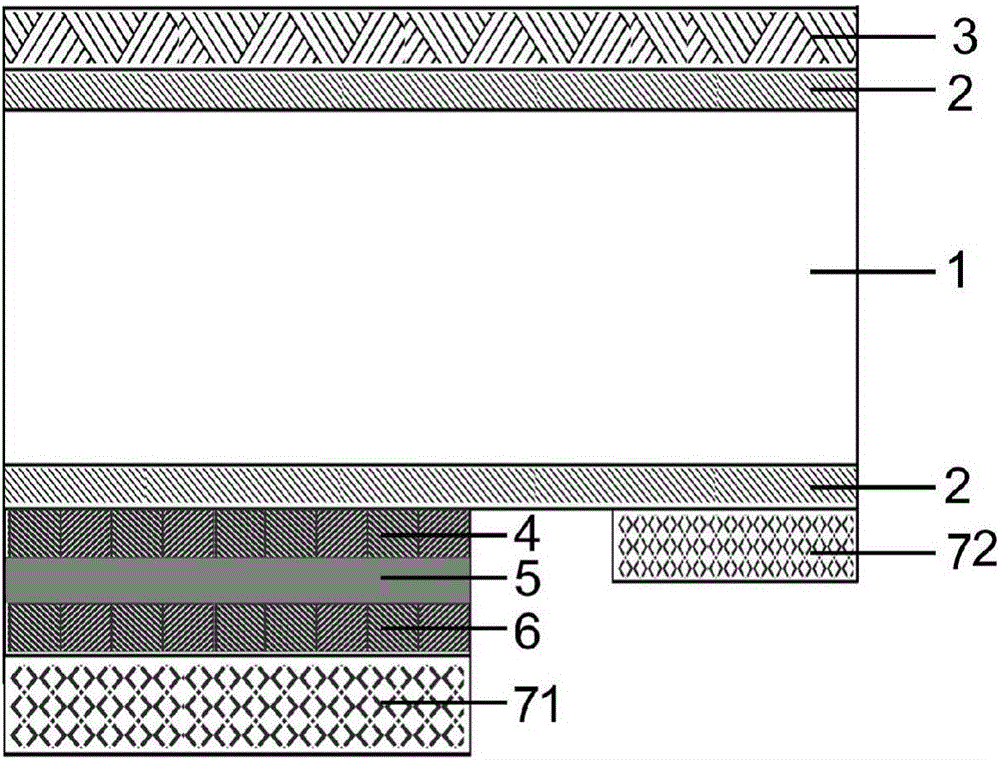

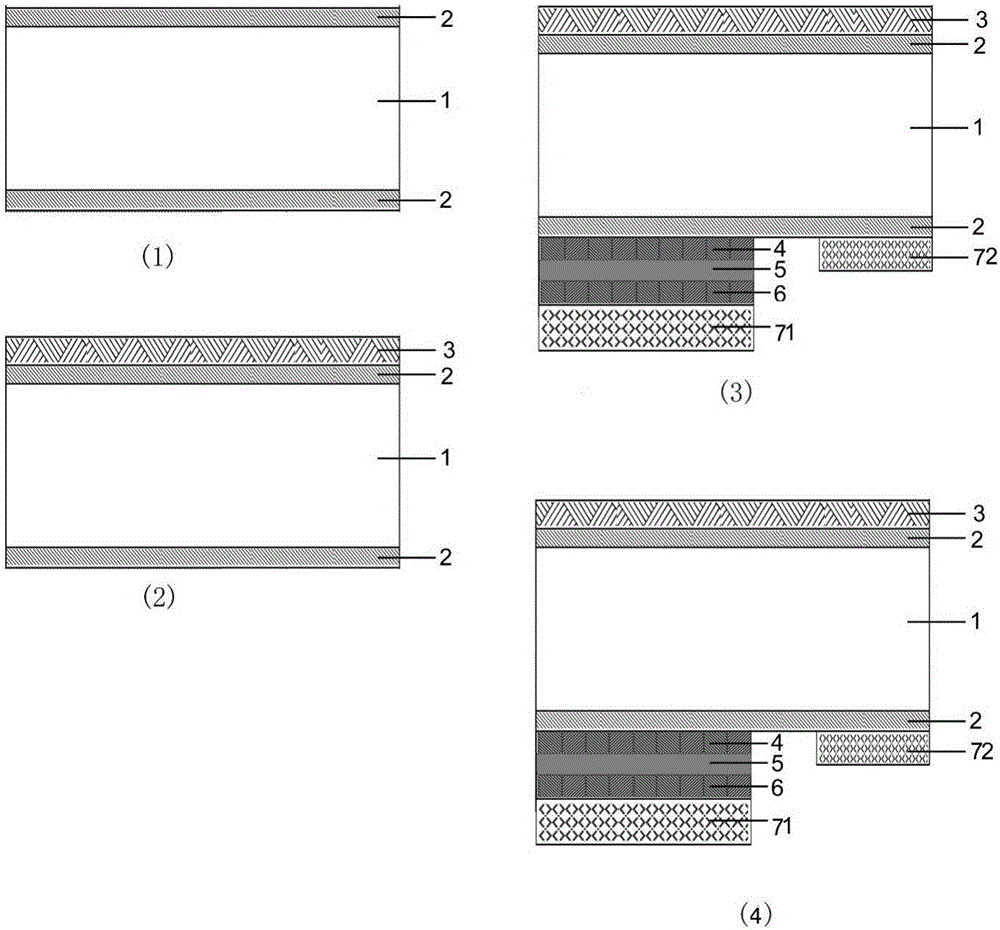

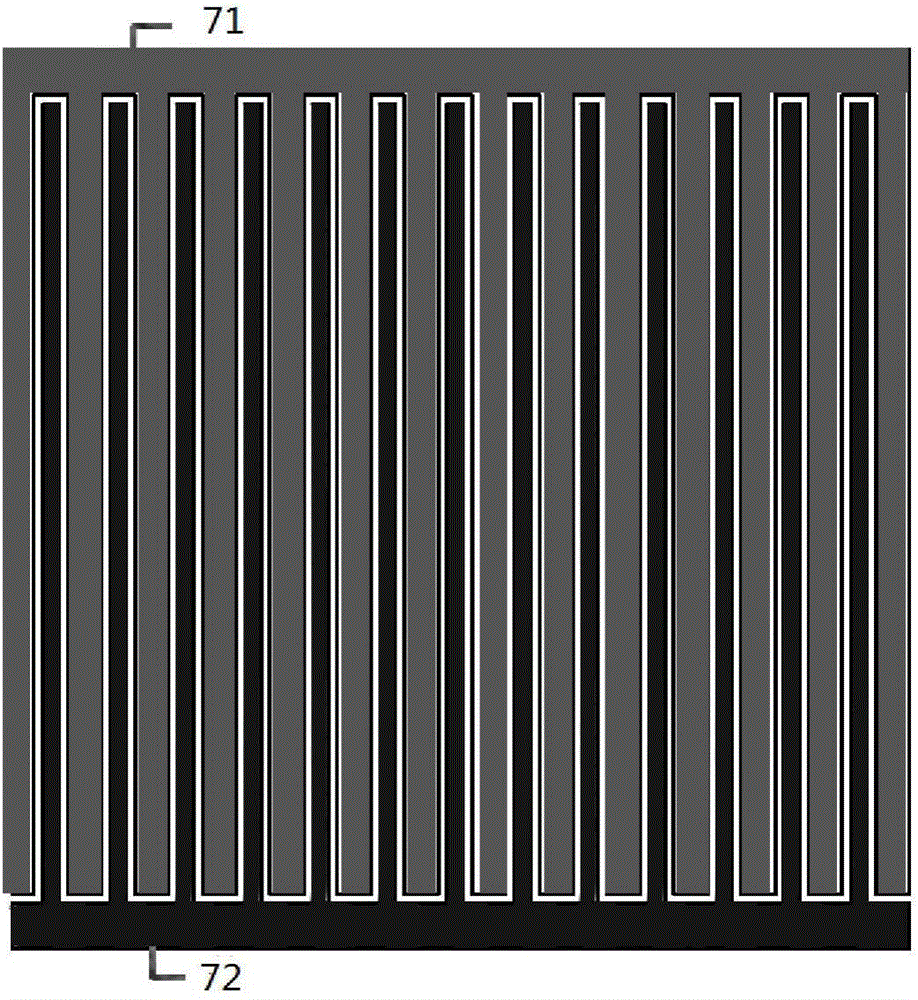

[0041] Such as figure 1 As shown in , the structure provided in this embodiment is an oxide-metal multilayer film back-contact crystalline silicon solar cell, including a crystalline silicon wafer 1, and a passivation layer 2 is provided on the front surface and the back surface of the crystalline silicon wafer 1. An emitter, an emitter metal electrode 71 and a base metal electrode 72 are arranged on the layer 2, and the emitter is composed of a first oxide film 4, a metal film 5 and a second oxide film 6; wherein the first oxide film 4 or for WO 3 film, the metal film is Ag film, and the second oxide film 6 is V 2 o 5 film.

[0042] The thickness of the first oxide film 4 is 5-30 nm, the thickness of the metal film 5 is 2-20 nm, and the thickness of the second oxide film 6 is 5-80 nm.

[0043] An antireflection film 3 is provided on the passivation layer 2 of the front surface of the crystalline silicon wafer 1 .

[0044] There is a gap between the emitter metal electrod...

Embodiment 2

[0053] The structure provided in this embodiment is an oxide-metal multilayer film back-contact crystalline silicon solar cell. The difference from Embodiment 1 is that the passivation layer 2 is Al 2 o 3 passivation layer, the first oxide film 4 is V 2 o 5 , the metal film 5 is an Au film, and the second oxide film 6 is a WO 3 .

[0054] The above structure is an oxide-metal multilayer film back-contact crystalline silicon solar cell, which is prepared by the following method:

[0055] (1) The n-type or p-type single crystal silicon wafer is cleaned by RCA process, and then a layer of Al is deposited on the front and rear surfaces of the silicon wafer by atomic layer deposition (ALD) technology. 2 o 3 Passivation layer, set the deposition temperature to 200°C, Al(TMA), N 2 、H 2 The pulse time of O is: 0.1s, 10s and 0.1s, the flow rates are: 150sccm, 150sccm and 200sccm, respectively, and 10-30 cycles are performed to deposit 1-3nm Al on the surface of the silicon wafer...

Embodiment 3

[0062] The structure provided in this embodiment is an oxide-metal multilayer film back-contact crystalline silicon solar cell. The difference from Embodiment 1 is that the passivation layer 2 is TiO 2 passivation layer, the first oxide film 4 is V 2 o 5 , the metal film 5 is a Pd film, and the second oxide film 6 is NiO.

[0063] The above structure is an oxide-metal multilayer film back-contact crystalline silicon solar cell, which is prepared by the following method:

[0064] (1) Clean the n-type or p-type single crystal silicon wafer with the RCA process, and then deposit a layer of TiO on the front and rear surfaces of the silicon wafer using atomic layer deposition (ALD) technology 2 Passivation layer, set the deposition temperature to 200-300°C, TiCl 4 , N 2 、H 2 The pulse time of O is: 1s, 3s and 1s respectively, the flow rate is respectively: 150sccm, 150sccm and 200sccm, carry out 10~30 cycles, deposit the titanium dioxide of 1~3nm on the silicon chip surface; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com