Solar cell and cell module

A technology of solar cells and conductive layers, applied in the field of solar cells, to achieve the effects of simplifying the process, improving conversion efficiency, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In the present application, a solar cell is provided, and only the portion related to the present application embodiment is shown in order to facilitate explanation.

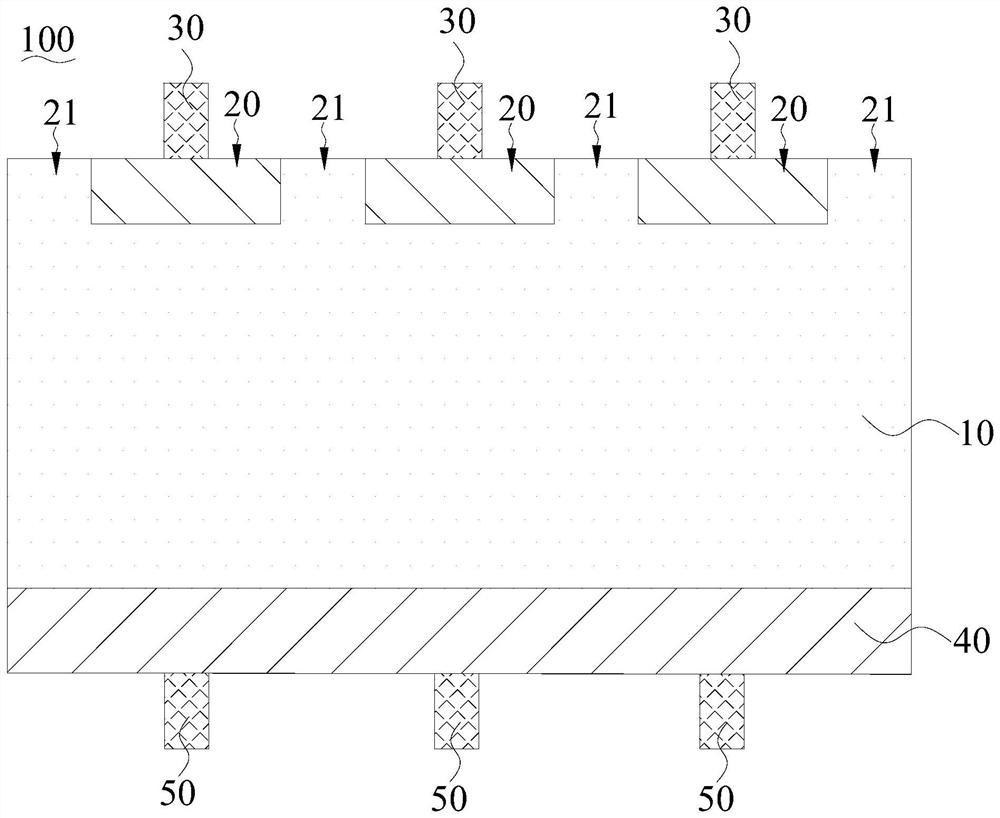

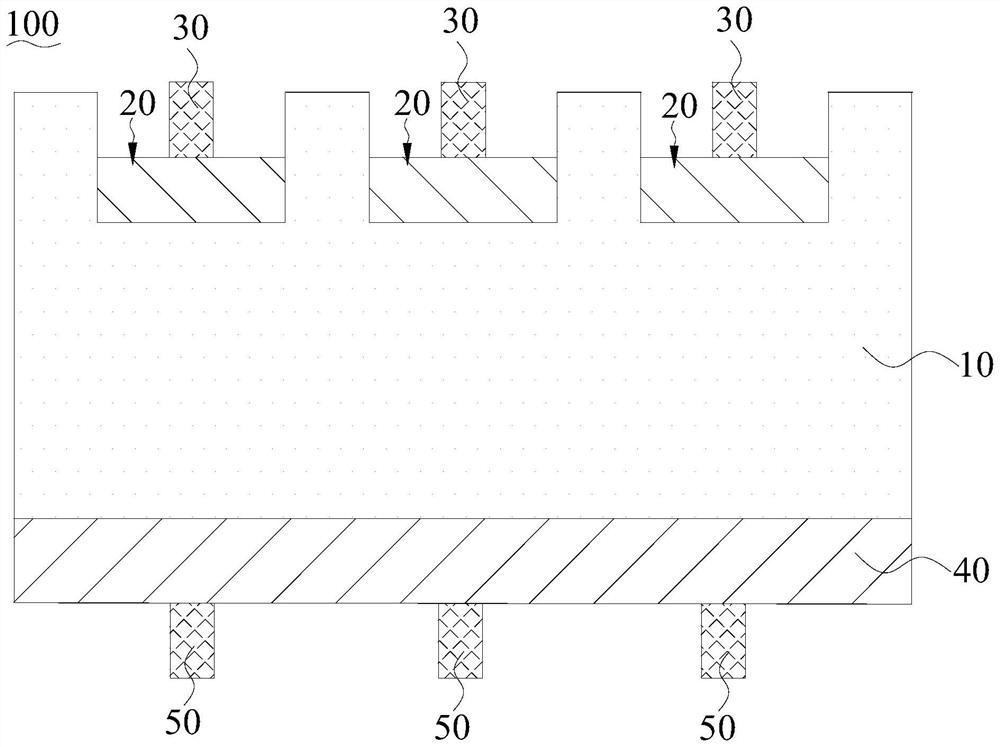

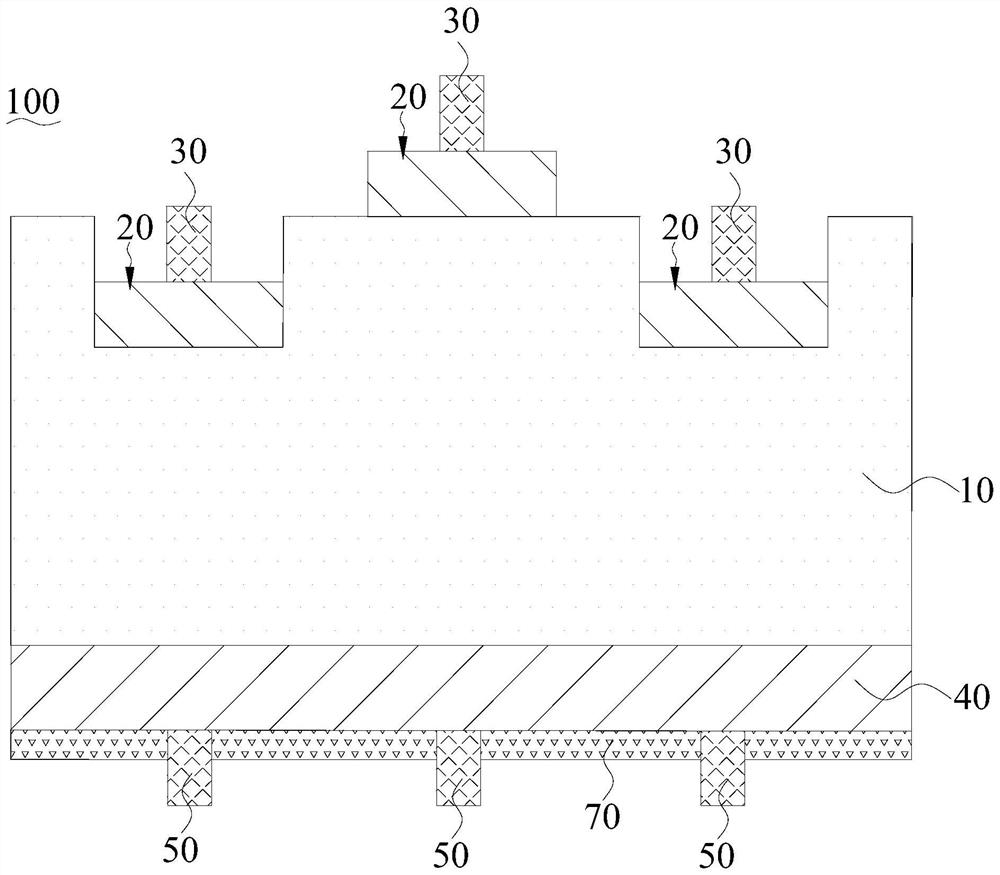

[0040] See figure 1 The solar cell 100 provided by the present application embodiment includes: silicon substrate 10, in which the first doped region 20 and the first conductive layer 30 are sequentially provided in the back surface of the silicon substrate 10. The back passivation contact structure 40 and the second conductive layer 50; the number of the first doped regions 20 is a plurality of first doped regions 20, and the doped polarity and silicon lining of the first doped region 20 is intervals. The polarity of the bottom 10 is the same, and the first conductive layer 30 is electrically contacted with the first doping region 20, and the second conductive layer 50 is electrically contacted with the back surface passivation contact structure 40.

[0041] The solar cell 100 of the present application embo...

Embodiment 2

[0128] The second embodiment of this application also provides a battery assembly comprising the solar cell 100 of the foregoing embodiment one.

[0129] The battery assembly of the second embodiment of the present application, since the solar cell 100 is the same as the first doped region 20 having the same polarity in the silicon substrate, most carriers can be transmitted through the body region of the silicon substrate 10 to the first A doped region 20, so that the first doped region 20 does not need to contact the silicon substrate 10, thereby reducing the Russian compound brought by using a diffusion process, or can reduce the passivation contact structure as a Parasitic absorption brought by a front surface field. At the same time, this can be adapted to the quality of the quality of the silicon substrate 10, which utilizes the advantages of high quality of the silicon substrate, so that the body region of the silicon substrate 10 is more fully transported, which is advanta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com