OLED light source driven by opv and preparation method thereof

A light source and controller technology, applied in the field of green lighting, can solve the problems of low integration and inconvenient use, and achieve the effect of reducing device heating, reducing Auger recombination, and improving PCE.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

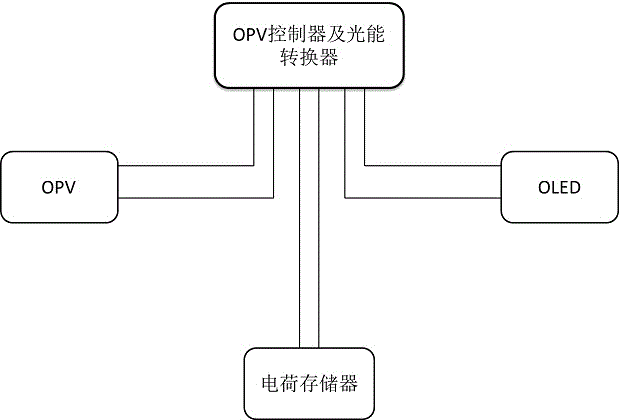

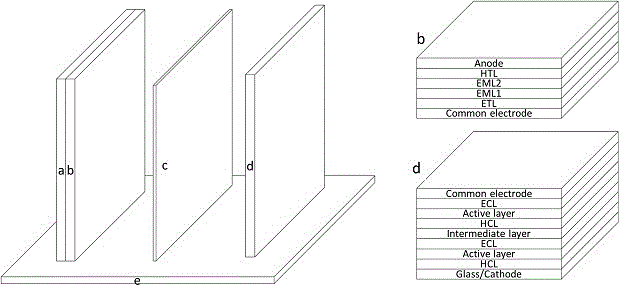

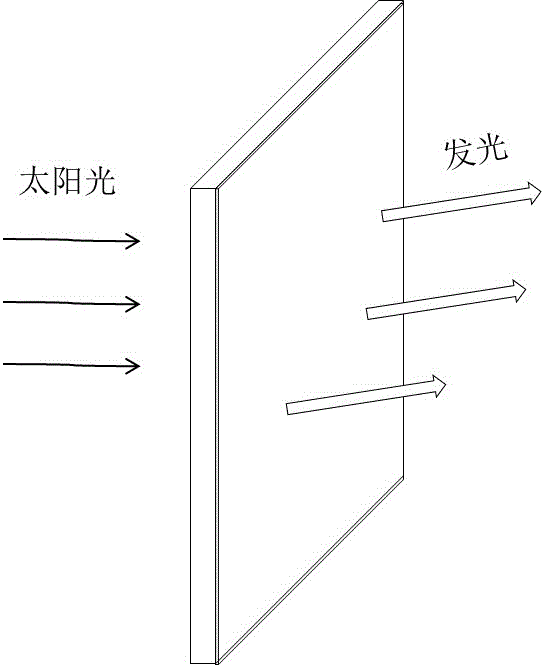

[0037] In this example, see Figure 1 ~ Figure 3 , an OPV-driven OLED light source, including a rigid transparent substrate a, OPV component b, common electrode layer c, OLED component d, OPV controller and memory e, the transparent substrate a adopts a rigid ITO substrate, and the OPV device b collects the sun The light energy is converted into electrical energy through the controller, powers the OLED light-emitting component d through the common electrode layer c, and stores it in the OPV controller and memory e. The OPV controller and memory e are made of organic materials. The OPV controller and memory e are effectively connected with OPV component b and OLED component d. The OPV controller, memory e, OPV component b and OLED component d are all transparent devices, which form a plate-shaped integrated system through stacked assembly and embedded assembly. The OPV controller and memory e automatically supply power to the OLED device d when the light is insufficient, so as ...

Embodiment 2

[0053] This embodiment is basically the same as Embodiment 1, especially in that:

[0054] In this embodiment, the transparent electrode substrate is prepared by using the transparent electrode to be deposited on a flexible plastic substrate with relatively high light transmittance. In this embodiment, the organic solar cell obtains electric energy by converting light energy and stores it, so that it can be released again to drive the OLED when the energy needs to be utilized. Since all components can be made into organic products, each component of the present invention can be made flexible and transparent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com