Manufacturing method of polarizing non sensitive semiconductor optical multiplier

A technology of optical amplifier and manufacturing method, applied in instruments, optics, nonlinear optics, etc., can solve the problems of large strain, insensitivity to polarization, etc., and achieve the effect of reducing noise index, easy inversion, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

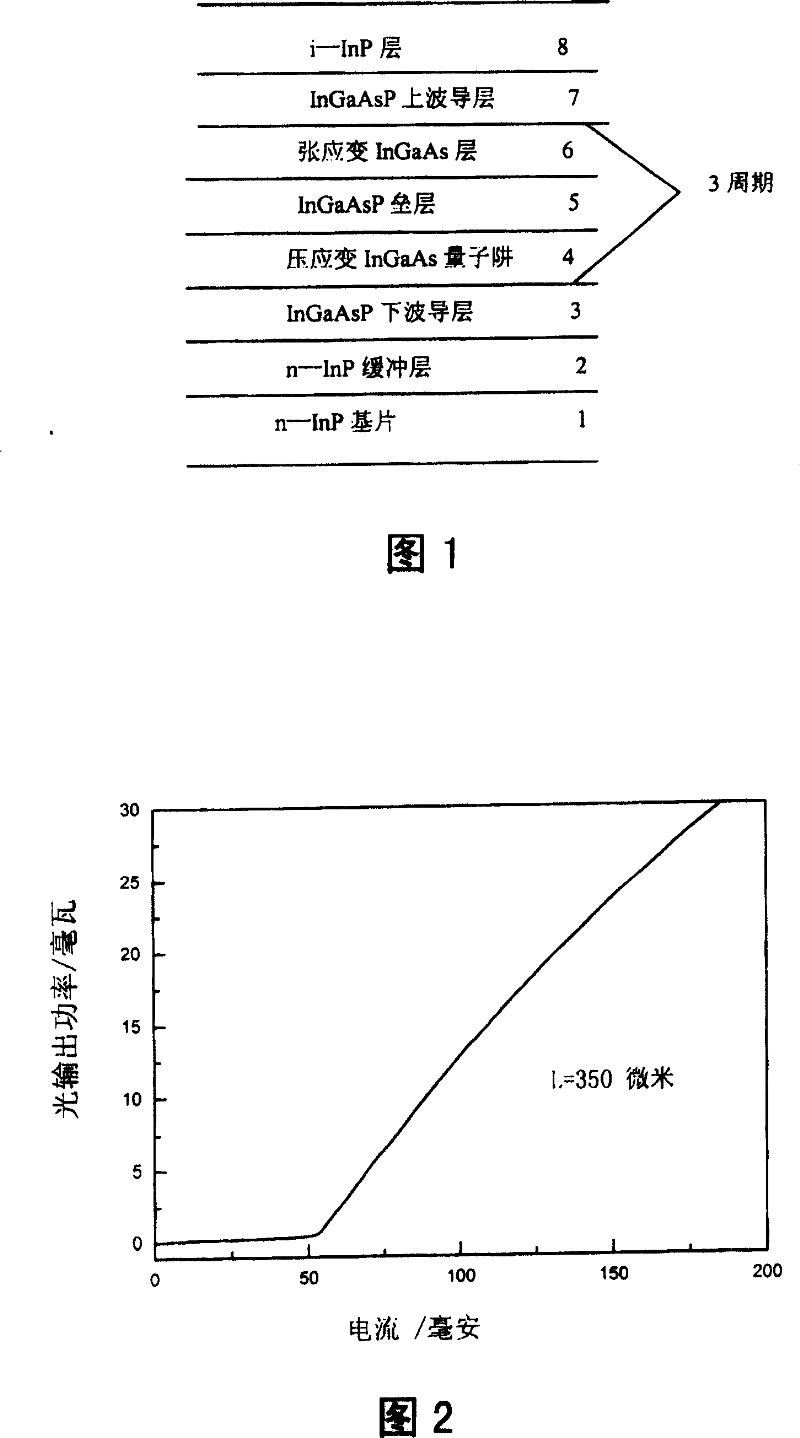

[0032] Please refer to shown in Fig. 1, a kind of preparation method of polarization insensitive semiconductor optical amplifier of the present invention, comprises the steps:

[0033] (1) First grow an epitaxially optimally designed quantum well mixed with quasi-body material on the n-type indium phosphide substrate 1. The active structure specifically includes the buffer layer 2, the lower waveguide layer 3, and the compressive strain quantum well 4. , matched barrier 5, tensile strained quasi-body material 6, in which three identical compressive strain quantum wells and three layers of the same quasi-body material are grown alternately, and the sandwich 5 layers are barriers 5 that are lattice-matched with indium phosphide , and finally the upper waveguide layer 7 and the protective layer 8 are epitaxially grown.

[0034] (2) On the epitaxial sample, grow a layer of silicon dioxide with a thickness of 1500 angstroms as a mask, etch out a strip with a width of 2 μm, and use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com