A preparation method of low surface concentration shallow diffusion junction solar cell

A shallow diffusion junction, solar cell technology, applied in the field of solar energy, can solve the problems of poor uniformity, inability to achieve industrialization, uneven square resistance, etc., and achieve the effects of low cost, improved photoelectric conversion efficiency, and improved minority carrier life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

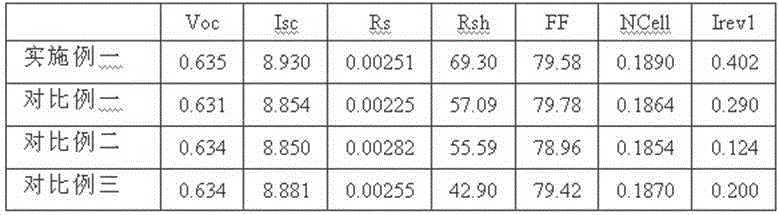

Examples

Embodiment 1

[0026] A method for preparing a low surface concentration shallow diffusion junction solar cell includes the following steps:

[0027] (1) After making the P-type monocrystalline silicon wafer, deposit 20nm thick microcrystalline silicon as a barrier layer on the light-receiving surface of the battery by PECVD;

[0028] (2) Put the deposited silicon wafers into a diffusion furnace for regular diffusion, and the square resistance after diffusion is 60Ω / □;

[0029] (3) Put the diffused silicon wafer into a 0.2% sodium hydroxide solution for cleaning, and the cleaning time is 1 min. The microcrystalline silicon layer is removed and the square resistance after cleaning is 75Ω / □;

[0030] (4) After removing the back electrode or cutting edge of the silicon wafer, put it in 3~5vol% HF for 200s;

[0031] (5) Depositing anti-reflection film, back electrode back field, and printing and sintering test packaging of positive electrode; low surface concentration and shallow diffusion junction solar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com