A diffusion technique applied on silicon solar battery

A silicon solar cell and diffusion process technology, applied in the field of diffusion process, can solve the problems of increasing, unable to form ohmic contact, increasing resistance, etc., and achieve the effects of optimizing doping curve, increasing surface doping concentration, and reducing Auger recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below through embodiments and in conjunction with the accompanying drawings.

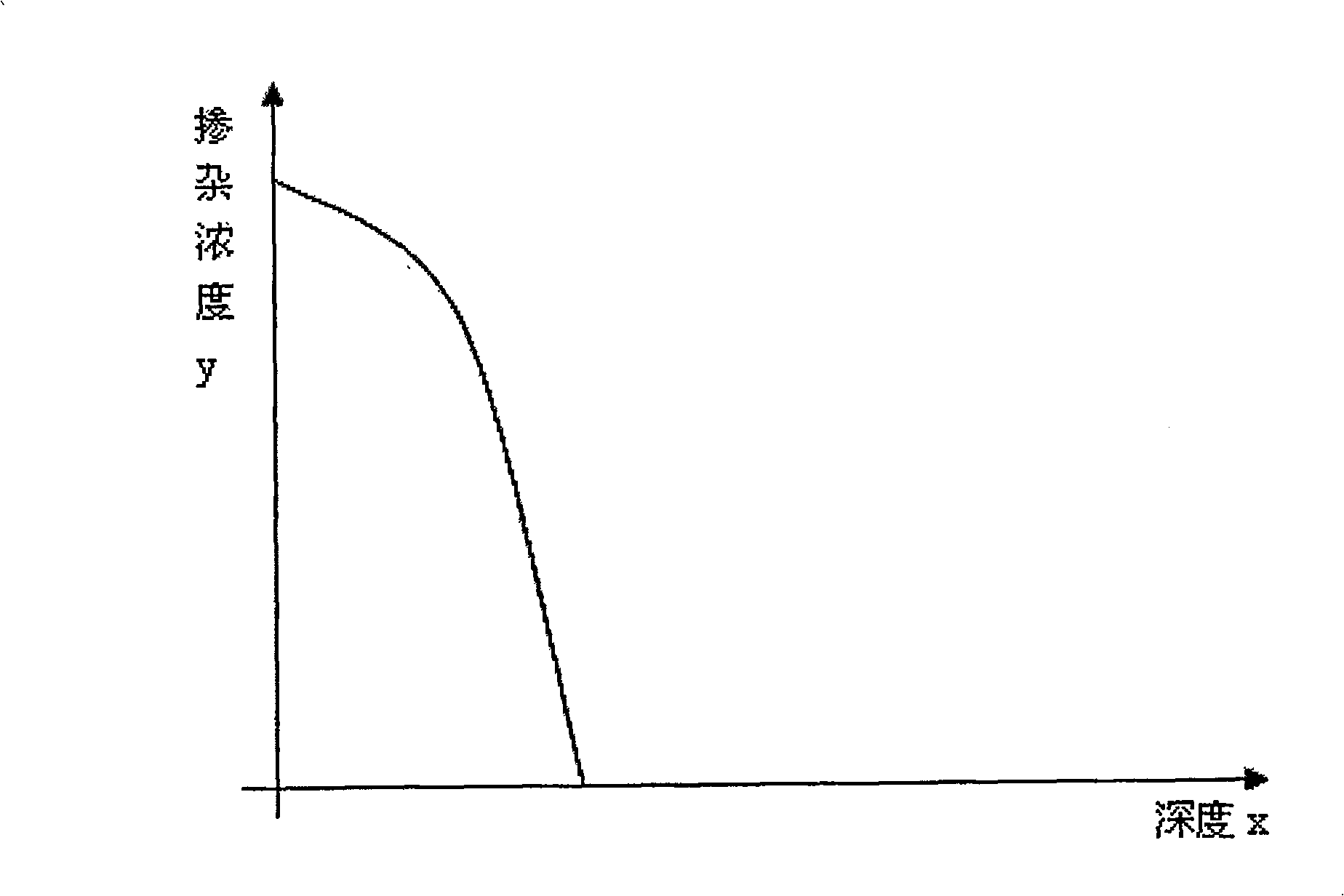

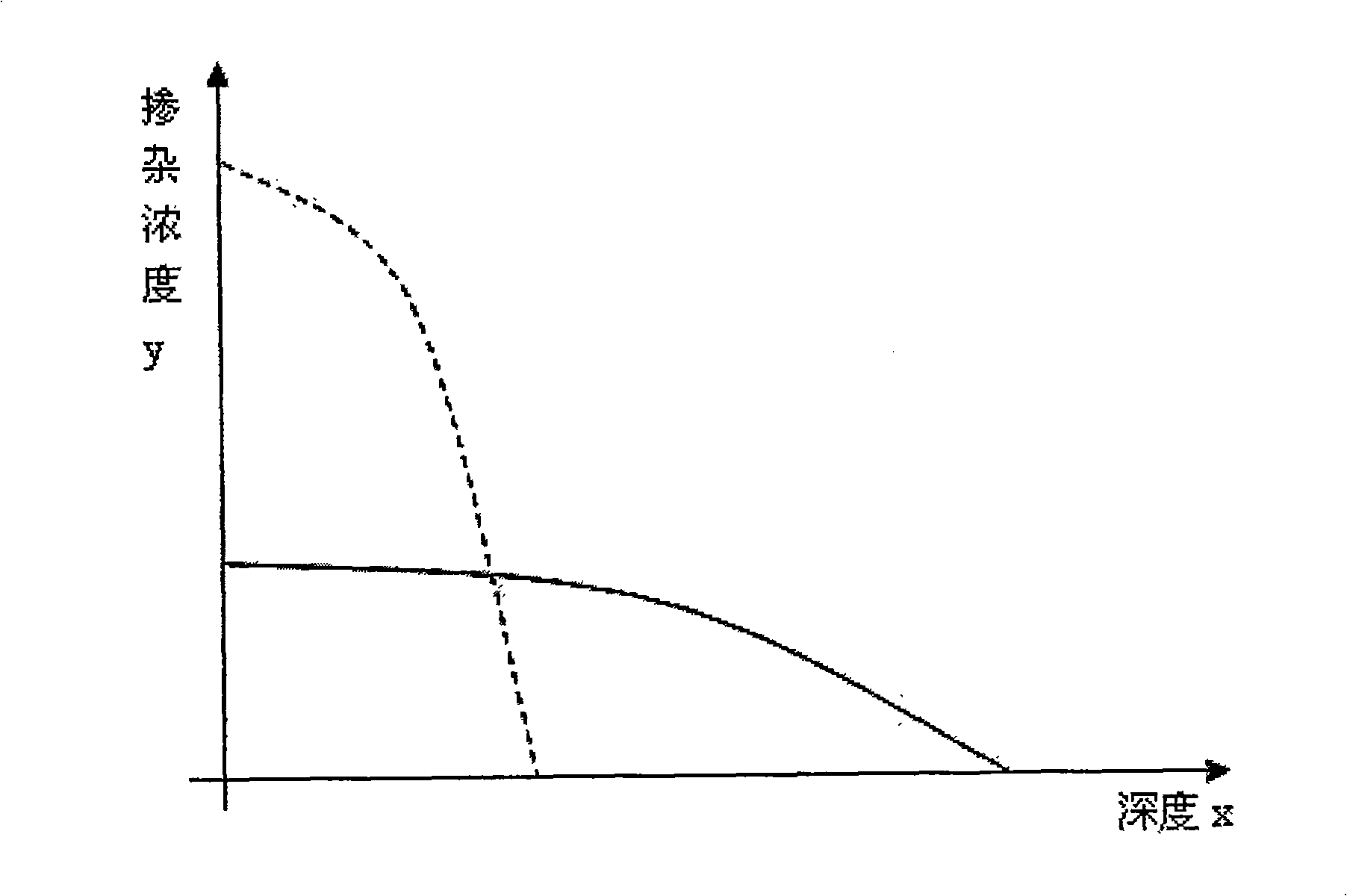

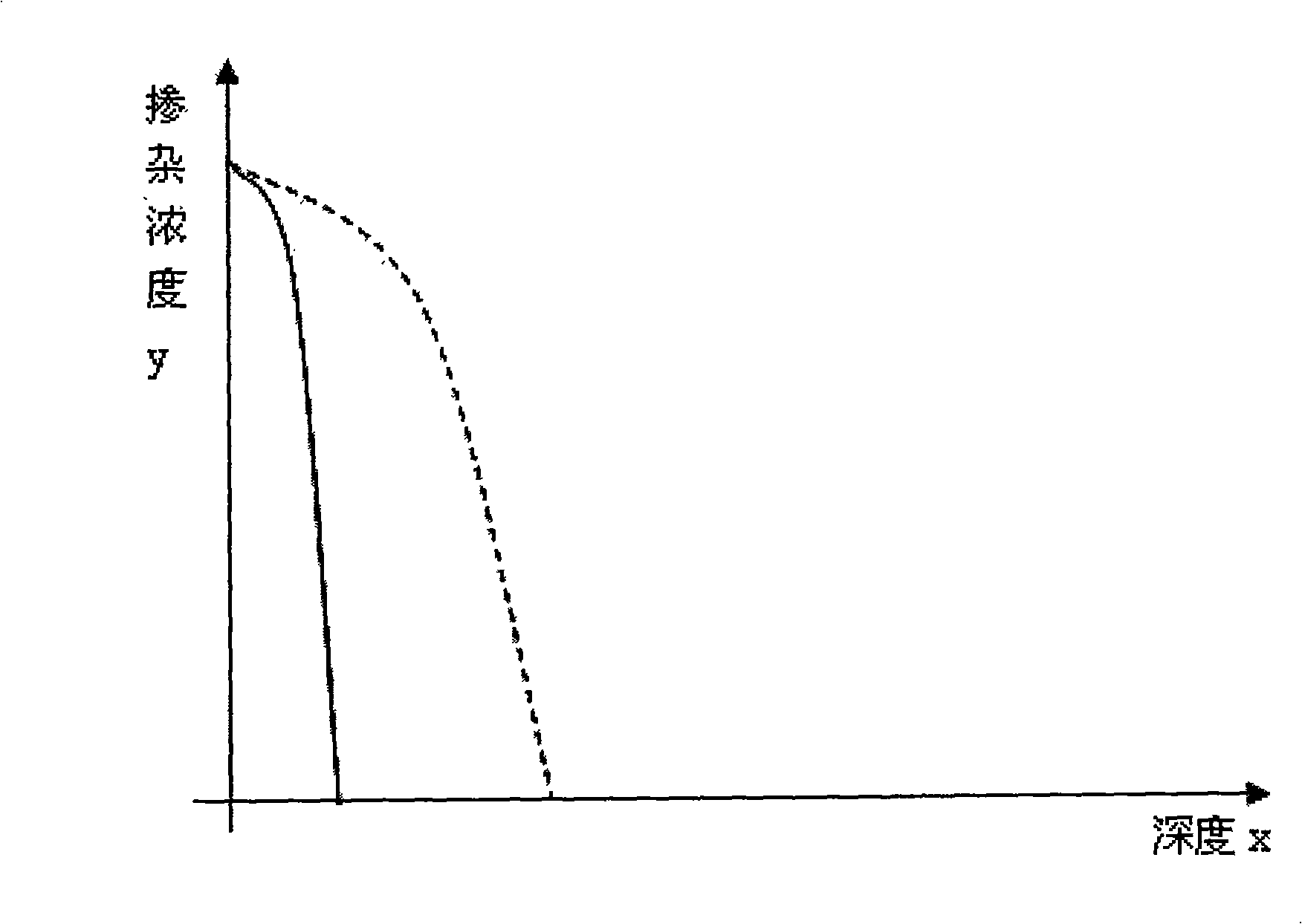

[0019] The purpose of the present invention is to make the distribution state of the doping curve more reasonable by the present invention through an improved diffusion method, reduce the highly doped region in the emission region to reduce the Auger recombination of the emission region, and improve the efficiency of the solar cell. performance. Due to the reduced recombination in the emitter region, the short-circuit current of the battery is increased by 0.5-1mA / cm 2 .

[0020] The present invention divides the usual one-step diffusion process at a constant temperature into two steps. The first step is to diffuse for a longer time at a lower temperature and redistribute to form a doped substance with a lower concentration and a deeper impurity distribution. impurity curve; the second step is to perform short-time diffusion under the condit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com