Construction method of complex geological conditions in the pit Larson steel plate pile in the pit

A Larsen steel sheet pile technology with complex geological conditions, applied in sheet pile wall, excavation, infrastructure engineering and other directions, can solve the problems of difficult construction and high safety risk, improve construction efficiency, reduce costs, and improve lateral The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

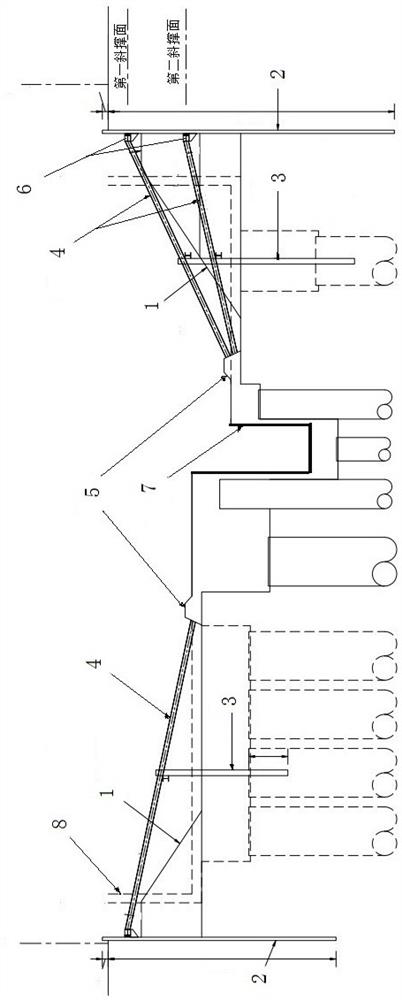

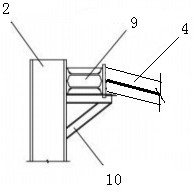

[0028] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0029] Such as figure 1 As shown, a pit-in-pit Larsen steel sheet pile construction method with complex geological conditions includes the following steps:

[0030] S1. Larsen steel sheet pile construction: According to the excavation depth of the pit-in-pit 7 foundation pit, surrounding environmental conditions, construction site layout and engineering geological conditions, use Larsen steel sheet pile 2 (Larsen 6# steel plate, 11m-15m in length) Stop water and protect the 7 foundation pits in the pit, and set up dewatering wells according to the groundwater conditions for dewatering treatment until the water level in the pit drops to 0.5 meters below the pit;

[0031] S2. Pit-in-pit construction: firstly reinforce the soil within the scope of the foundation pit, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com