A space cable suspension bridge main cable construction auxiliary device and main cable construction method

An auxiliary device and suspension bridge technology, which is applied in the direction of suspension bridges, bridges, bridge construction, etc., can solve the problems of complex construction procedures, difficult angle control, and difficult control of precision, so as to solve structural safety and durability, avoid uneven force, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Comply with above-mentioned technical solution, the specific embodiment of the present invention is given below, it should be noted that the present invention is not limited to following specific embodiment, all equivalent transformations done on the basis of the technical solution of the present application all fall within the scope of protection of the present invention .

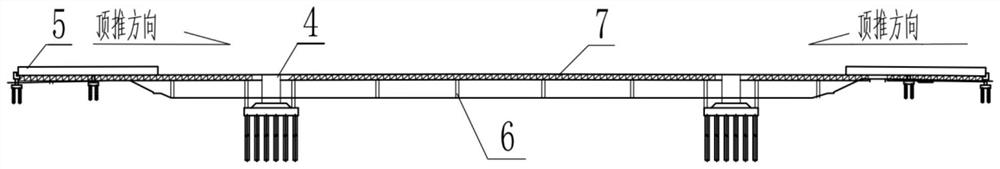

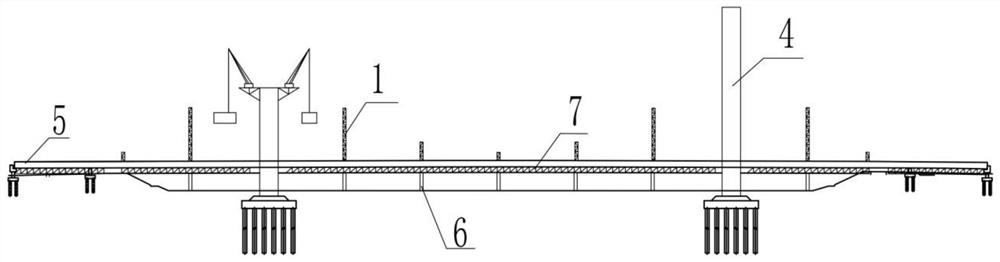

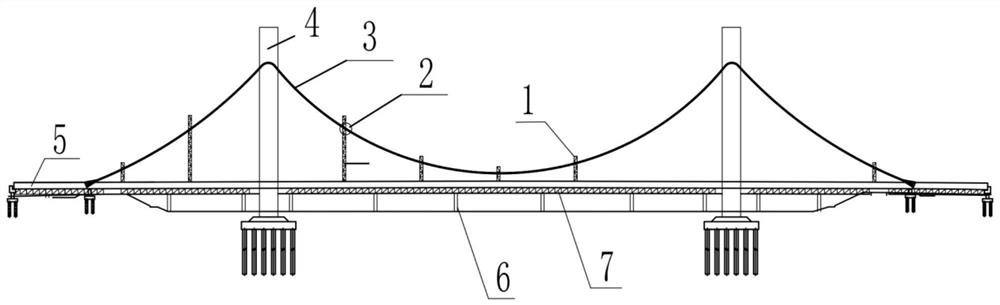

[0054] Such as figure 2 , image 3 as well as Figure 7 ~ Figure 12 As shown, a space cable suspension bridge main cable construction auxiliary device includes a space cable fixing bracket 1 and a main cable strand temporary fixing device 2; wherein the space cable fixing bracket 1 is provided with a transverse support and two longitudinal supports, and the longitudinal The top end of the support is connected with the transverse support to form a trapezoidal bracket, and the bottom end of the longitudinal support is connected with the steel box girder of the main bridge; a plurality of space cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com