Direction-changing quantitatively-adjustable air distribution sleeve at vault of clean heat recovery coke oven

A quantitative adjustment and heat recovery technology, which is applied to coke ovens, coke oven heating, coke oven parts, etc., can solve the problems of coke cake surface coking and poor adjustability, so as to reduce coal consumption, control burning loss, and improve competition force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

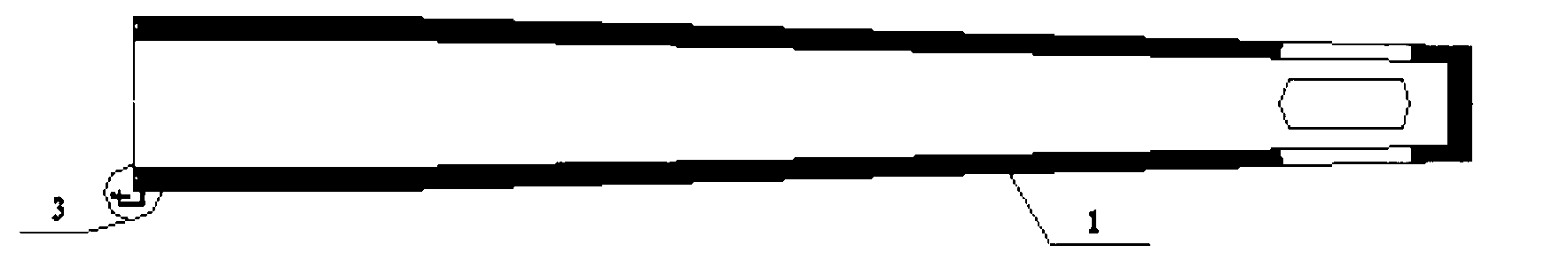

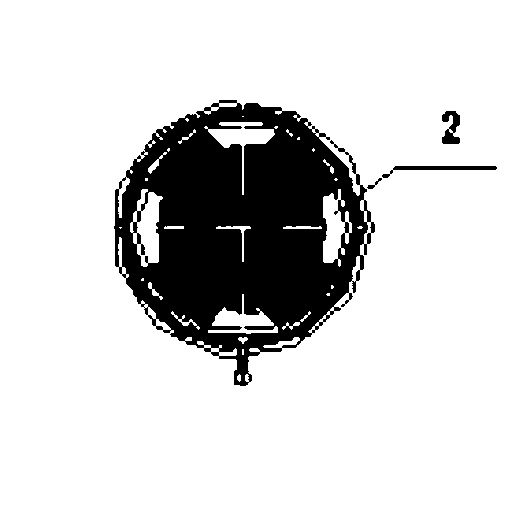

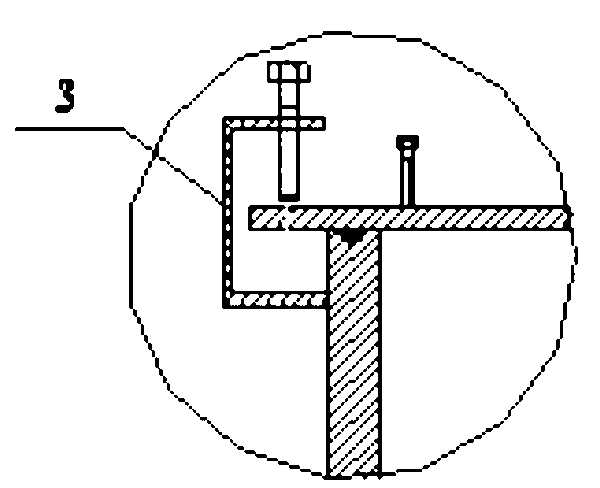

[0014] A clean heat recovery coke oven vault redirection quantitative adjustment air distribution sleeve, which includes a sleeve 1, a redirection device 2, a sealing device 3, an adjustment device 4, an indicating device 5 and a limit device 6, the sleeve 1 There is an upper device 2 installed on it, and an adjusting device 4 , an indicating device 5 , and a limit device 6 are arranged on the redirecting device 2 , and a sealing device 3 is arranged between the casing 1 and the redirecting device 2 . The size of the sleeve 1 is equivalent to the size of the originally designed air distribution port on the top of the furnace, and it is directly inserted from the top air distribution port. The air distribution adjustment is controlled by the adjustment device 4, the indicator device 5, and the limit device 6. The operation is simple and the instructions are clear. It is easy to replace; the air distribution redirection function is realized by the bushing 1 and the redirectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com