Installation method of self-aligning roller bearing in rocker arm of coal mining machine

A technology of self-aligning roller bearing and installation method, which is applied in the direction of shaft and bearing, bearing element, rigid support of bearing parts, etc. Difficulty in operation and other problems, to achieve the effect of good use effect, easy disassembly and assembly, and simple installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

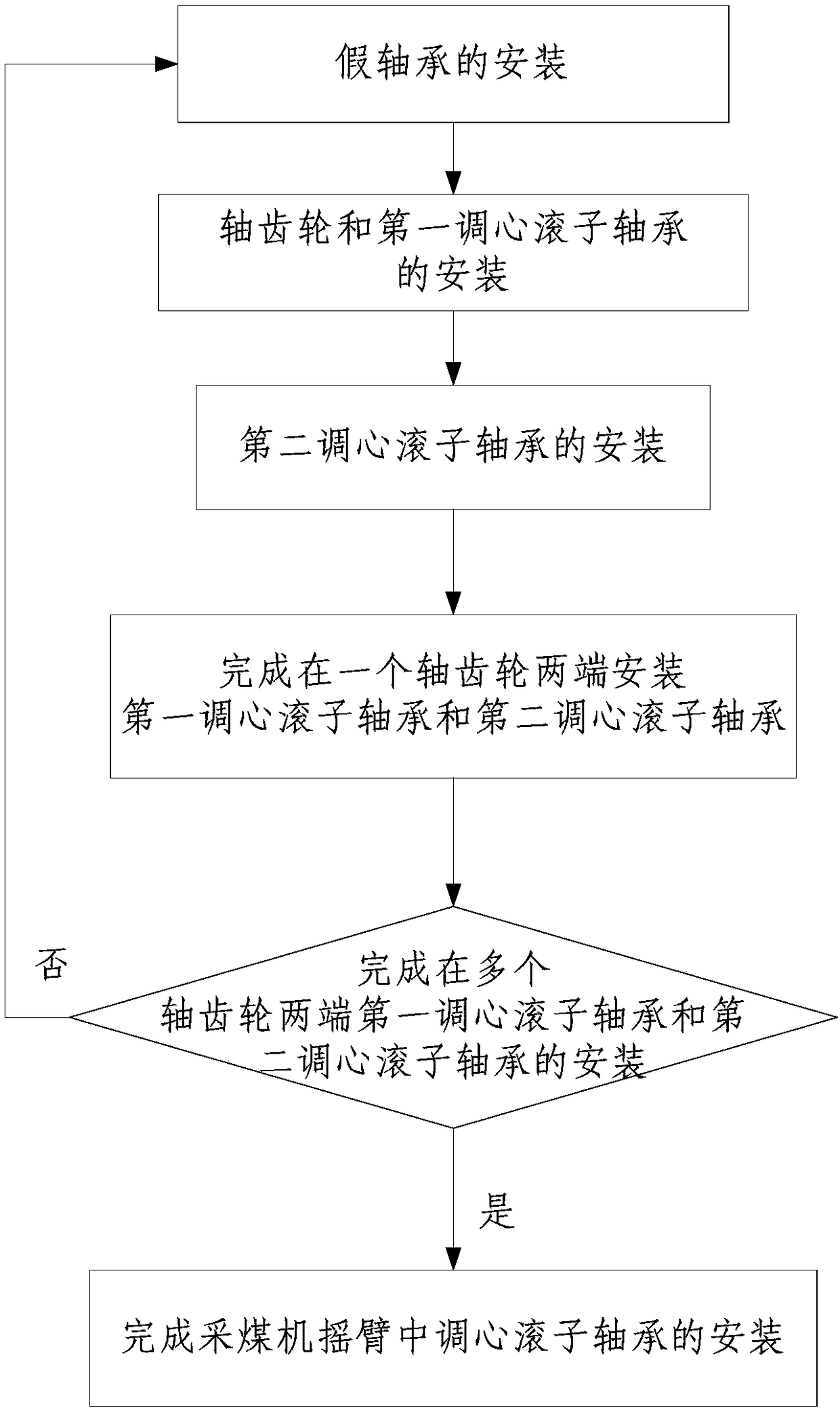

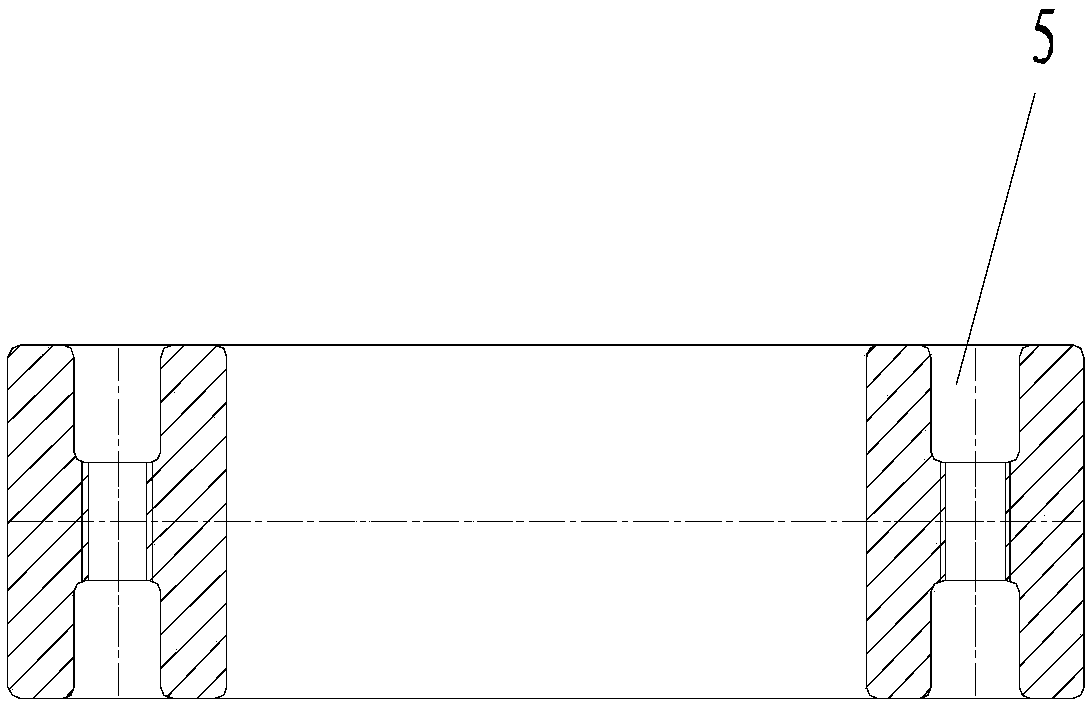

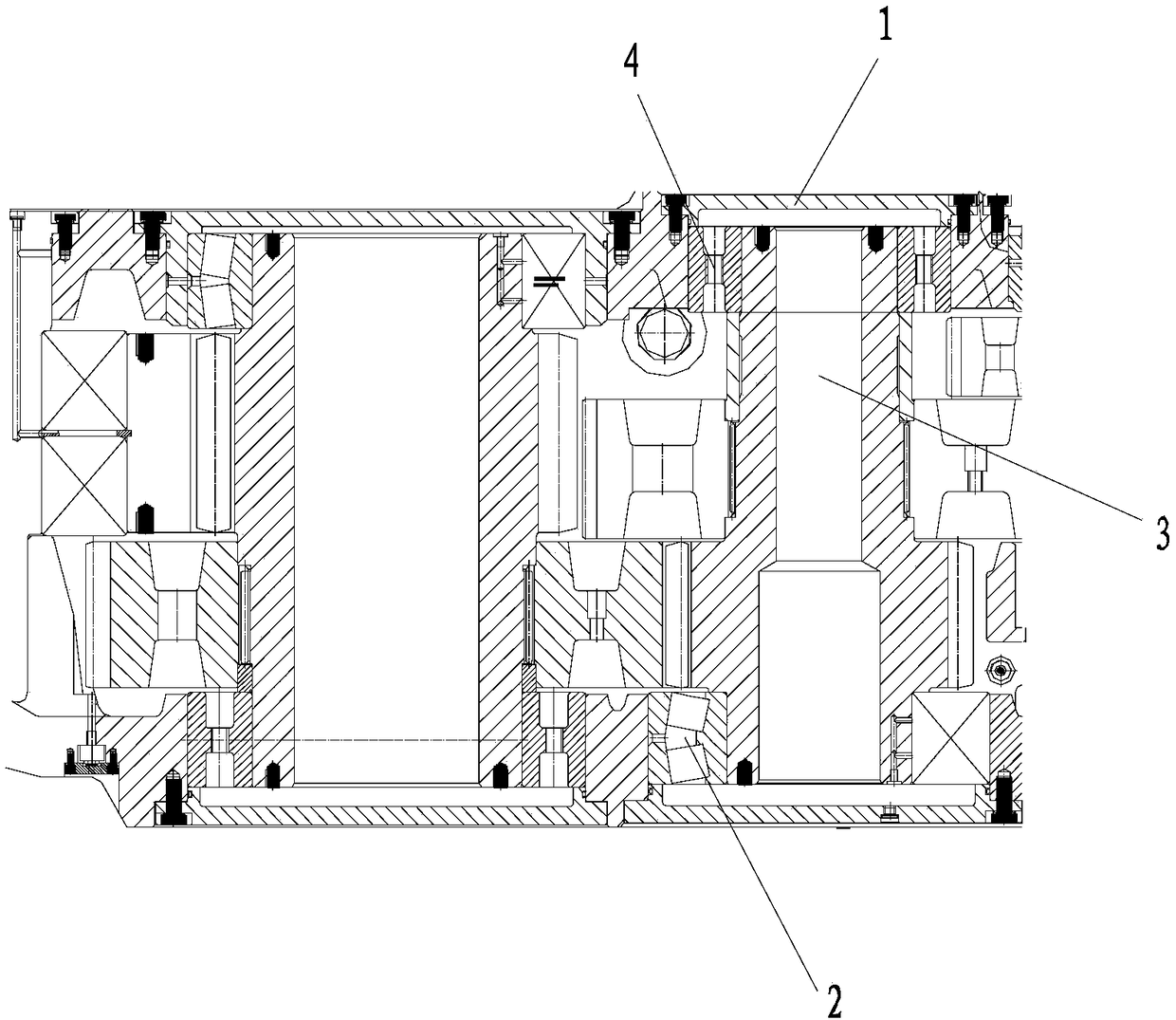

[0036] like figure 1 , figure 2 and image 3 As shown, the shearer rocker arm of the present invention includes a housing, cover end covers 1 arranged on both sides of the housing, and a plurality of shaft gears 3 arranged in the housing and connected by transmission, each of which The two ends of the shaft gear 3 are equipped with self-aligning roller bearings 2, and the self-aligning roller bearings 2 are fixedly connected with the cover end cover 1. The self-aligning roller bearings 2 include a first self-aligning roller bearing and a second self-aligning roller bearing. The self-aligning roller bearing is characterized in that the method comprises the following steps: the method of installing the first self-aligning roller bearing and the second self-aligning roller bearing respectively at both ends of the plurality of shaft gears 3 are the same, wherein , install the first spherical roller bearing and the second spherical roller bearing at both ends of any shaft gear 3...

Embodiment 2

[0050] In this embodiment, the difference from embodiment 1 is:

[0051] In this embodiment, the first self-aligning roller bearing and the second self-aligning roller bearing are self-aligning roller bearings with a diameter of 200 mm to 300 mm.

[0052] In this embodiment, when the diameters of the first self-aligning roller bearing and the second self-aligning roller bearing are 200 mm to 300 mm, the heat treatment of the first self-aligning roller bearing in step 2 and the first self-aligning roller bearing in step 3 The heat treatment process of two spherical roller bearings is as follows:

[0053] Step A, heating for the first time: use bearing heaters to heat the inner rings of the first spherical roller bearing and the second spherical roller bearing once, wherein the first heating temperature is 15°C, and the first heating time is 5 minutes;

[0054] Step B, standing still: After heating the first spherical roller bearing and the second spherical roller bearing in st...

Embodiment 3

[0058] In this embodiment, the difference from embodiment 1 is:

[0059] In this embodiment, the first spherical roller bearing and the second spherical roller bearing are spherical roller bearings with a diameter larger than 300mm.

[0060] In this embodiment, when the diameters of the first spherical roller bearing and the second spherical roller bearing are greater than 300mm, the heat treatment of the first spherical roller bearing in step 2 and the second adjustment in step 3 The heat treatment process of the inner roller bearing is as follows:

[0061] Step 1. First heating: use a bearing heater to heat the inner rings of the first spherical roller bearing and the second spherical roller bearing, wherein the heating temperature for the first heating is 15°C, and the heating time for the first heating is 5 minutes;

[0062] Step Ⅱ, standing still: After heating the first spherical roller bearing and the second spherical roller bearing in step Ⅰ, put the first spherical r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com