Patents

Literature

30 results about "Indium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Indium phosphide (InP) includes phosphorus and indium and is a binary semiconductor. It has a zincblende crystal structure similar to GaAs and almost all the III-V semiconductors.

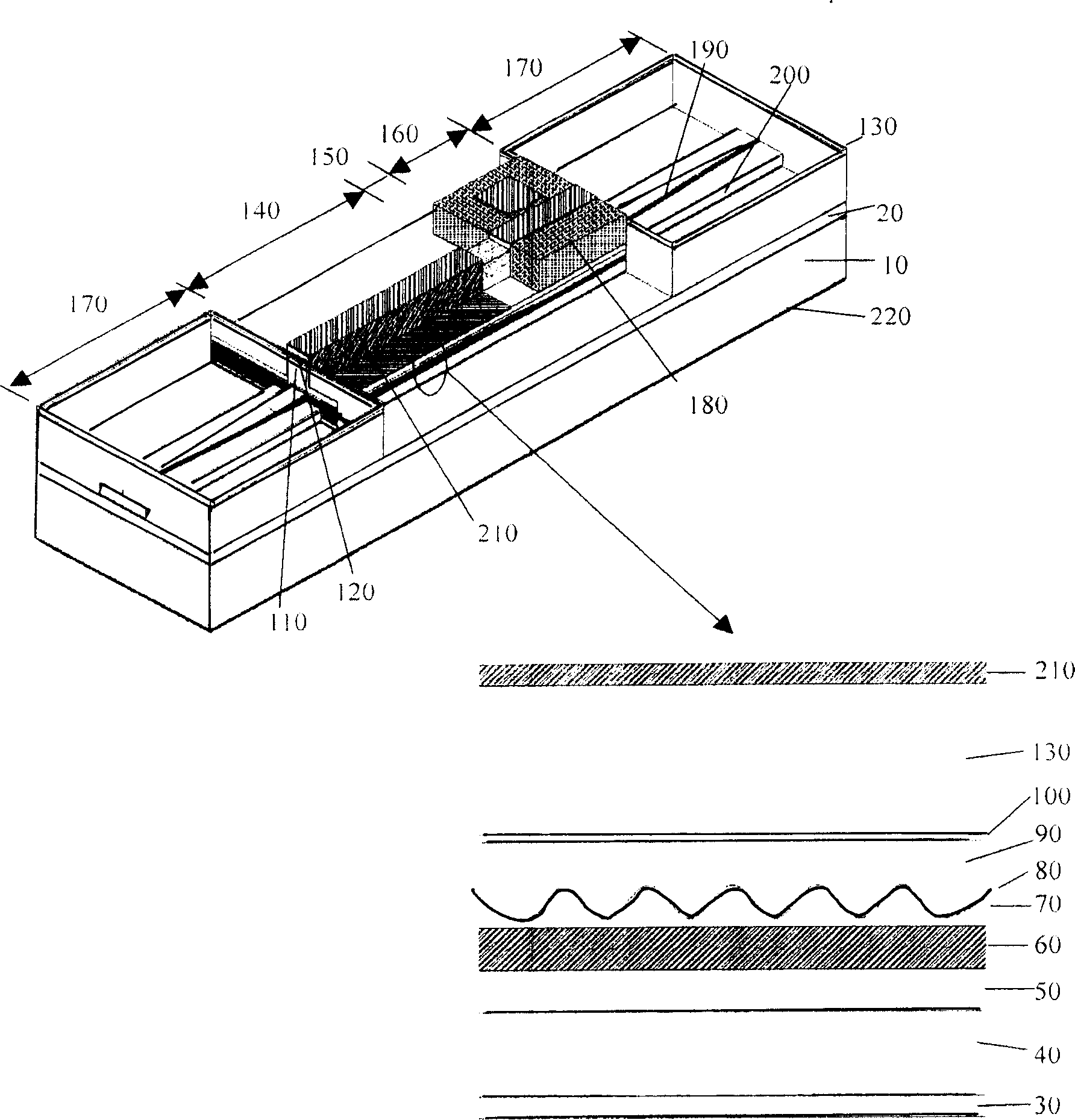

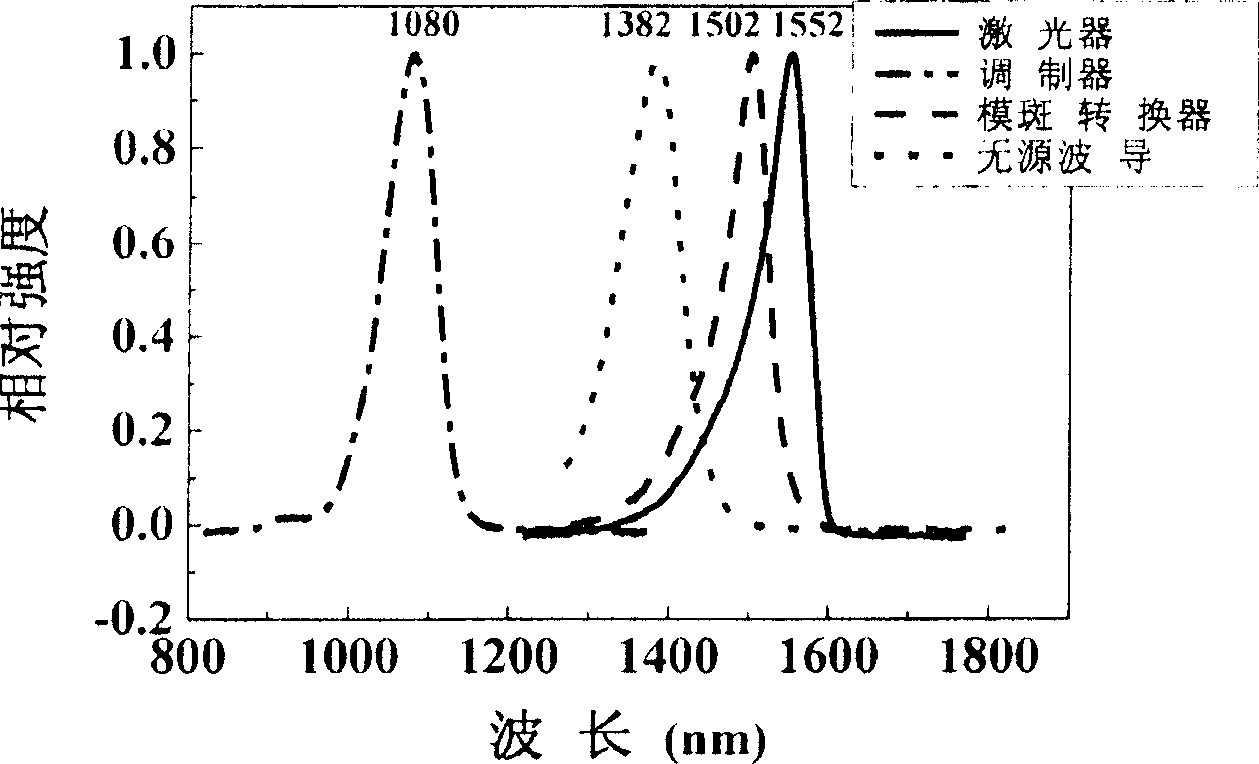

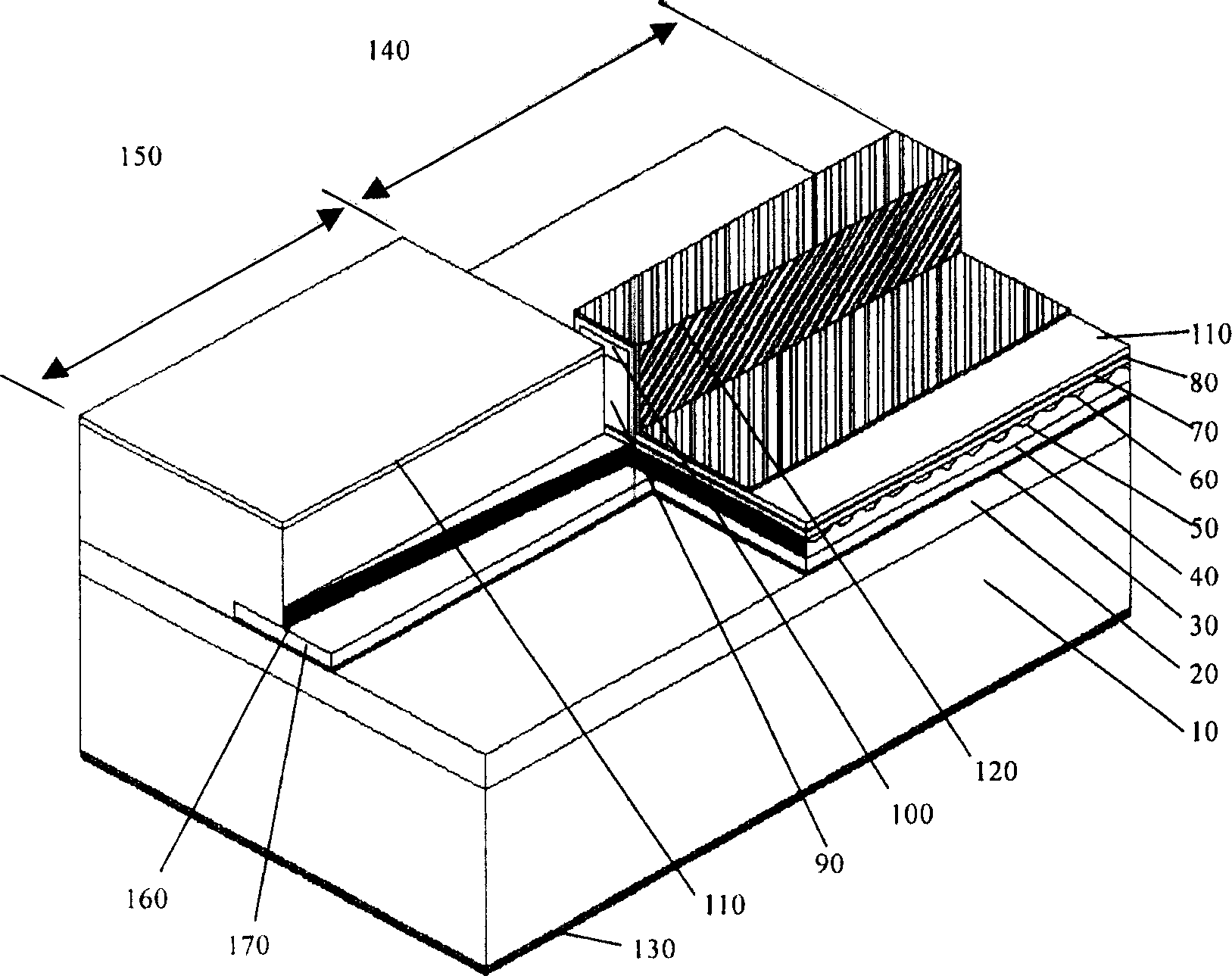

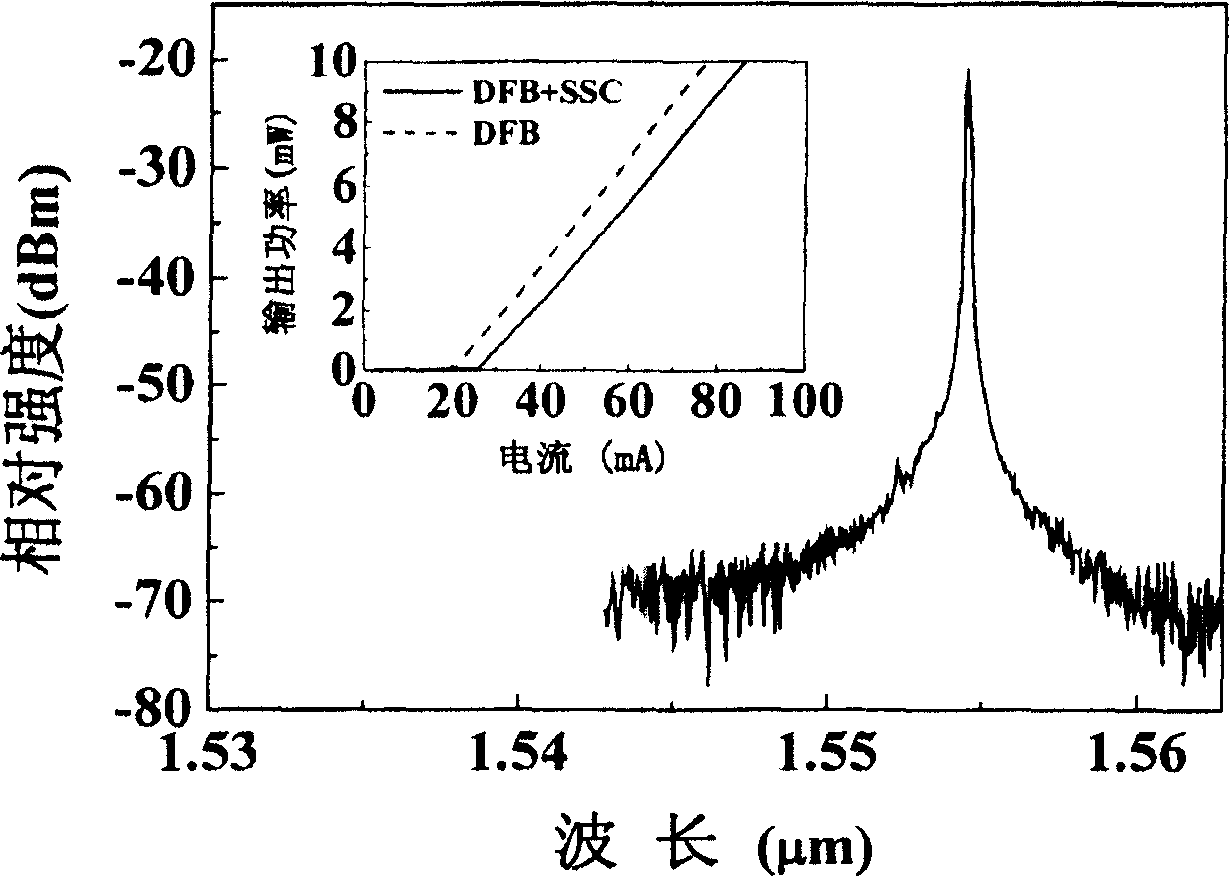

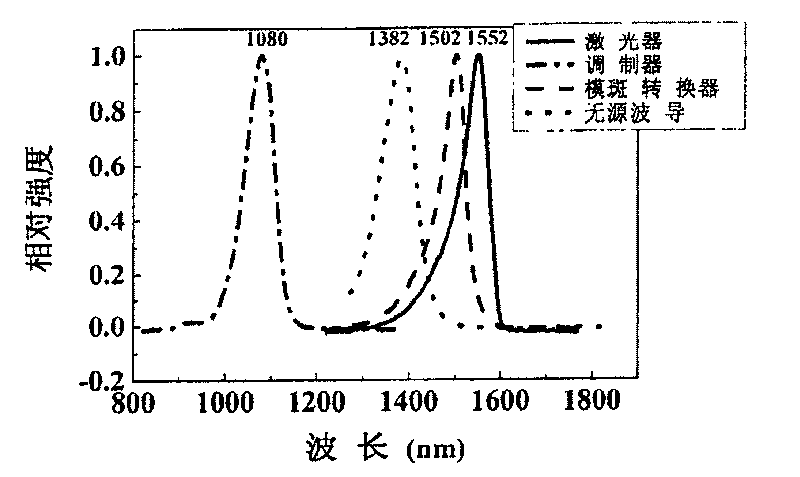

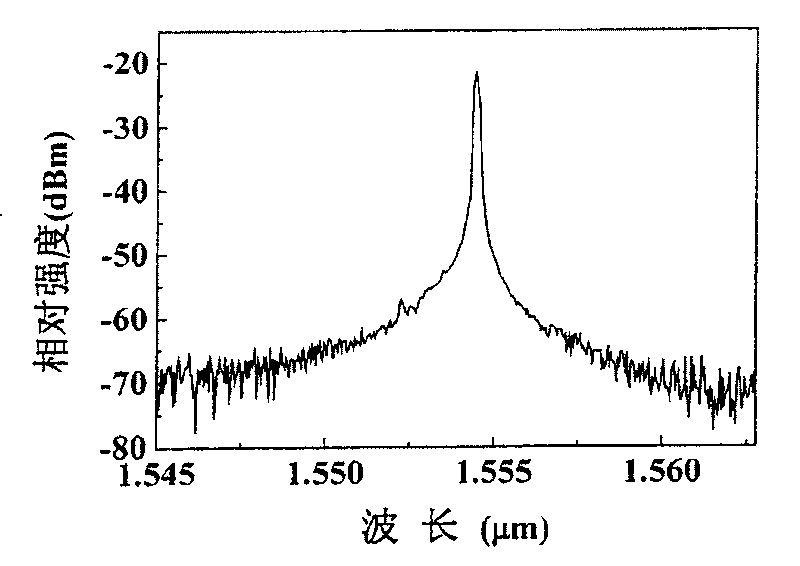

Integration method for electric absorption modulation laser and modular spot converter

InactiveCN1909309AReduce the number of growthHas an effectLaser detailsSemiconductor lasersPhosphate ionSilicon dioxide

The invention relates to an integration method of electric adsorption modulation laser and mode speckle converter, which comprises: growing n-type indium phosphate buffer layer on the substrate; corroding the upper 1.1Q layer on the chip, to grow buffer layer; growing silica dioxide protective layer on the whole chip, and corroding the silica dioxide protective layer at two ends of mode speckle converter; pouring low-energy phosphate ion; growing the silica dioxide protective layer again; heating, keeping warm, anneal on the chip; corroding silica dioxide protective layer; using relative light etching plate to mask the laser and modulator, to form the upper ridge and lower ridge on the converter; growing p-type indium phosphate and indium gallium arsenic phosphate etching stop layer; etching ridge pilot structure; depositing medlin at two sides of laser and modulator; opening the electrode windows of laser and modulator; etching the electrode images on the laser and modulator to splash the P electrode and remove the P electrode; extending the substrate, and splashing n electrode; slicing the sample to form tubular chip.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Preparation of semiconductor substrates

InactiveUS6036769APromotes impurity atom removalPromotes any tendencySemiconductor/solid-state device manufacturingBy pulling from meltImpuritySemiconductor

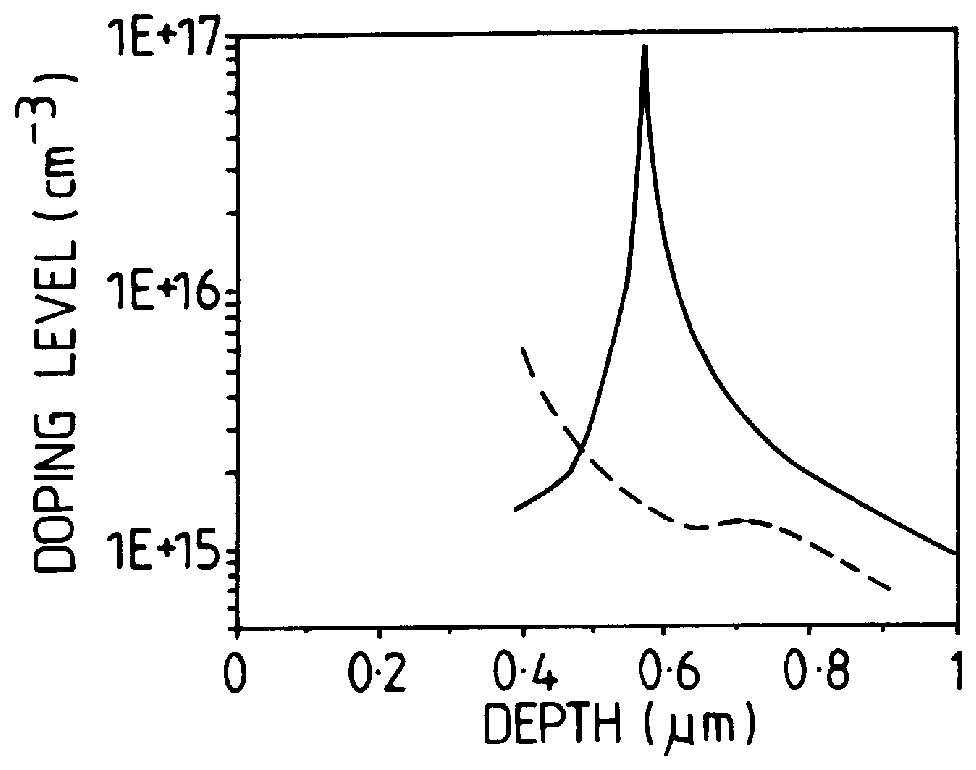

An indium phosphate semiconductor substrate is prepared for subsequent growth of epitaxial layers to form a semiconductor device. In the preparation, the substrate is first annealed to promote any tendency for surface accumulation of impurity atoms by diffusion from the substrate and to promote impurity atom removal from the surface of the substrate. The substrate is then surface etched to remove further impurities and to provide a clean, flat surface for subsequent epitaxial layer growth. The final stage of preparation involves growing a semi-insulating buffer layer on the substrate to isolate the device epitaxial layers from the substrate.

Owner:IPG PHOTONICS CORP

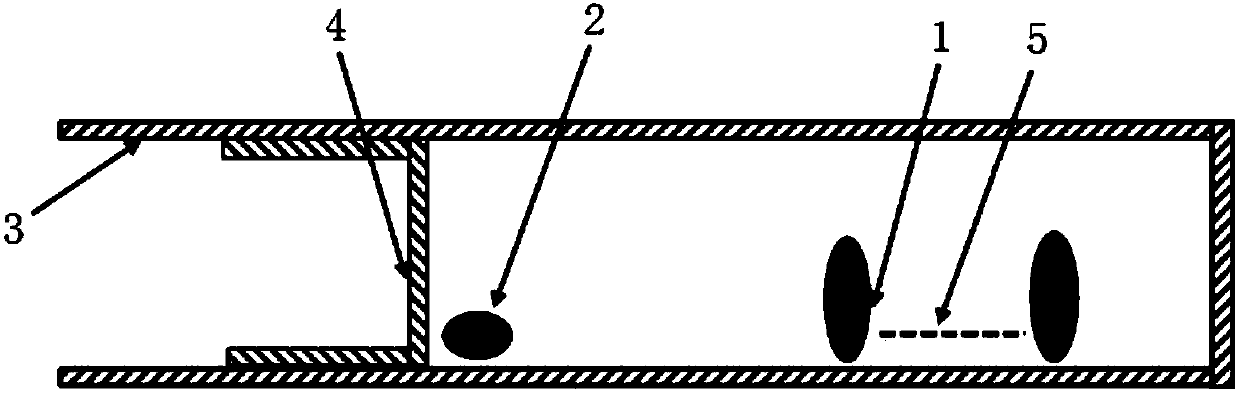

Annealing method of ferric-doped indium phosphate monocrystal chips

InactiveCN107675262AEfficient removalReduce defect densityPolycrystalline material growthAfter-treatment detailsHigh concentrationPhosphate

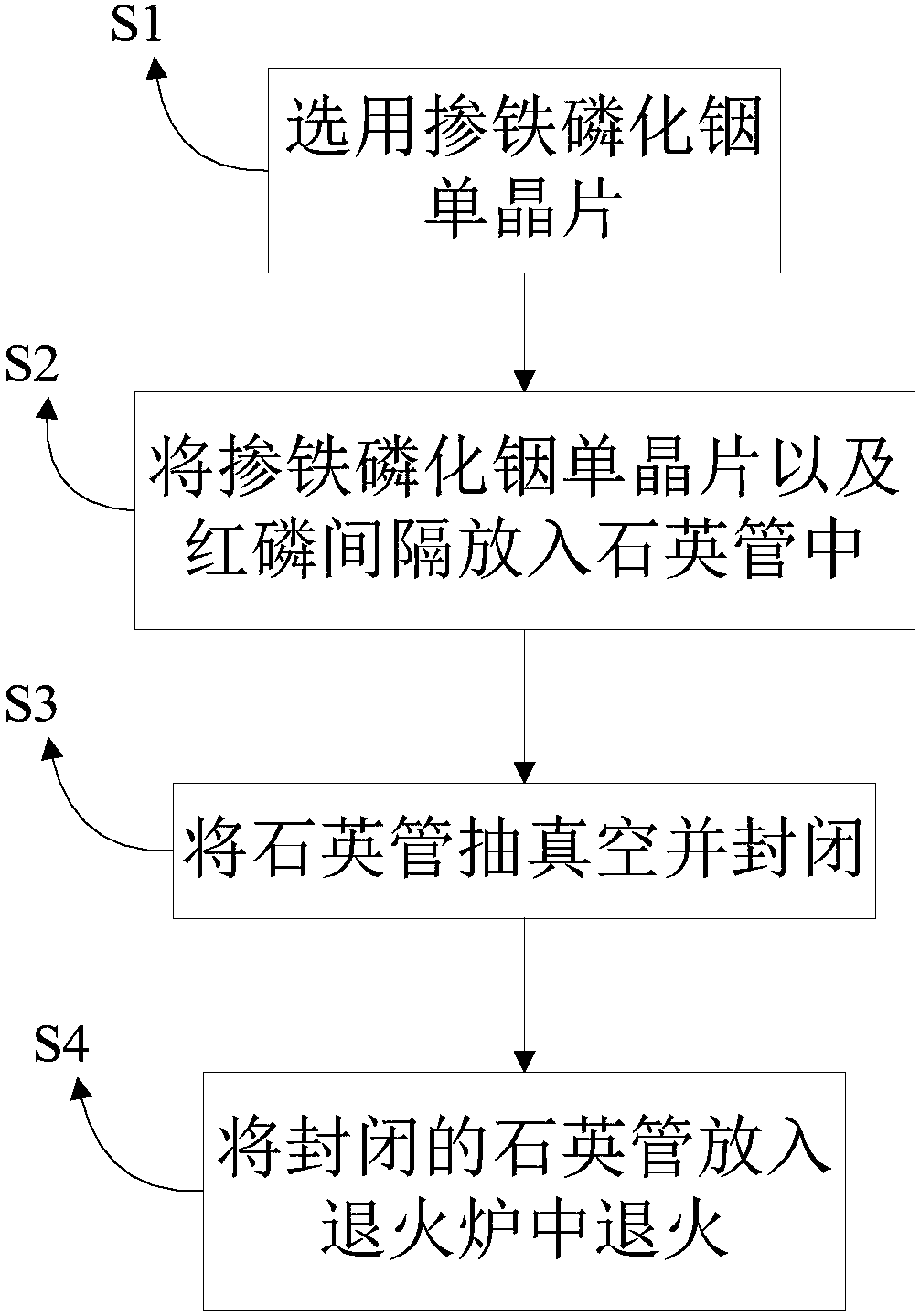

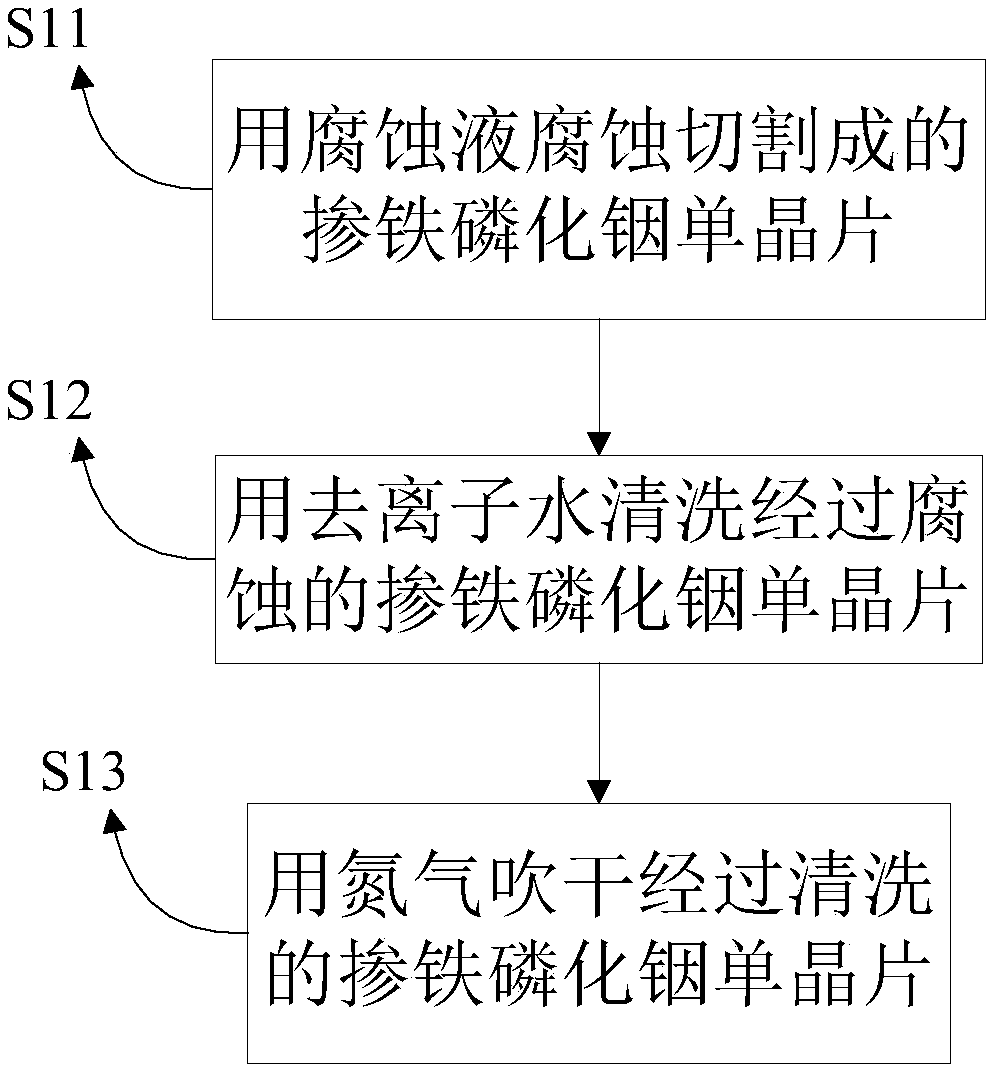

The invention discloses an annealing method of ferric-doped indium phosphate monocrystal chips. The annealing method includes the steps of S1, selecting the ferric-doped indium phosphate monocrystal chips; S2, putting the ferric-doped indium phosphate monocrystal chips and red phosphorus into a quartz tube at intervals; S3, vacuumizing and enclosing the quartz tube; S4, placing the enclosed quartztube into an annealing furnace for annealing. The ferric-doped indium phosphate monocrystal chips are subjected to annealing treatment, gathering of impurities in indium phosphate monocrystal materials is effectively avoided, defects of complexes are reduced, shortcomings of high concentration of ferric-doped indium phosphate crystal materials, poor uniformity and stability and the like are overcome, activating efficiency of ferric is effectively improved, resistivity of the materials is improved, and semi-insulation and stability of the ferric-doped phosphate monocrystal materials are improved.

Owner:珠海鼎泰芯源晶体有限公司

Photocatalyst deodorant and preparation method thereof

InactiveCN109569288AReduce light requirementsEliminate odorGas treatmentDispersed particle separationSodium bicarbonatePhosphoric acid

The invention discloses a photocatalyst deodorant and a preparation method thereof. The photocatalyst deodorant comprises, by weight, 5-10 parts of nanometer titanium dioxide, 1-3 parts of anion powder, 1-2 parts of phosphoric acid, 1-5 parts of penetrating agents, 1-5 parts of dispersing agents, 5-10 parts of sodium bicarbonate, 70-90 parts of deionized water, 3-5 parts of aloe gel and 10-15 parts of tea polyphenol. The invention further discloses the preparation method of the photocatalyst deodorant, and through adsorption and degradation of a super catalyst indium phosphate in the night orin a dark condition, requirements on light condition can be reduced.

Owner:广州爱居环保科技有限公司

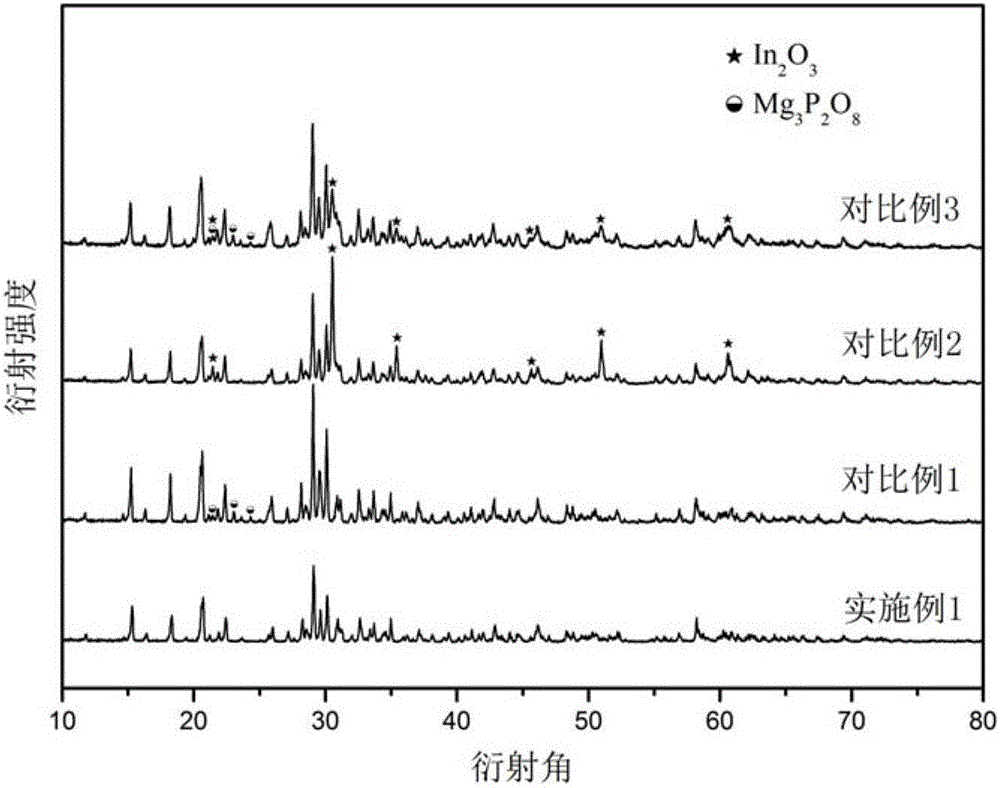

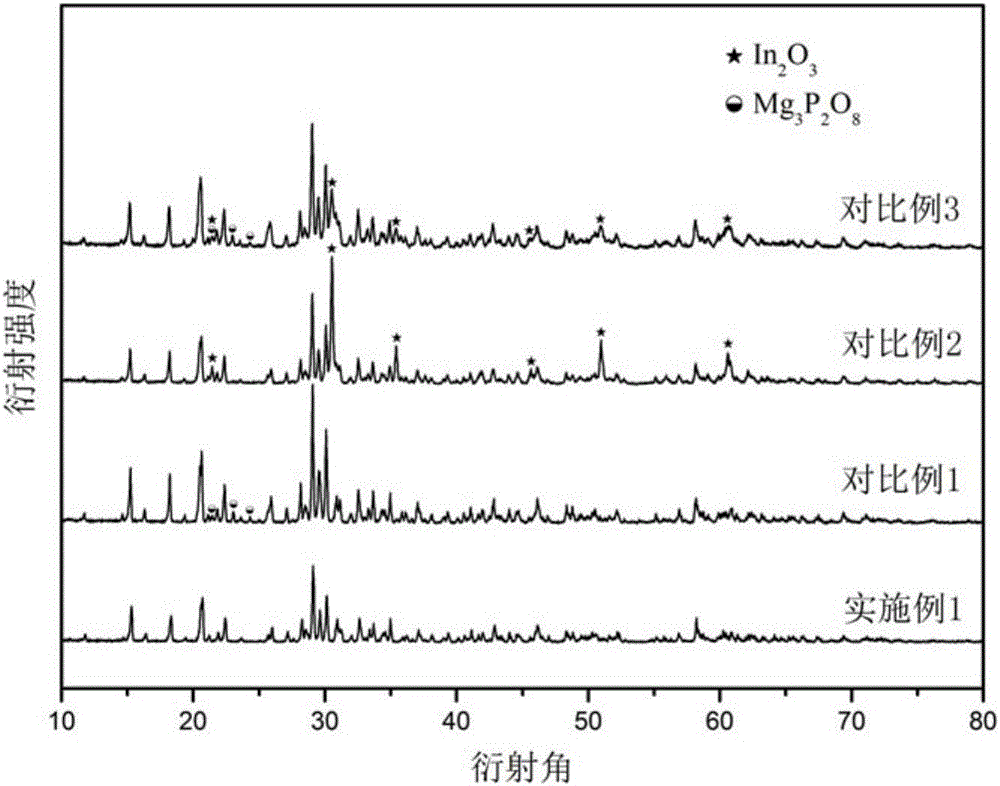

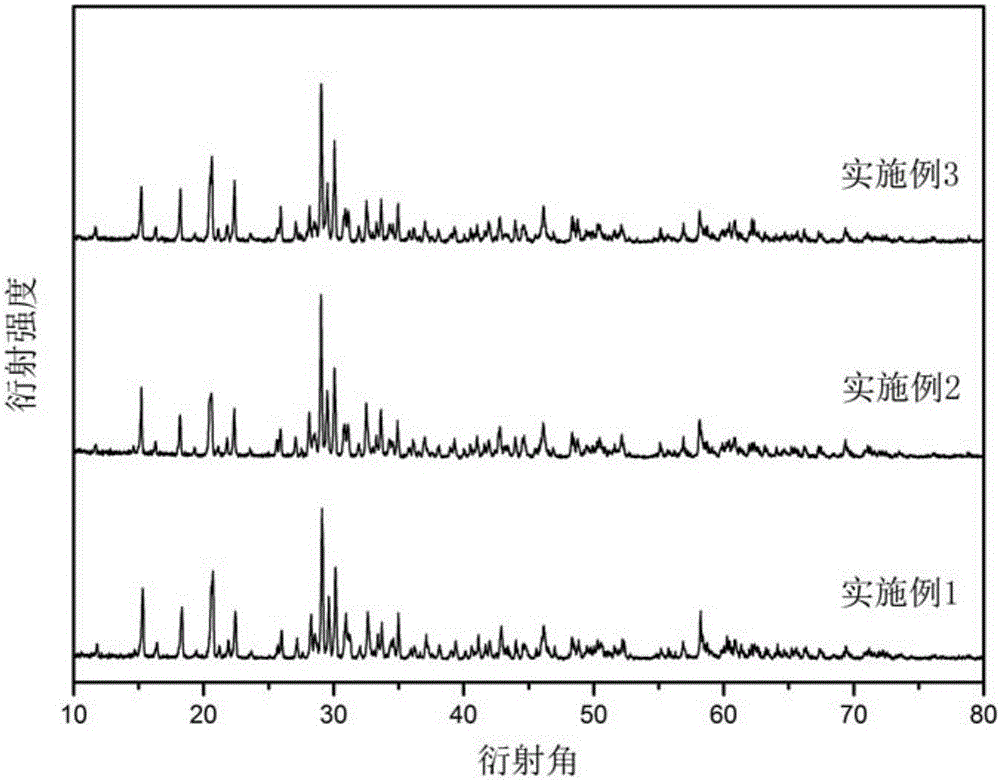

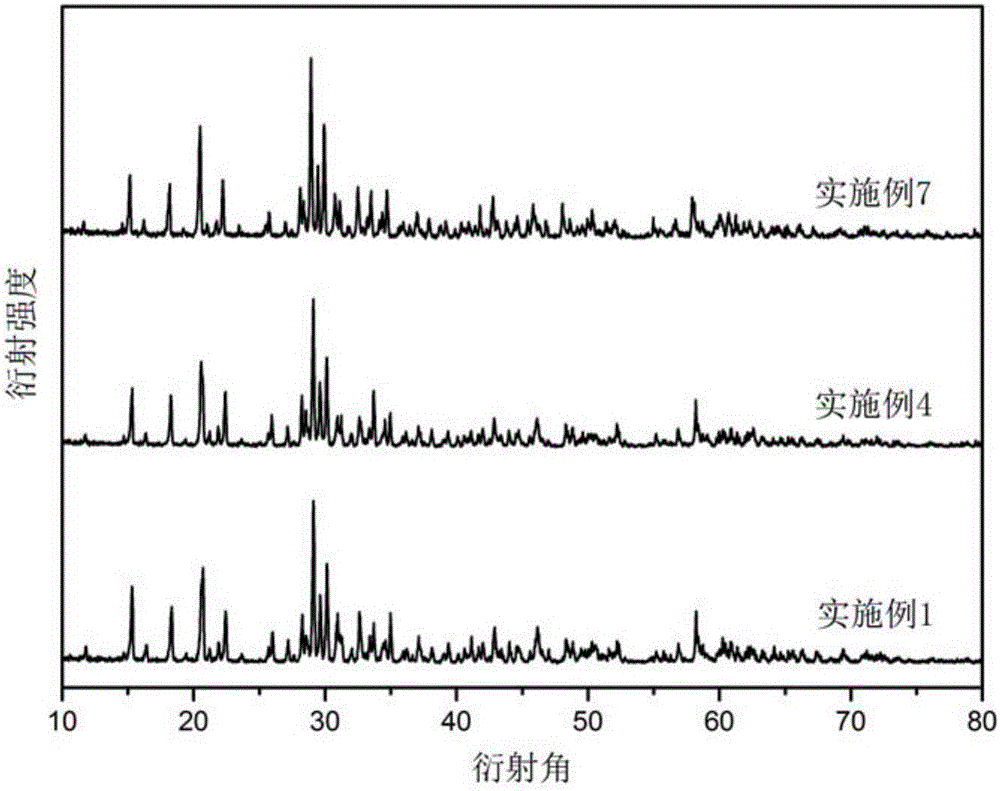

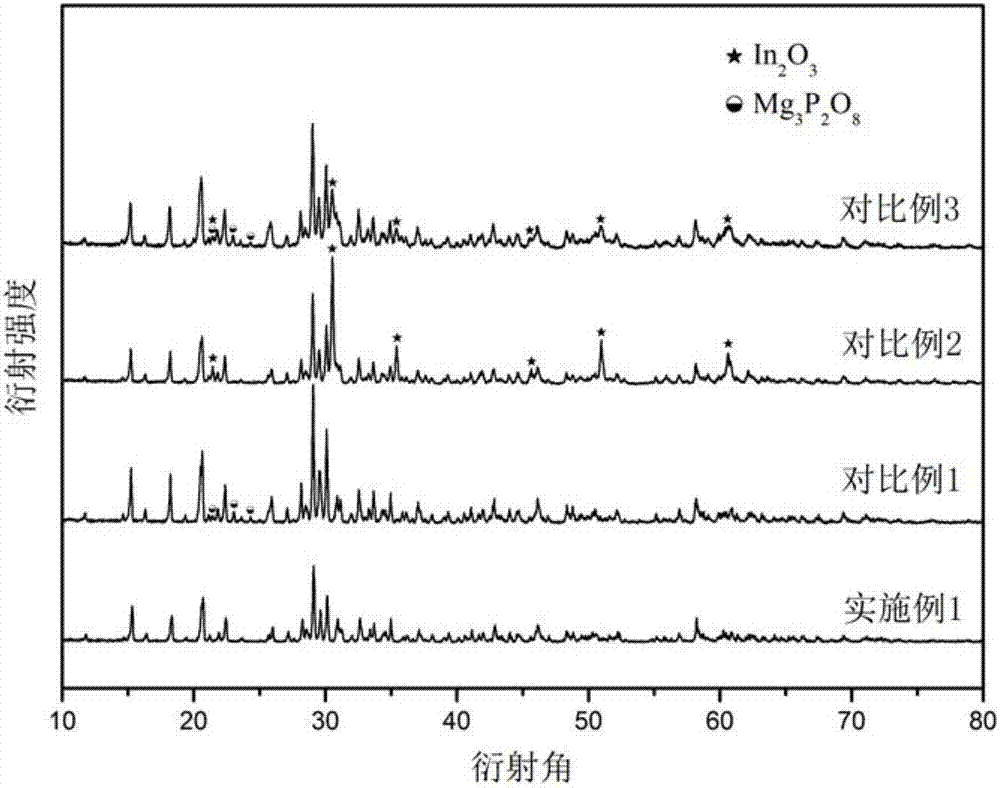

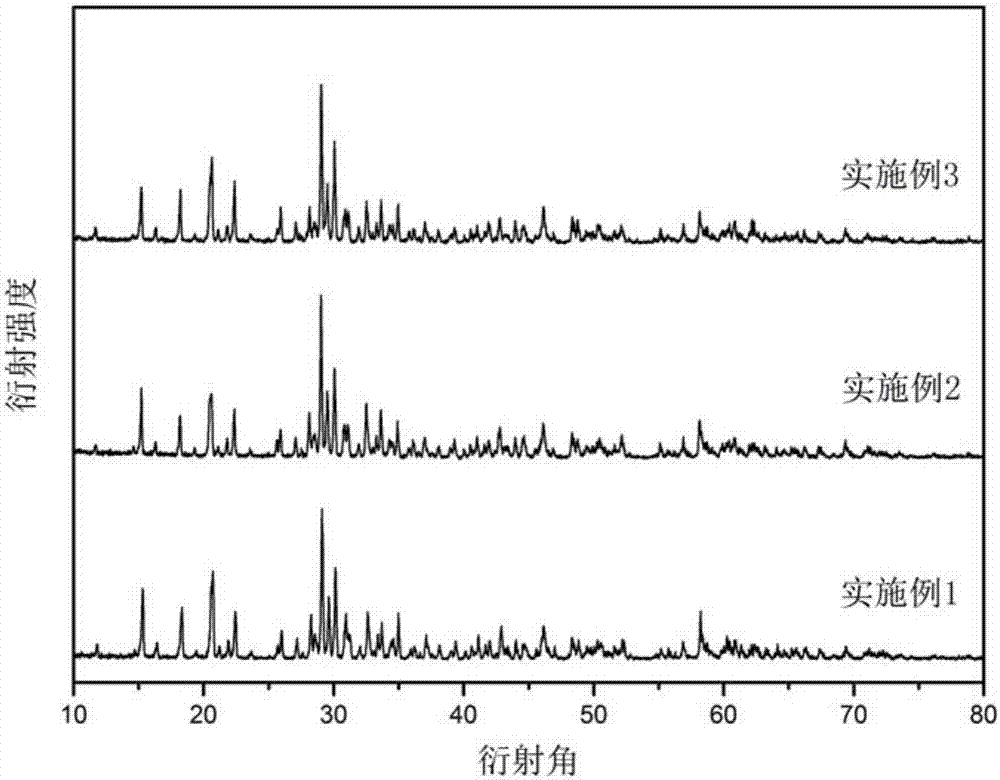

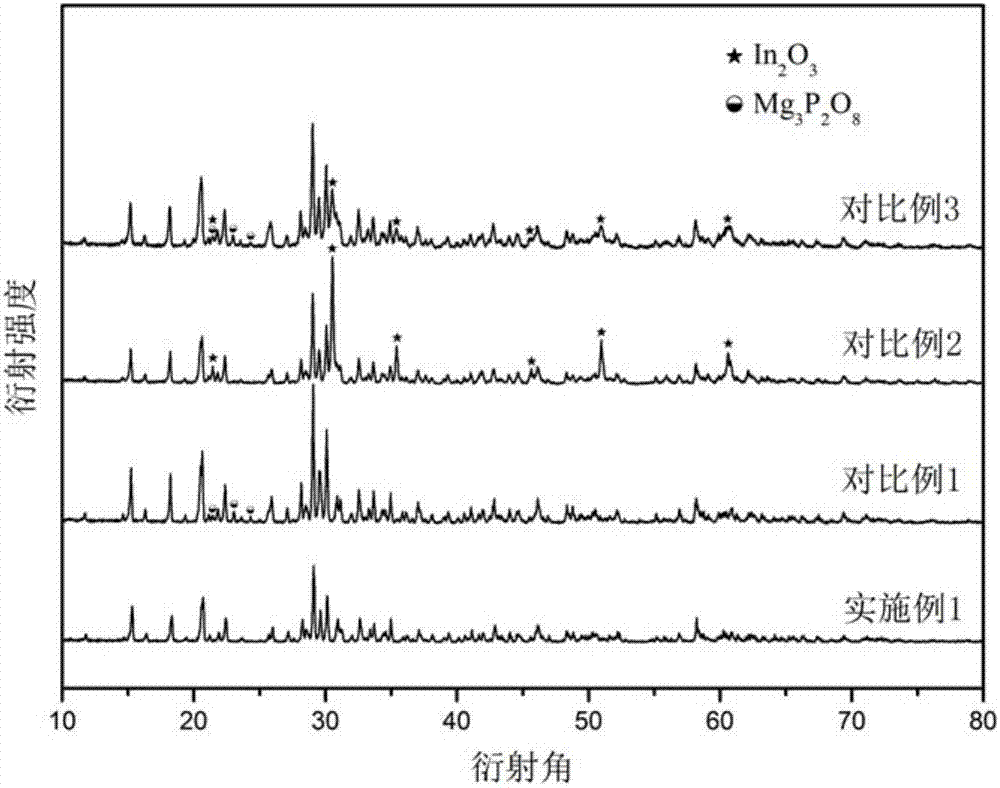

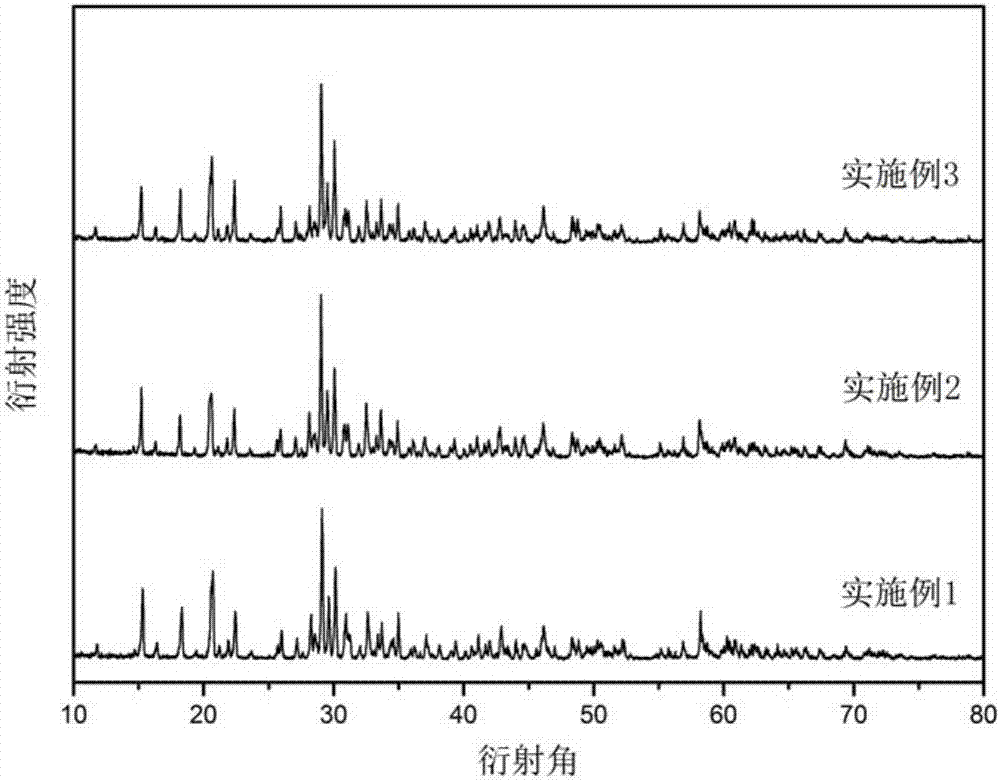

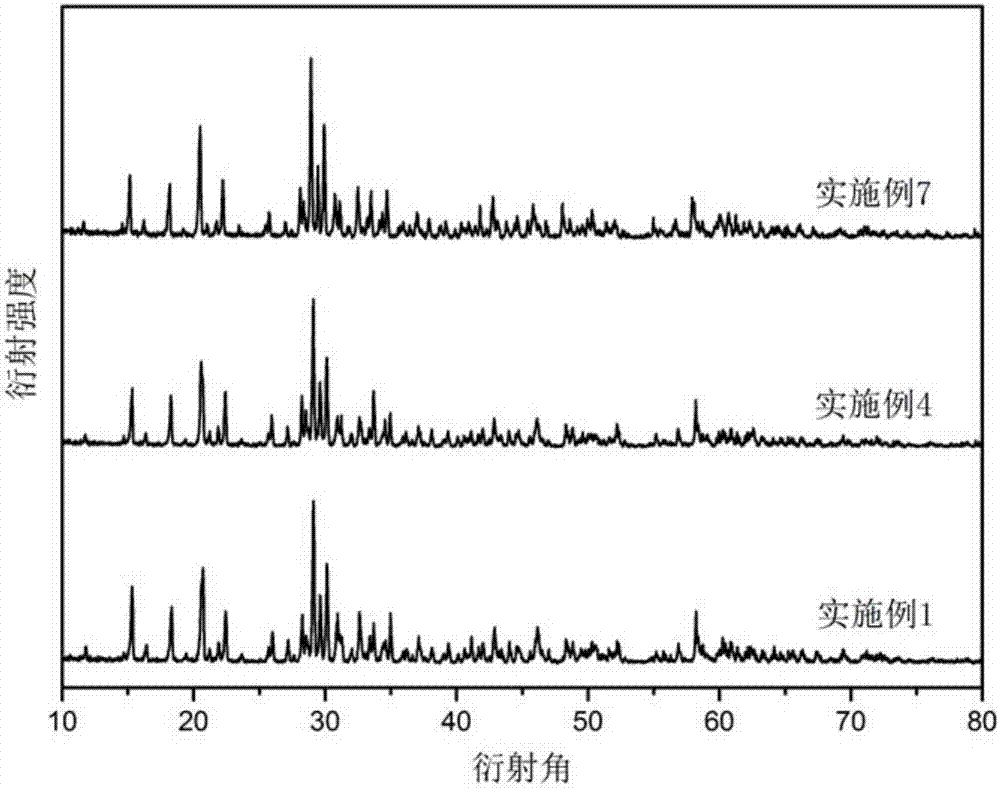

Magnesium and indium phosphate matrix material for rare-earth phosphor and method for preparing magnesium and indium phosphate matrix material

ActiveCN105694880ASimple preparation processLuminescent compositionsRare-earth elementChemical composition

The invention discloses a magnesium and indium phosphate matrix material for rare-earth phosphor and a method for preparing the magnesium and indium phosphate matrix material. Chemical composition of the magnesium and indium phosphate matrix material is Mg21-28In28-34P42-48Oy (the y is equal to 168-199). The method includes preparing the magnesium and indium phosphate matrix material by the aid of wet-chemical and solid-phase sintering processes. The magnesium and indium phosphate matrix material and the method have the advantages that a novel phosphate compound which can be used as a phosphor matrix material is successfully researched and developed and contains indium elements, rare-earth elements which are used as activation centers can partially replace the indium elements to enter matrix crystal lattices, and accordingly the compound prepared by the aid of the method can be used as the matrix material for the phosphor; reports on magnesium and indium phosphate matrix materials are unavailable in the prior art; processes for preparing the magnesium and indium phosphate matrix material are simple, and the like.

Owner:CENT SOUTH UNIV

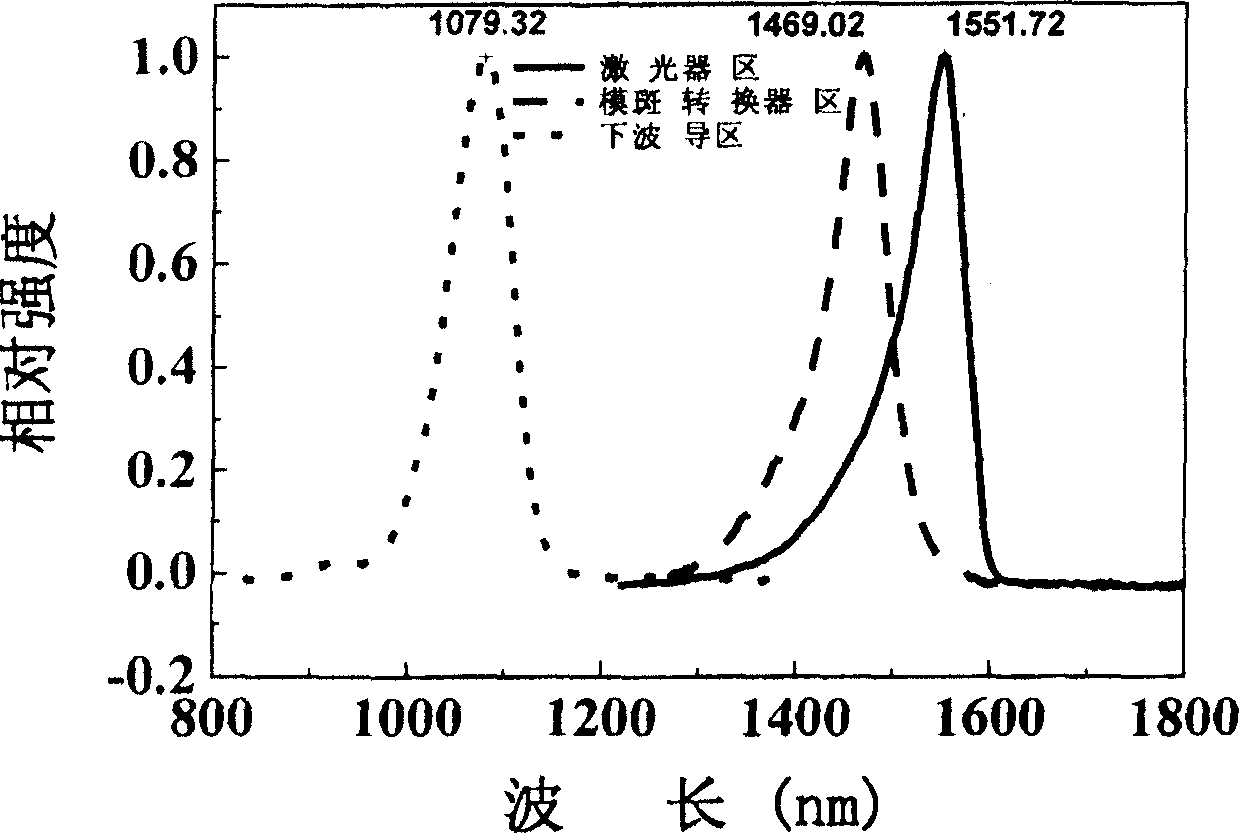

Method for making modular spot converting distributed-feedback Prague laser by using quantum trap confounding

InactiveCN1909310AReduce the number of growthHas an effectOptical wave guidanceLaser detailsGratingPhosphate

The invention relates to a method for using quantum well mixing to produce mode speckle conversion distributed feedback Bragg lasers, which comprises: growing n-type indium phosphate buffer layer on the substrate; using silica dioxide to mask the distributed feedback Bragg lasers, and generating point corrosion on the characteristic indium phosphate pour buffer layer at the mode speckle converter; corroding the silica dioxide protective layer; heating chip, keeping warm and annealing; corroding the protective layer; grating the whole chip; corroding the characteristic indium phosphate pour buffer layer; etching the upper and lower ridge pilot structures on the converter; cleaning the chip; growing p-type indium phosphate layer, indium gallium arsenic phosphate etching stopping layer, p-type indium phosphate package and high-doping p-type indium gallium arsenic ohm electrode contact layer; growing silica dioxide insulated layer on the whose chip; opening electrode window at the laser, and splashing p electrode; extending the substrate; boiling n electrode at the back; slicing the sample into tubular core.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

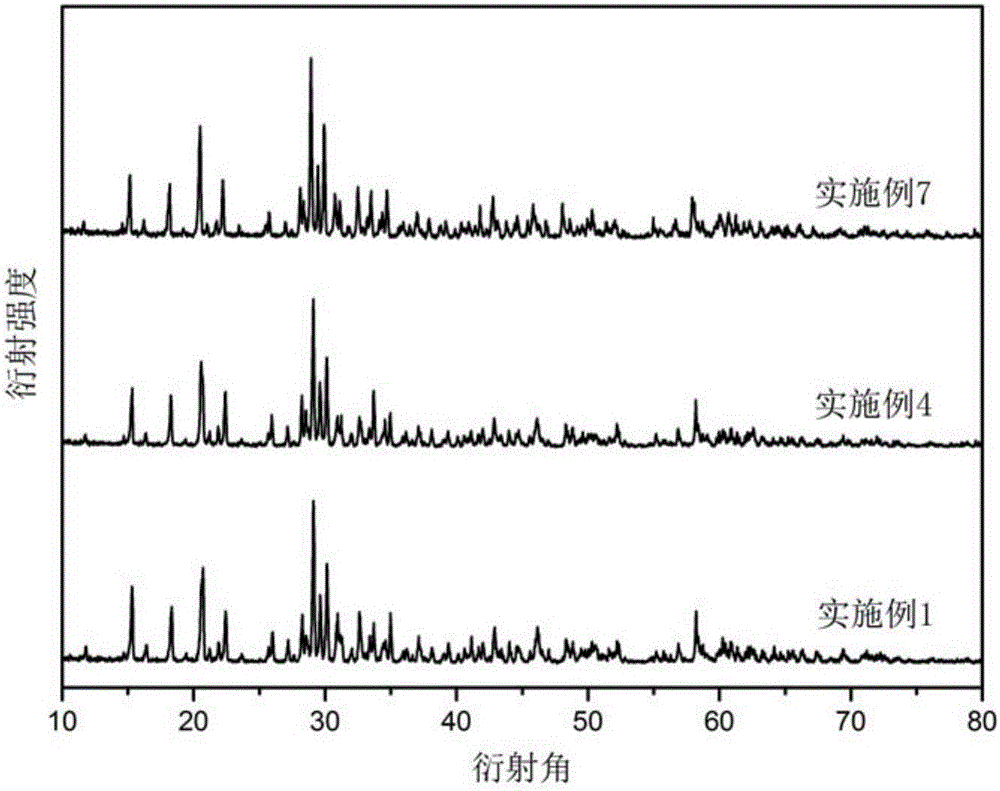

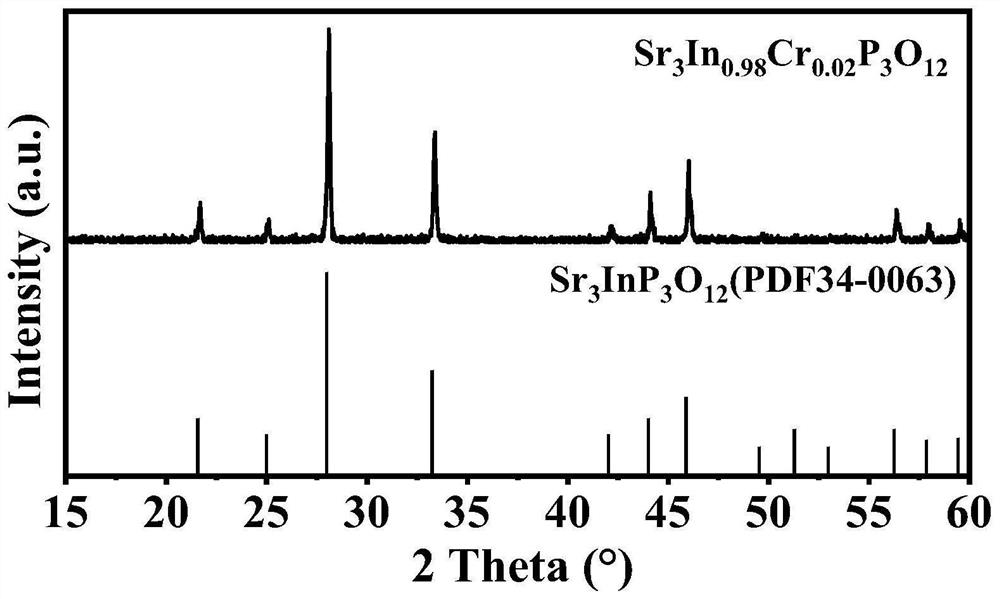

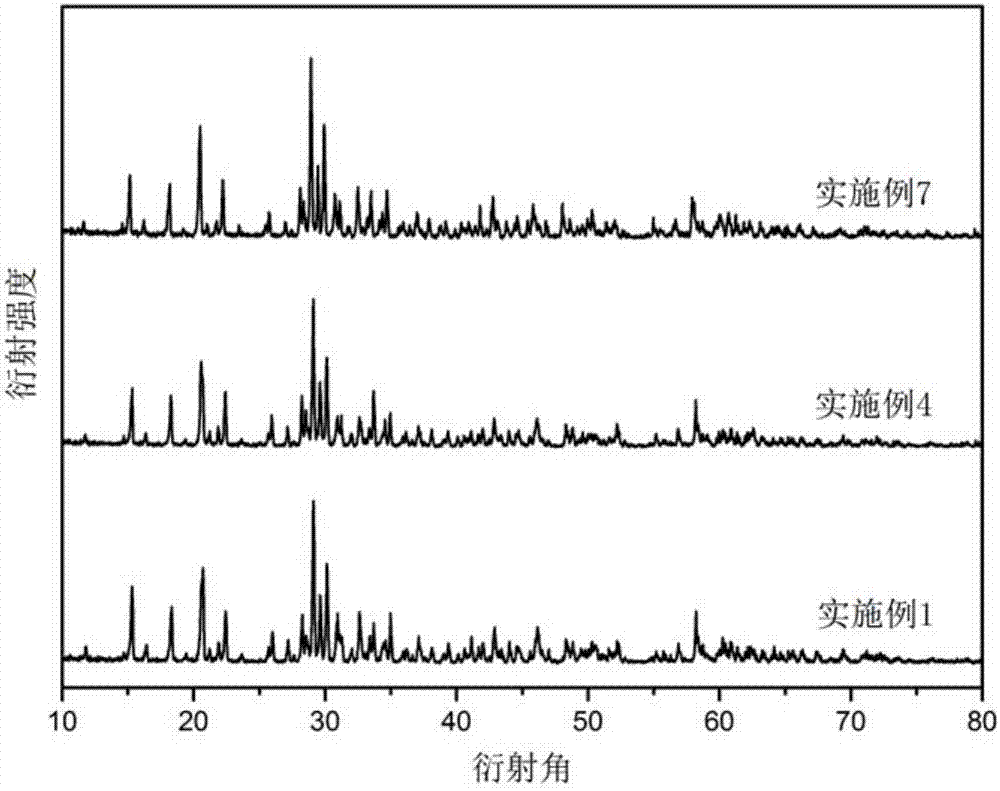

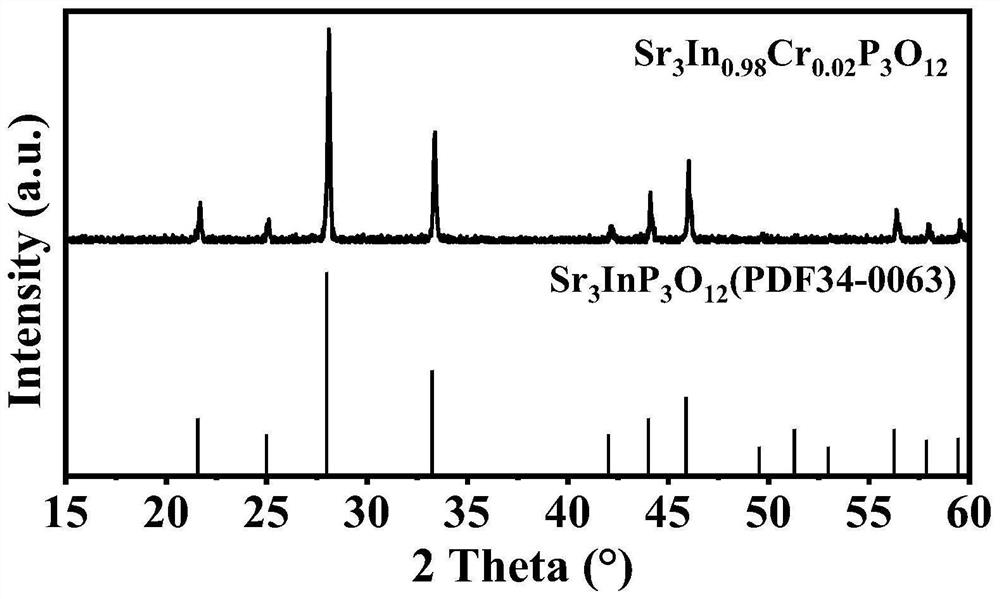

Cr<3+>-doped strontium indium phosphate broadband near-infrared luminescent material and preparation method thereof

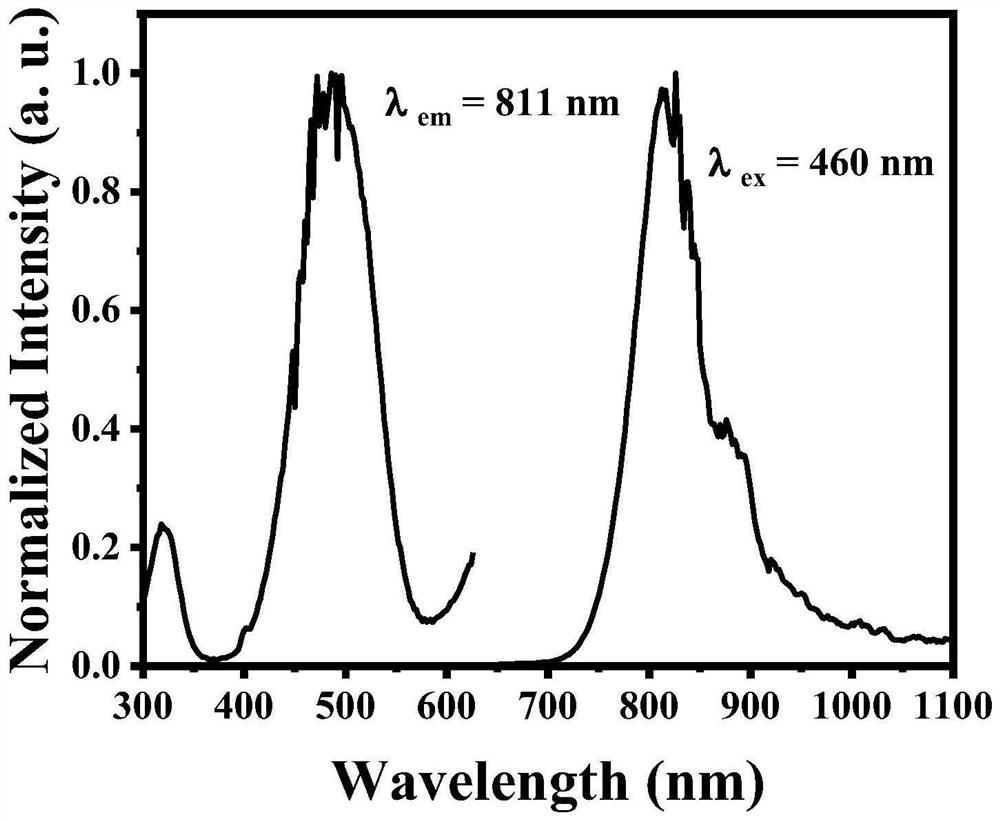

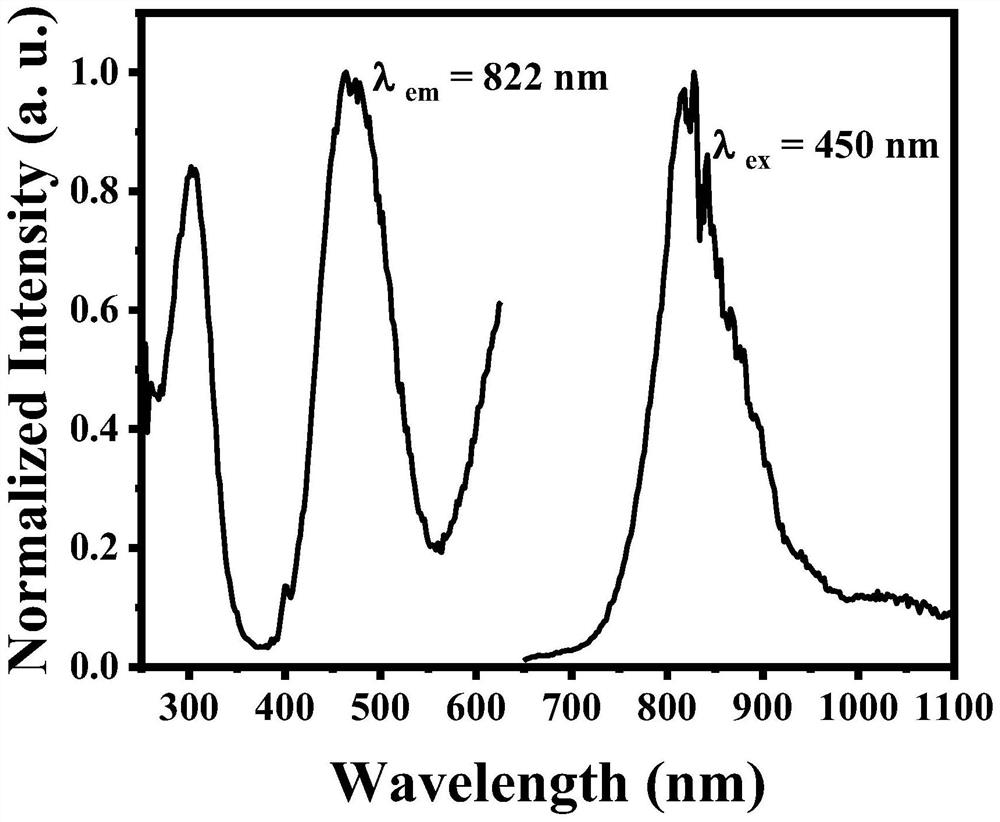

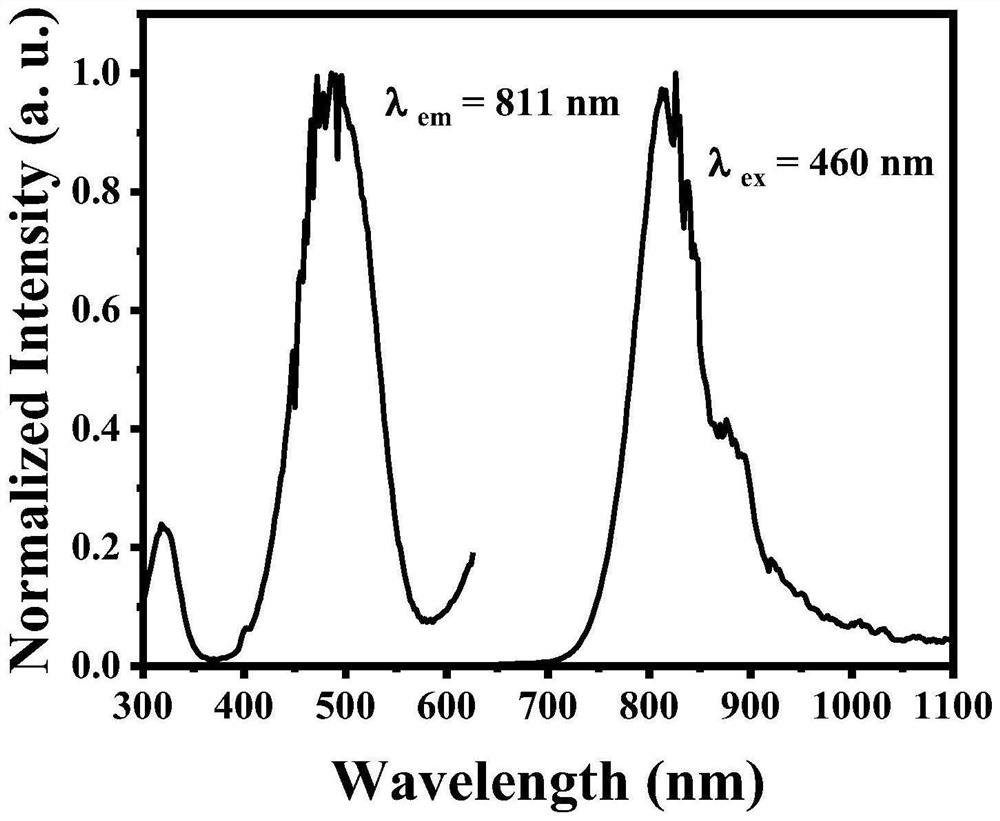

ActiveCN112300797ASimple preparation processEasy to mass produceLuminescent compositionsSemiconductor devicesCrystal systemUltraviolet lights

The invention discloses a Cr<3+>-doped strontium indium phosphate broadband near-infrared luminescent material and a preparation method. The general chemical formula of the luminescent material is Sr3In1-x-yMyP3O12:xCr<3+>, M is one or more of Sc and Lu elements, x is greater than or equal to 0.001 and less than or equal to 0.11, and y is greater than or equal to 0 and less than or equal to 1. Thenear-infrared luminescent material belongs to a cubic crystal system, has a crystal structure of the same type as Sr3InP3O12, and has a space group of I-43d. The material is wide in excitation spectrum, the excitation wavelength is within the range of 250-600 nm, the material can be excited by ultraviolet light and visible light, and the emission wavelength range of the material is 700-1100 nm. The broadband near-infrared luminescent material can be matched with a blue light or ultraviolet light LED chip for use in manufacturing of a broadband near-infrared light source, and has important application value in the fields of food nondestructive quality analysis, human physiological status non-invasive detection and the like. The preparation process is simple, raw materials are low in price,and industrial production is easy.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of nano indium phosphate photocatalyst

InactiveCN107308966AImprove dispersionImprove stabilityPhysical/chemical process catalystsWater/sewage treatment by irradiationDistilled waterIndium(III) chloride

The invention discloses a preparation method of a nano indium phosphate photocatalyst. The preparation method comprises the following steps: dropwise adding an ammonium phosphate solution into an indium chloride solution during stirring at a rotating speed of 200 to 400 r / s, then continuously stirring the solutions at the same rotating speed for 55 to 65 minutes after dropwise adding is completed, thus forming colloid, centrifugally separating the colloid, washing the colloid with distilled water for 3 to 5 times, and drying, thus obtaining the nano indium phosphate photocatalyst. The catalyst is high in dispersivity, high in stability and excellent in photocatalysis performance; the visible photocatalysis efficiency is substantially improved when compared with that of a conventional catalyst such as TiO2.

Owner:柳州若思纳米材料科技有限公司

Preparation method of halloysite loaded indium phosphate catalyst

InactiveCN107308964AImprove surface roughnessIncrease roughnessPhysical/chemical process catalystsWater/sewage treatment by irradiationHalloysiteNanoparticle

The invention discloses a preparation method of a halloysite loaded indium phosphate catalyst. The preparation method comprises the following steps: acidizing halloysite, dissolving an aluminum oxide structure of halloysite to be favorable for loading; adding the processed halloysite into an indium chloride solution, adding an ammonium phosphate solution dropwise so as to cover a colloid on the surface of the halloysite, finally centrifuging, separating, washing and drying to obtain the halloysite loaded indium phosphate catalyst. The adsorption action between the uneven surface of the halloysite and an indium phosphate colloid particle is utilized, an indium phosphate nanoparticle is loaded on the surface of the halloysite, and the fixing of the catalyst is promoted.

Owner:柳州若思纳米材料科技有限公司

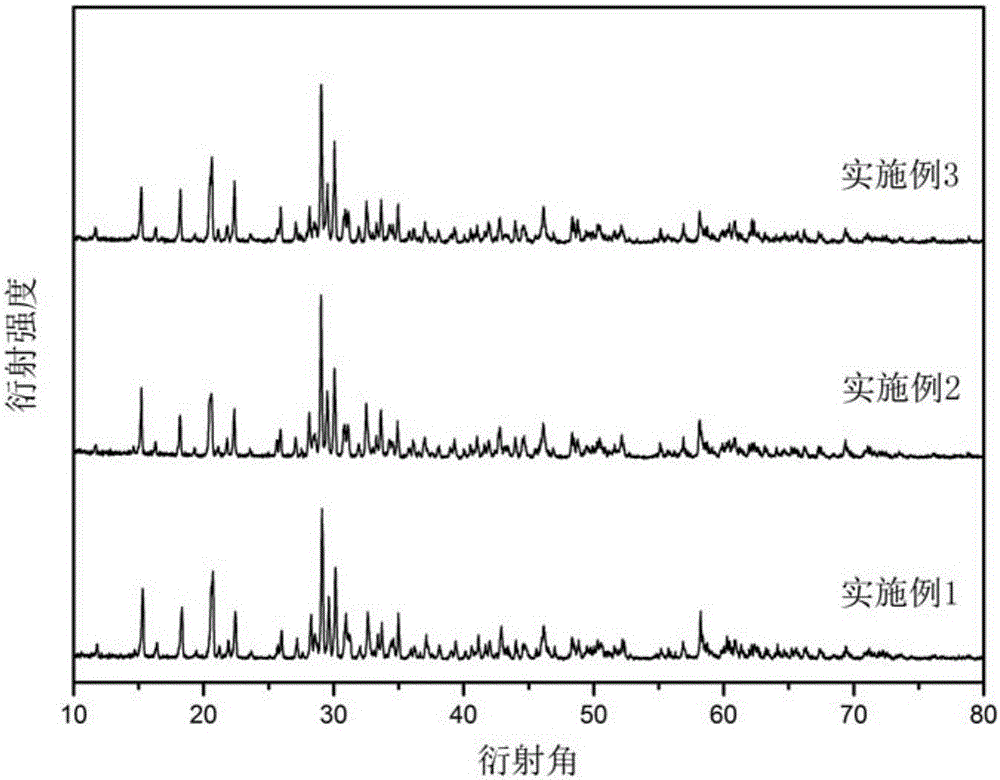

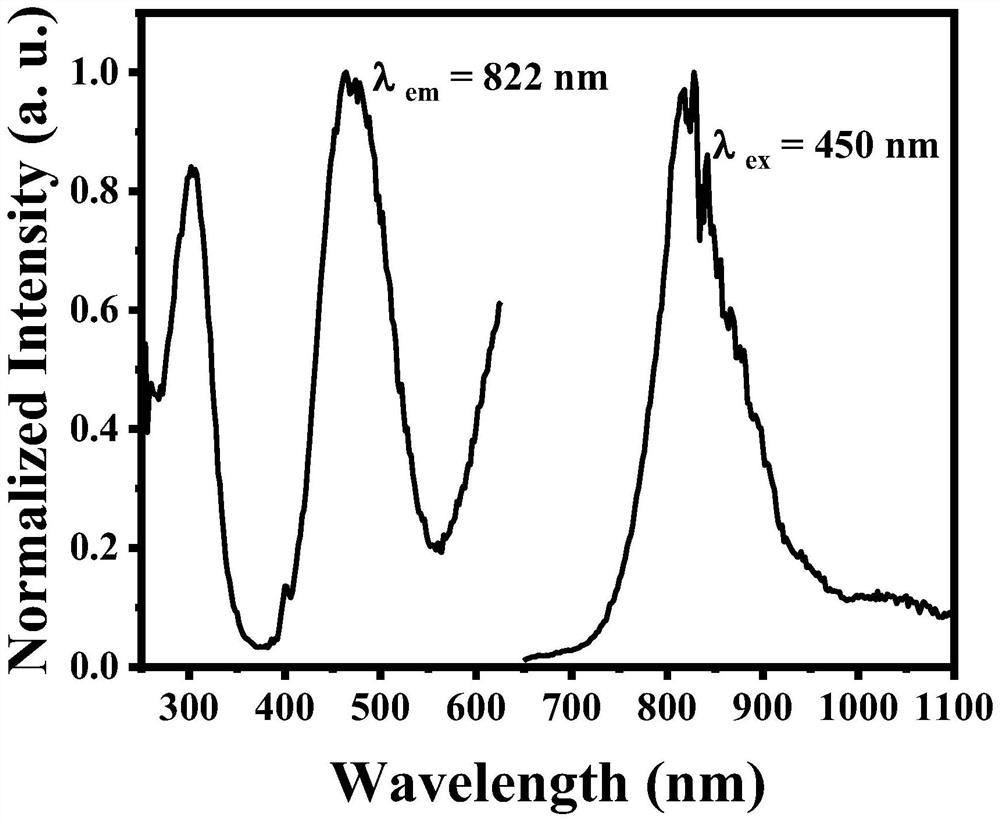

Magnesium-indium phosphate red and green fluorescent powder and preparation method thereof

ActiveCN105860973AImprove transmittanceHigh luminous intensityLuminescent compositionsRare-earth elementPhosphate

The invention provides magnesium-indium phosphate red and green fluorescent powder and a preparation method thereof. The chemical formula of the magnesium-indium phosphate red and green fluorescent powder is Mg21-28(In1-xLnx)28-34P42-48Oy (x=0.02-0.11, y=168-199), wherein Ln is rare earth ion Eu or Tb. In the fluorescent powder, a novel phosphate compound Mg21-28In28-34P42-48Oy (y=168-199) is used as a substrate, different rare earth elements are added into the substrate, and therefore the fluorescent material having strong emission in different spectral regions under ultraviolet excitation can be obtained. The preparation method is a wet-chemical-solid phase sintering method. The fluorescent powder has good optical performance and can well meet the requirements of a three-band-color fluorescent lamp.

Owner:CENT SOUTH UNIV

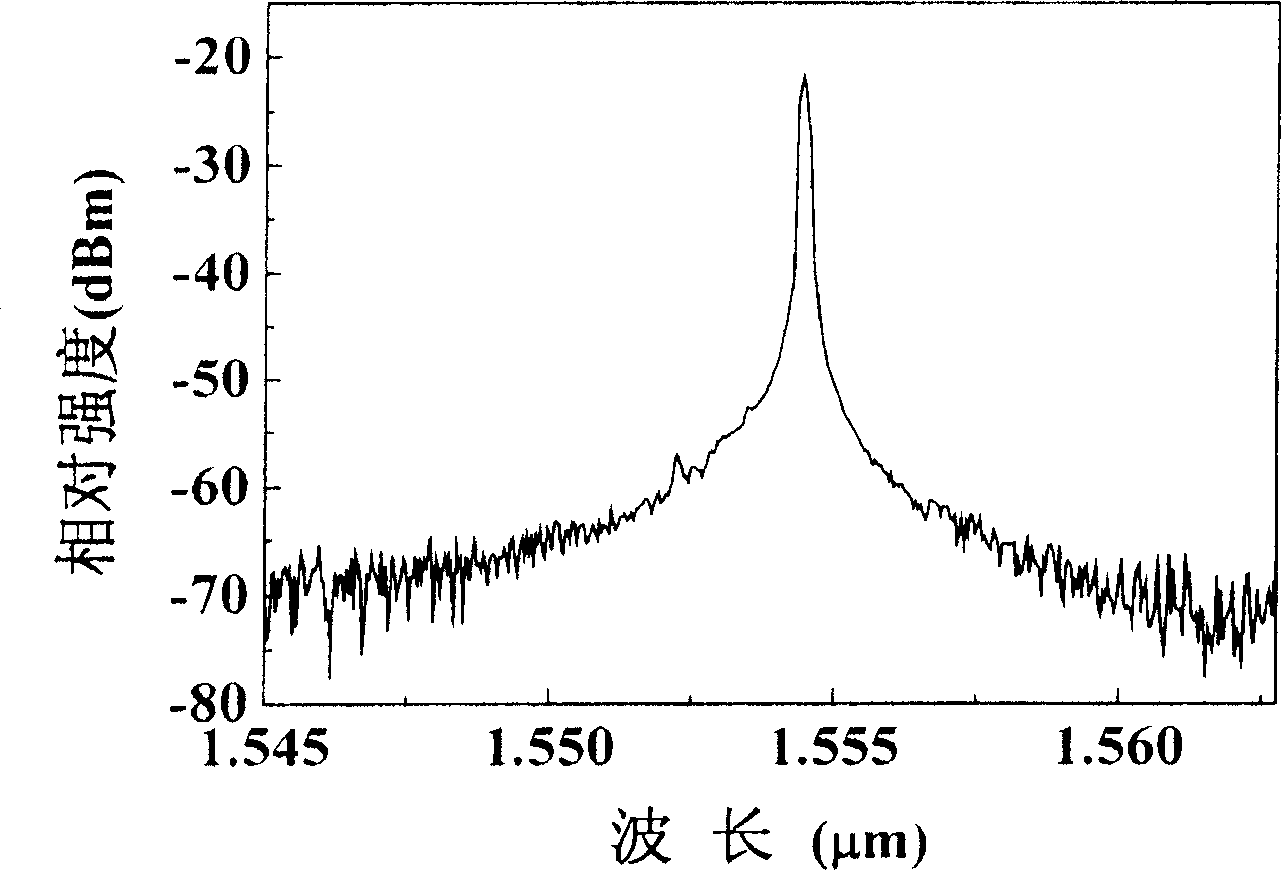

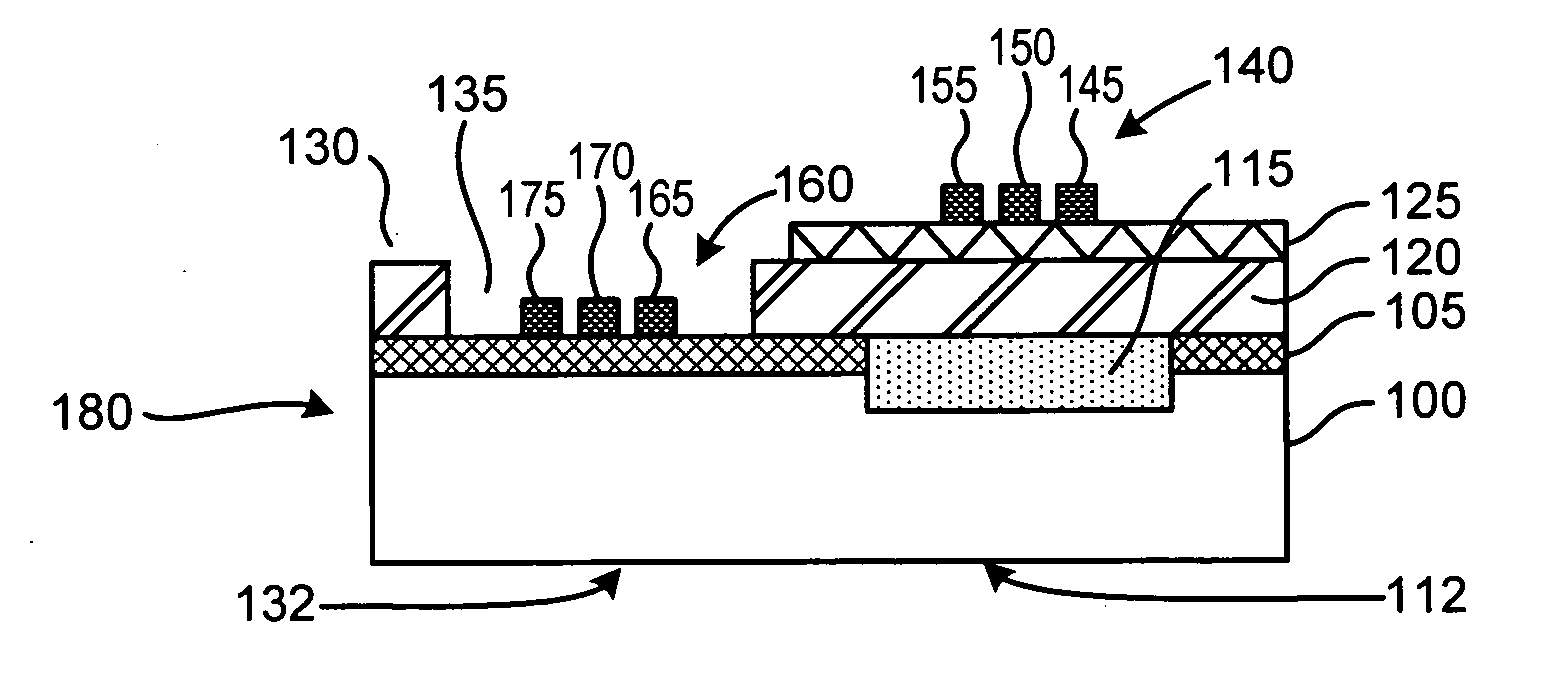

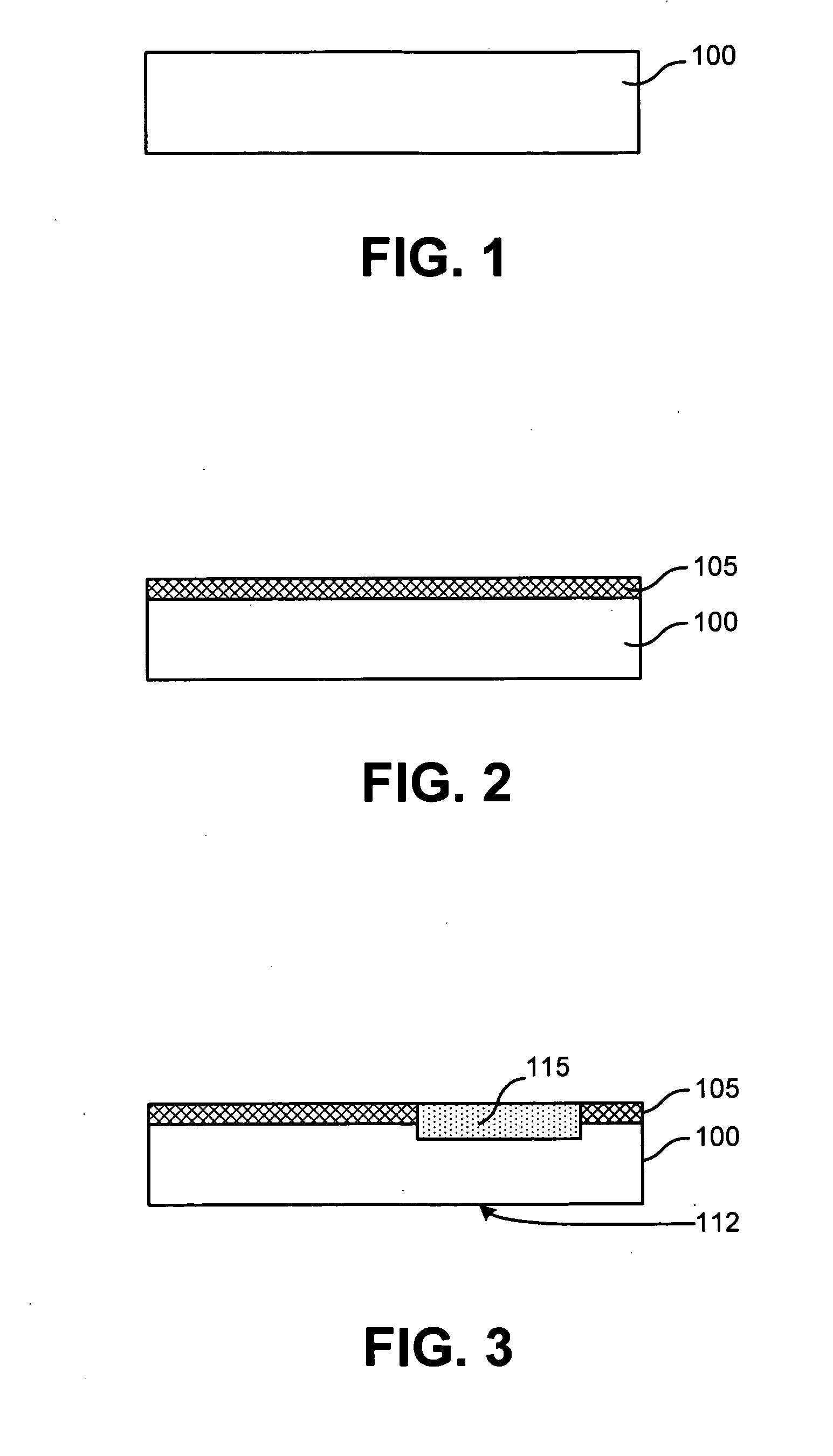

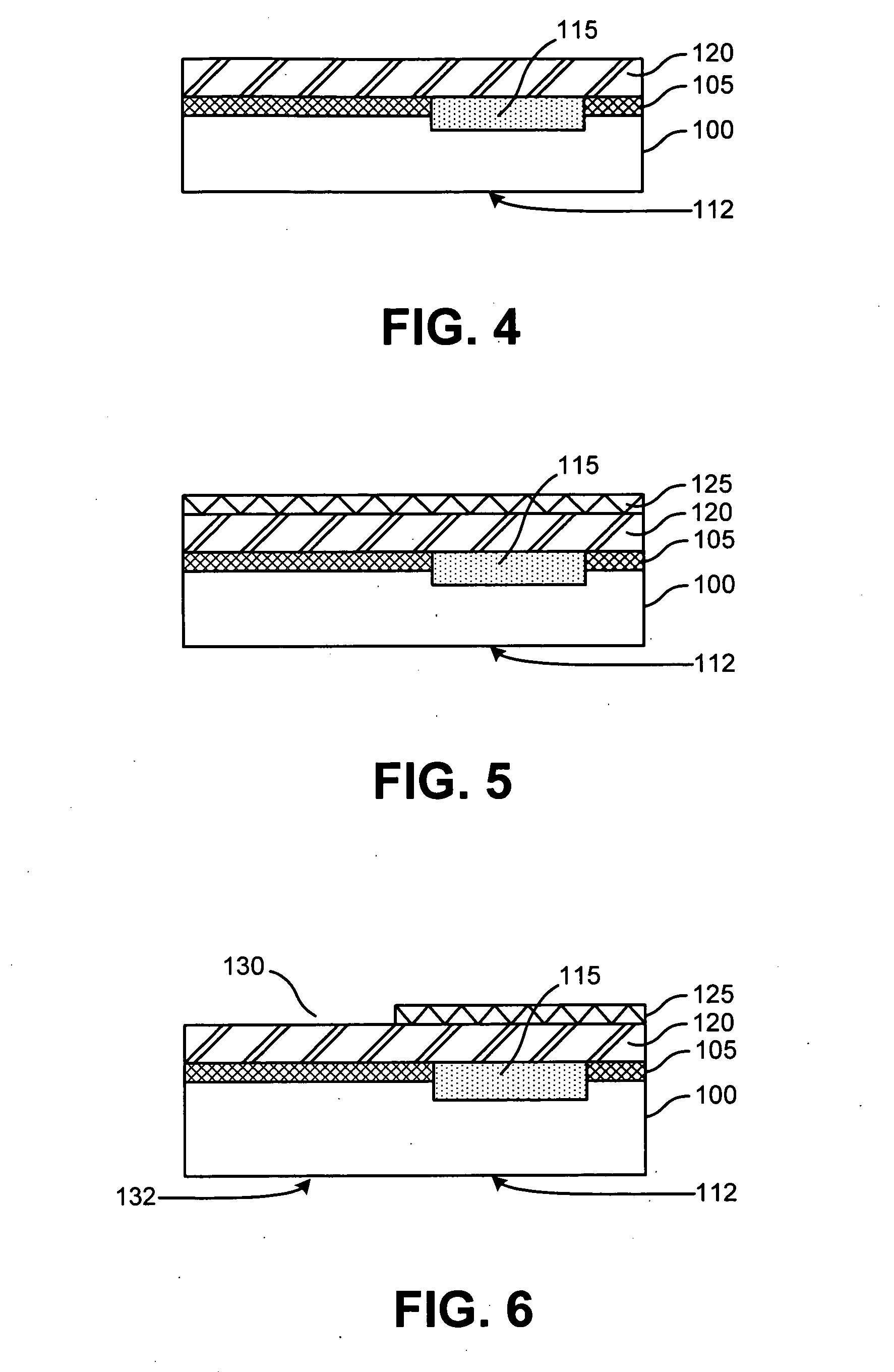

Heterogeneous integration of low noise amplifiers with power amplifiers or switches

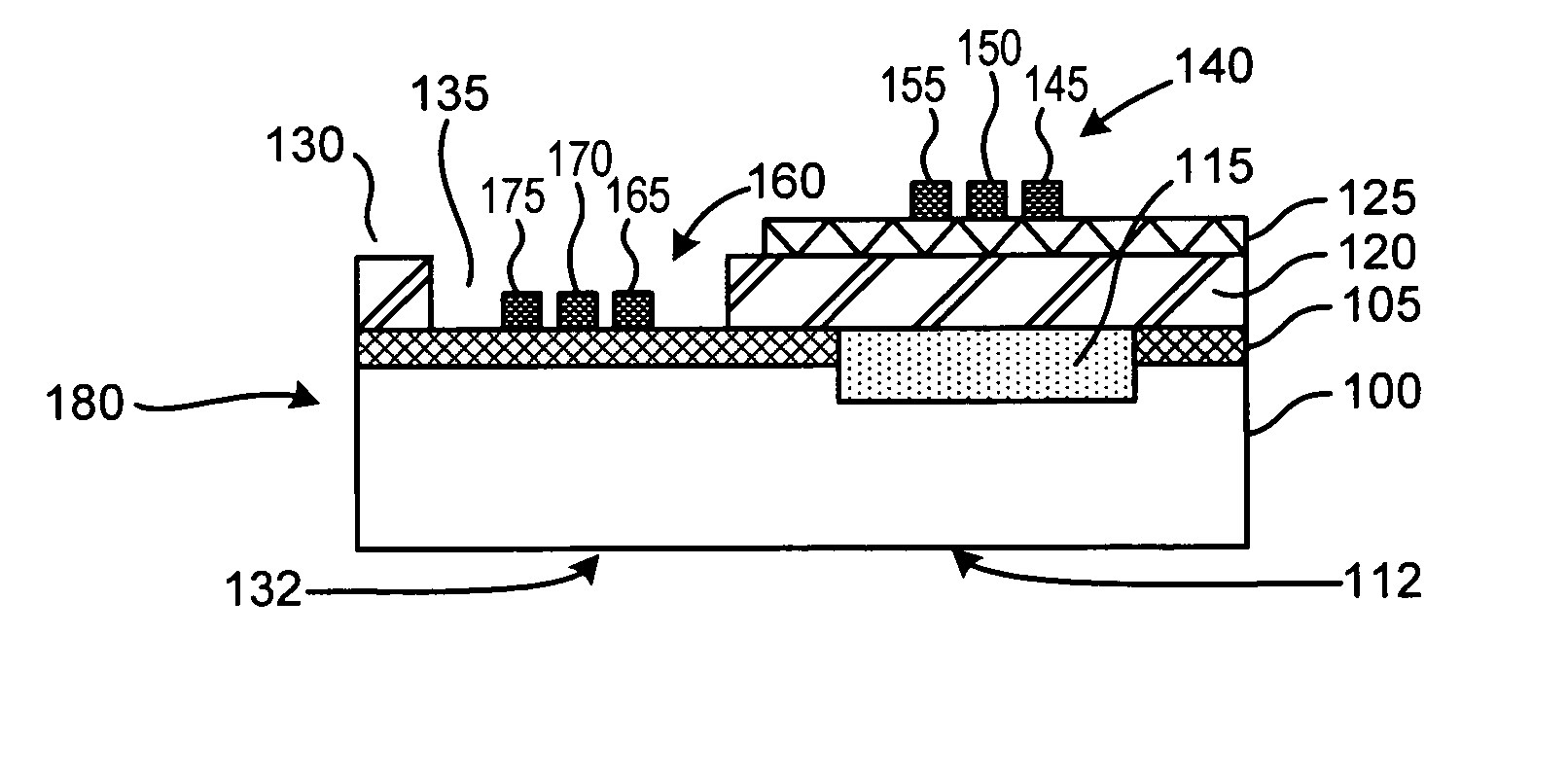

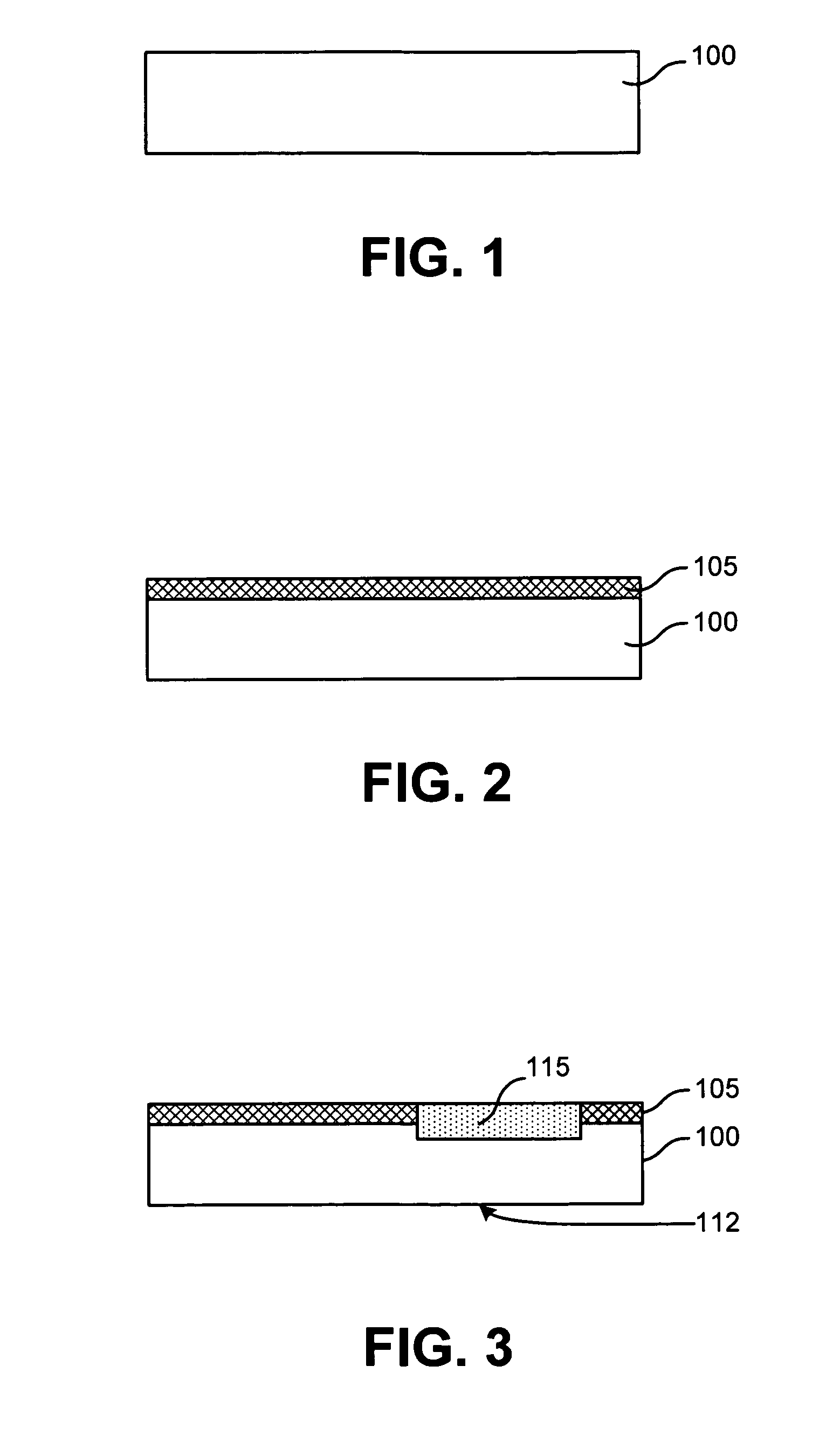

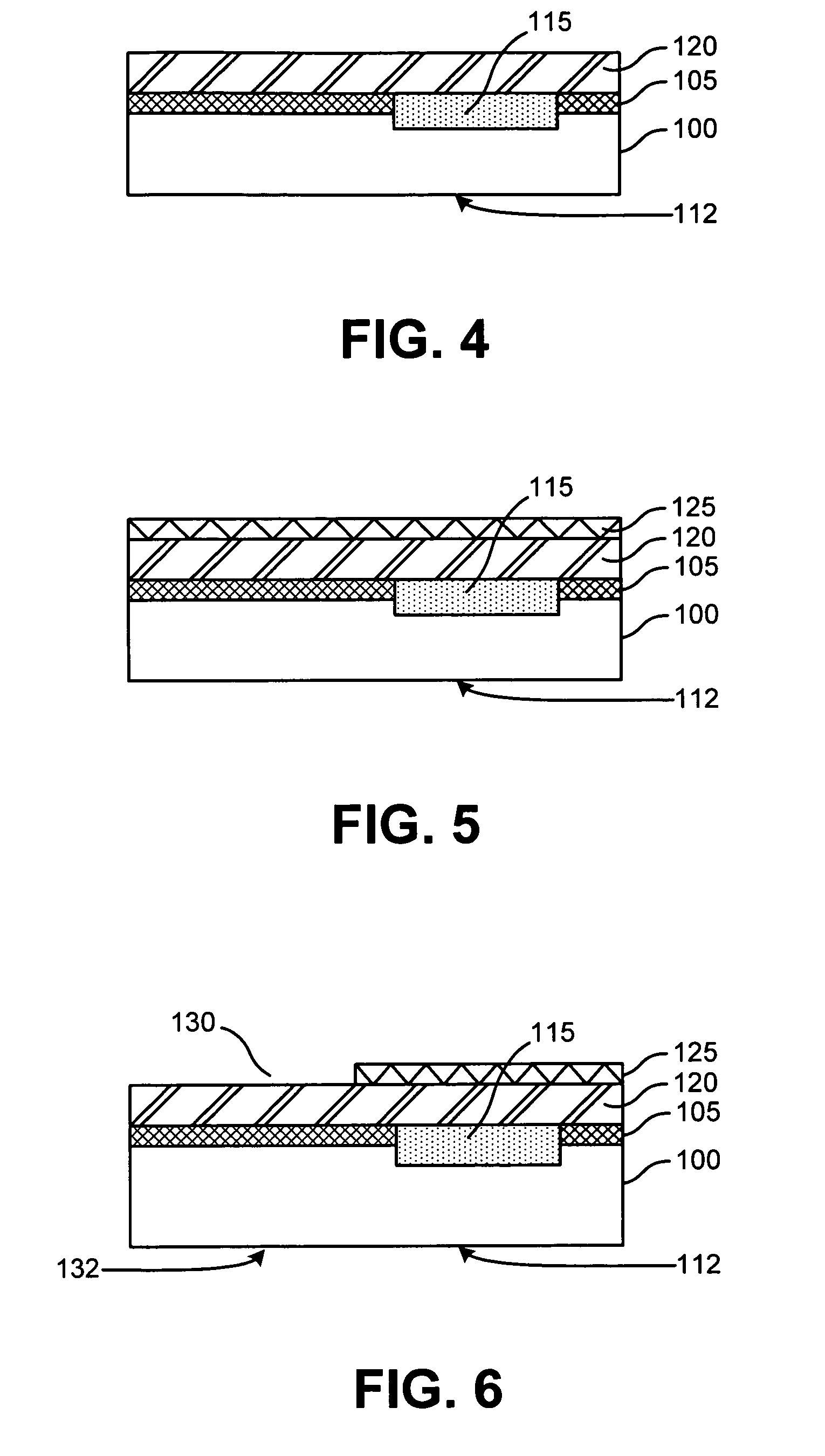

InactiveUS20080067559A1High electron mobilityTransistorSolid-state devicesLow noiseGallium antimonide

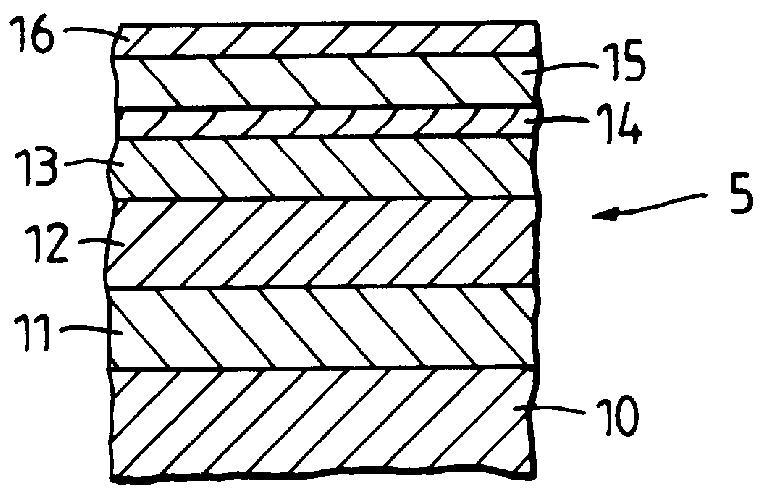

A transistor heterogeneously integrating a power amplifier or switch with a low-noise amplifier having a substrate wafer selected from a group consisting of Gallium Arsenide (GaAs), Indium Phosphate (InP) and Gallium Antimonide (GaSb), the substrate wafer having a first end and a second end, a conducting layer above the first end of the substrate wafer, an isolation implant providing lateral isolation in the conducting layer, a first active layer deposited above the conducting layer and configured for the low-noise amplifier, and a buffer layer deposited above the conducting layer and configured for the low-noise amplifier.

Owner:TELEDYNE SCI & IMAGING

Heterogeneous integration of low noise amplifiers with power amplifiers or switches

InactiveUS7808016B2Solid-state devicesSemiconductor/solid-state device manufacturingLow noiseGallium antimonide

Owner:TELEDYNE SCI & IMAGING

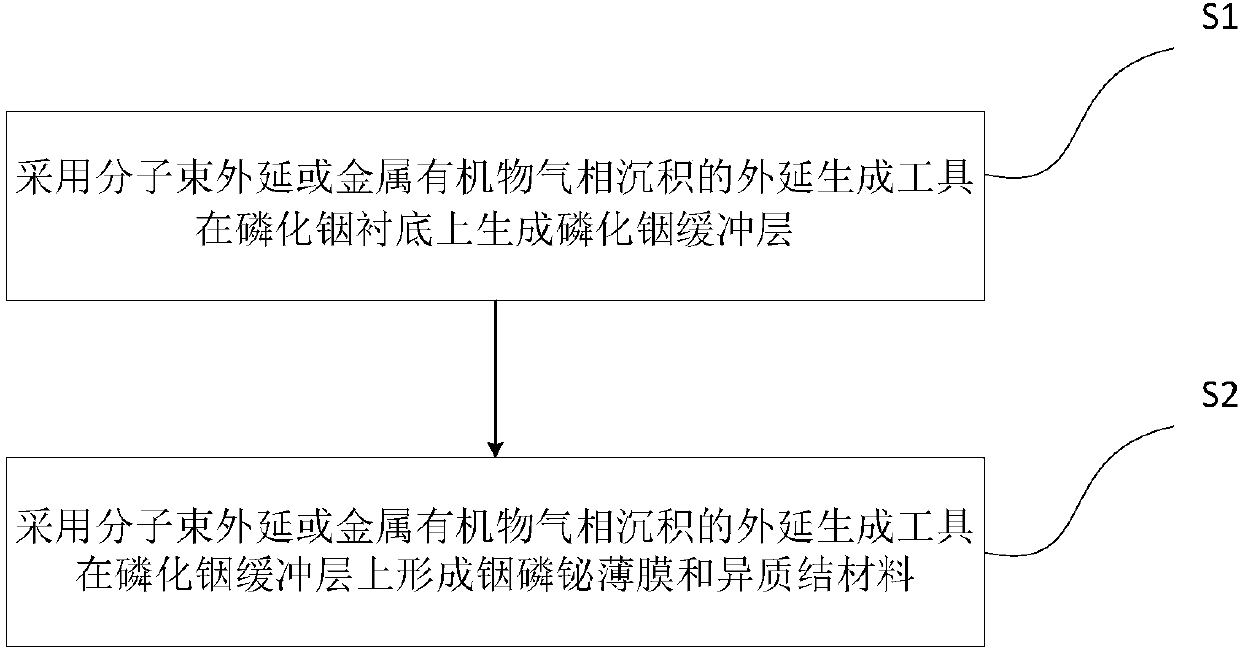

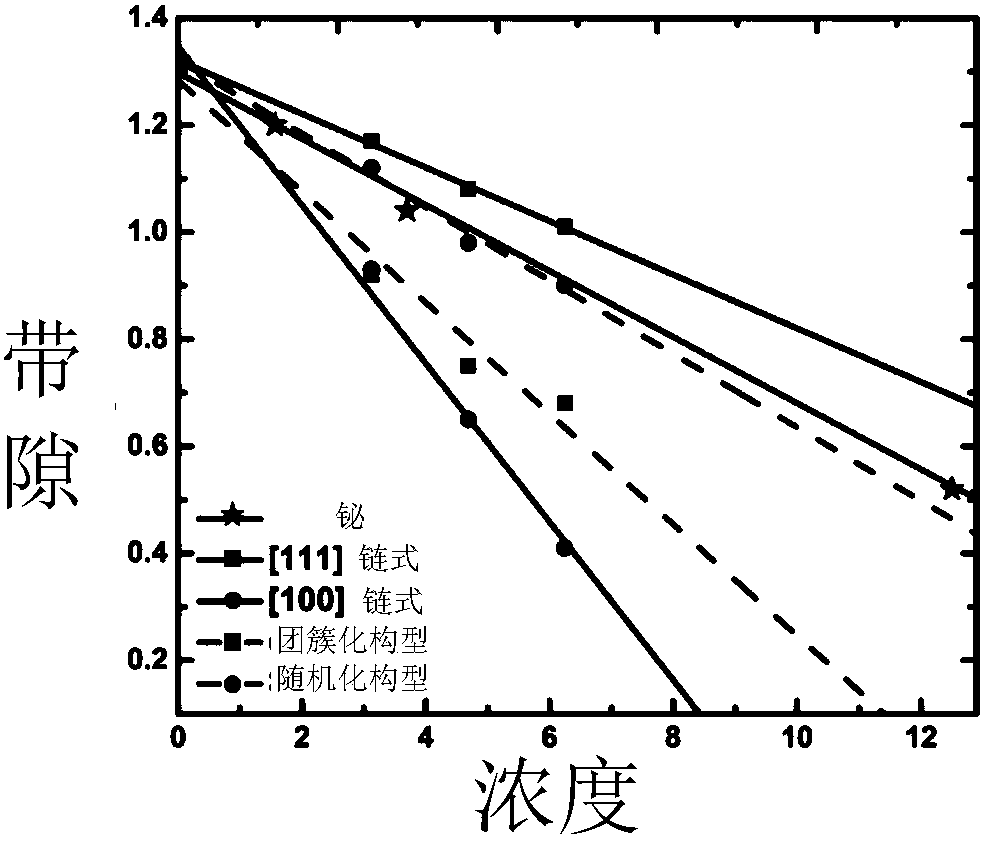

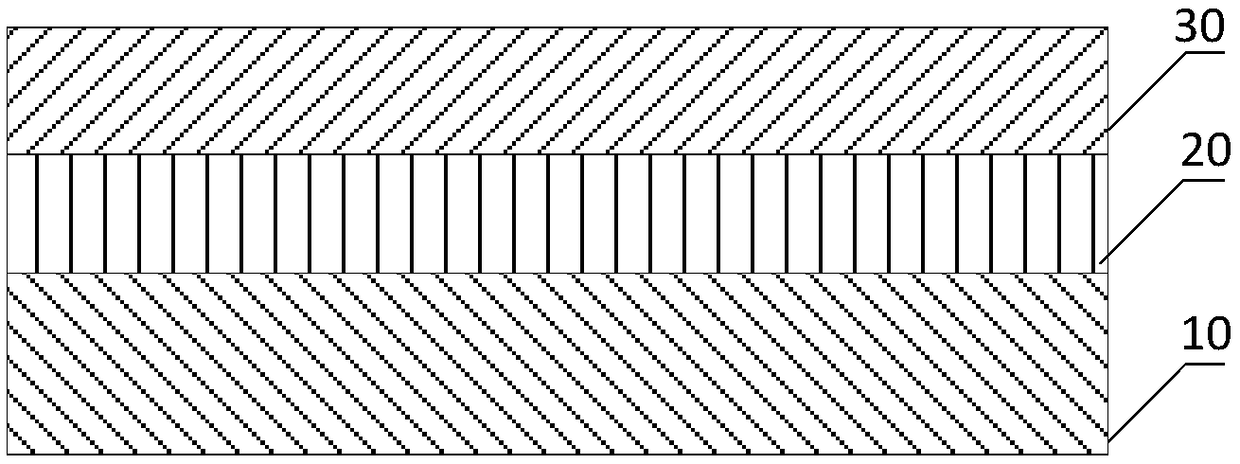

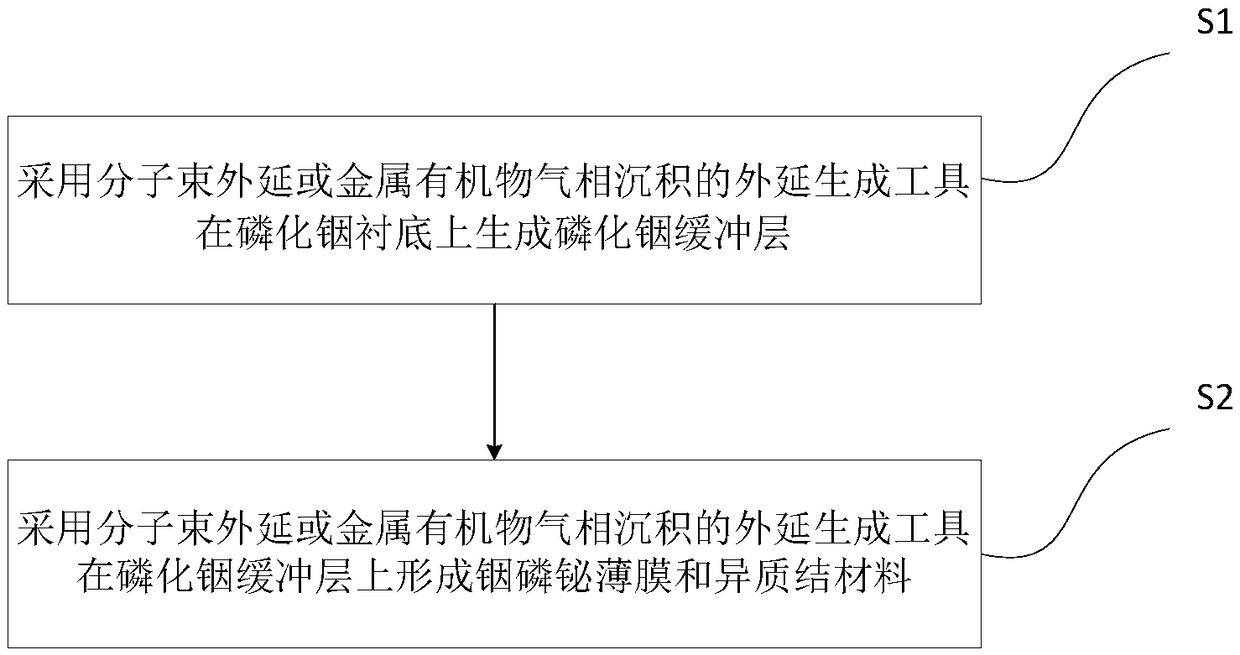

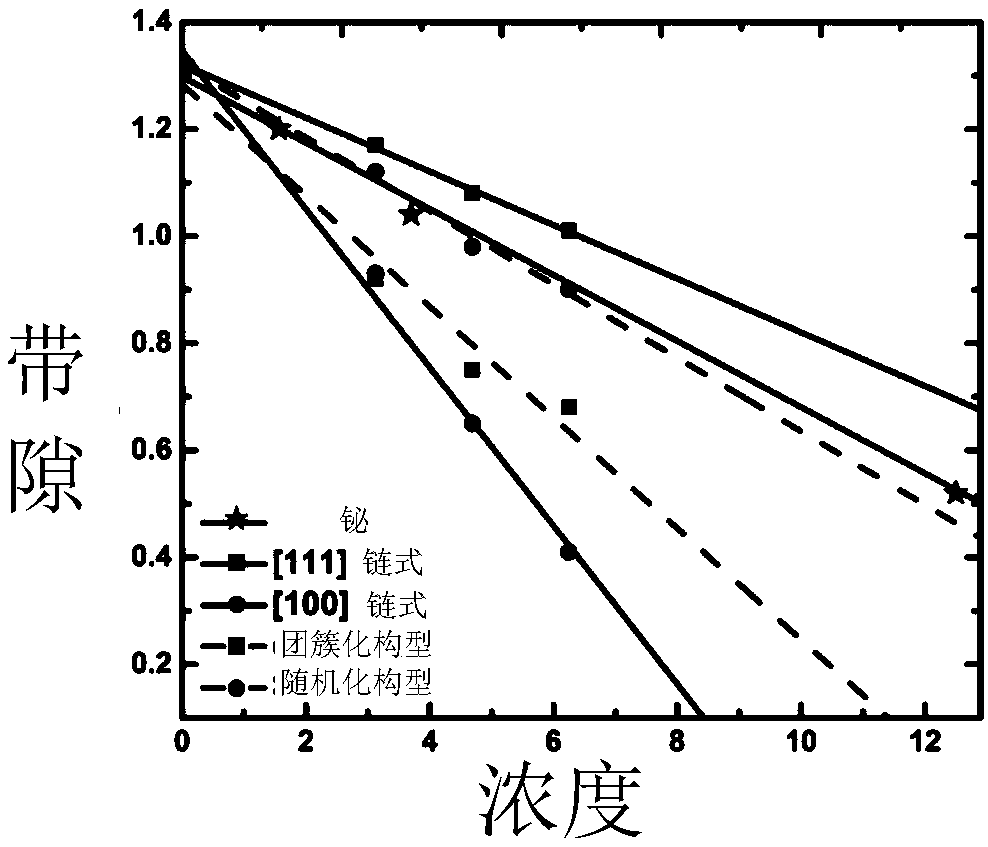

Indium phosphate bismuth material and preparation method thereof, laser using indium phosphate bismuth material and production method of laser

ActiveCN107565383ANarrow bandgapGood semiconductor performanceLaser active region structureBismuth IndiumLaser

The invention relates to the field of materials science, in particular to an indium phosphide bismuth material and a preparation method thereof, and a laser using the material and a preparation method thereof. The indium phosphide bismuth material comprises: an indium phosphide substrate; an indium phosphide buffer layer, disposed on the indium phosphide substrate; and an indium phosphide bismuth body disposed on the indium phosphide buffer layer; the chemical formula of the indium phosphide bismuth body is InP1-xBix, wherein x is the concentration of bismuth atoms percentage, and 0

Owner:CHAOJING TECH BEIJING CO LTD

A kind of indium phosphobismuth material and its preparation method, laser using the material and its preparation method

ActiveCN107565383BNarrow bandgapGood semiconductor performanceLaser active region structureLanthanumMaterials science

The invention relates to the field of materials, in particular to an indium phosphate bismuth material and a preparation method thereof, a laser using the indium phosphate bismuth material and a production method of the laser. The indium phosphate bismuth material comprises an indium phosphate substrate, an indium phosphate buffer layer arranged on the indium phosphate substrate and an indium phosphate bismuth body arranged on the indium phosphate buffer layer; the chemical formula of the indium phosphate bismuth body is: InP1-xBix, wherein x is percent concentration of bismuth atoms, 0 is smaller than x smaller than or equal to 12.5%. The indium phosphate bismuth material is small in forbidden bandwidth, easy to grow and stable.

Owner:CHAOJING TECH BEIJING CO LTD

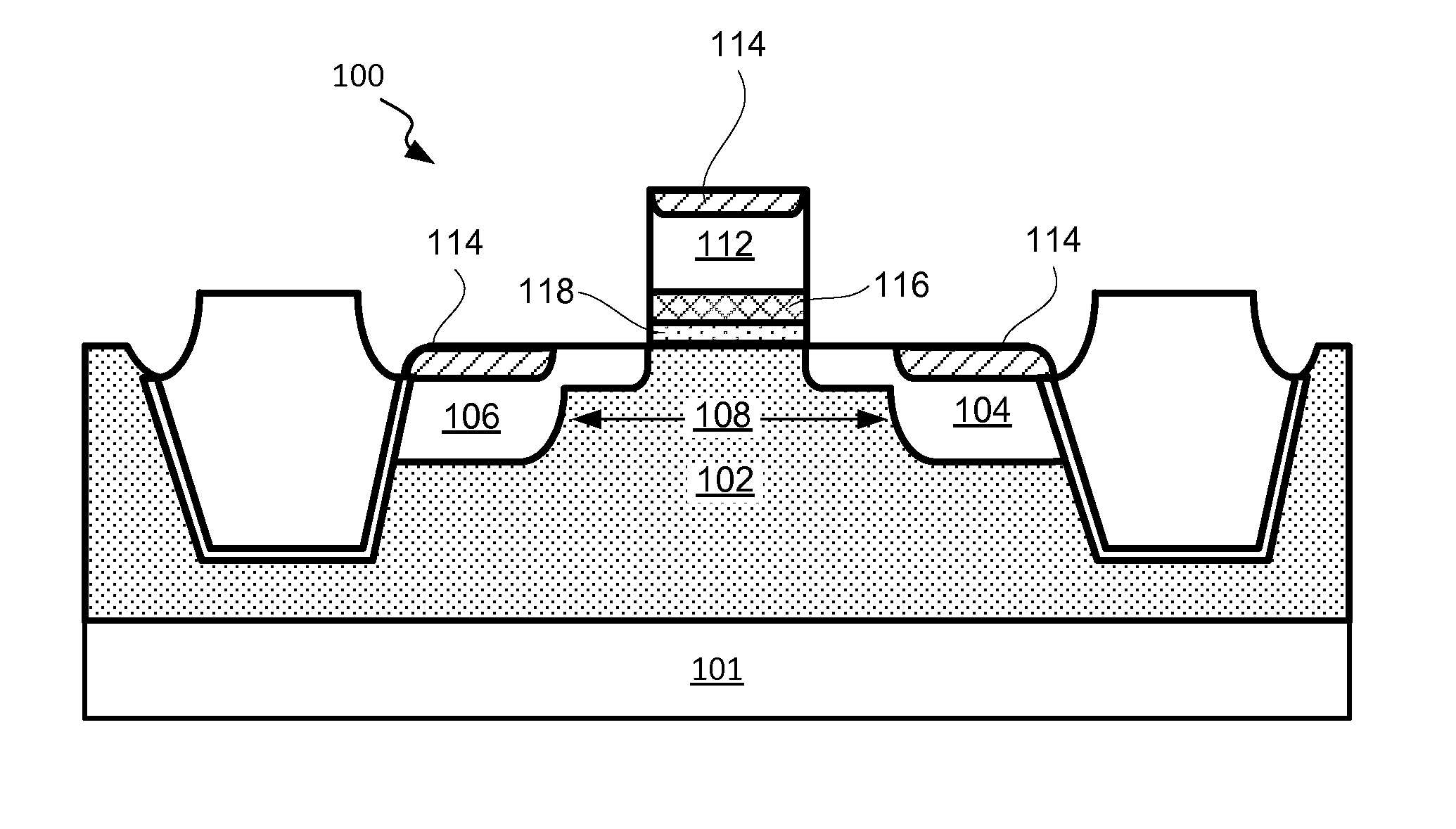

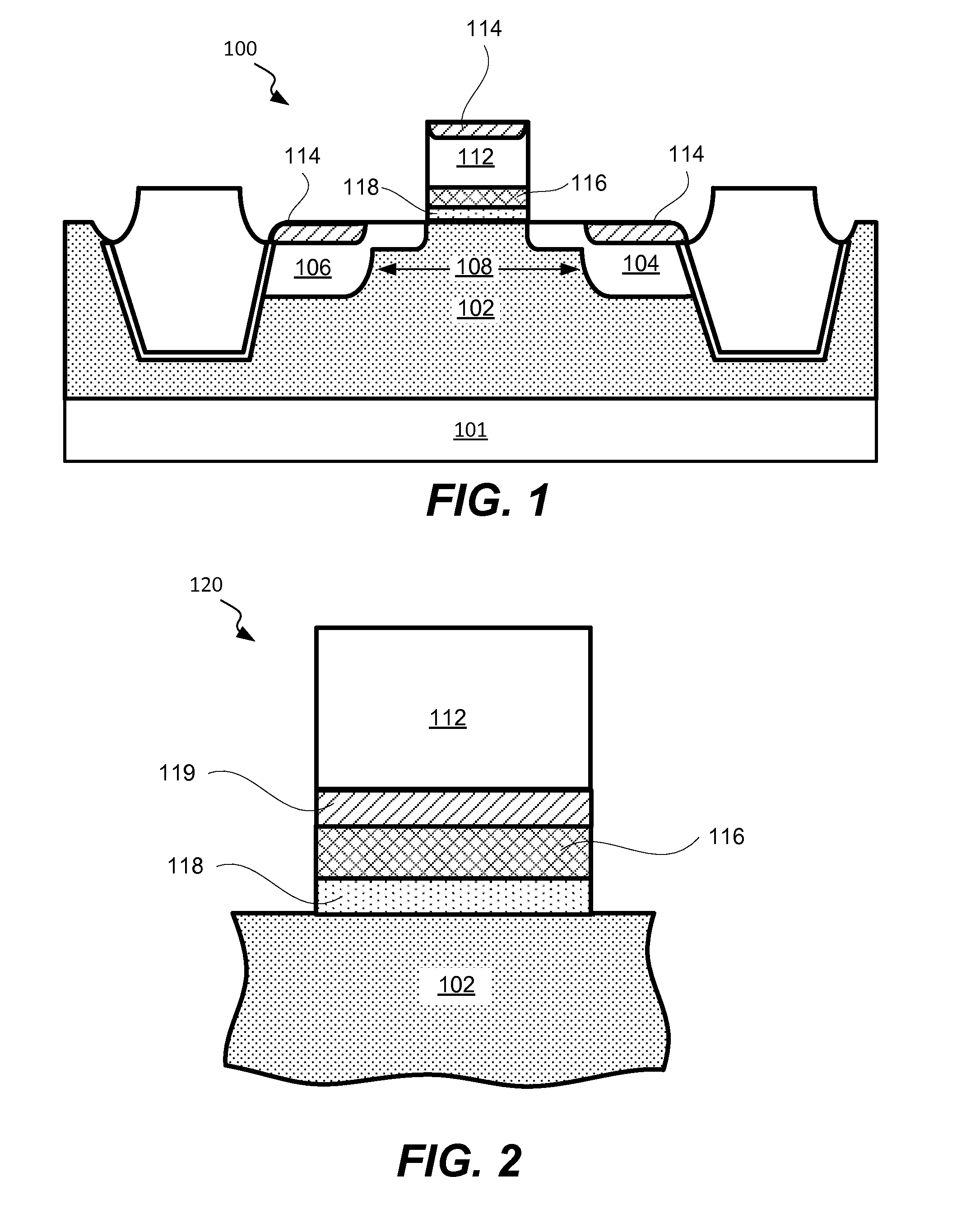

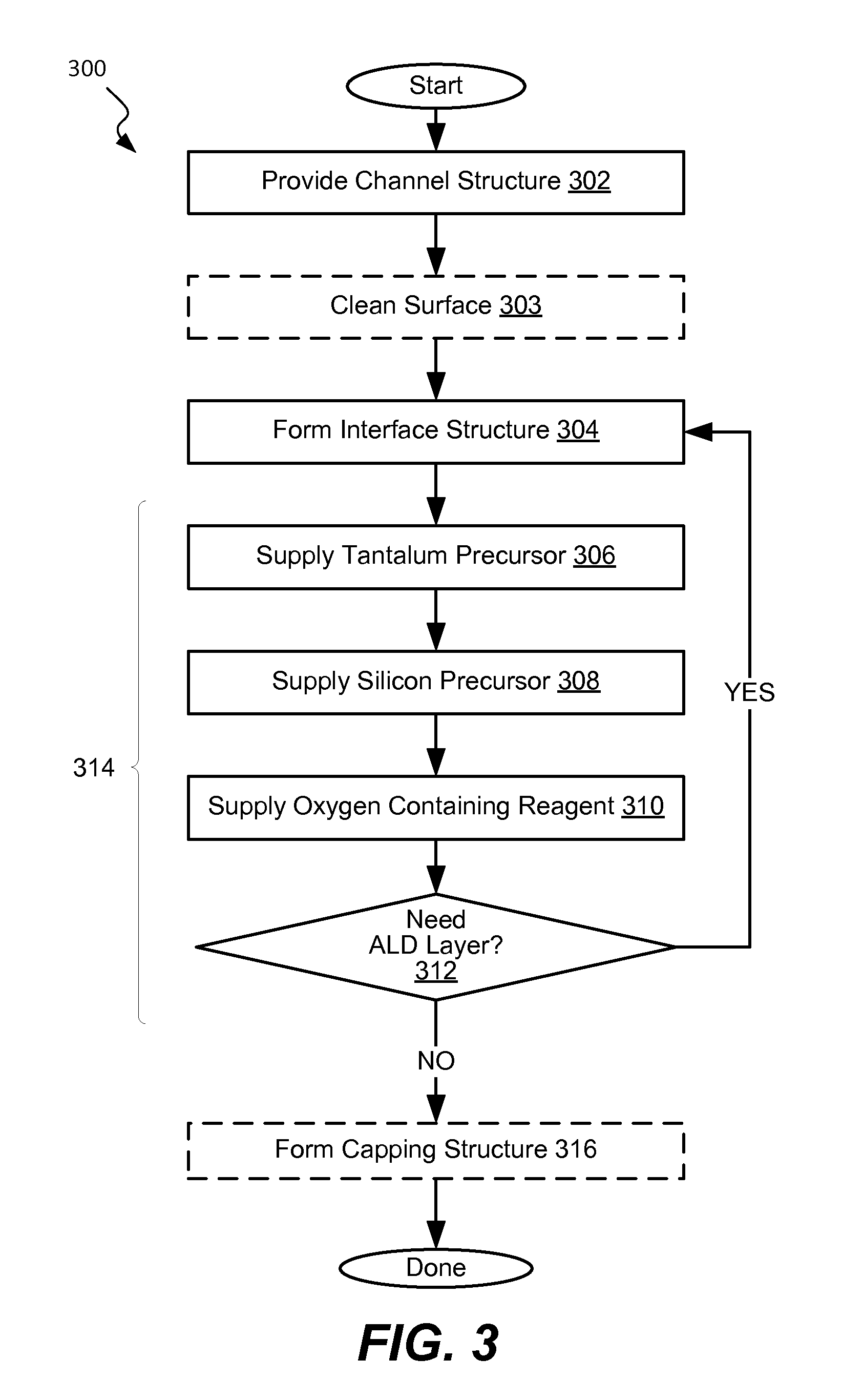

Gate stacks including TaXSiYO for MOSFETS

InactiveUS8975706B2Uncontrolled oxidationMaintain oxygen concentrationTransistorSemiconductor/solid-state device manufacturingMOSFETHigh energy

Provided are field effect transistor (FET) assemblies and methods of forming thereof. An FET assembly may include a dielectric layer formed from tantalum silicon oxide and having the atomic ratio of silicon to tantalum and silicon (Si / (Ta+Si)) of less than 5% to provide a low trap density. The dielectric layer may be disposed over an interface layer, which is disposed over a channel region. The same type of the dielectric layer may be used a common gate dielectric of an nMOSFET (e.g., III-V materials) and a pMOSFET (e.g., germanium). The channel region may include one of indium gallium arsenide, indium phosphate, or germanium. The interface layer may include silicon oxide to provide a higher energy barrier. The dielectric layer may be formed using an atomic layer deposition technique by adsorbing both tantalum and silicon containing precursors on the deposition surface and then oxidizing both precursors in the same operation.

Owner:INTERMOLECULAR

Preparation method of carbon composite indium phosphate photocatalytic material

InactiveCN107497464AFacilitates electron transferNot easy to peel offCatalyst activation/preparationArtificial filament chemical after-treatmentCarbon compositesFiber

Owner:柳州若思纳米材料科技有限公司 +1

A kind of etching solution and etching method for identifying twins on indium phosphide surface

ActiveCN110453289BEasy to identifyImprove stabilityPolycrystalline material growthAfter-treatment detailsAcetic acidSemiconductor materials

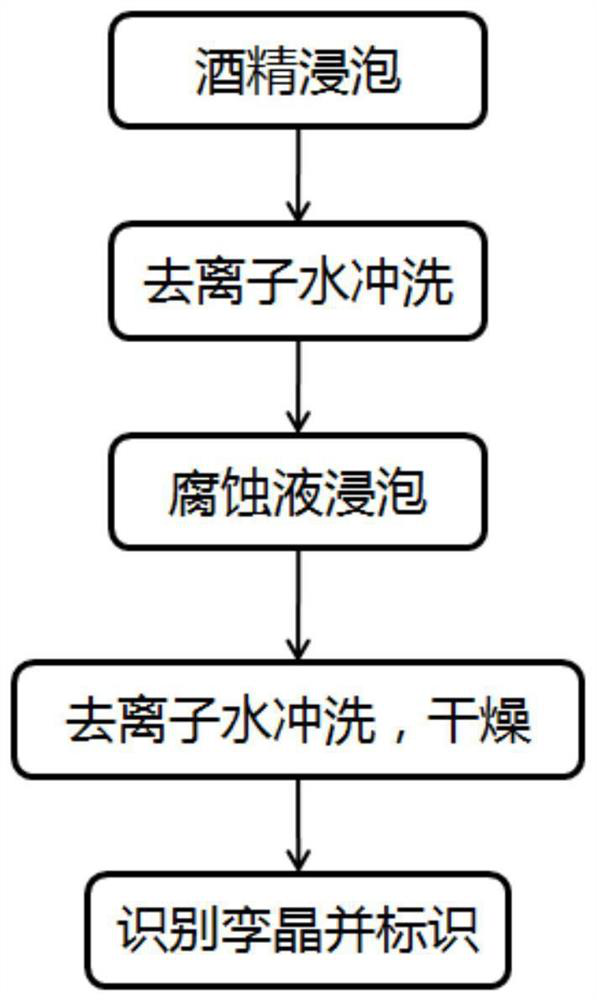

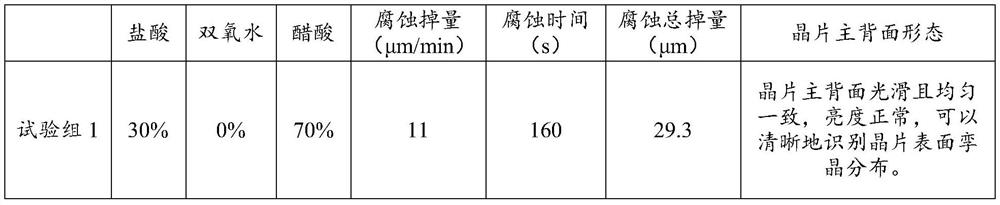

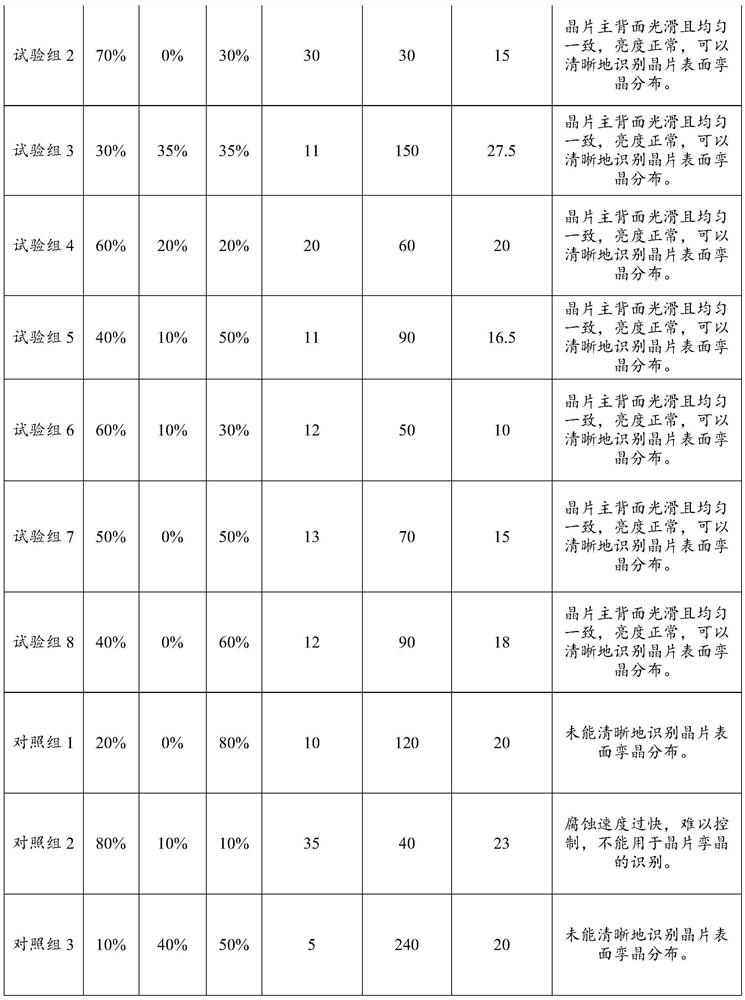

The invention relates to an etching solution and an etching method for identifying twins on the surface of indium phosphide, belonging to the field of semiconductor materials. The corrosion solution used for twin identification on the surface of indium phosphide of the present invention comprises the following components in volume percentage: 30%-70% of hydrochloric acid, 0%-35% of hydrogen peroxide, and 20%-70% of acetic acid. The present invention is used for the etching method of twin identification on the surface of indium phosphide, comprising the following steps: (1) soaking the indium phosphide wafer with alcohol; (2) washing the surface of the indium phosphide wafer with deionized water; (3) phosphiding The indium wafer is soaked in the corrosive solution; (4) the surface of the indium phosphide wafer is rinsed with deionized water, and the indium phosphide wafer is dried; (5) the surface of the indium phosphide wafer is observed under a fluorescent lamp and the distribution of twins is marked. The corrosion solution and the corrosion method of the invention are used for the identification of twin crystals on the indium phosphide surface, and have high stability, good repeatability and controllable corrosion speed.

Owner:广东先导微电子科技有限公司

A method for synthesizing indium phosphide by liquid phosphorus injection

ActiveCN111424310BReduce volatilityQuality improvementPolycrystalline material growthBy pulling from meltPhysical chemistrySingle crystal

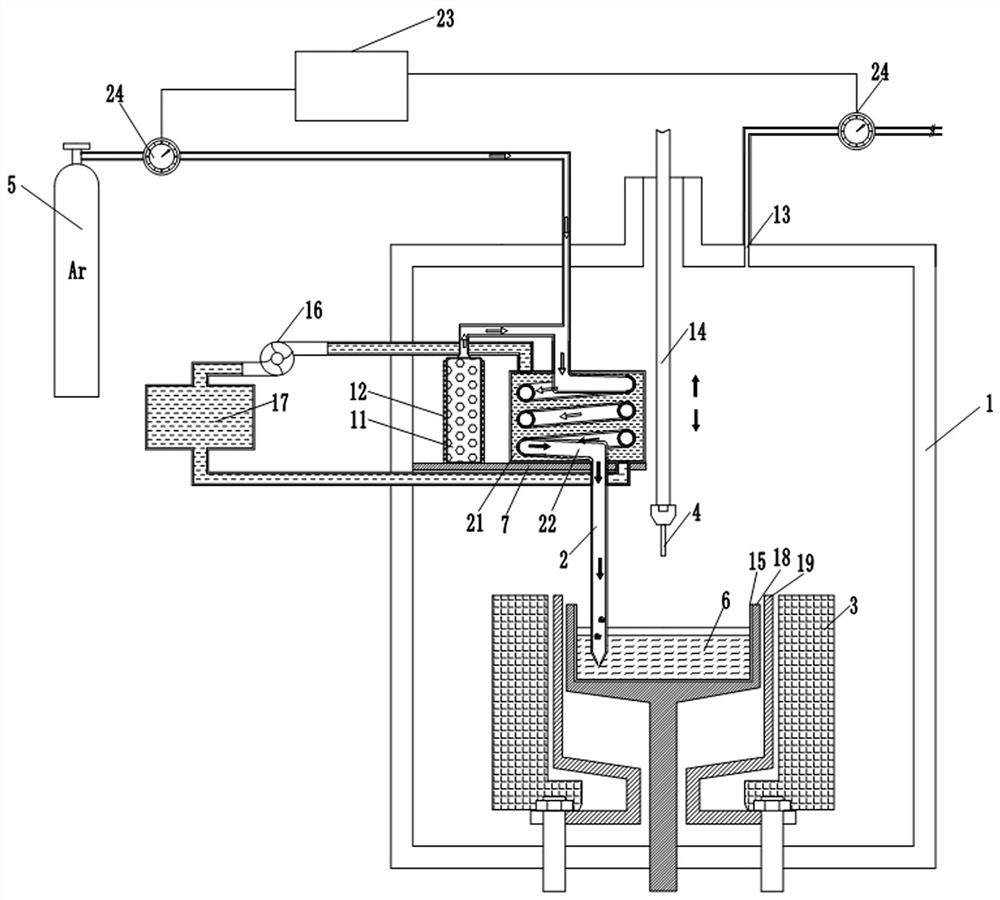

The invention relates to a method for synthesizing indium phosphide by liquid phosphorus injection, which belongs to the field of semiconductor technology. The method converts gaseous phosphorus into liquid phosphorus through a condenser, injects liquid phosphorus into indium solution, and prevents Phosphorus gasification makes liquid phosphorus and liquid indium melt instantaneously react, and can synthesize indium phosphide solution at a relatively low temperature, high efficiency, high purity ratio, and large capacity, which is conducive to the growth of phosphorus-rich indium phosphide polycrystalline, easy Growth of indium phosphide single crystals. Including: indium cleaning, phosphorus charging, furnace charging, condenser connection, synthesis, crystal preparation and other steps.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

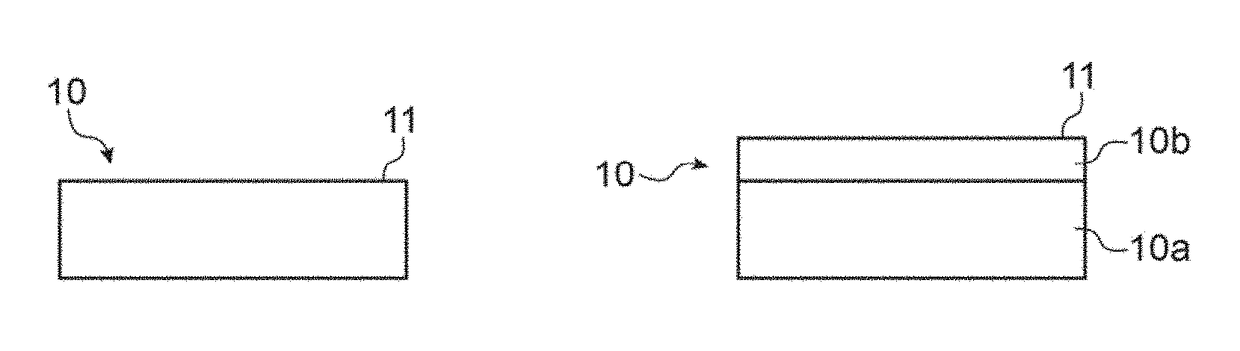

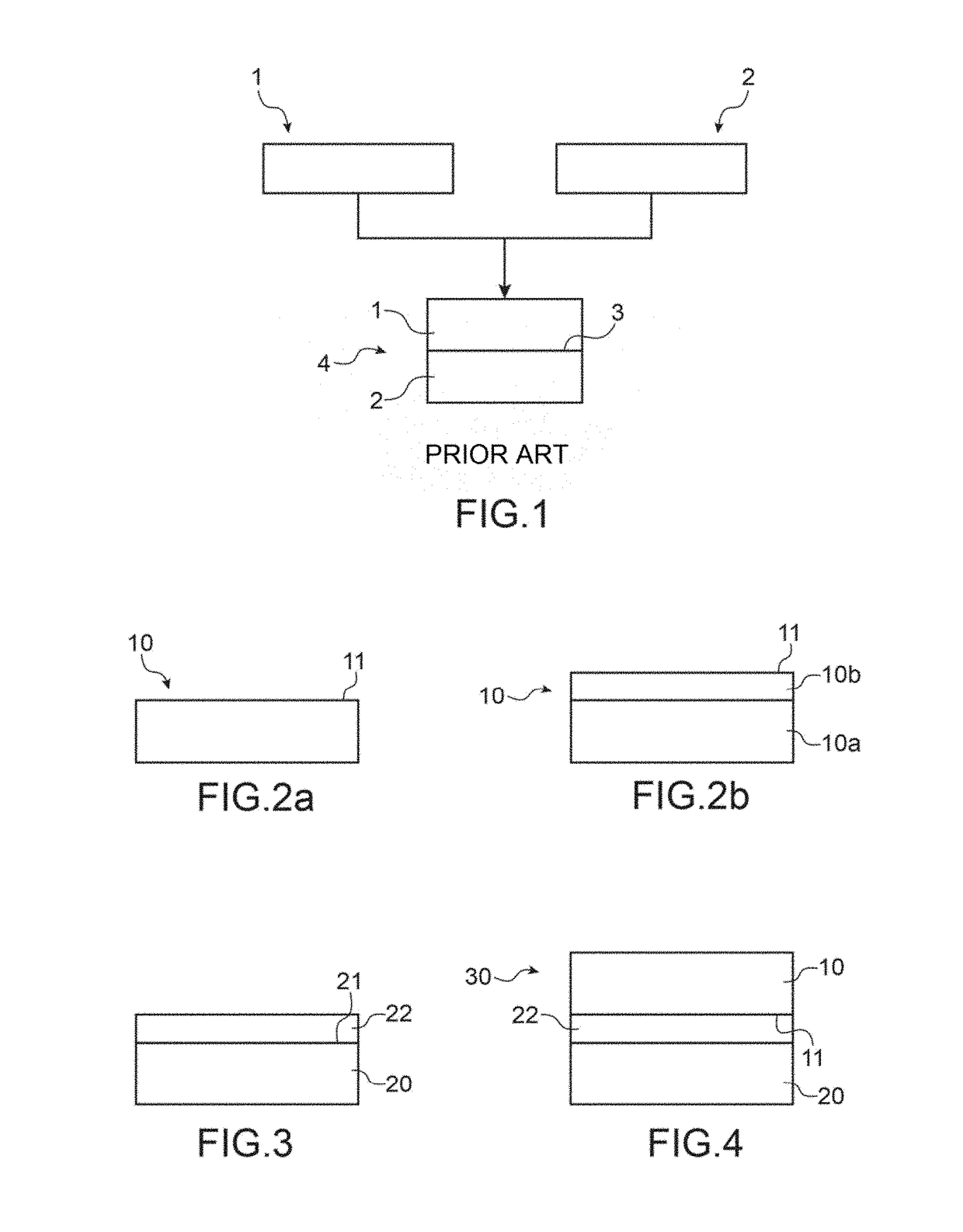

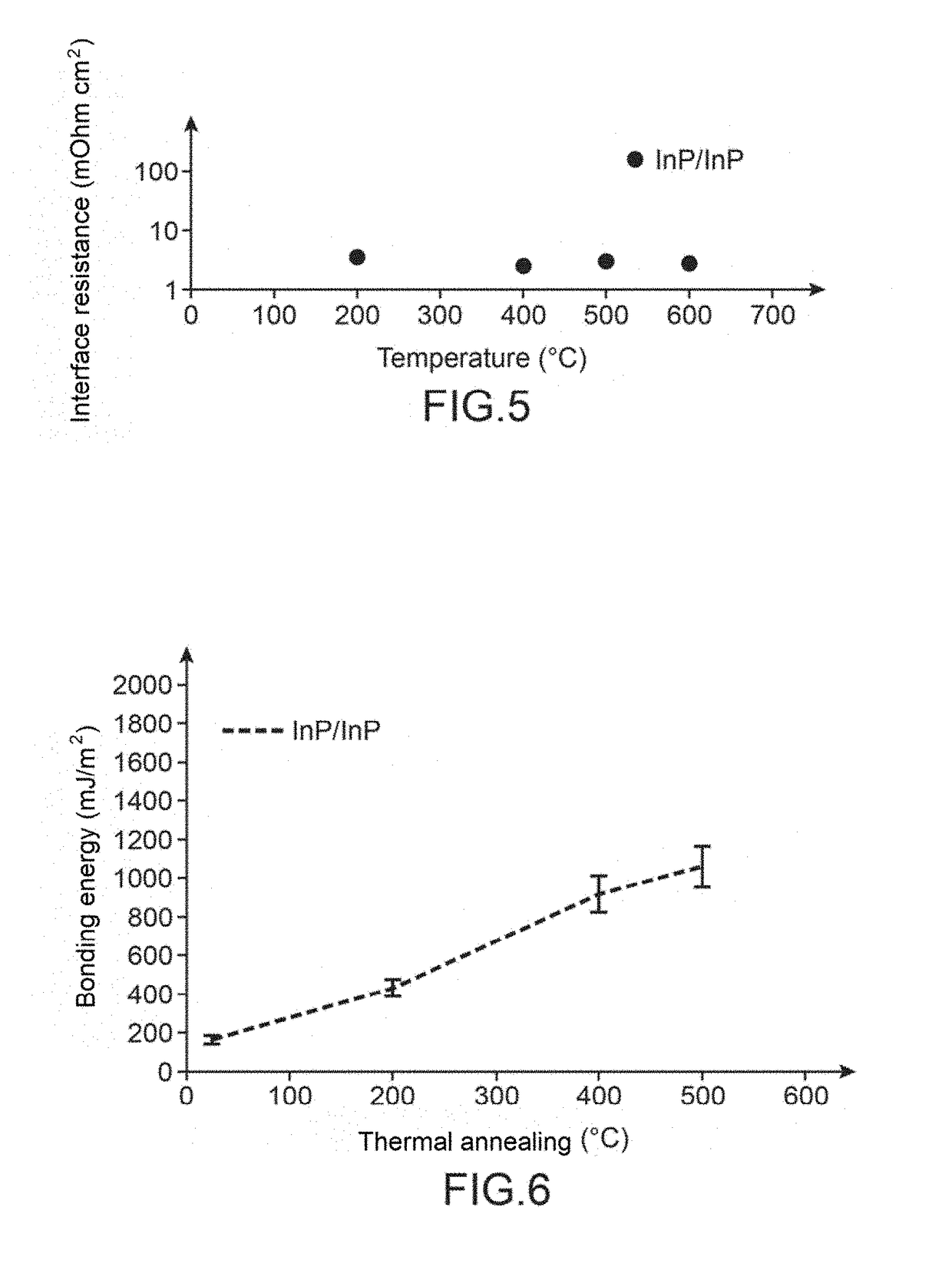

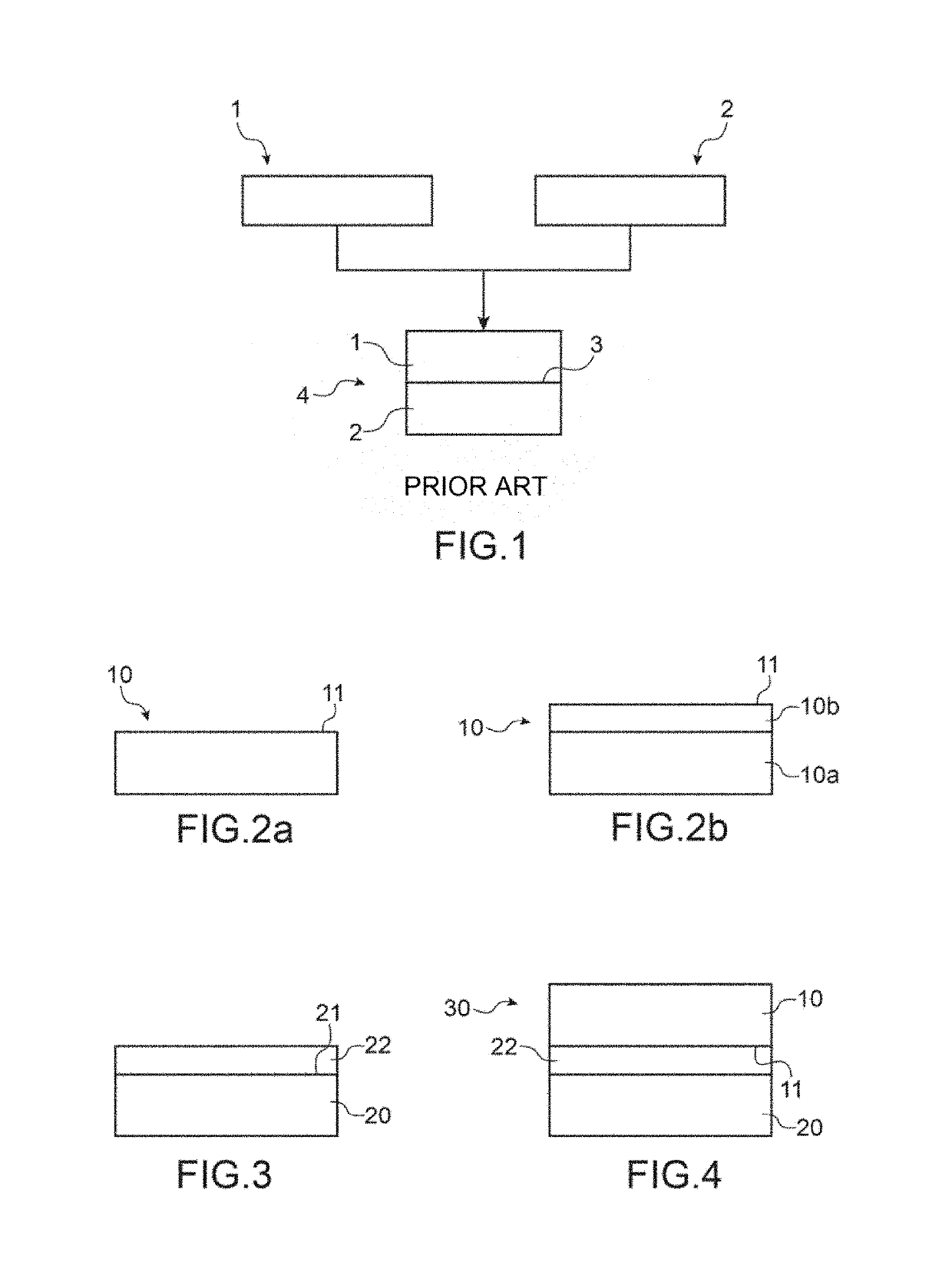

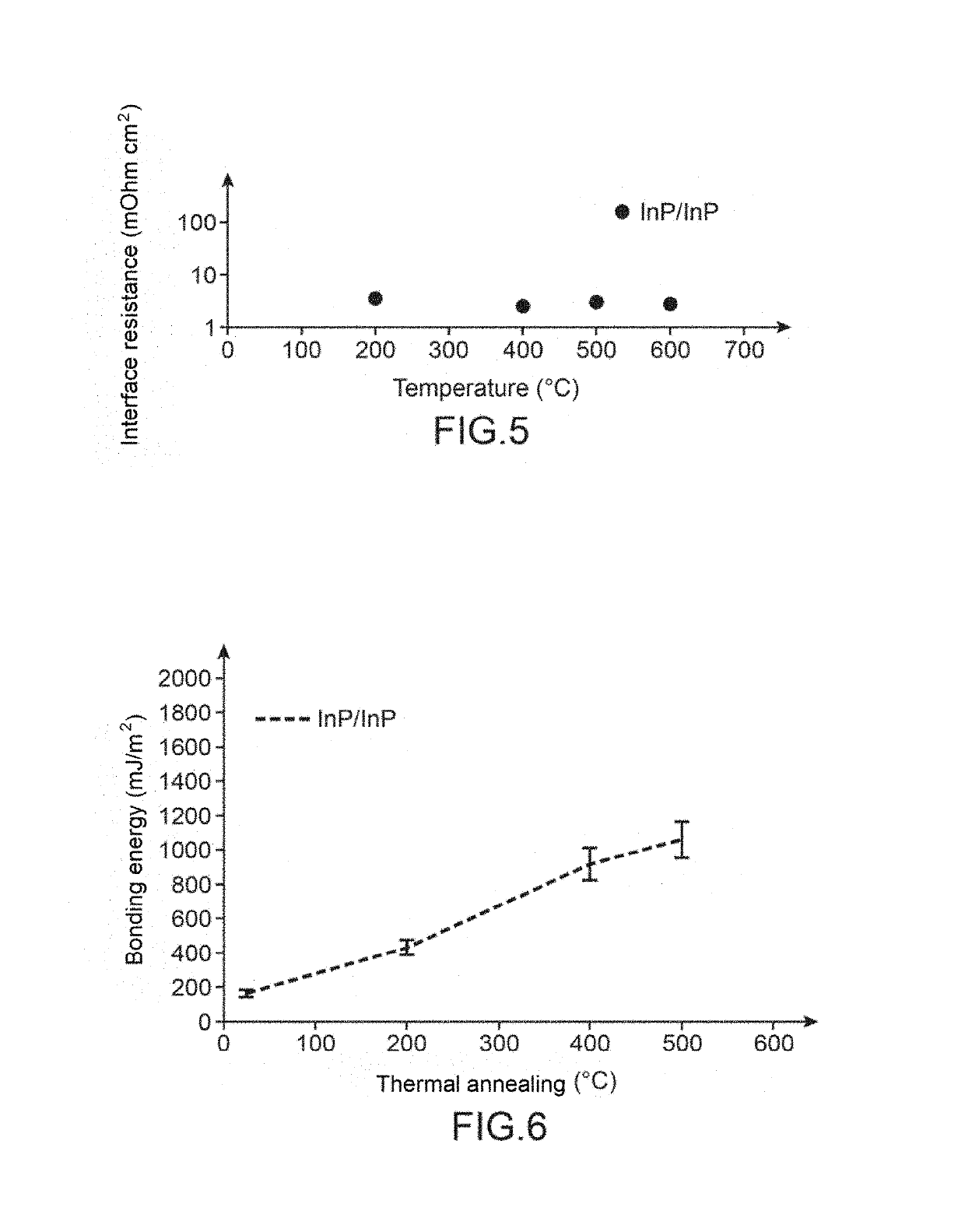

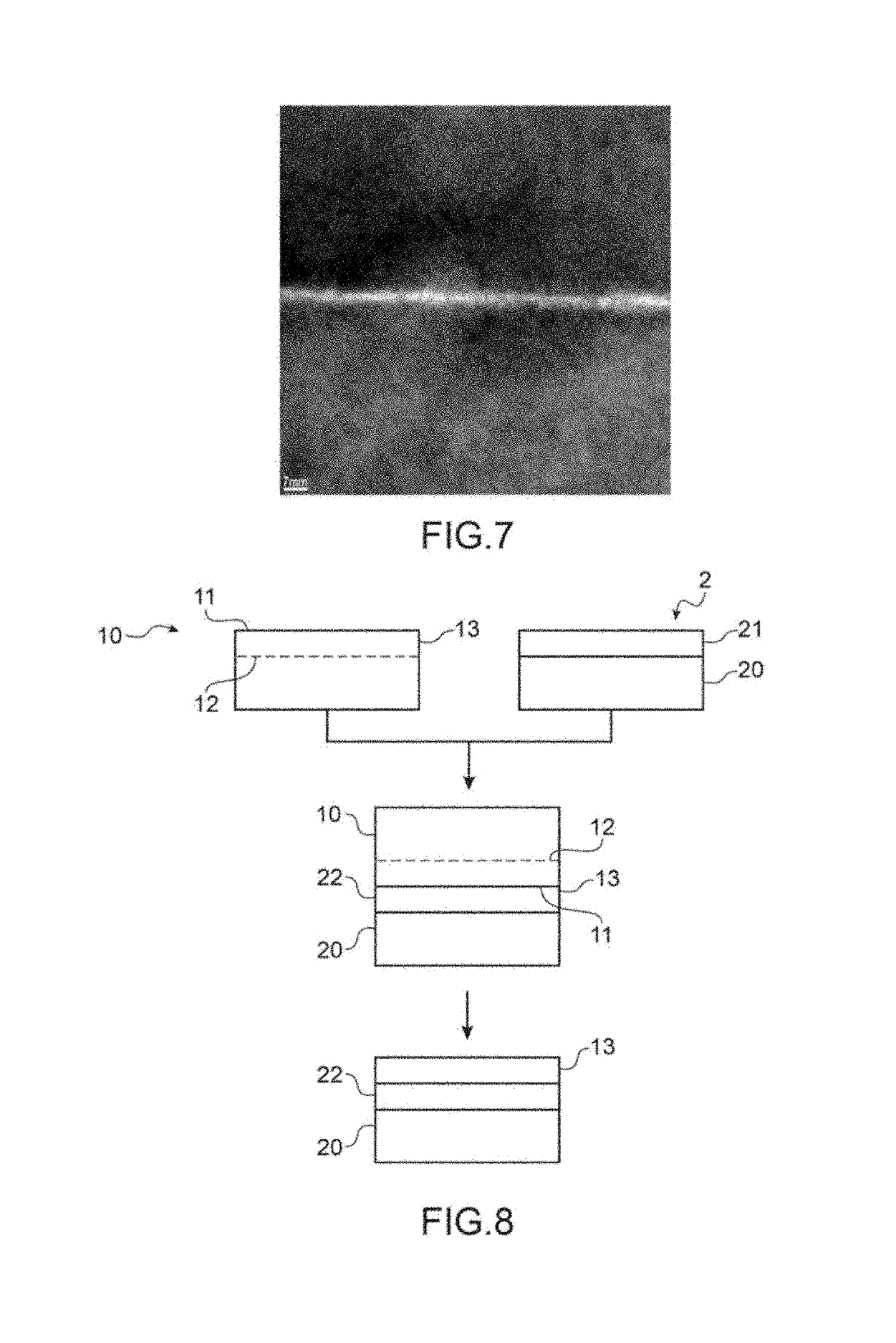

Method for assembling substrates by bonding indium phosphate surfaces

InactiveUS20180330950A1Prevent degradationSemiconductor/solid-state device detailsSolid-state devicesCrystallographyPhosphoric acid

The invention concerns an assembly method comprising the following steps: a) providing a first substrate comprising a first face made from crystalline indium phosphide, b) providing a second substrate comprising a second crystalline face different from the indium phosphide, c) forming an intermediate layer of crystalline indium phosphide on the second face of the second substrate, d) forming an assembly, via a direct bonding step, by bringing the first face of the first substrate into contact with the intermediate layer, the direct bonding step being carried out in an atmosphere having a pressure greater than 10−4 Pa, and preferably higher than 10−3 Pa, e) subjecting the assembly formed in step d) to heat treatment.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Integration method for electric absorption modulation laser and modular spot converter

InactiveCN1909309BReduce the number of growthHas an effectLaser detailsSemiconductor lasersPhosphate ionSilicon dioxide

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Method for preparing photocatalytic materials with silver phosphate loaded on porous indium phosphate

InactiveCN107413357AFast degradationPhysical/chemical process catalystsWater/sewage treatment by irradiationFiberPhosphoric acid

The invention discloses a method for preparing photocatalytic materials with silver phosphate loaded on porous indium phosphate. The method particularly includes steps of adding indium chloride into diethyl ether, ultrasonically dissolving the indium chloride and the diethyl ether, then adding polyacrylamide into the indium chloride and the diethyl ether, stirring the polyacrylamide, the indium chloride and the diethyl ether to obtain homogenous spinning solution and carrying out electrostatic spinning to obtain polyacrylamide nano-fibers with the indium chloride; calcining the polyacrylamide nano-fibers with the indium chloride in a tube furnace to obtain porous indium chloride; placing the obtained porous indium chloride in phosphoric acid solution, impregnating the porous indium chloride in the phosphoric acid solution and removing the phosphoric acid solution to obtain photocatalytic materials with the porous indium phosphate; adding the photocatalytic materials with the porous indium phosphate into silver nitrate solution, dropwise adding disodium hydrogen phosphate solution into the silver nitrate solution under continuous stirring conditions, and separating, washing and drying precipitates to obtain the photocatalytic materials with the silver phosphate loaded on the porous indium phosphate. The method has the advantages that mutual promotion effects can be realized by the aid of adsorption characteristics of porous materials and catalytic characteristics of the silver phosphate, and the photocatalytic materials with the silver phosphate loaded on the porous indium phosphate are high in degradation speed.

Owner:柳州若思纳米材料科技有限公司 +1

Magnesium indium phosphate matrix material for rare earth phosphor and preparation method thereof

ActiveCN105694880BSimple preparation processLuminescent compositionsRare-earth elementChemical composition

The invention discloses a magnesium and indium phosphate matrix material for rare-earth phosphor and a method for preparing the magnesium and indium phosphate matrix material. Chemical composition of the magnesium and indium phosphate matrix material is Mg21-28In28-34P42-48Oy (the y is equal to 168-199). The method includes preparing the magnesium and indium phosphate matrix material by the aid of wet-chemical and solid-phase sintering processes. The magnesium and indium phosphate matrix material and the method have the advantages that a novel phosphate compound which can be used as a phosphor matrix material is successfully researched and developed and contains indium elements, rare-earth elements which are used as activation centers can partially replace the indium elements to enter matrix crystal lattices, and accordingly the compound prepared by the aid of the method can be used as the matrix material for the phosphor; reports on magnesium and indium phosphate matrix materials are unavailable in the prior art; processes for preparing the magnesium and indium phosphate matrix material are simple, and the like.

Owner:CENT SOUTH UNIV

Preparation method of porous indium phosphate loaded copper manganate photocatalytic material

InactiveCN107597154AFast degradationPhysical/chemical process catalystsWater/sewage treatment by irradiationWater bathsPhosphoric acid

The invention discloses a preparation method of a porous indium phosphate loaded copper manganate photocatalytic material. The preparation method comprises the following steps: adding indium chlorideinto diethyl ether, dissolving with ultrasound, then adding polyacrylamide, stirring to obtain a uniform spinning solution, and carrying out electrostatic spinning to obtain polyacrylamide nanofiber containing indium chloride; putting the obtained product into a tubular furnace, and heating to 450 to 500 DEG C to obtain porous indium chloride; putting the obtained product into a phosphoric acid solution to obtain a porous indium phosphate photocatalytic material; weighing copper nitrate and manganese nitrate, stirring until the copper nitrate and manganese nitrate are dissolved, then adding acetic acid, stirring until the acetic acid is completely dissolved, adding the porous indium phosphate photocatalytic material, then putting the solution in a water bath for stirring, adding sodium citrate, continuously stirring and carrying out water bath for 6 to 8 hours, separating obtained precipitate, and carrying out calcinations at the temperature of 450 to 505 DEG C to obtain the porous indium phosphate loaded copper manganate photocatalytic material. After porous indium phosphate is loaded with copper manganate, the adsorbing effect is good, and simultaneously, the indium phosphate isbeneficial for promoting the copper manganate to improve the degrading speed.

Owner:柳州若思纳米材料科技有限公司 +1

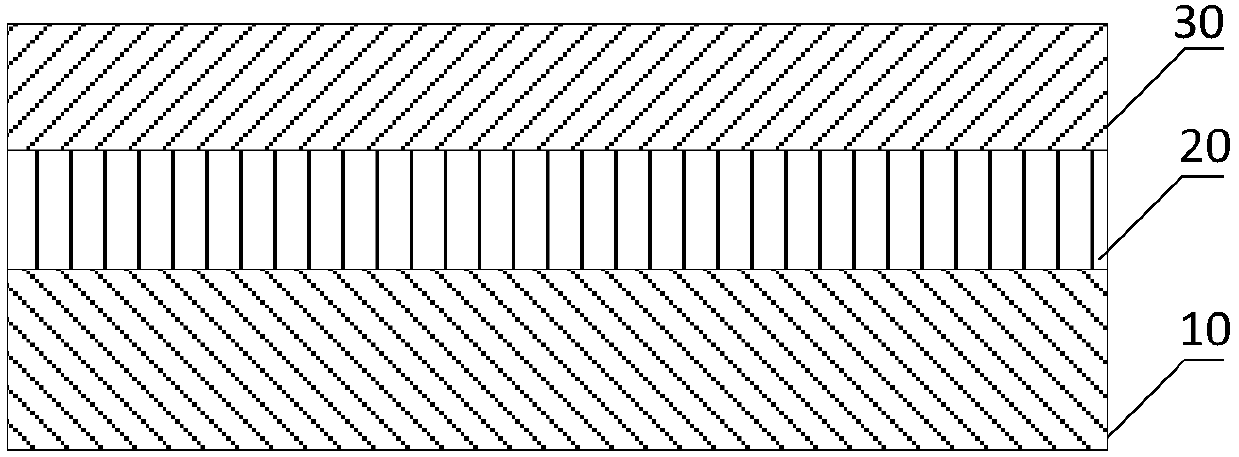

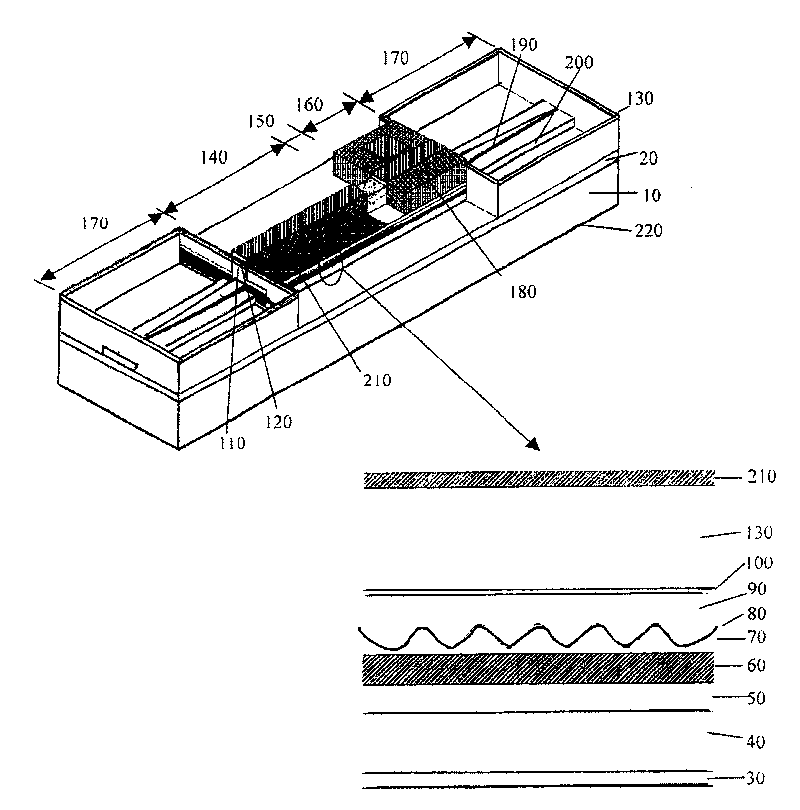

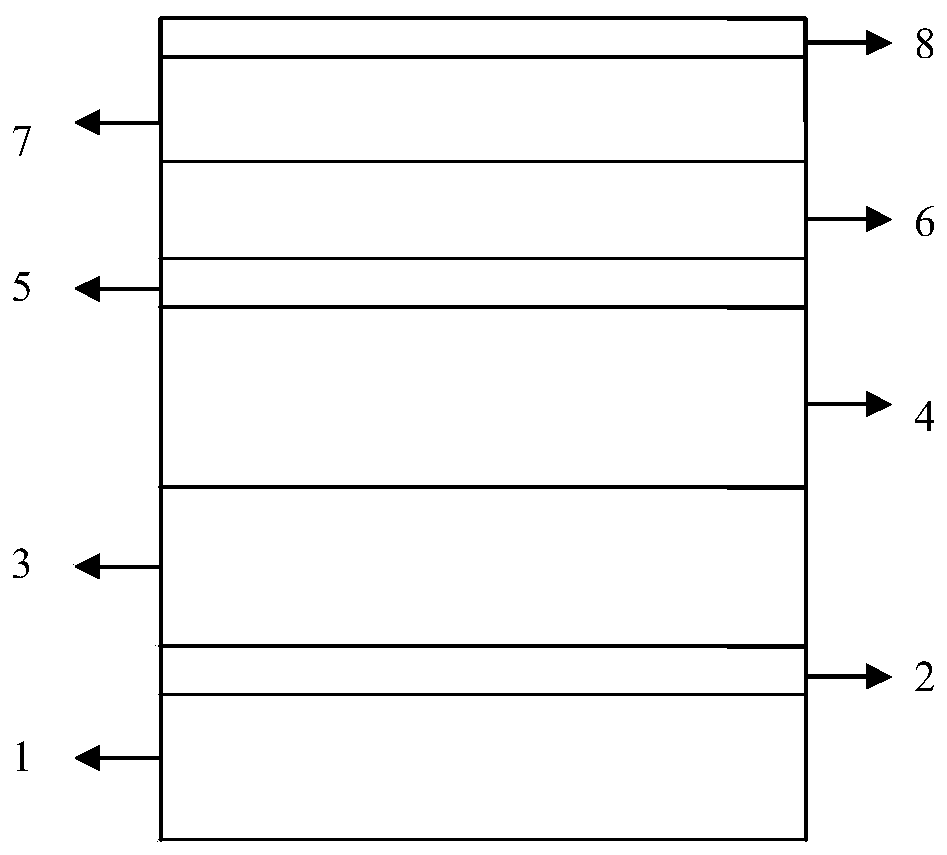

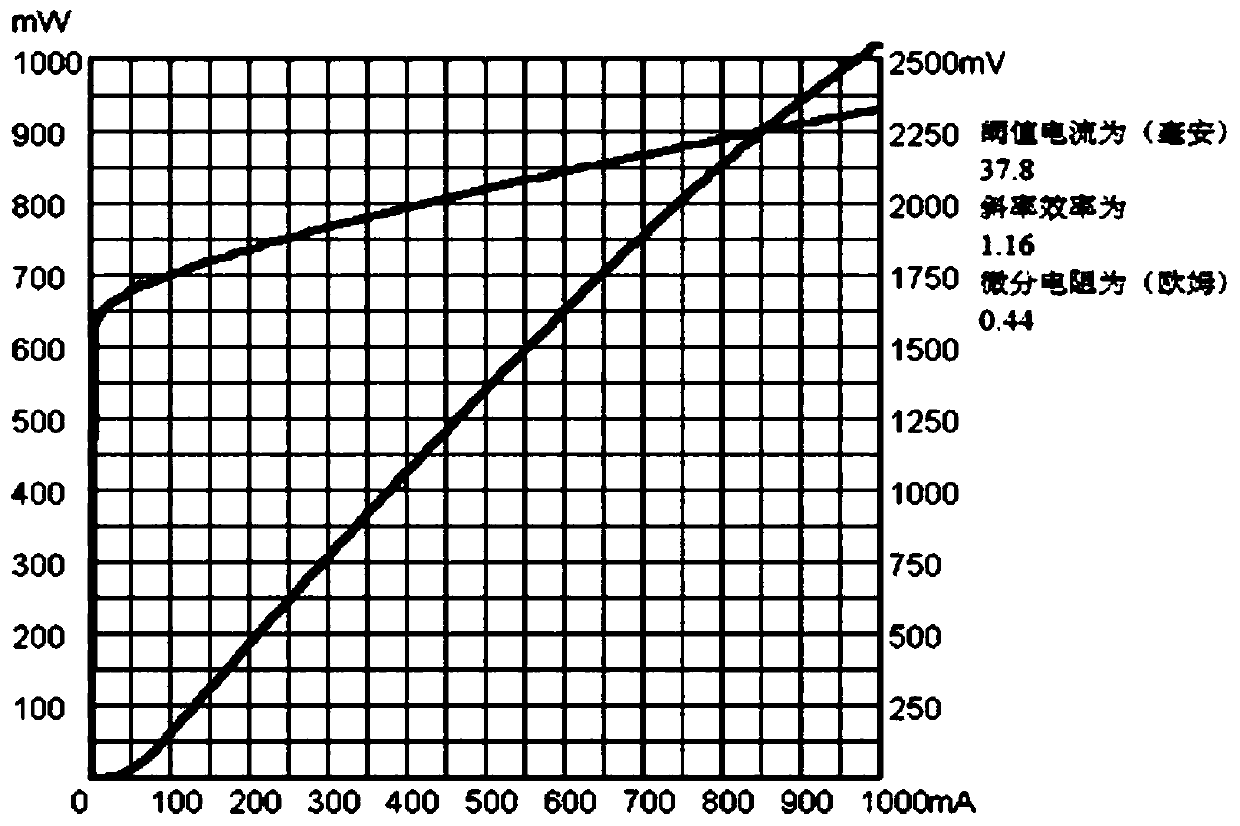

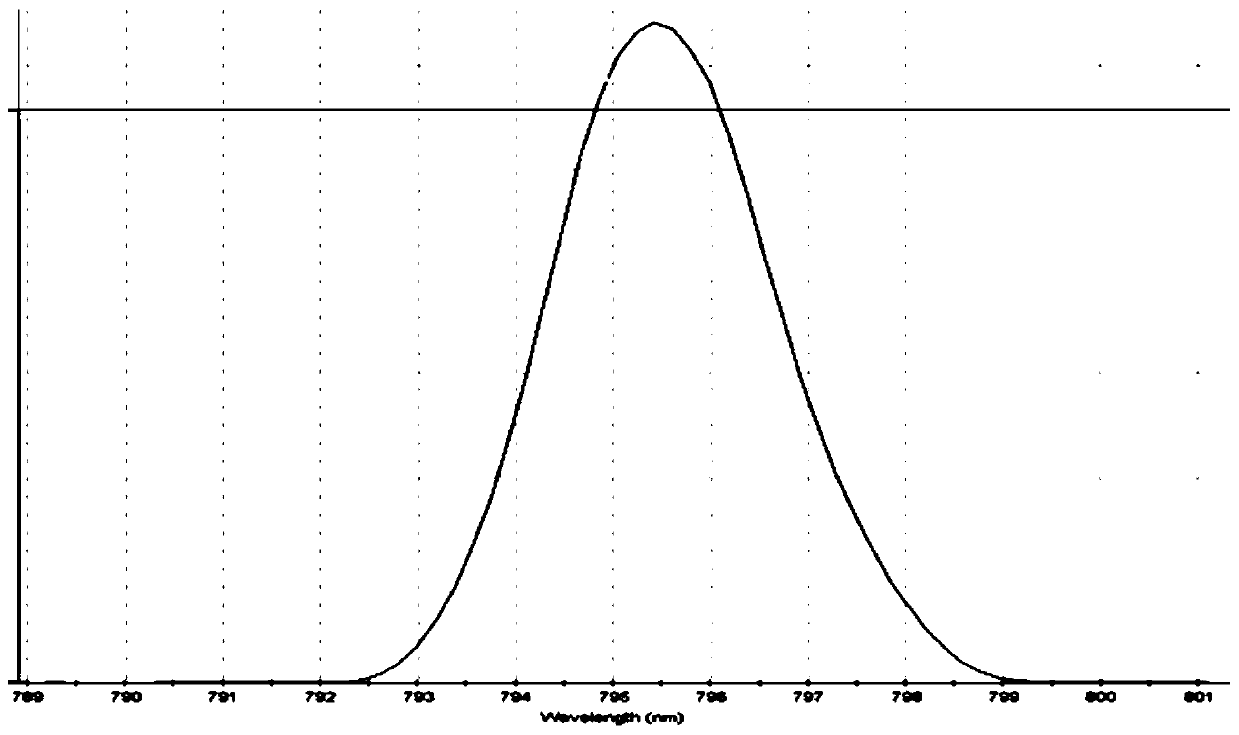

A 795nm quantum well laser based on algaas/gainp active region

ActiveCN108346973BGood lattice matchingQuality assuranceLaser detailsLaser active region structureLower limitGallium arsenate

The present invention provides a 795nm quantum well laser based on an AlGaAs / GaInP active region. The epitaxial structure comprises a substrate, a buffer layer, an N-type lower limit layer, a lower waveguide layer, a quantum well layer, an upper waveguide layer, and P-type upper limit layer and an ohmic contact layer from the bottom to the top. The upper waveguide layer and the lower waveguide layer are made of an aluminum-free material gallium indium phosphate, the quantum well layer is made of an aluminum gallium arsenide material, and a wide waveguide semi-aluminum-free active region is formed by the waveguide layers and the quantum well layer. According to the 795nm quantum well laser, the special requirements of a pump laser with the application of a small and simplified self-doubledlaser crystal can be satisfied, at the same time, the influence of the roughness of a growth interface and an episodic field at a cavity surface on the service and reliability of the laser can be reduced effectively by an optimized laser structure.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

Preparation method of calcium phosphate loaded indium phosphate catalyst

InactiveCN107308965ANot easy to fall offLarge specific surface areaPhysical/chemical process catalystsTri calcium phosphateIon

The invention discloses a preparation method of a calcium phosphate loaded indium phosphate catalyst. The preparation method comprises the following steps of: stirring at a rotating speed of 250-450r / s, dropwise adding a calcium chloride solution into a newly prepared sodium tripolyphosphate solution, adding an indium chloride solution at the same time, continuing to stir for 50-70min after dropwise adding is finished, performing centrifugal separation, washing a solid with distilled water, and drying the solid to prepare the calcium phosphate loaded indium phosphate catalyst. The loading is neither common grinding and mixing, nor simple surface deposition, but is combination of phosphate radicals and indium ions in a carrier body; an indium phosphate crystal is formed on the surface; the combination is firm; indium phosphate does not fall easily; the specific surface area is increased; and a better catalytical effect can be obtained.

Owner:柳州若思纳米材料科技有限公司

Method for assembling substrates by bonding indium phosphate surfaces

InactiveUS10283364B2Prevent degradationSemiconductor/solid-state device detailsAdhesive processes with surface pretreatmentOptoelectronicsHeat treated

The invention concerns an assembly method comprising the following steps: a) providing a first substrate comprising a first face made from crystalline indium phosphide, b) providing a second substrate comprising a second crystalline face different from the indium phosphide, c) forming an intermediate layer of crystalline indium phosphide on the second face of the second substrate, d) forming an assembly, via a direct bonding step, by bringing the first face of the first substrate into contact with the intermediate layer, the direct bonding step being carried out in an atmosphere having a pressure greater than 10−4 Pa, and preferably higher than 10−3 Pa, e) subjecting the assembly formed in step d) to heat treatment.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Preparation method of plate like zirconium phosphate loaded indium phosphate catalyst

InactiveCN107308963AImprove bindingNot easy to fall offPhysical/chemical process catalystsIndium(III) chlorideMicroemulsion

The invention discloses a preparation method of a plate like zirconium phosphate loaded indium phosphate catalyst. The preparation method comprises the following steps: dissolving zirconium chloride into water to prepare a zirconium chloride solution with the concentration of 0.1-0.5 mol / L, taking the solution as an aqueous phase, stirring TrionX-100, n-butyl alcohol, cyclohexane and the aqueous phase at the ratio of 1:(2-20):(2-40):(0.2-0.4) to prepare a microemulsion, adding an indium chloride solution dropwise while stirring the microemulsion, dropping a sodium triphosphate solution after finishing adding the sodium triphosphate dropwise, continuing to stir after finishing dropping, finally centrifugally separating, washing a solid with ethyl alcohol, and drying in vacuum to obtain the plate like zirconium phosphate loaded indium phosphate catalyst.

Owner:柳州若思纳米材料科技有限公司

a cr 3 + Doped strontium indium phosphate broadband near-infrared luminescent material and preparation method

ActiveCN112300797BImprove featuresWide excitation spectrumLuminescent compositionsSemiconductor devicesCrystal systemPhosphate

The invention discloses a Cr 3+ Doped strontium indium phosphate broadband near-infrared luminescent material and preparation method, its general chemical formula is: Sr 3 In 1‑x‑y m y P 3 o 12 :xCr 3+ , wherein: M is one or more of Sc and Lu elements, 0.001≤x≤0.11, 0≤y≤1. The near-infrared luminescent material belongs to the cubic crystal system, and has the 3 InP 3 o 12 Crystal structure of the same type, space group I‑43d. The material of the invention has a wide excitation spectrum, the excitation wavelength is in the range of 250-600nm, can be excited by ultraviolet light and visible light, and the emission wavelength range is 700-1100nm. The invention can be used to manufacture a broadband near-infrared light source when matched with a blue or ultraviolet LED chip, and has important application value in the fields of non-destructive quality analysis of food and non-invasive detection of human physiological state. The preparation process of the invention is simple, the raw material price is low, and the industrial production is easy.

Owner:UNIV OF SCI & TECH BEIJING

A kind of magnesium indium phosphate red or green fluorescent powder and its preparation

ActiveCN105860973BImprove transmittanceHigh luminous intensityLuminescent compositionsRare-earth elementMagnesium phosphate

The invention provides magnesium-indium phosphate red and green fluorescent powder and a preparation method thereof. The chemical formula of the magnesium-indium phosphate red and green fluorescent powder is Mg21-28(In1-xLnx)28-34P42-48Oy (x=0.02-0.11, y=168-199), wherein Ln is rare earth ion Eu or Tb. In the fluorescent powder, a novel phosphate compound Mg21-28In28-34P42-48Oy (y=168-199) is used as a substrate, different rare earth elements are added into the substrate, and therefore the fluorescent material having strong emission in different spectral regions under ultraviolet excitation can be obtained. The preparation method is a wet-chemical-solid phase sintering method. The fluorescent powder has good optical performance and can well meet the requirements of a three-band-color fluorescent lamp.

Owner:CENT SOUTH UNIV

Method for preparing porous indium phosphate photocatalytic material

InactiveCN107555409AImprove adsorption capacityFast degradationPhysical/chemical process catalystsWater/sewage treatment by irradiationAir atmospherePhosphoric acid

The invention discloses a method for preparing a porous indium phosphate photocatalytic material. The method specifically comprises the following steps: adding indium chloride into diethyl ether, dissolving with ultrasonic waves, adding polyacrylamide and stirring to obtain a uniform spinning liquid, and electrospinning to obtain indium chloride-containing polyacrylamide nanofibers; placing the obtained indium chloride-containing polyacrylamide nanofibers in a tube furnace, heating in an air atmosphere at a speed of 10 DEG C per min to a temperature of 450 to 500 DEG C, keeping the temperaturefor 3 to 5 h, and then stopping heating, naturally cooling to room temperature to obtain porous indium chloride; placing the resulting porous indium chloride in 50 to 100 mL of a phosphoric acid solution with a concentration of 2 to 20 mg / L, impregnating for 10 to 25 h and then removing the phosphoric acid solution, cleaning with pure water for 2 to 3 times, and drying at a temperature of 60 to 80 DEG C to obtain a porous indium phosphate photocatalytic material. The method provided by the invention has the advantages that 1) the porous indium chloride reacts with phosphoric acid to obtain porous indium phosphate; 2) the porous indium phosphate has high adsorption, a condensation effect on pollutants and high degradation speed.

Owner:柳州若思纳米材料科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com