Annealing method of ferric-doped indium phosphate monocrystal chips

A technology of indium phosphide and indium single crystal, which is applied in the annealing field of iron-doped indium phosphide single wafer, can solve the problems of occupying interstitial sites and reducing the activation rate of Fe, so as to increase material resistivity and improve semi-insulating properties and stability, to overcome the effect of high iron doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

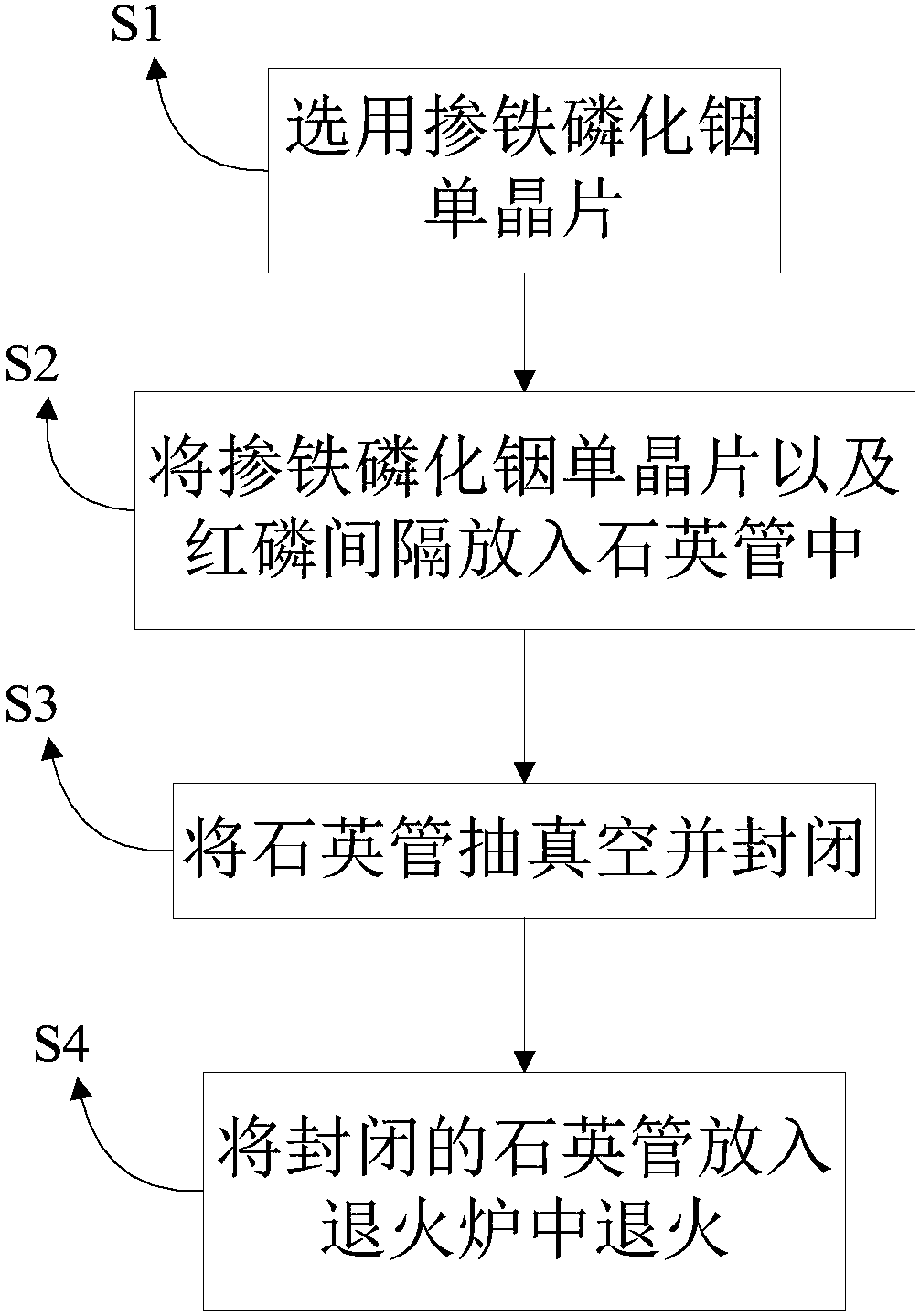

[0050] In the present invention, the iron-doped indium phosphide single wafer is annealed, and the specific steps are as follows:

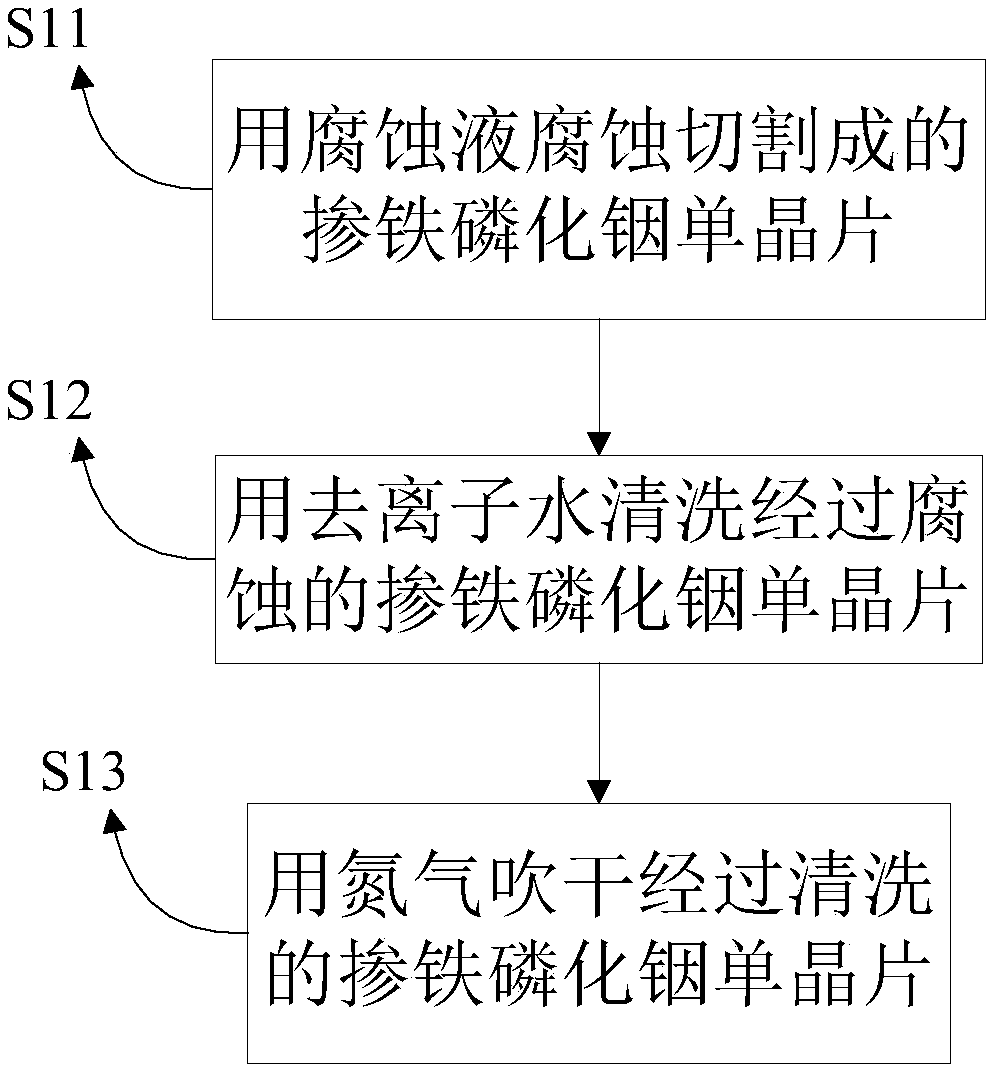

[0051] First, the iron-doped indium phosphide material prepared by the VGF method is selected, and the iron doping concentration is greater than or equal to 3×10 16 cm -3 , the dislocation density is less than or equal to 1000cm -2 , the above-mentioned iron-doped indium phosphide material was cut into pieces, chemically etched with an etching solution prepared by hydrochloric acid and nitric acid with a volume ratio of 3:1 for 2 minutes, cleaned with deionized water, and dried with nitrogen for subsequent use. use.

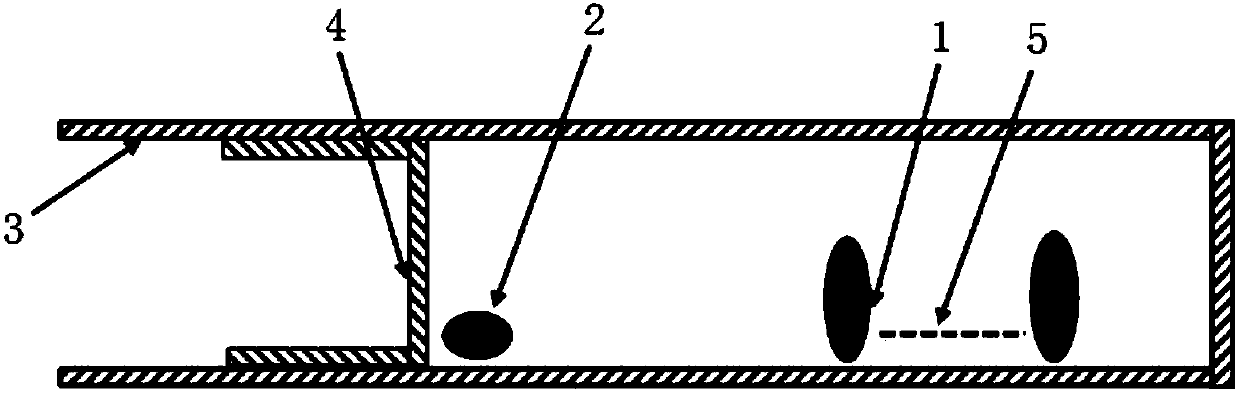

[0052] Secondly, choose massive red phosphorus with a purity greater than 6N, estimate the amount of red phosphorus used, put the massive red phosphorus into a quartz container, put the quartz container into a quartz tube; put the treated iron-doped indium phosphide single chip into On the quartz sample holder, put the quartz samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com