A method for synthesizing indium phosphide by liquid phosphorus injection

A liquid indium phosphide technology, applied in chemical instruments and methods, self-melting liquid pulling method, single crystal growth, etc., can solve the problems of increasing material preparation cost, affecting synthesis effect, cost increase, etc., to reduce material adhesion The risk of pollution, the cost saving of raw materials, and the effect of saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

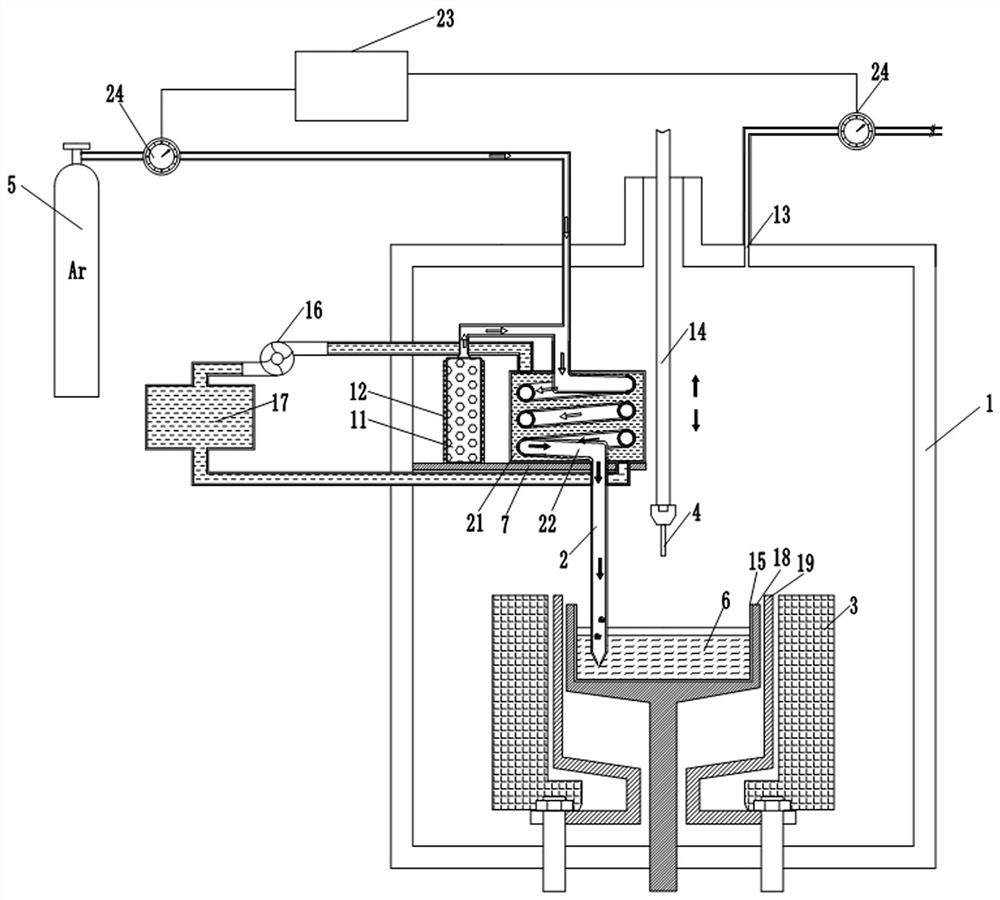

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0033]A method for synthesizing indium phosphide by liquid phosphorus injection, the method is based on a system for synthesizing indium phosphide by liquid phosphorus injection, the system includes an InP single crystal furnace 1 based on the in-situ synthesis method, and the single crystal furnace 1 includes a vacuum system, charging and discharging Gas system, temperature and pressure control system, electrical control system, cooling circulation system, weighing system, seed rod 14 pulling and lifting mechanism, crucible 15 and crucible 15 supporting heating, heat preservation, lifting mechanism. The crucible 15 is located on the graphite holder 18, the heater 19 is arranged on the periphery of the graphite holder 18, and the insulation cover 3 is arranged on the periphery of the heater 19. The bottom end of the graphite holder 18 extends beyond t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com