Magnesium-indium phosphate red and green fluorescent powder and preparation method thereof

A technology of phosphors and phosphates, applied in luminescent materials, chemical instruments and methods, etc., can solve problems such as the rareness of exploring new matrix materials, and achieve the effects of short afterglow time, high transmittance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

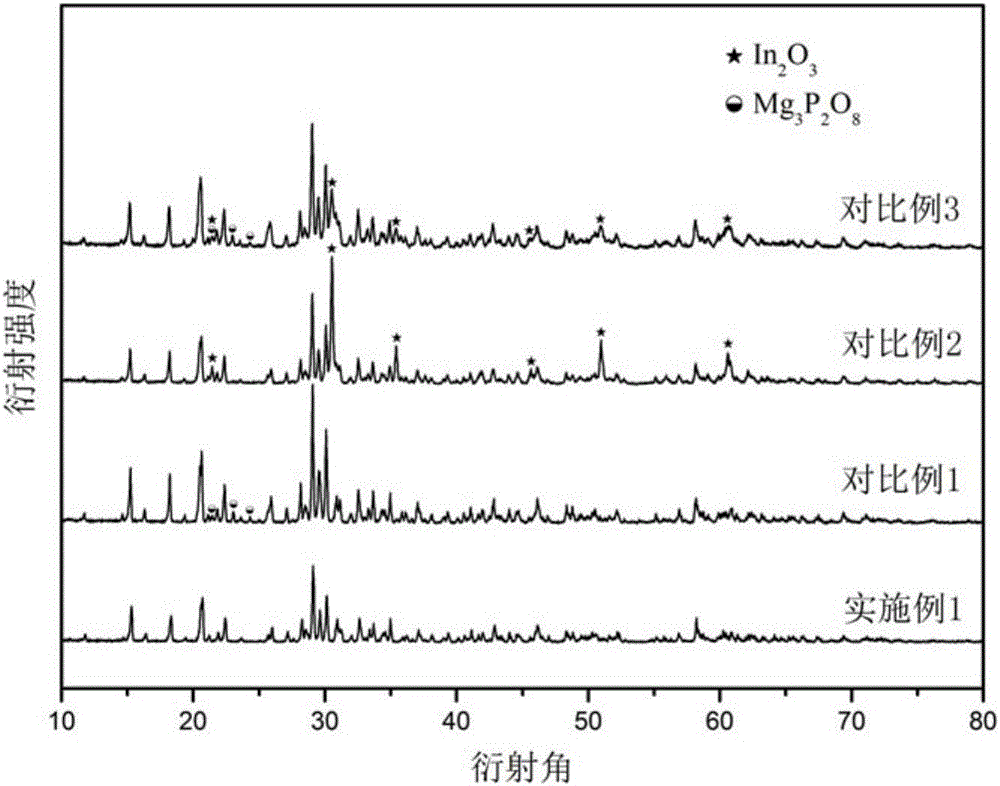

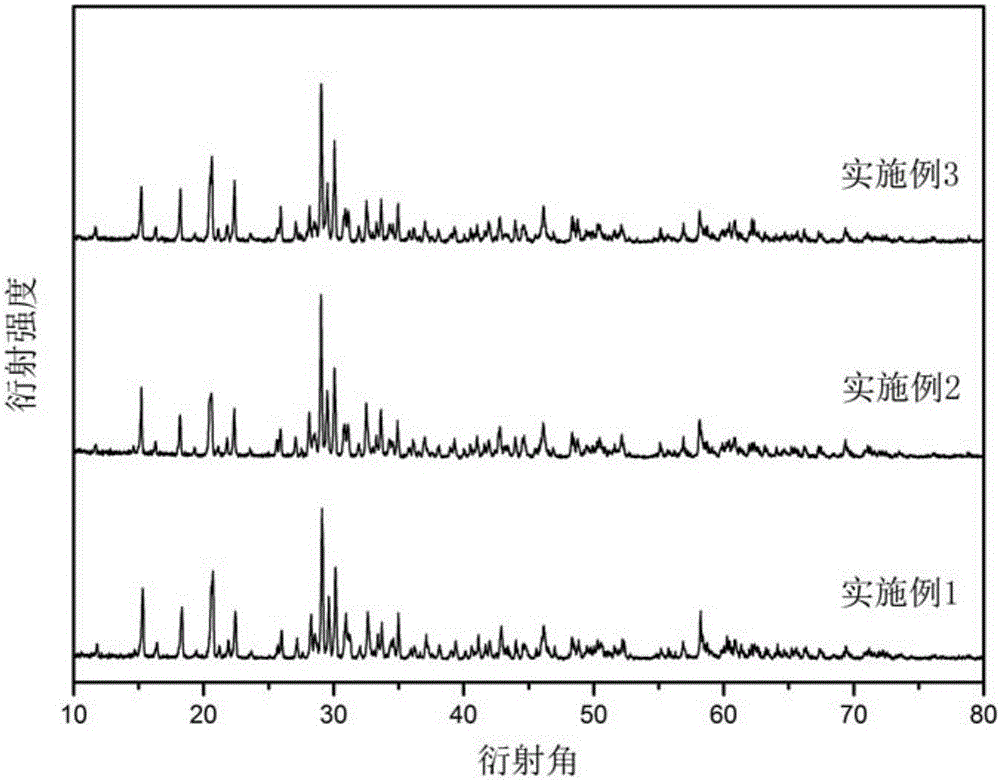

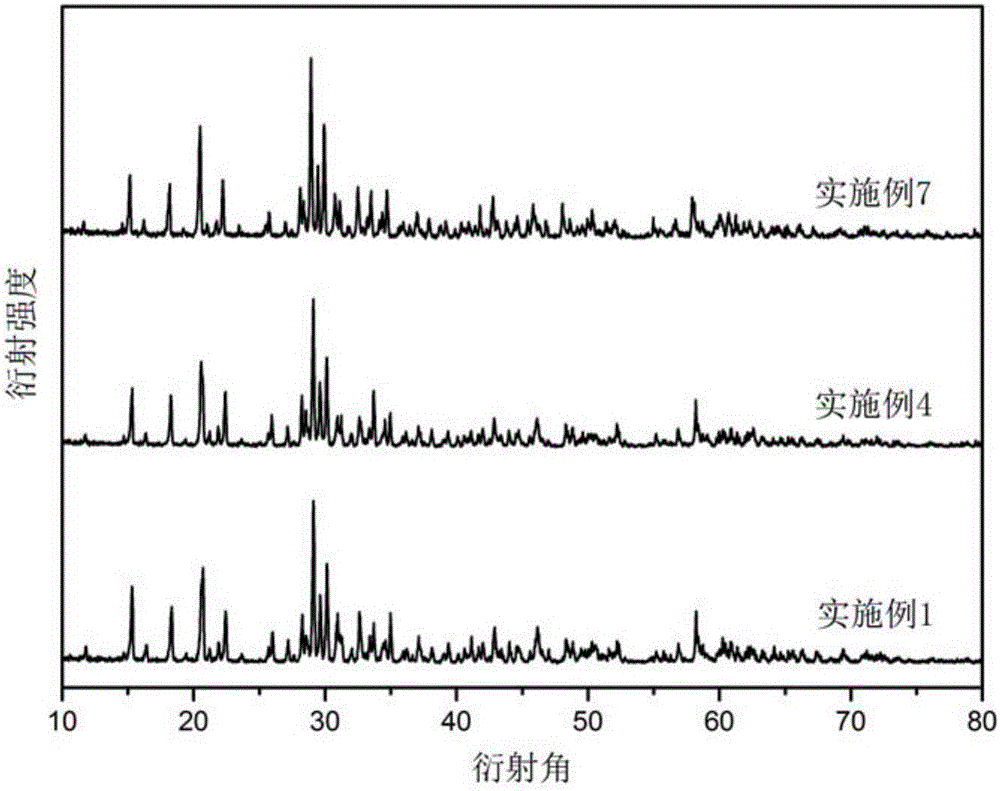

[0048] Example 1: Mg 25 In 30 P 45 o 182.5 Preparation of Phosphor Matrix

[0049] Weigh 0.1947g MgO, 0.8049g In 2 o 3 , 1.0004g NH 4 h 2 PO 4 Put it in a beaker, add an appropriate amount of nitric acid to dissolve the raw materials, add a small amount of polyvinyl alcohol and an appropriate amount of deionized water after the solution is clarified, heat and stir until it is completely evaporated, put the beaker in a drying oven to dry and grind it evenly; then carry out two final steps Sintering (the sintering temperature of the first stage is 1200°C, after 15 hours of heat preservation, it is cooled to room temperature with the furnace, and ground for 10 minutes; the sintering temperature of the second stage is 1200°C, and it is cooled to room temperature with the furnace after 15 hours of heat preservation, and the heating rate of the two steps of sintering is 5 °C / min). Take out the burnt sample and grind it to get Mg 25 In 30 P 45 o 182.5 Phosphor matrix. A...

Embodiment 2

[0050] Example 2: Mg 23 In 29 P 44 o 176.5 Preparation of Phosphor Matrix

[0051] Weigh 0.1851g MgO, 0.8040g In 2 o 3 , 1.0108g NH 4 h 2 PO 4 , the rest of the steps are the same as in Example 1.

Embodiment 3

[0052] Example 3: Mg 27 In 33 P 47 o 194 Preparation of Phosphor Matrix

[0053] Weigh 0.1965g MgO, 0.8272g In 2 o 3 , 0.9763g NH 4 h 2 PO 4 , the rest of the steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence lifetime | aaaaa | aaaaa |

| fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com