A kind of indium phosphobismuth material and its preparation method, laser using the material and its preparation method

A technology of indium phosphobismuth and indium phosphide bismuth, which is applied in the field of materials science, can solve the problems of inability to improve semiconductor performance, limit, narrow band gap, etc., and achieve suppression of Auger recombination effect, increase of spin-orbit splitting, The effect of good semiconductor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

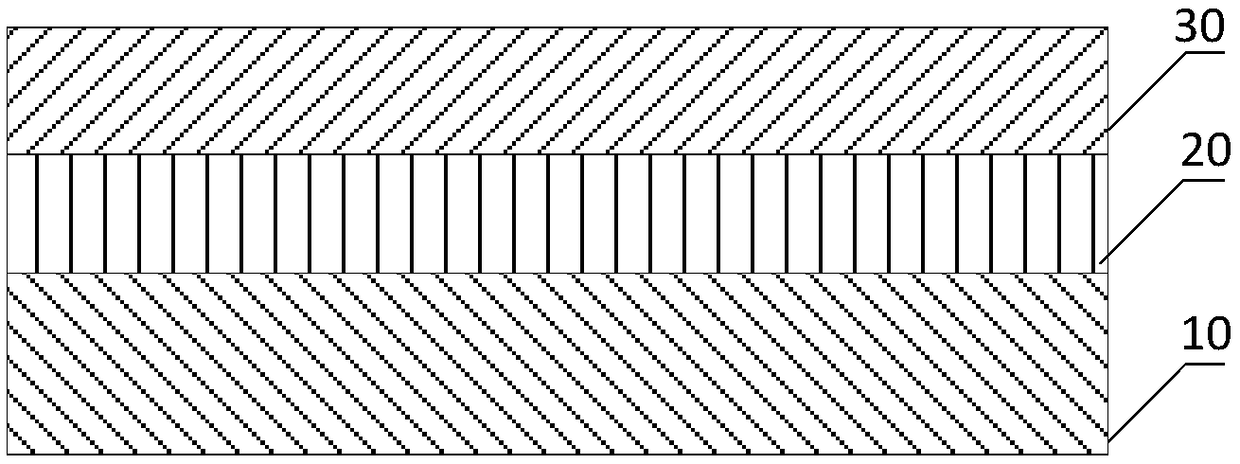

[0048] Please refer to figure 1 , in this embodiment, the indium phosphide bismuth material includes: an indium phosphide substrate 10 , an indium phosphide buffer layer 20 and an indium phosphide bismuth body 30 . Wherein the indium phosphide buffer layer 20 is disposed on the indium phosphide substrate. The indium phosphide bismuth body 30 is disposed on the indium phosphide buffer layer 20 . The chemical formula of indium phosphobismuth bulk is InP 1-x Bi x , where x is the concentration percentage of bismuth atoms, and 3.6≤x≤12.5%. In other embodiments of the present application, the indium phosphide substrate may also be other auxiliary substrates.

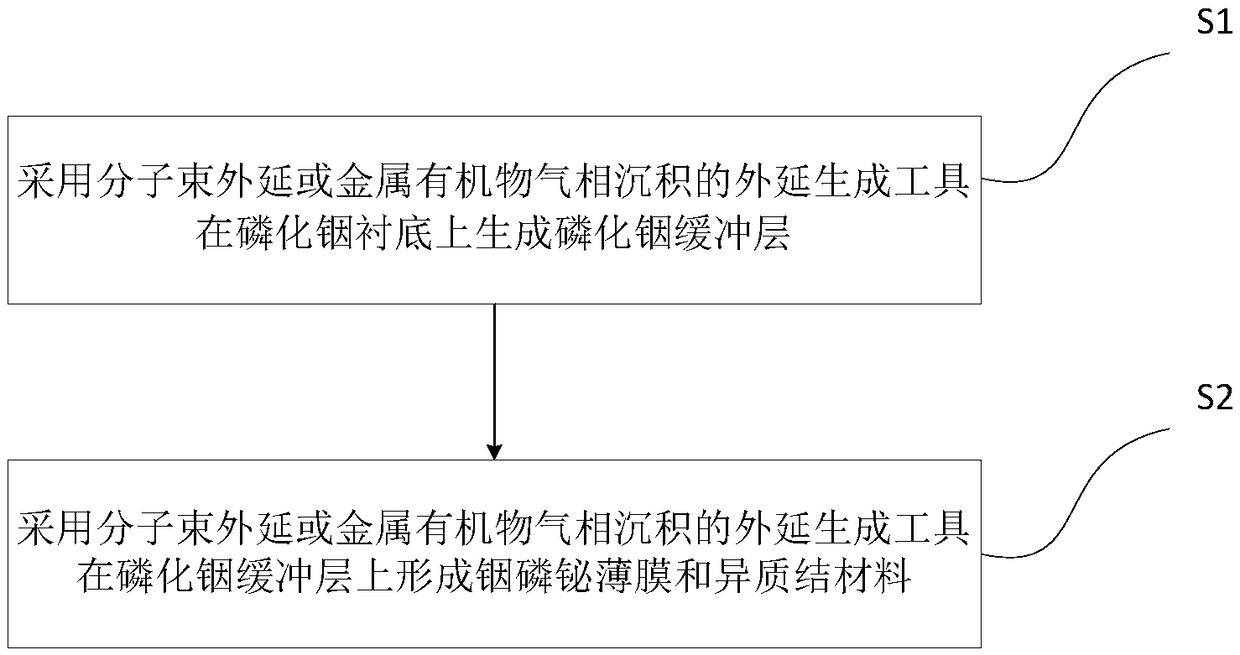

[0049] Please refer to figure 2 , in this embodiment, the preparation method of indium phosphide bismuth material comprises the following steps:

[0050] S1: An indium phosphide buffer layer is formed on an indium phosphide substrate by molecular beam epitaxy or metal-organic vapor deposition.

[0051] S2: Form an ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com