Wet method etching process

A wet etching and process technology, applied in the field of solar cells, can solve the problems of reducing quantum efficiency in the long-wave band, increasing back recombination, and reducing Isc, and achieves the effects of increasing Voc, strengthening back reflection, and increasing Isc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The wet etching process of the crystalline silicon wafer provided in this embodiment comprises the following steps:

[0026] (1) Select cells after doping and diffusion treatment;

[0027] (2) Etch the above cell to remove the surrounding PN junction, etch by chain wet etching, using 3% HF and 40% HNO by mass percentage 3 Mix the solution to remove the PN junction around the silicon wafer;

[0028] (3) Polish the backside of the cell with the peripheral PN junction removed at 5°C for 10 seconds using a polishing solution. The polishing solution used contains the following components in mass percentage: HF10%, HNO 3 55%, H 2 SO 4 10%, acetic acid 5%, and additives ammonium fluoride, potassium nitrite, potassium sulfate 10%;

[0029] (4) 10% HF is used to remove phosphosilicate glass PSG;

[0030] (5) Dry the above-mentioned cell sheets by air drying.

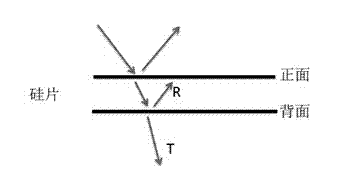

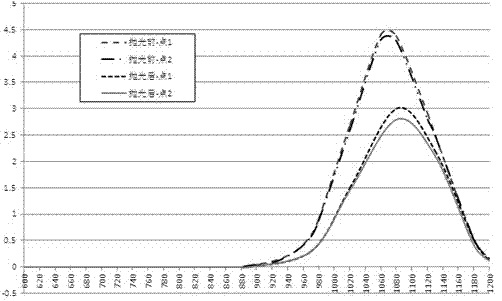

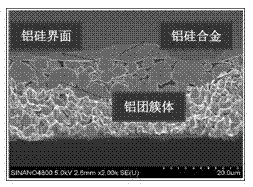

[0031] Such as figure 1 As shown in , after removing the edge junction, increasing the back polishing process c...

Embodiment 2

[0033] The wet etching process of the crystalline silicon wafer provided in this embodiment comprises the following steps:

[0034] (1) Select cells after doping and diffusion treatment;

[0035] (2) Etch the above cell to remove the surrounding PN junction, etch by chain wet etching, using 3% HF and 40% HNO by mass percentage 3 Mix the solution to remove the PN junction around the silicon wafer;

[0036] (3) Remove phosphosilicate glass PSG by mass percentage content 5% HF;

[0037] (4) Polish the backside of the cell with the peripheral PN junction removed at 30°C for 10 minutes with a polishing solution. The polishing solution used contains the following components in mass percentage: HF 0.5%, HNO 3 5%, H 2 SO 4 50%, acetic acid 30% and additives potassium nitrite, potassium citrate, potassium lauryl sulfate 10%;

[0038] (5) Dry the above-mentioned cells by spinning.

[0039] Such as figure 1 As shown in , after removing the edge junction, increasing the back poli...

Embodiment 3

[0042] The wet etching process of the crystalline silicon wafer provided in this embodiment comprises the following steps:

[0043] (1) Select cells after doping and diffusion treatment;

[0044] (2) Etch the above-mentioned cells to remove the surrounding PN junctions, and dry plasma etching is used for etching;

[0045] (3) 20% HF by mass percentage is used to remove phosphosilicate glass PSG;

[0046] (4) Polish the backside of the cell with the peripheral PN junction removed at 15°C for 5 minutes using a polishing solution. The polishing solution used contains the following components in mass percentage: HF 1%, HNO 3 30%, H 2 SO 4 5%, acetic acid 25% and additives ammonium fluoride, potassium nitrite, potassium citrate, potassium lauryl ether phosphate and potassium lauryl sulfate 20%;

[0047] (5) Dry the above-mentioned cell sheets by air drying.

[0048] Such as figure 1 As shown in , after removing the edge junction, increasing the back polishing process can ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com