Strain multiple quantum well laser device based on GeSn/SiGeSn material and manufacturing method thereof

A technology of strained multiple quantum well and fabrication method, applied in the field of strained multiple quantum well laser, can solve the problem of increasing the carrier concentration, weakening the optical gain of the laser, increasing the threshold value of the laser, etc., so as to reduce the threshold value and improve the absorption coefficient. , the effect of reducing the band gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

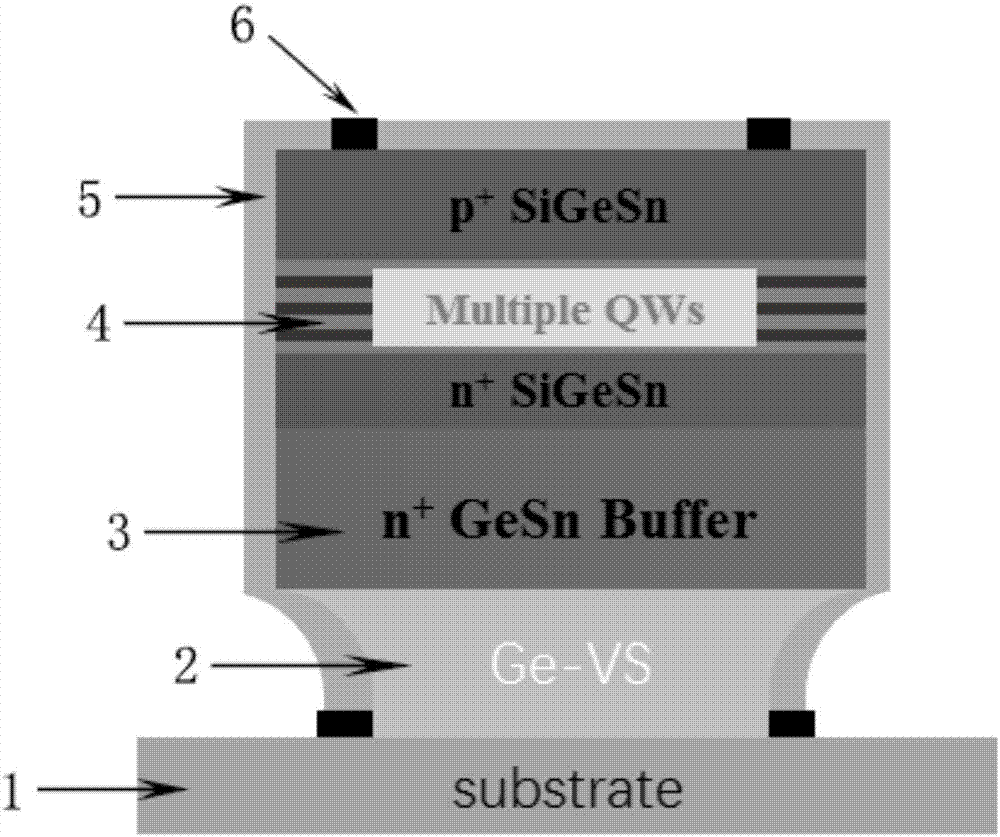

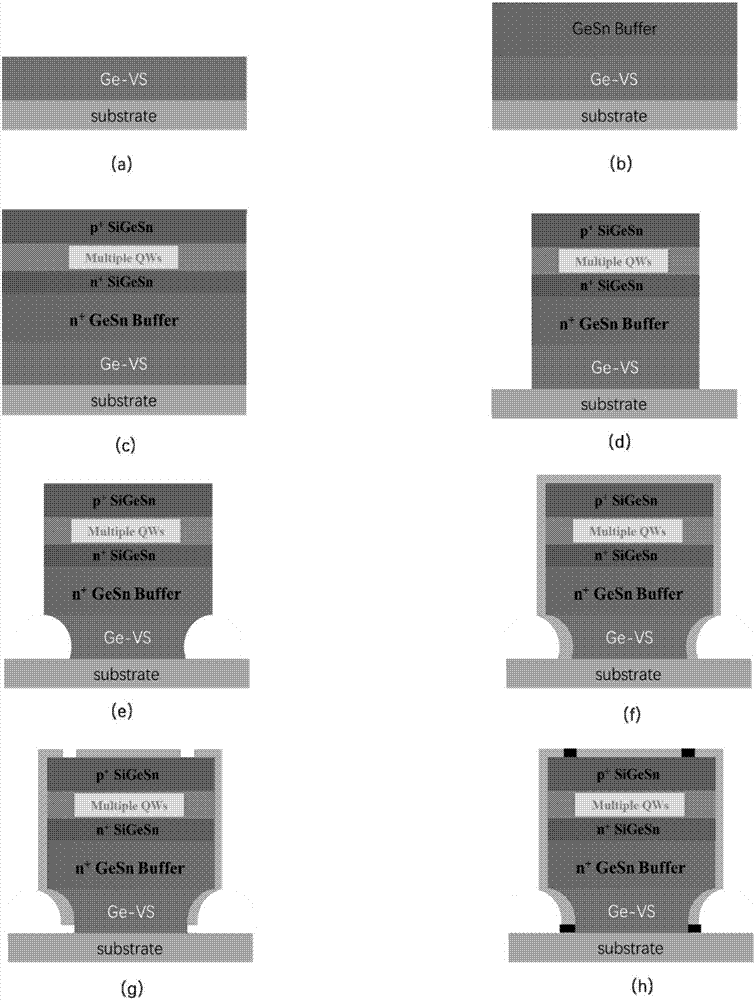

[0044] Example: Ge 0.9 sn 0.1 / Ge 0.695 Si 0.161 sn 0.144 Fabrication method of strained multiple quantum well laser.

[0045] Step 1: Prepare a Ge pseudosubstrate.

[0046] Using the solid-source molecular beam epitaxy process, on the undoped (100) Si substrate (1), the GeH 4 As a Ge source, after growing a 30nm thick Ge buffer layer in an environment of 350°C, the temperature was quickly raised to 600°C and epitaxially grown several hundred nanometers of Ge film as a pseudo-substrate such as figure 2 (a);

[0047] Step 2: Phosphorus ion implantation.

[0048] At an energy of 50KeV and an implant dose of 10 15 cm -2 , The implanted ions are P(31) under the condition that the substrate is tilted at an angle of 7° + Phosphorus ion implantation process to form Ge N + Type pseudosubstrate (2);

[0049] Step 3: Prepare a GeSn buffer layer.

[0050] Using low-temperature solid-source molecular beam epitaxy, the Ge N + Intrinsic Ge with a thickness of 100nm was epitax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com