Low-roll-off quasi-two-dimensional perovskite light emitting diode and preparation method thereof

A technology of light-emitting diodes and perovskites, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices. It can solve the problems of device efficiency roll-off, many thin film grain boundaries, and poor film quality, etc., to achieve suppression efficiency Roll-off, suppression of non-radiative recombination, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

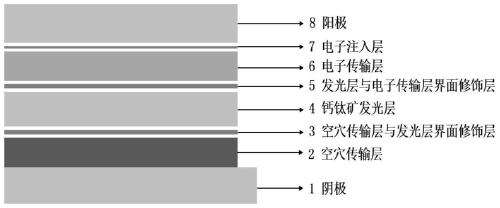

[0050] In this example, see figure 1, a low-roll-off quasi-two-dimensional perovskite light-emitting diode, in which a cathode (1), a hole transport layer (2), an interface modification layer (3) between the hole transport layer and the light-emitting layer, and a perovskite Mineral luminescent layer (4), luminescent layer and electron transport interface modification layer (5), electron transport layer (6), electron injection layer (7), anode (8);

[0051] The thickness of the negative electrode (1) is 150nm, and the grid (1) adopts ITO conductive glass film; the thickness of the hole transport layer (2) is 50nm, and the hole transport layer (2) adopts PEDOT: Made of PSS; the thickness of the interface modification layer (3) between the hole transport layer and the light-emitting layer is 10nm, and cesium carbonate (Cs 2 CO 3 ) is made; the thickness of the perovskite light-emitting layer (4) is 100nm; the thickness of the light-emitting layer and the electron transport int...

Embodiment 2

[0075] This embodiment is basically the same as Embodiment 1, especially in that:

[0076] In this example, see figure 1 , a low-roll-off quasi-two-dimensional perovskite light-emitting diode, in which a cathode (1), a hole transport layer (2), an interface modification layer (3) between the hole transport layer and the light-emitting layer, and a perovskite Mineral luminescent layer (4), luminescent layer and electron transport interface modification layer (5), electron transport layer (6), electron injection layer (7), anode (8);

[0077] The thickness of the negative electrode (1) is 100nm, and the grid (1) adopts ITO conductive glass film; the thickness of the hole transport layer (2) is 40nm, and the hole transport layer (2) adopts PEDOT: Made of PSS; the thickness of the interface modification layer (3) between the hole transport layer and the light-emitting layer is 1nm, and cesium carbonate (Cs 2 CO 3 ) is made; the thickness of the perovskite light-emitting layer (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com