Extension developing method for high-power semiconductor quanta point laser material

A technology of quantum dots and quantum dot materials, applied in the field of semiconductor lasers, can solve the problems of quantum dot disorder, distribution uniformity and difficult density control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with accompanying drawing

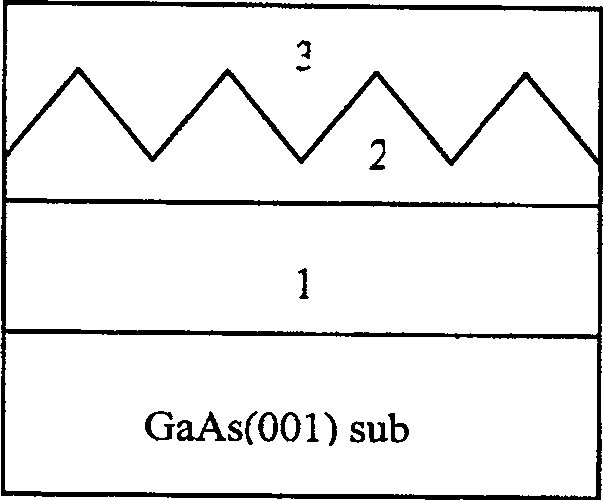

[0053] figure 1 It is the core idea of the present invention, that is, the formation process of epitaxial growth of high-density quantum dots.

[0054] Firstly, a GaAs transition layer 1 is formed on a GaAs(001) substrate with a thickness of 300-500nm and a growth temperature of 600-610°C, and then pause for 20-40 seconds while lowering the temperature to 480-520°C;

[0055] Secondly, the InGaAs quantum dot structure 2 is grown on the GaAs transition layer 1 with a thickness of 5-8ML. The layer point is grown according to the following steps: first, deposit an InAs material layer with a thickness of 0.7-1.4ML, a growth rate of 0.2-0.5ML / s, a temperature of 480-510°C, and a pause of 1-10 seconds, and then deposit a GaAs layer , the thickness is 0.7-1.4ML, the growth rate is 0.2-0.5ML / s, the temperature is 480-510°C, and the pause is 1-10 seconds; repeat the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com