Ge/gesn heterojunction laser and its preparation method

A laser and heterojunction technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of many high-reflection coating layers, difficult process, easy to fall off, etc., to improve the limiting factor, simple process, Loss factor reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In order to solve the problem that the luminous efficiency of the traditional Ge-based laser is not high, the threshold current density is relatively large, and its preparation process is difficult, this embodiment provides a method for preparing a Ge / GeSn heterojunction laser and the Ge / GeSn heterojunction laser prepared by this method. GeSn heterojunction lasers.

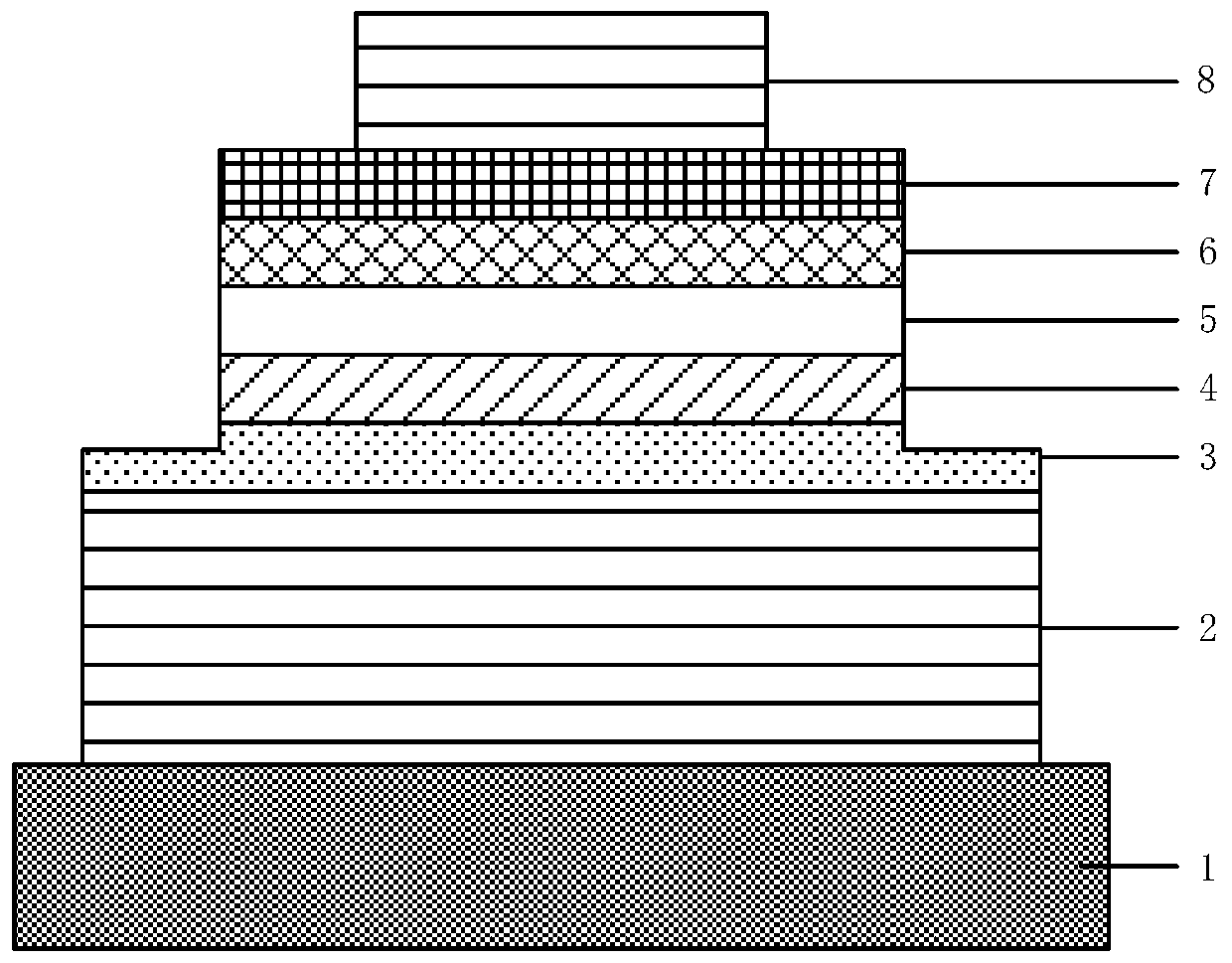

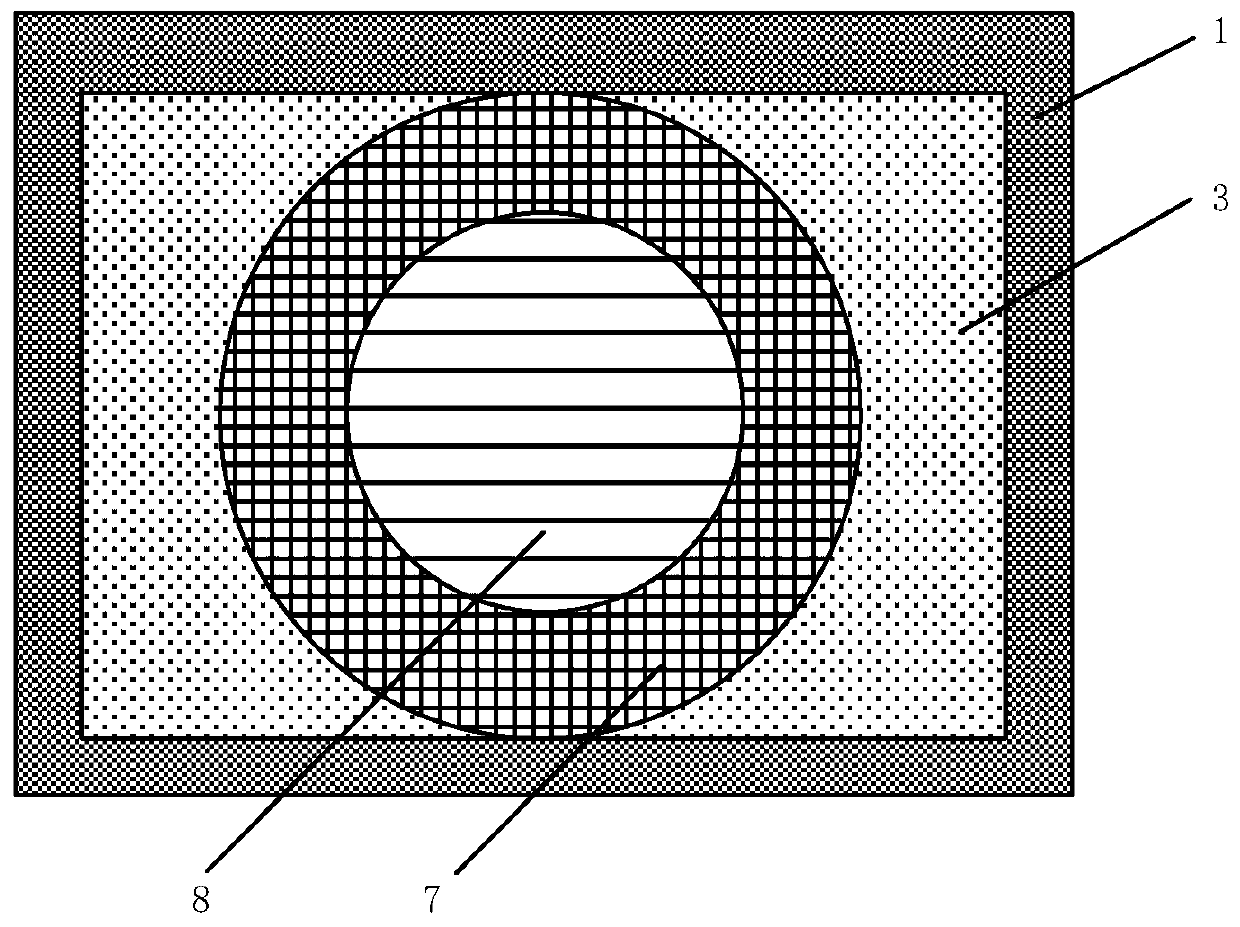

[0049] See figure 1 and figure 2 , figure 1 It is a schematic cross-sectional view of a Ge / GeSn heterojunction laser of the present invention, figure 2 It is a schematic top view of the Ge / GeSn heterojunction laser of the present invention. The Ge / GeSn heterojunction laser structure of the present invention is as follows from bottom to top: substrate 1, first Bragg mirror layer 2, first n-type Ge layer 3, second n-type Ge layer 4, GeSn layer 5, The first p-type Ge layer 6, the second p-type Ge layer 7, the second Bragg mirror layer 8; the second Bragg mirror layer 8 is columnar, the first n-type Ge la...

Embodiment 2

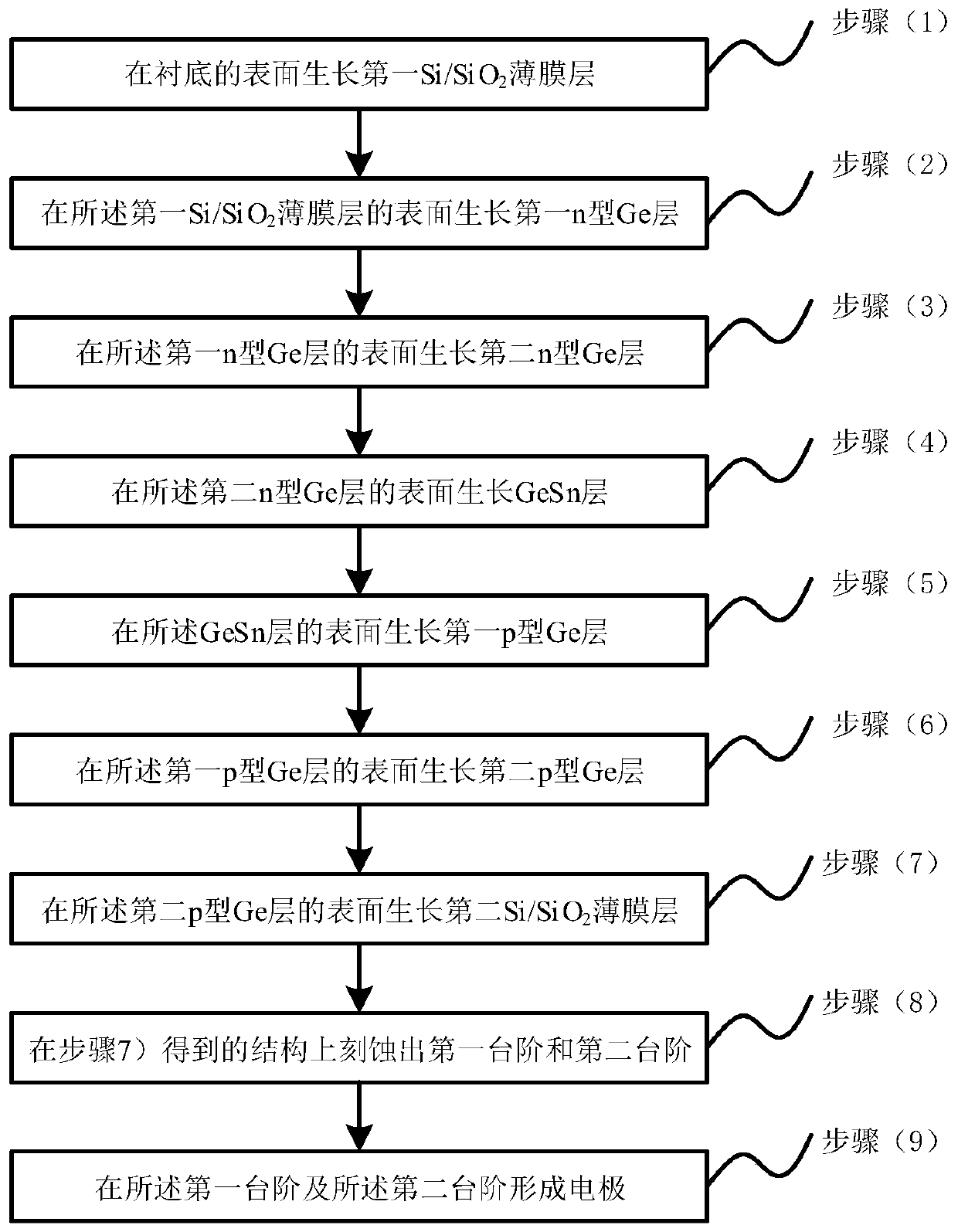

[0085] See 4(a) to 4(h), and figure 1 In this embodiment, on the basis of the above-mentioned embodiments, the preparation method of the Ge / GeSn heterojunction laser and the prepared Ge / GeSn heterojunction laser of the present invention are described in detail as follows:

[0086] Step (1), please refer to Fig. 4 (a), select the silicon material on the insulator or the bulk silicon material as the substrate, usually the substrate 1 is rectangular, and use plasma enhanced chemical vapor deposition (PECVD) to grow the first Si / SiO 2 film layer.

[0087] The switch of the mass flowmeter is controlled by the computer, so that the reaction gas in the reaction chamber alternates in the SiH 4 (+Ar) and O 2 Exchange between, so that the decomposition of SiH 4 Deposition of polysilicon film and pure oxygen layer-by-layer plasma oxidation are carried out alternately.

[0088] The substrate 1 temperature was kept at 250°C, Si and SiO 2 The thicknesses are 143nm and 233nm respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com