Method for manufacturing semiconductor laser diode and semiconductor laser diode

A technology of laser diode and manufacturing method, which is applied to the structural details of semiconductor lasers, the structure of semiconductor lasers, and optical waveguide semiconductors, etc., can solve the problems of light absorption on the end face of resonators and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

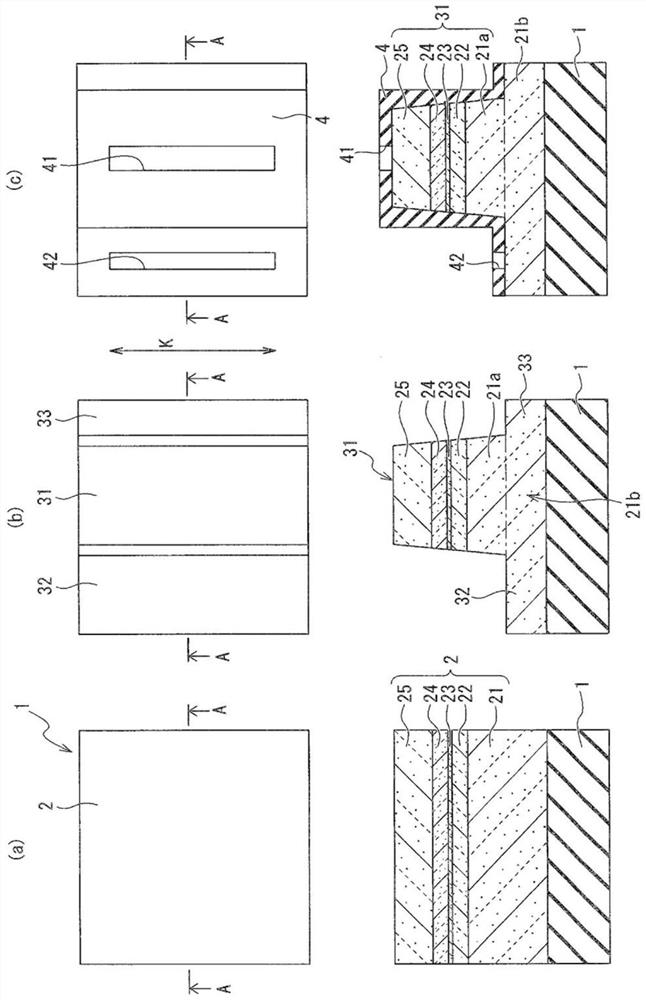

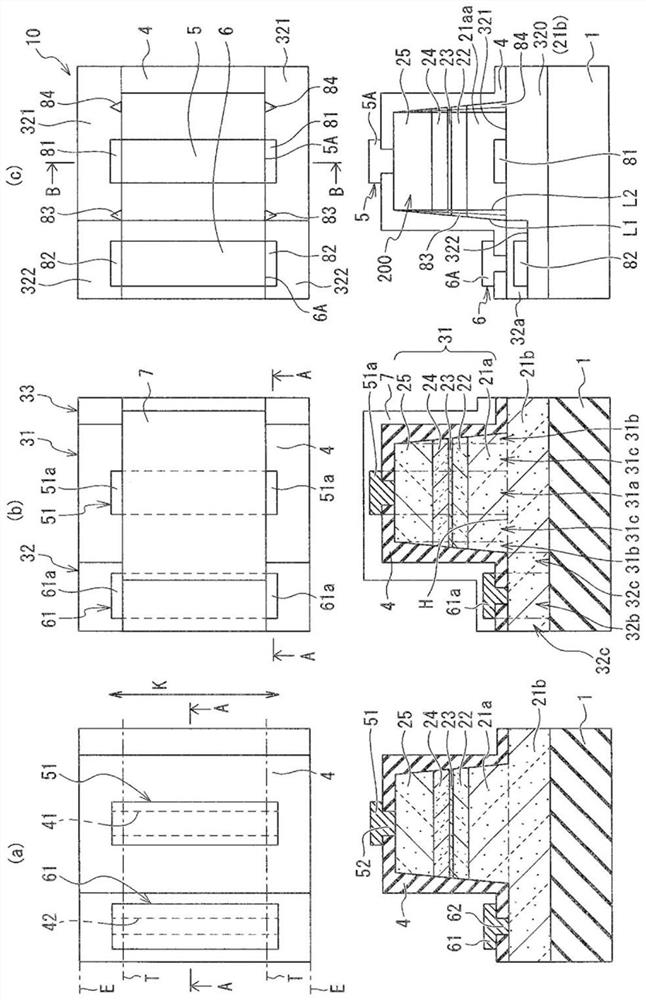

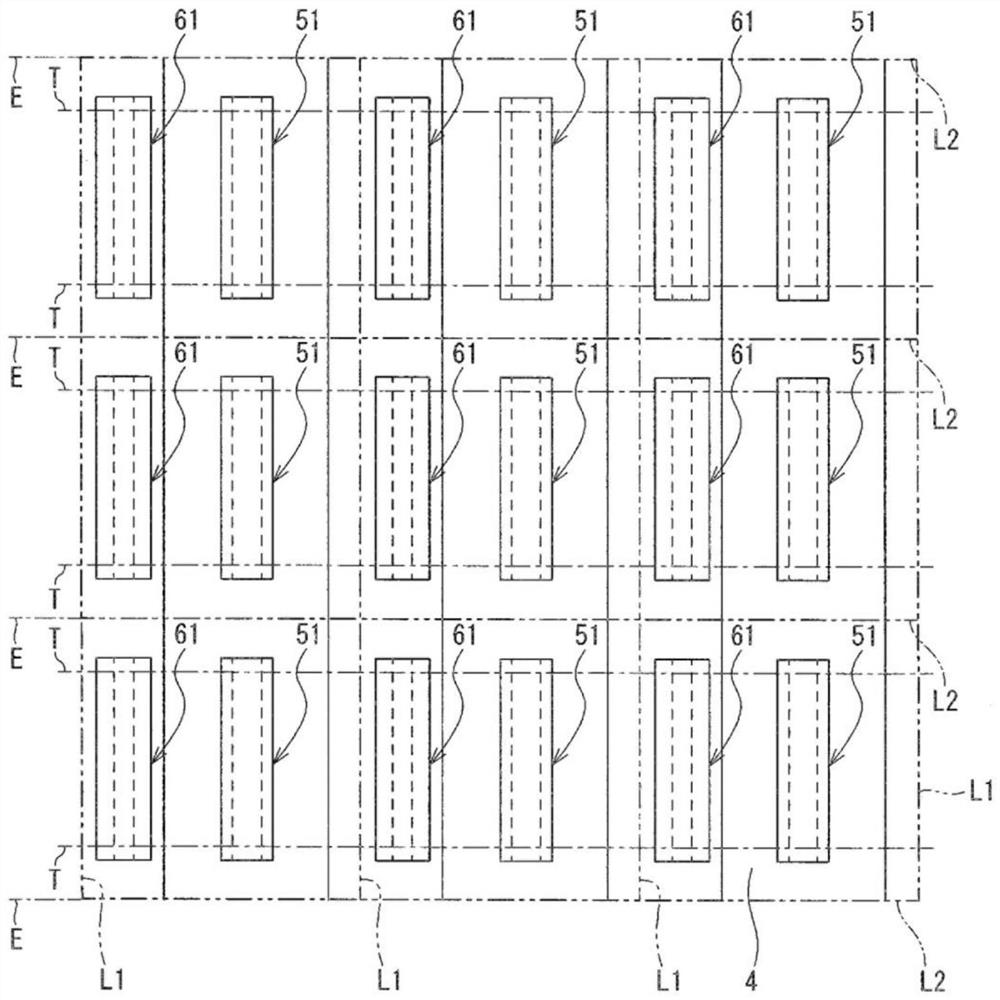

Embodiment Construction

[0041]Obtained the following insight: when the resonator end face is formed by using the etching technique, the resonator end face and the end face in the resonance direction of the resonance region of the second electrode are not in the same plane, and the resonator end face exists in a plane that is lower than that of the electrode when viewed from above. This is one of the reasons for increasing the threshold current density.

[0042] In addition, it was found that: before the process of dividing, if the inspection of the characteristics of each semiconductor laser diode is performed by contacting the terminal connected to the external power supply with the second electrode and the first electrode, the defective wafer can be removed and the reduction can be reduced. manufacturing cost.

[0043] [implementation mode]

[0044] Embodiments of the present invention will be described below, but the present invention is not limited to the embodiments shown below. In the embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com