Method for mixing organic gallium source selective zone growing indium-gallium-arsenic-phosphor multiple quantum well

A technology of multiple quantum wells and indium gallium arsenide phosphide, applied in the field of optimized selective growth technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

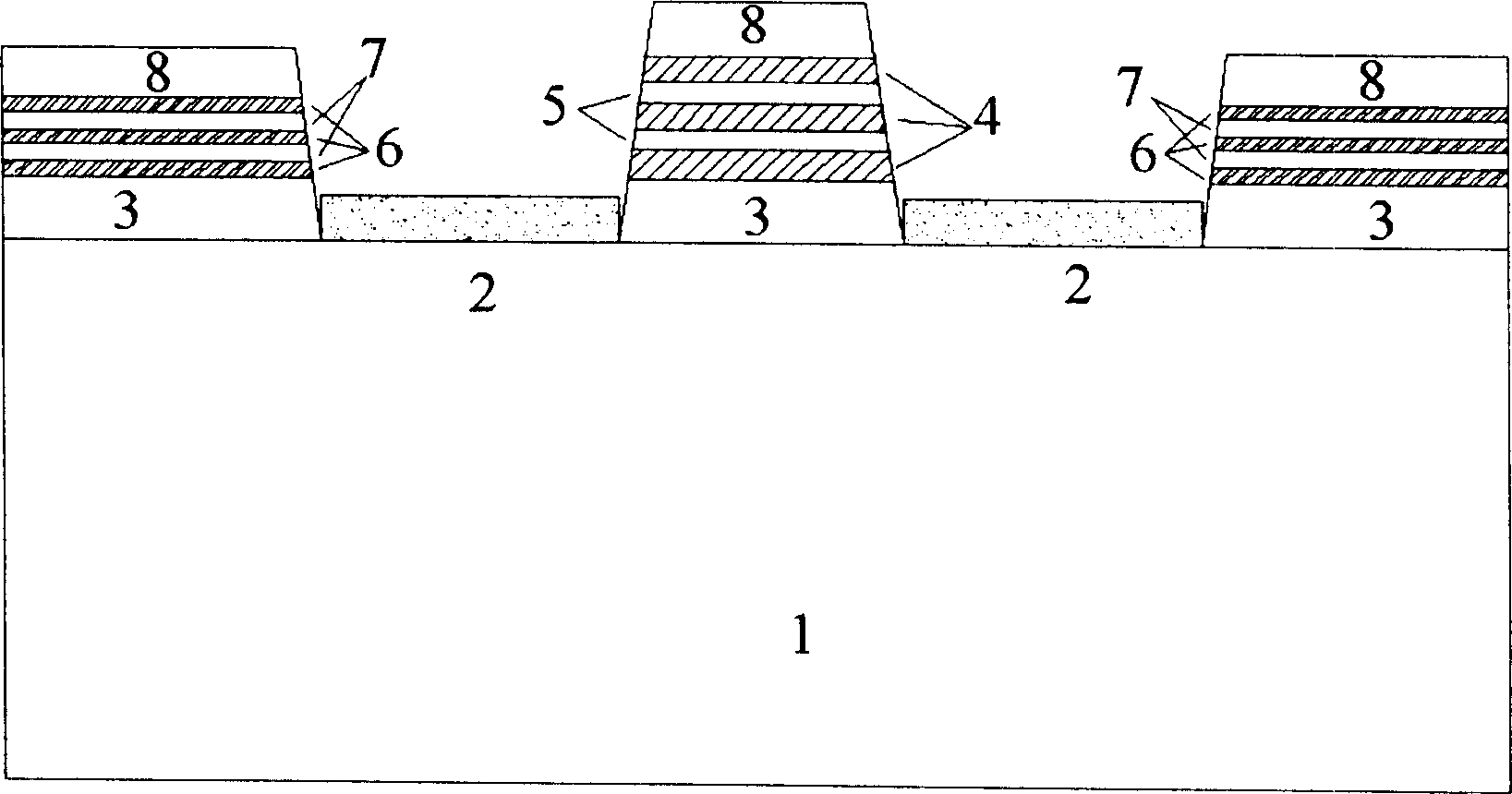

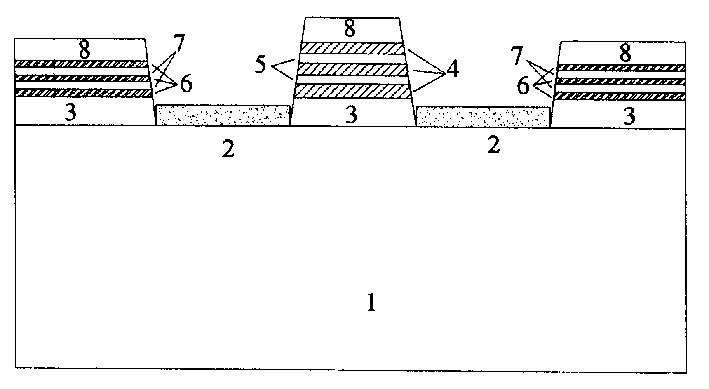

[0018] In order to make an electroabsorption modulated laser, the energy bandgap difference between the selected region and the non-selected region material is required to be greater than 30meV, which can be achieved in two ways: increasing the thickness of the quantum well in the selective growth region or increasing the strain of the quantum well in the selective growth region. When TMGa and TMIn are used to grow quantum wells, because the cracking temperature of TMGa is lower than that of TMIn, more indium diffuses to the selective growth region through gas phase diffusion, so the strain of the well in the selective growth region increases, and the thickness also increases to a certain extent. The energy bandgap difference of materials inside and outside the growth region can meet the requirements, but the strain of the barrier also increases at the same time, so that the material can easily reach the critical thickness and generate dislocations, thereby reducing the luminous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com