A single-mode silicon-based hybrid laser light source with silicon waveguide output

A technology of laser light source and silicon waveguide, which is applied in the direction of semiconductor lasers, optical waveguide semiconductor structures, lasers, etc., can solve problems such as limiting the development of single-mode silicon-based hybrid semiconductor lasers, reducing laser mode gain, and increasing threshold current density. Facilitate large-scale production, achieve single longitudinal mode output, and reduce the effect of threshold current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

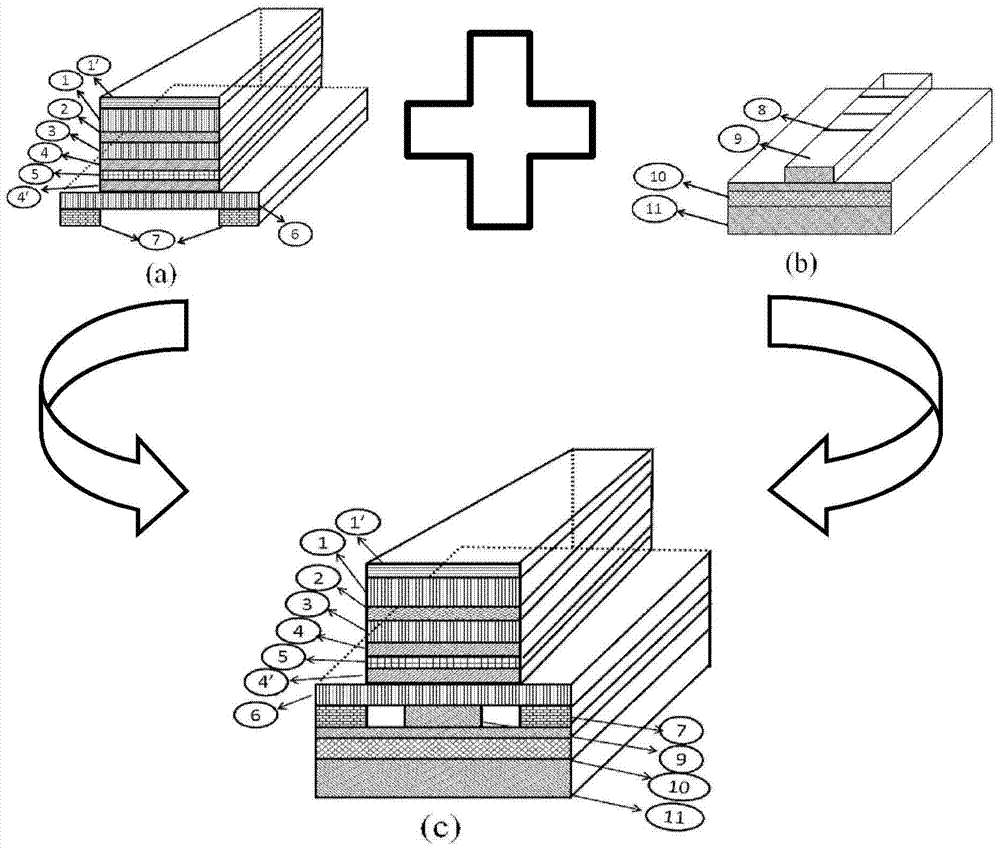

[0040] figure 1 (a) to figure 1 (c) is a schematic diagram of the evolution of the three-dimensional structure of a single-mode silicon-based hybrid laser light source output by a silicon waveguide according to an embodiment of the present invention. figure 1 (a) is a III-V taper gain structure, where the length of the taper is 500 μm and the width of the top is 0.4 μm; figure 1 (b) is an SOI ridge waveguide structure, in which the height of the silicon on the top layer of SOI is 0.34 μm, and the etching depth of the silicon waveguide and the periodic microgrooves are both 0.2 μm; figure 1 (c) is a single-mode silicon-based hybrid laser light source obtained after reflow soldering. The reflow soldering metal is an AuSn alloy, which forms an ohmic contact after annealing and is used as the negative electrode of the device; the lasing wavelength of the single-mode silicon-based hybrid laser source is 1490nm. The total device length is 1000 μm.

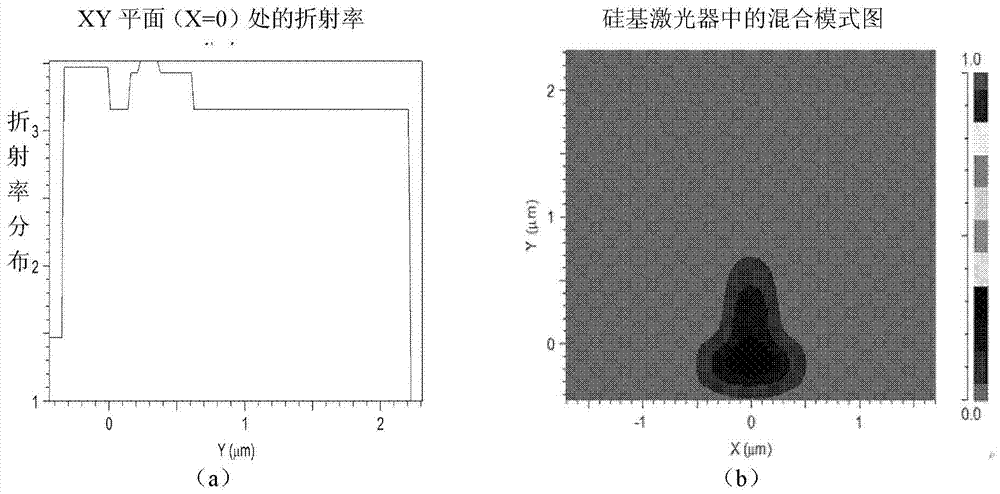

[0041] figure 2 (a) is a sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com