Making method for micro-hole vertical cavity radiation laser

A vertical cavity surface emission, laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of low yield, poor process repeatability, short device life and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

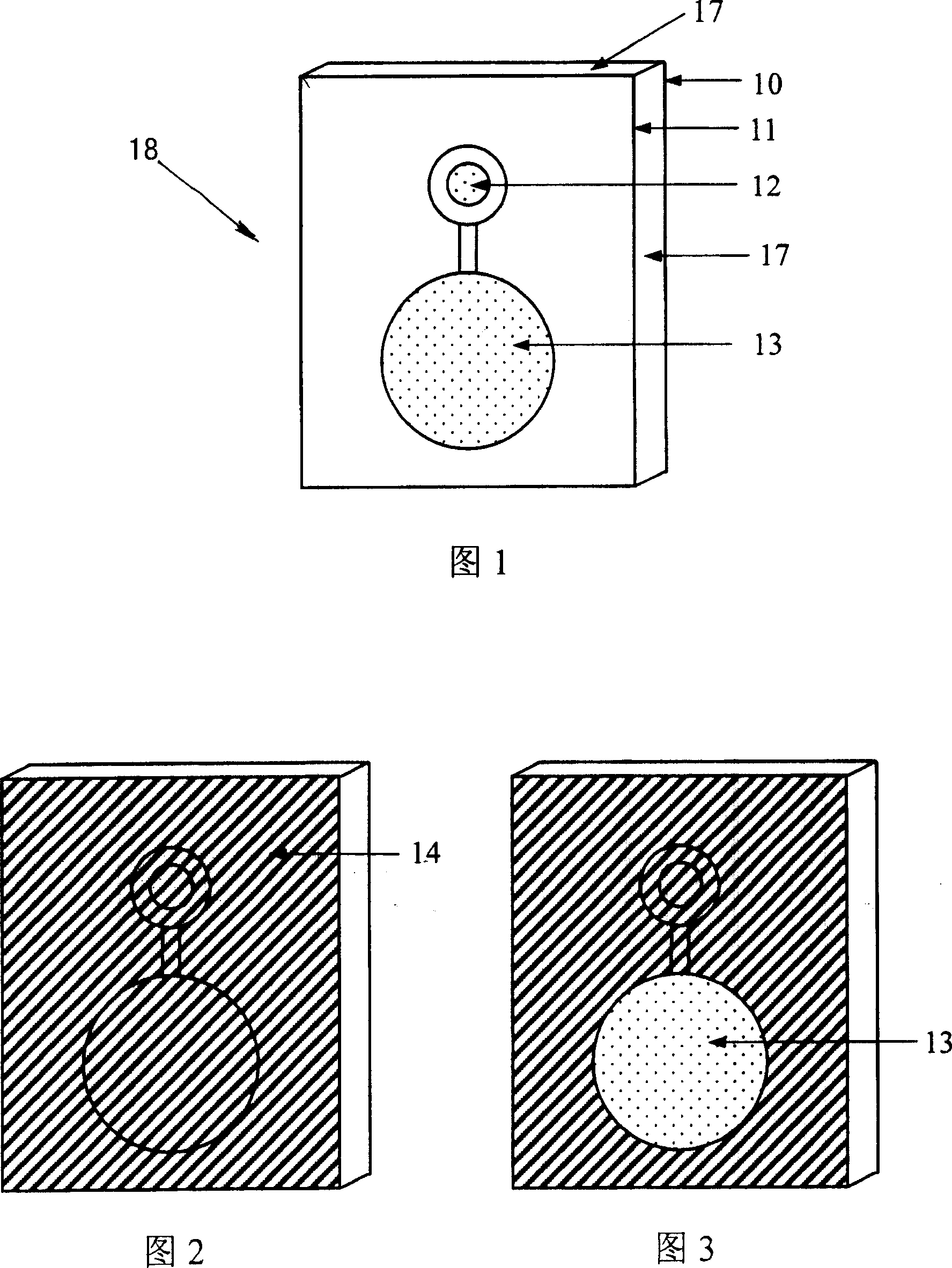

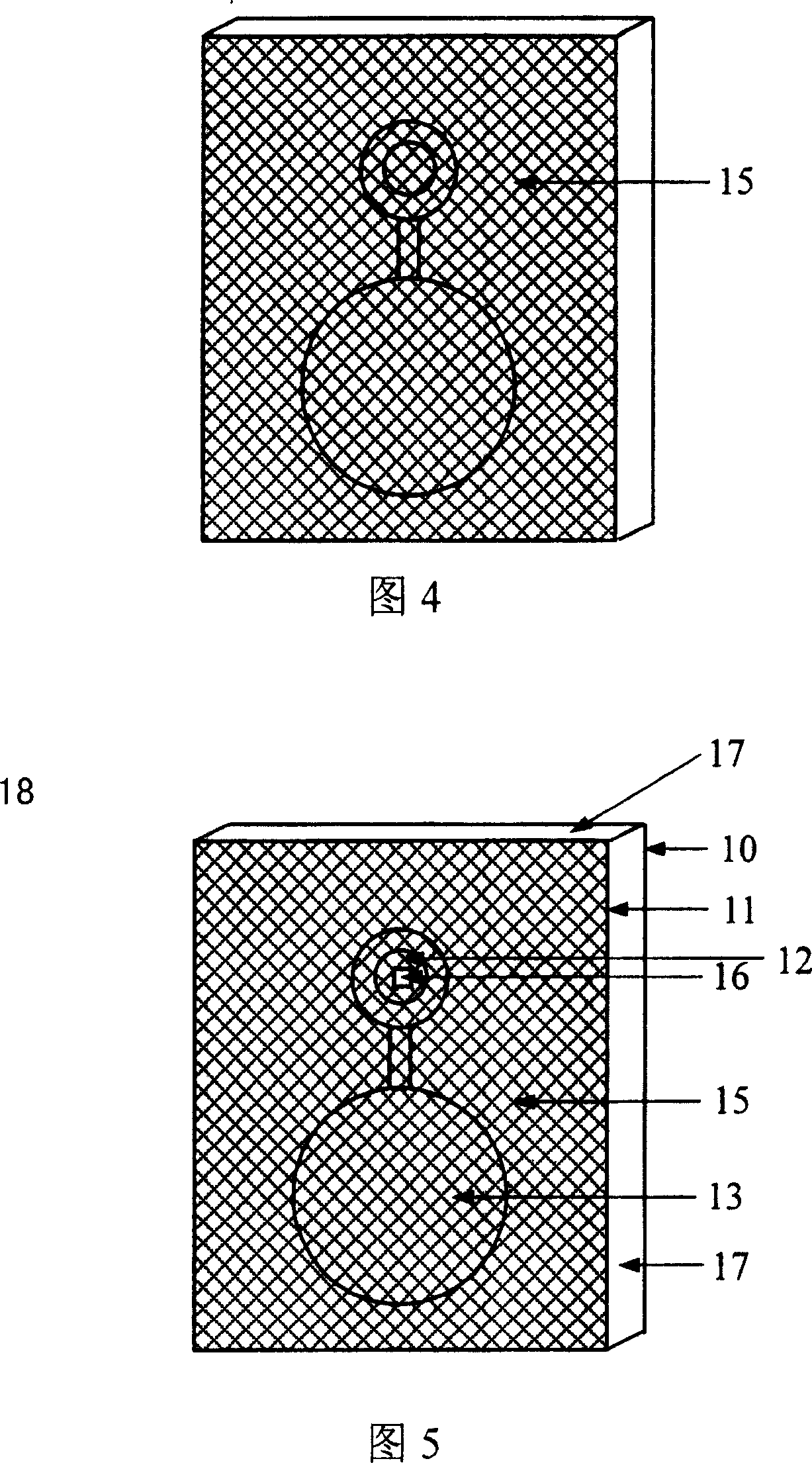

[0026] Please refer to Fig. 1-shown in Fig. 5, a kind of micro hole vertical cavity surface emitting laser of the present invention, comprises the following steps:

[0027] (1) Deposit an anti-reflection film 14 by electron cyclotron resonance plasma chemical vapor deposition (ECR plasma CVD) on the light exit cavity surface 11 of a common VCSEL (Fig. 1), as shown in Fig. 2, the material is SiO 2 and SiN x mixture, or for Al 2 o 3 , MgF and other materials, the thickness is 200nm-400nm. The anti-reflection film 14 is used as an insulating film to avoid direct contact between the metal and the light exit cavity surface 11 in the next step, thereby protecting the light exit cavity surface 11 .

[0028] (2) Etching away the anti-reflection film 14 on the P-surface electrode 13 by using a focused ion beam system, as shown in FIG. 3 , so that the P-surface electrode 13 and the N-surface electrode 10 can form a current injection channel. The etching time is 30s-120s.

[0029] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com