Epitaxial structure with interposed layer quantum well semiconductor laser

A technology of epitaxial structure and insertion layer, applied in the field of epitaxial structure, can solve the problem of difficult to obtain interface quality quantum well and quantum barrier layer and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

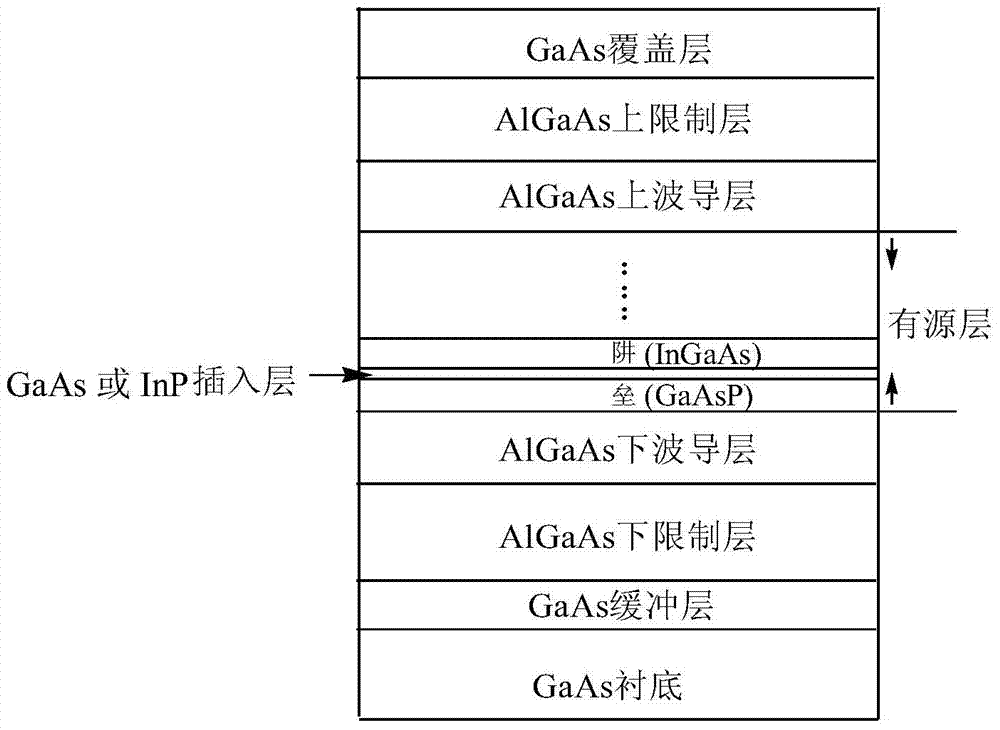

[0010] Reference attached figure 1 , The invention relates to an epitaxial structure of a semiconductor laser with an insertion layer quantum well, and the invention discloses a preparation method of a semiconductor laser with a special structure. The structure includes from bottom to top: GaAs substrate; GaAs buffer layer; AIGaAs lower confinement layer; AIGaAs lower waveguide layer; active layer is InGaAs / GaAsP (the insertion layer in the active layer is GaAs or InP); Waveguide layer; AIGaAs upper confinement layer; GaAs cladding layer. In this structure, a thin layer of GaAs or InP is inserted between the quantum well of the active layer and the barrier, which can effectively alleviate the lattice adaptation between the quantum well and the barrier, improve the interface quality, reduce the stress, and obtain a higher The low threshold current density improves the optoelectronic performance of semiconductor laser devices.

Embodiment 2

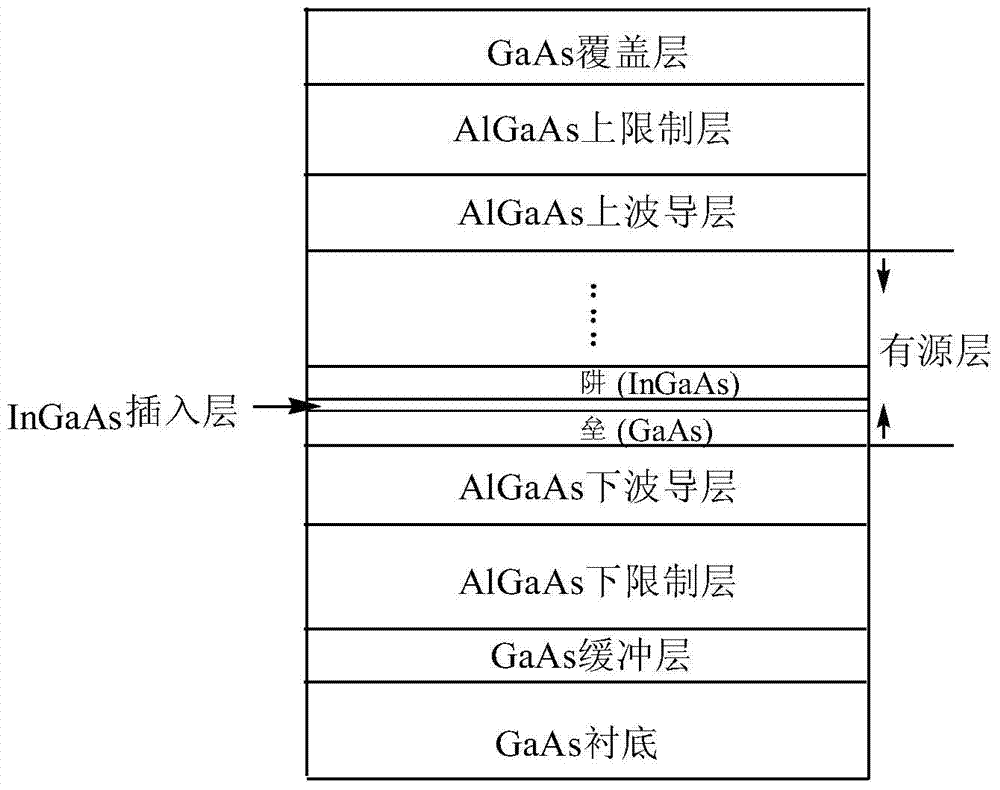

[0012] Reference attached figure 2 , The invention relates to an epitaxial structure of a semiconductor laser with an insertion layer quantum well, and the invention discloses a preparation method of a semiconductor laser with a special structure. The structure includes from bottom to top: GaAs substrate; GaAs buffer layer; AIGaAs lower confinement layer; AIGaAs lower waveguide layer; layer); AIGaAs upper waveguide layer; AIGaAs upper confinement layer; GaAs cladding layer. The content of In in the InGaAs insertion layer with relatively low content of In is between 0.02 and 0.1 (mole mass fraction). The period number of the active layer is 5-10, and the In content is between 0.16-0.2 (mole mass fraction). In this structure, a thin layer of InGaAs is inserted between the quantum wells and the barriers of the active layer, which can effectively reduce the lattice mismatch between the quantum wells and the barriers, smooth the interface components, and eliminate stress, thereb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com