Method for preparing wave guide and grating structure of adjustable distributive feedback quantum cascade laser and above said grating

A technology of distributed feedback and quantum cascade, which is applied in the structure of optical waveguide semiconductors, the structure of optical resonators, lasers, etc., can solve the problem of rising laser threshold current density, increasing laser waveguide loss, laser mode and plasmon coupling Strong and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 18

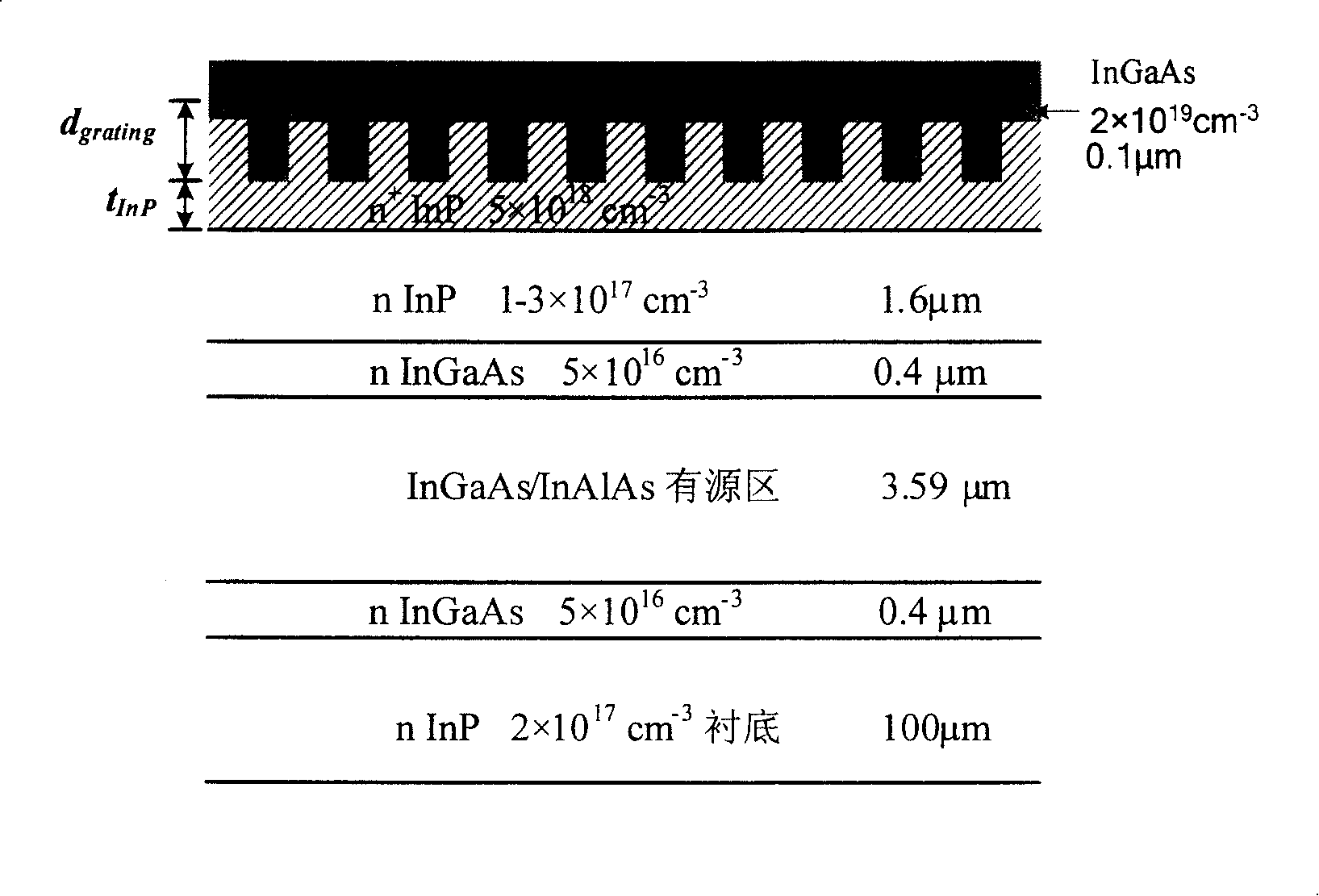

[0041] Embodiment 18.4 μm InGaAs / AlInAs / InP distributed feedback quantum cascade laser

[0042] figure 1 A schematic diagram of the waveguide and grating structure of the InGaAs / AlInAs / InP tunable distributed feedback quantum cascade laser with a wavelength of 8.4 μm. The active layer region includes 60 periods of "active layer + injection region" structure with a thickness of 3.59 μm. The thickness of the upper and lower active regions is 0.4 μm, and the n-type doping concentration is 5×10 16 cm -3 InGaAs waveguide layer. Above the upper waveguide layer is an n-type moderately doped confinement layer InP (1-3×10 17 cm -3 , thickness 1.6μm), n-type heavily doped InP confinement layer (5×10 18 cm -3 , thickness 1.0μm), and n-type heavily doped InGaAs capping layer (2×10 19 cm -3 , thickness 0.1 μm). The substrate is moderately doped n-type InP (2×10 17 cm -3 ).

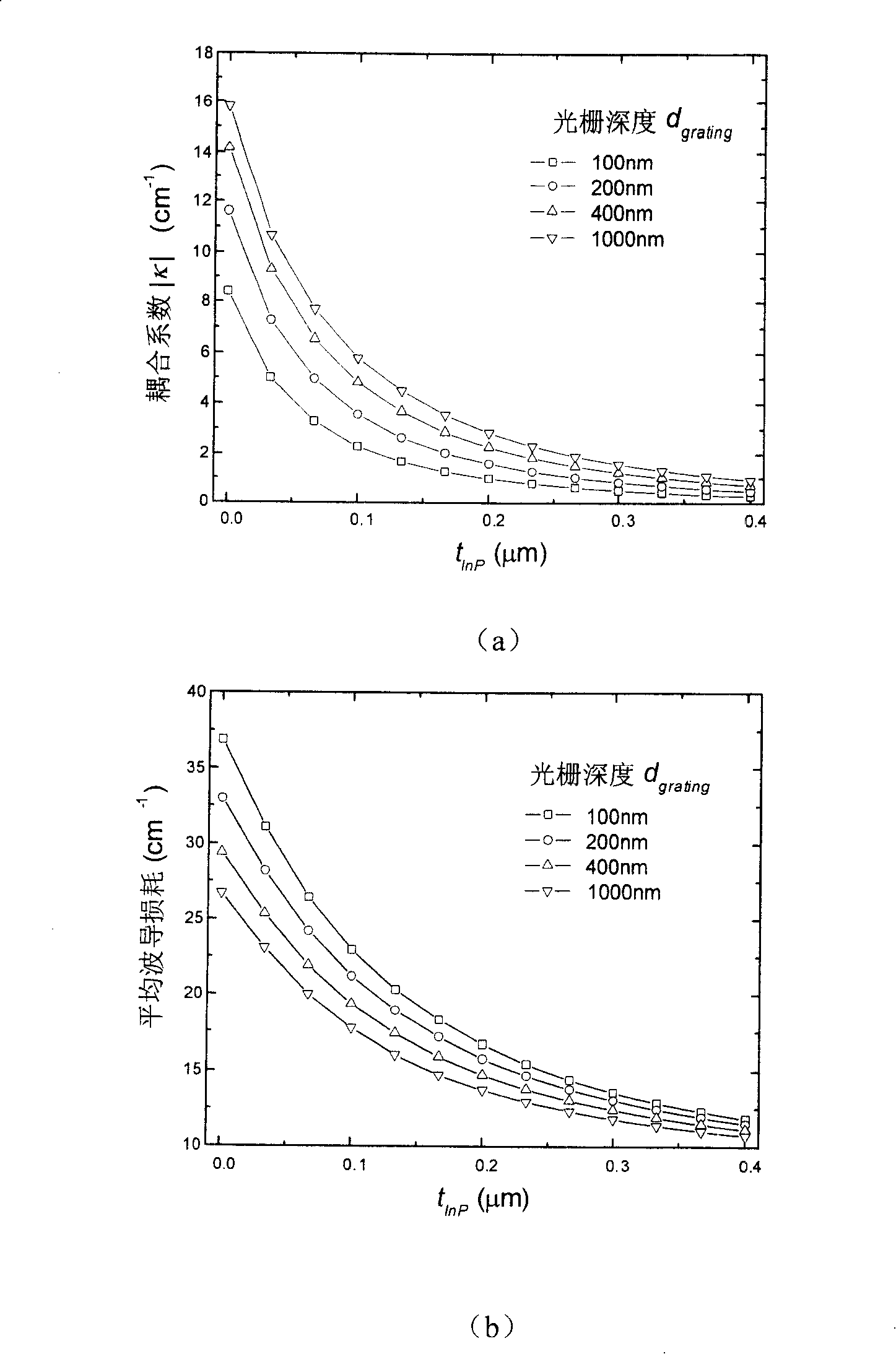

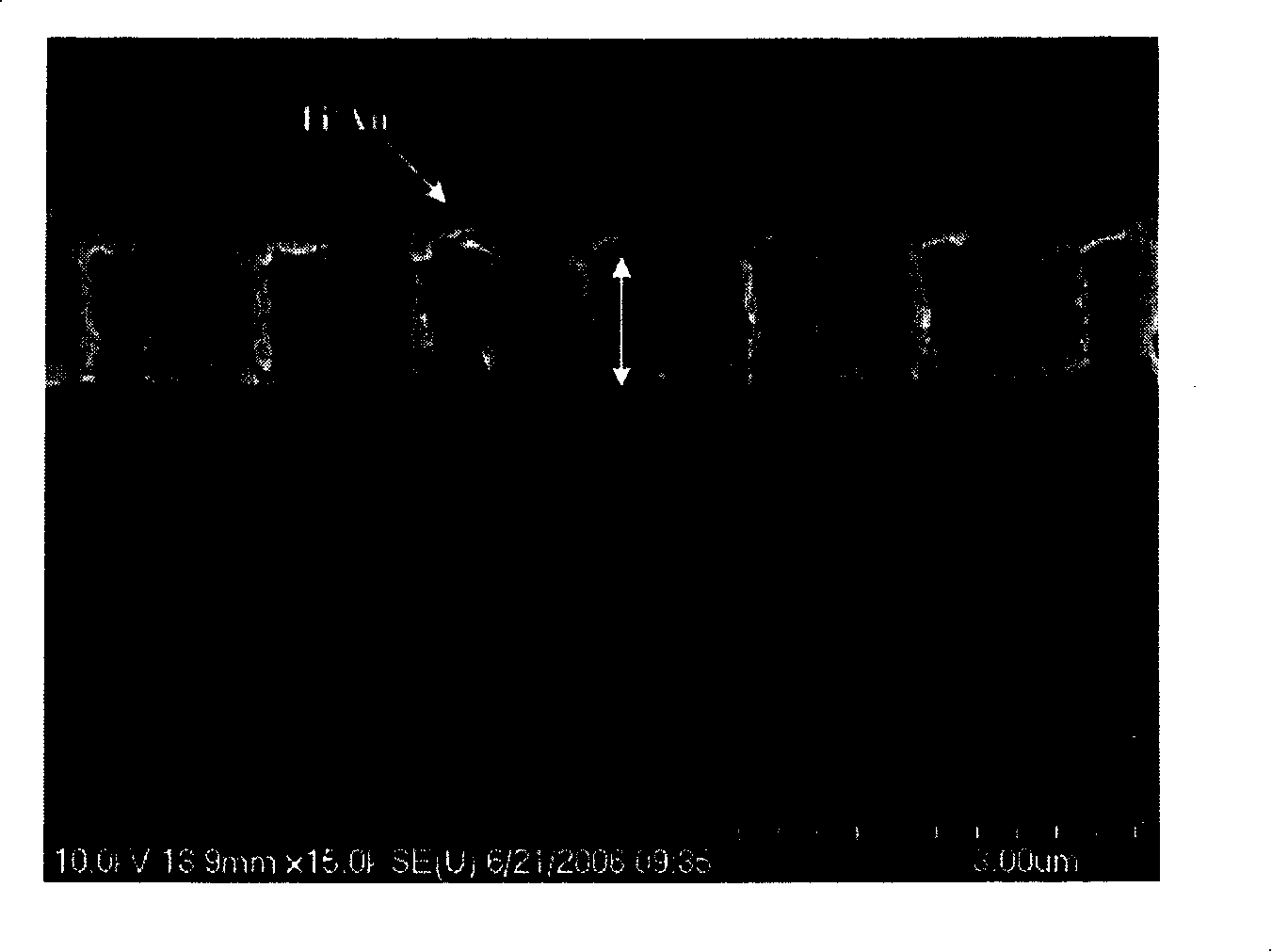

[0043] Using the method described in the summary of the invention in the specification of the invention...

Embodiment 27

[0048] Example 27.7 μm InGaAs / AlInAs / InP distributed feedback quantum cascade laser

[0049] Figure 6 It is the waveguide structure of InGaAs / InP tunable distributed feedback quantum cascade laser with laser wavelength of 7.7 μm. The active layer region includes 60 periods of "active layer + injection region" structure with a thickness of 2.66 μm. The thickness of the upper and lower active regions is 0.7μm, and the n-type doping concentration is 5×10 16 cm -3 InGaAs waveguide layer. Above the upper waveguide layer is an n-type moderately doped confinement layer InP (1-3×10 17 cm -3 , thickness 1.6μm), n-type heavily doped InP confinement layer (5×10 18 cm -3 , thickness 0.7μm), and n-type heavily doped InGaAs cap layer (2×10 19 cm -3 , thickness 0.1 μm). The substrate is moderately doped n-type InP (2×10 17 cm -3 ).

[0050] According to the same design principle and combined with numerical calculations, we designed the thickness of the heavily doped InGaAs cap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com