Method for preparing GaN basal keel type laser diode

A laser diode and ridge-type technology, which is applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of difficult control of the opening conditions of the insulating layer, and difficulty in aligning the electrode windows of the ridge-type laser diode, so as to avoid the process of plate alignment , save equipment and manpower input, and achieve regular effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

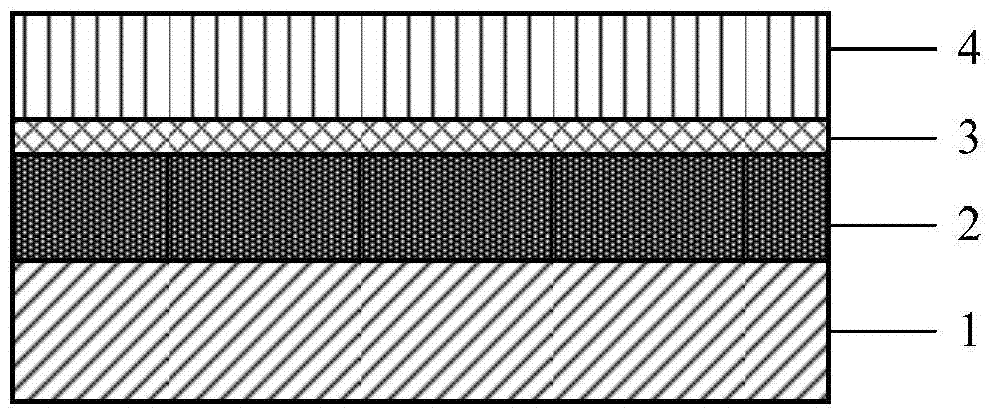

[0029] A GaN-based LD epitaxial layer 2 grown on a back-polished sapphire substrate 1, on the front of the GaN-based LD epitaxial layer 2, Ni / Au is deposited as a light-shielding layer 3 by electron beam deposition, and a photoresist is coated with a coater 4, such as Picture 1-1 shown.

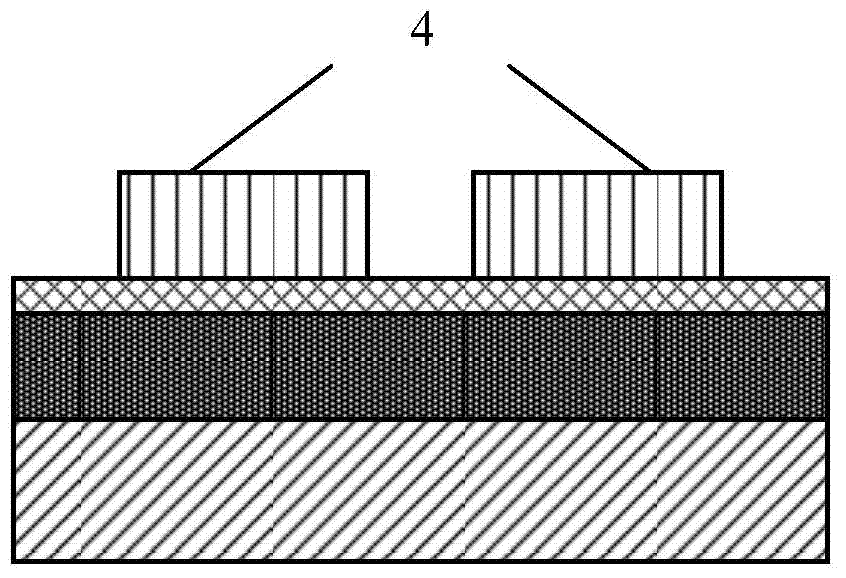

[0030] Use a ridge photolithography plate to expose, develop, and remove the base film with a plasma stripper to form a strip photoresist 4, such as Figure 1-2 shown.

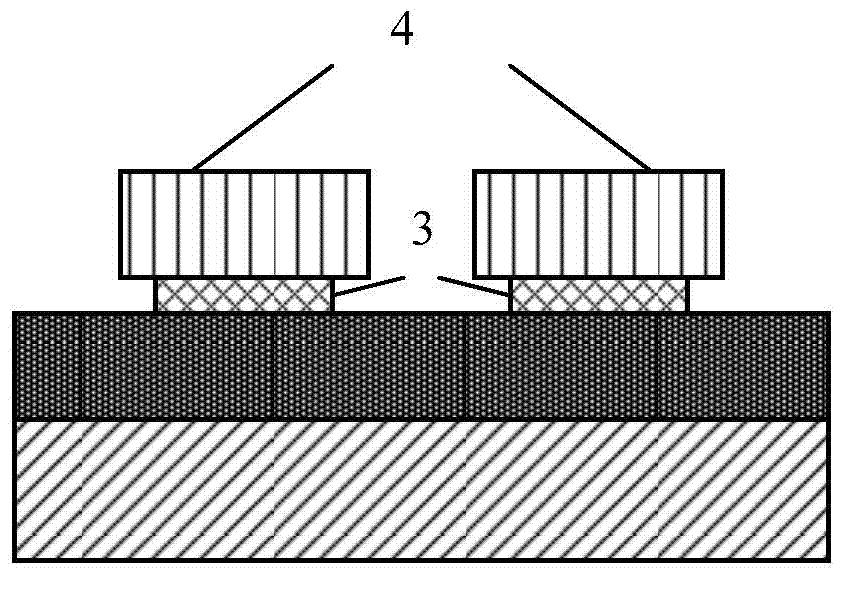

[0031] Use Ni / Au etching solution to etch the Ni / Au not protected by photoresist at room temperature, and the remaining Ni / Au light-shielding layer is strip-shaped 3, such as Figure 1-3 shown.

[0032] Use ICP to etch out the P-region ridge structure 5 of the laser diode, such as Figure 1-4 shown.

[0033] Clean the photoresist 4, and then anneal the alloy to form an ohmic contact, such as Figure 1-5 shown.

[0034] Coat the photoresist 6 with a glue leveler, use an N-type mesa photolithography plate to pass throug...

Embodiment 2

[0046] A GaN-based LD epitaxial layer 2 grown on a back-polished gallium nitride substrate, on the front side of the GaN-based LD epitaxial layer 2, Ni / Au is deposited as a light-shielding layer 3 by electron beam, and the photolithographic layer is coated with a coater Glue 4, such as diagram 2-1 shown.

[0047] Use a ridge photolithography plate to expose, develop, and remove the bottom film with a plasma stripper to form a strip photoresist, such as Figure 2-2 shown.

[0048] Use Ni / Au etching solution to etch the Ni / Au not protected by photoresist at room temperature, and the remaining Ni / Au light-shielding layer is strip-shaped 3, such as Figure 2-3 shown.

[0049] Use ICP to etch out the P-region ridge structure 5 of the laser diode, such as Figure 2-4 shown.

[0050] Clean the photoresist 4, and then anneal the alloy to form an ohmic contact, such as Figure 2-5 shown.

[0051] Apply a negative photosensitive heat-curing polyimide coating glue 10 on the epita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com