Semiconductor laser light source for emitting nanometer dimension vertical to cavity surface and method for making

A vertical cavity surface emission, nanoscale technology, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of difficult measurement and control, complex devices with high resolution in the near field or high storage density, and achieve threshold current Low density, good for integration, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

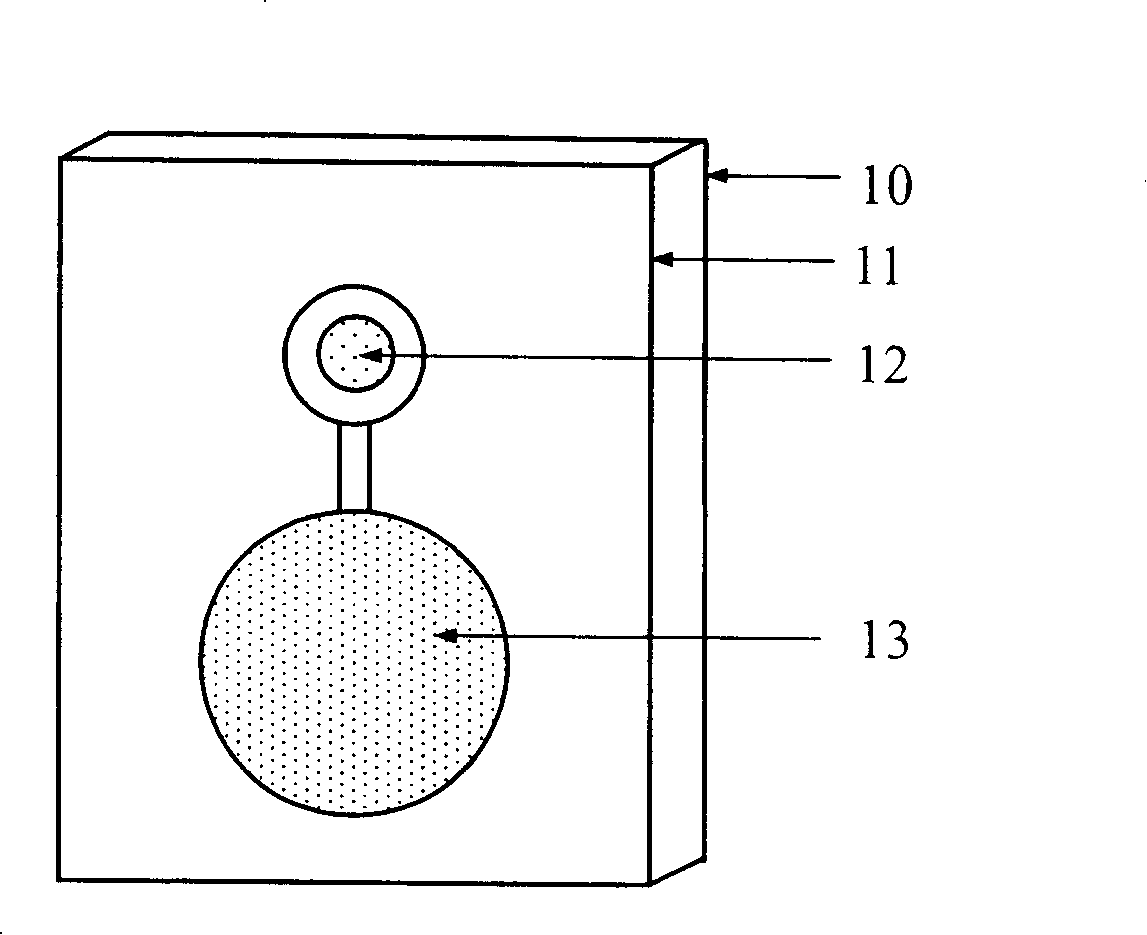

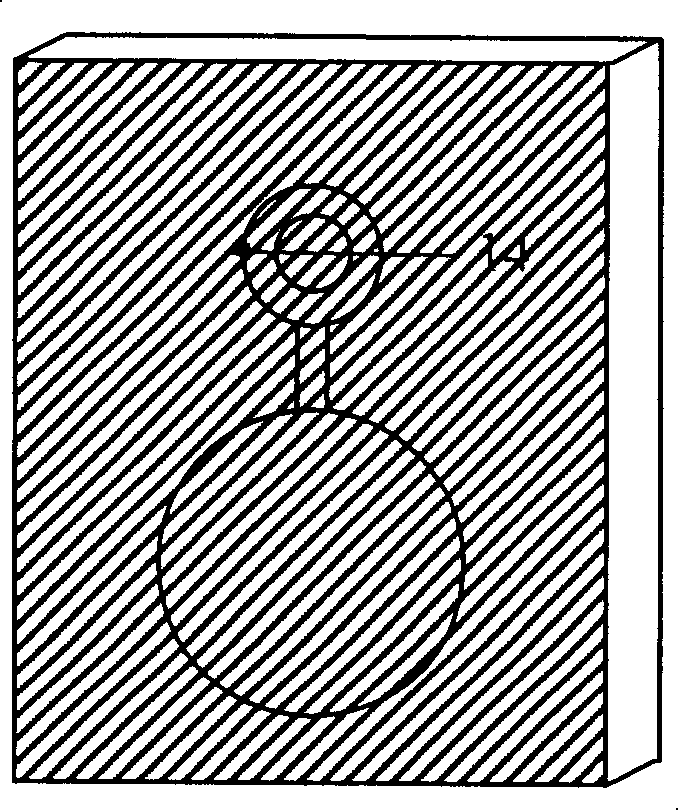

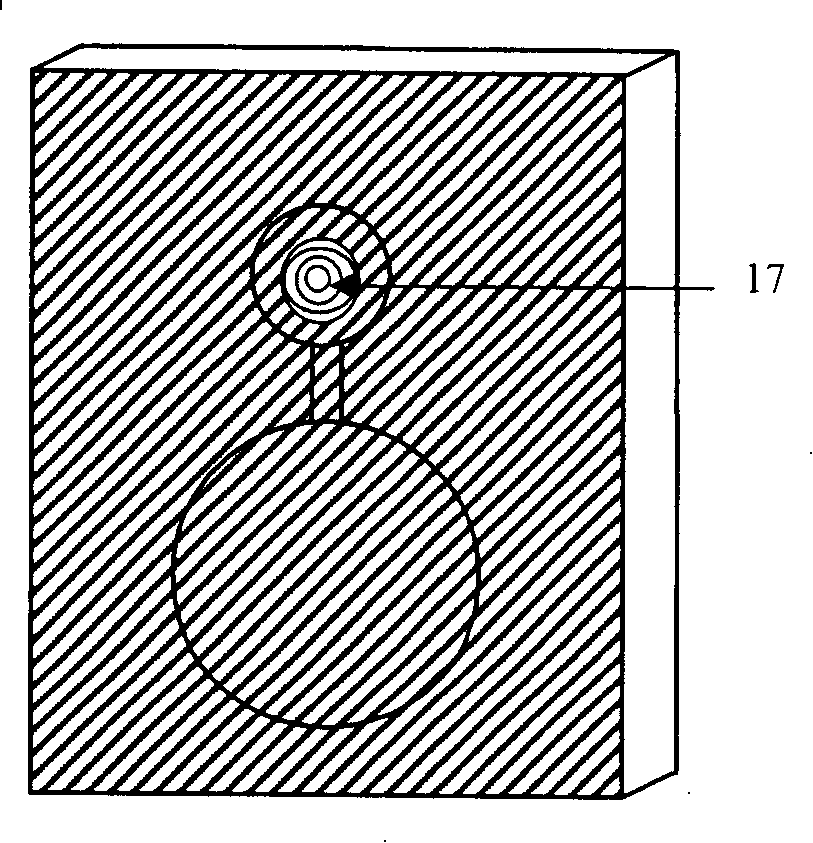

[0033] The vertical-cavity surface-emitting nanoscale semiconductor laser light source with surface plasmon modulation effect of the present invention is prepared on the basis of common vertical-cavity surface-emitting lasers. It is prepared on the basis of common vertical cavity surface emitting laser. The specific preparation process includes coating a layer of anti-reflection film on the surface of the light exit cavity of the ordinary vertical cavity surface emitting laser, making a ring and other periodic structures on the anti-reflection film medium within the range of the light exit hole, removing the insulating layer on the P surface electrode and then plating A layer of metal film, and then use the method of focused ion beam etching to prepare a small hole of sub-wavelength size on the light exit hole, confine the light in the low-loss micro-resonator cavity, make the light exit through the tiny opening, and make a ring around the small hole Equal periodic structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com