Sub-wavelength self-focusing radial polarization vertical-cavity surface-emitting laser and preparation method thereof

A vertical cavity surface emission, laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of limited application, large volume, complexity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

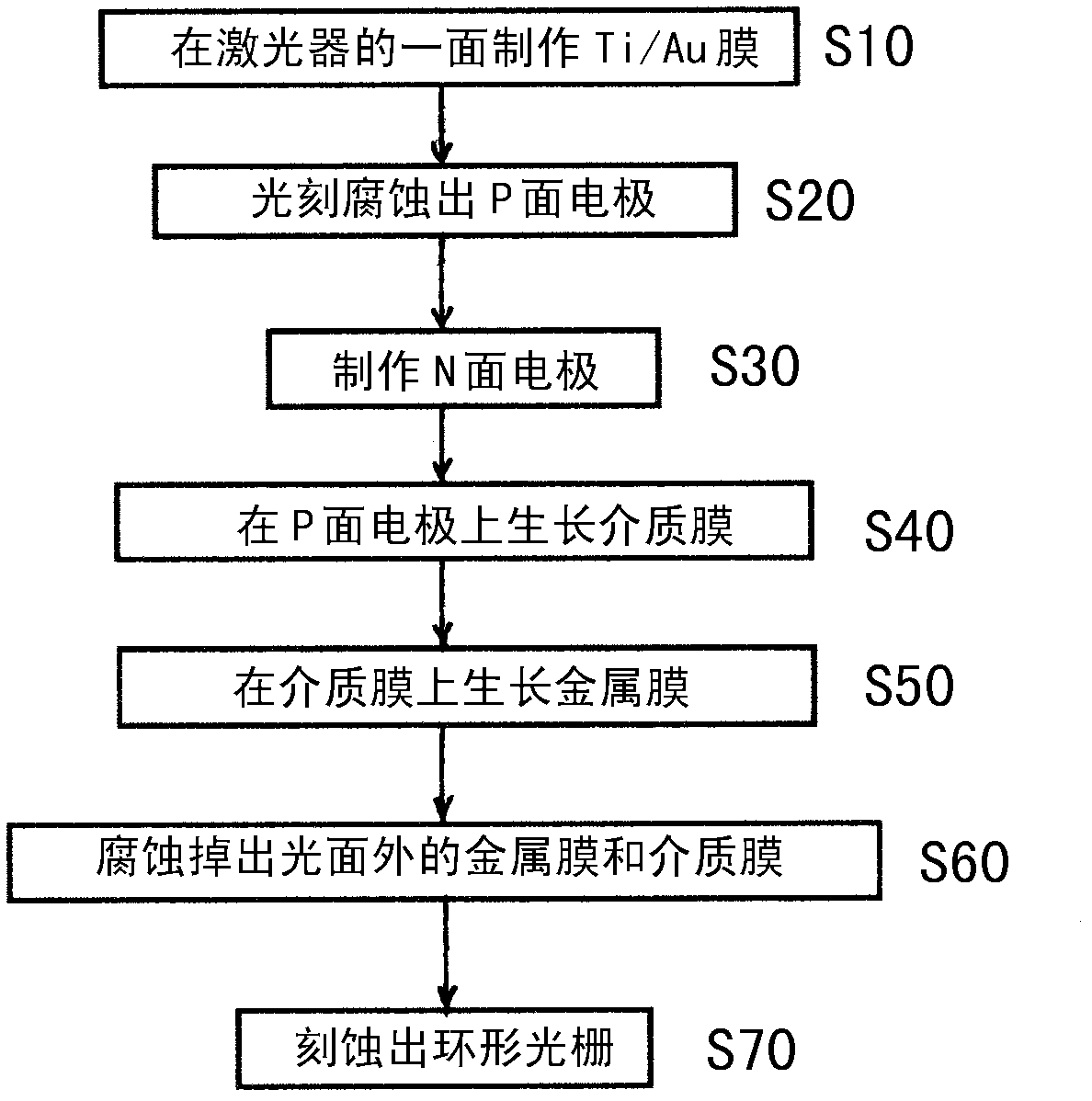

Method used

Image

Examples

Embodiment Construction

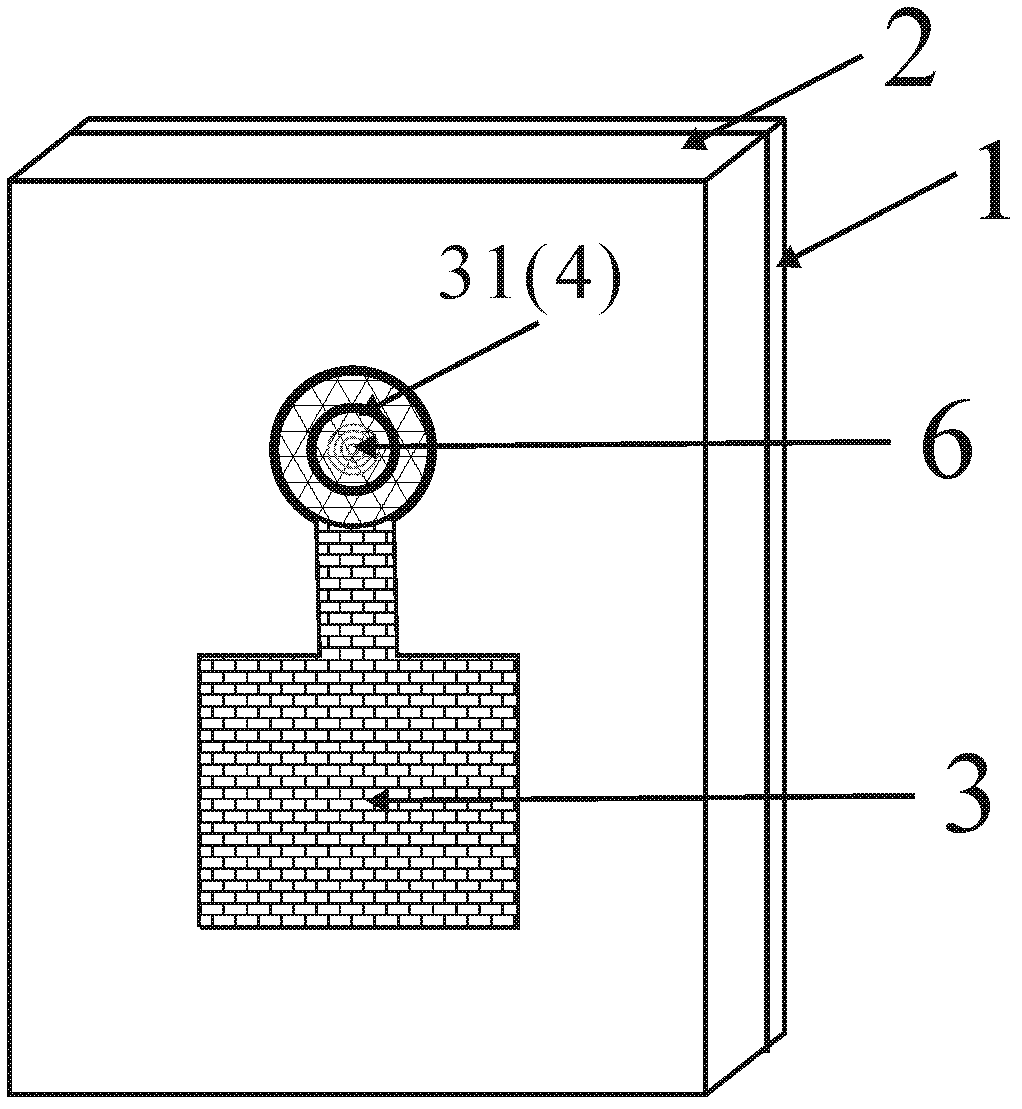

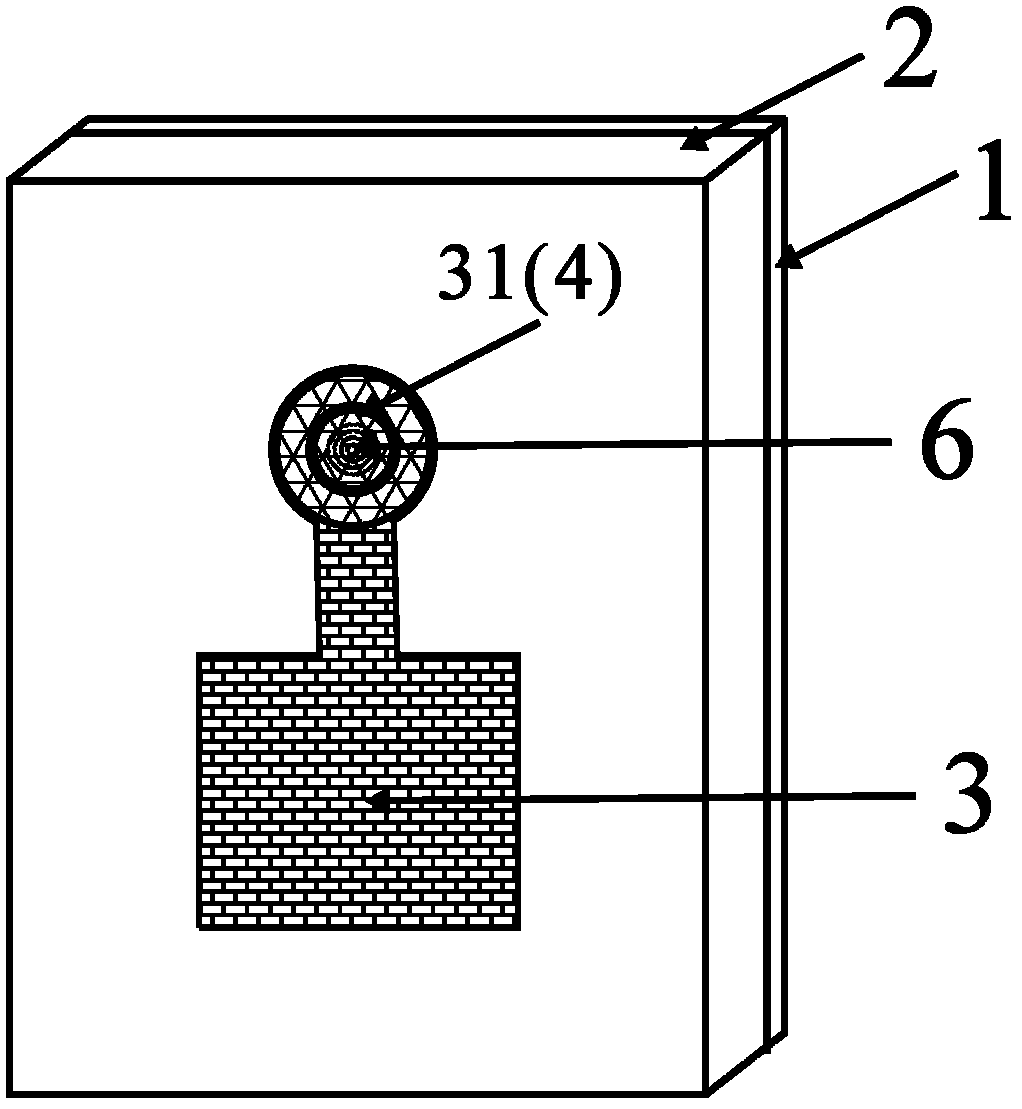

[0020] see figure 2 , the present invention provides a sub-wavelength self-focusing radially polarized vertical cavity surface emitting laser, comprising:

[0021] A vertical cavity surface-emitting laser 2, one side of which is made with a P-surface electrode 3, the middle of the annular part of the P-surface electrode 3 is a light-emitting surface 31, and the size of the electrode should be designed according to the oxidation aperture of the laser to ensure uniform current injection;

[0022] An N-surface electrode 1, the N-surface electrode 1 is fabricated on the other surface of the VCSEL 2;

[0023] A dielectric film 4, which is made on the light-emitting surface 31 of the P-face electrode 3, the material of the dielectric film 4 is SiO 2 、SiN x 、Al 2 o 3 、TiO 2 or ZrO 2 , the thickness is 1 / 4 of the laser wavelength, and the thickness of the grown dielectric film 4 can modulate the phase of the transmission electric field and enhance the laser transmission. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com