Preparation method of GaN based laser diode with naturally cleaved cavity surface

A laser diode and natural cleavage technology, which is applied in the field of GaN-based laser diode chip preparation, can solve the problems of poor electrical conductivity and difficulty in preparing natural cleavage planes, and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The technical scheme of embodiment one:

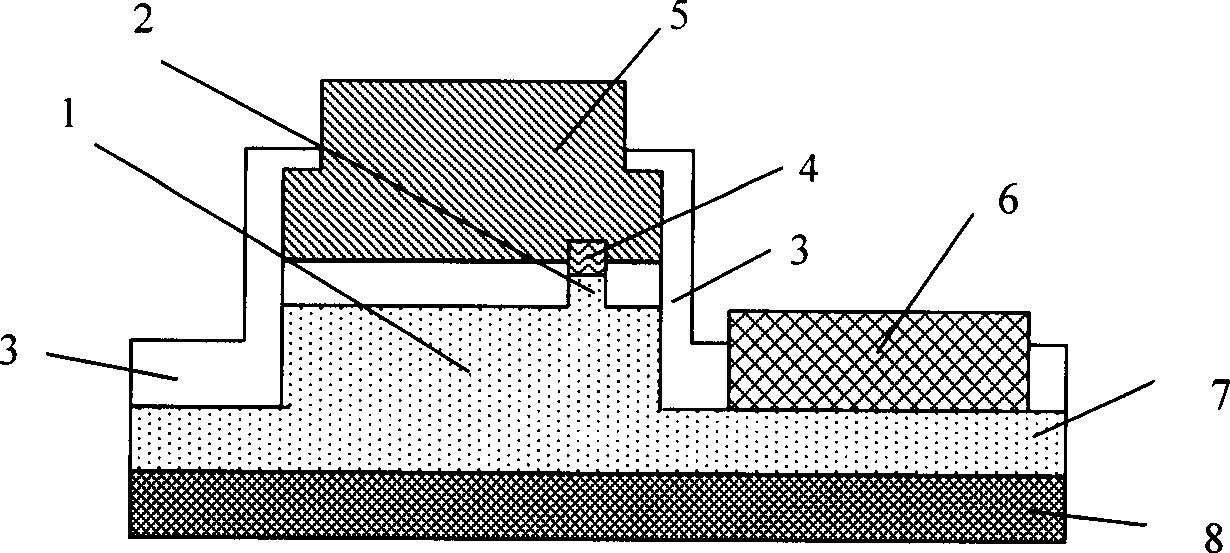

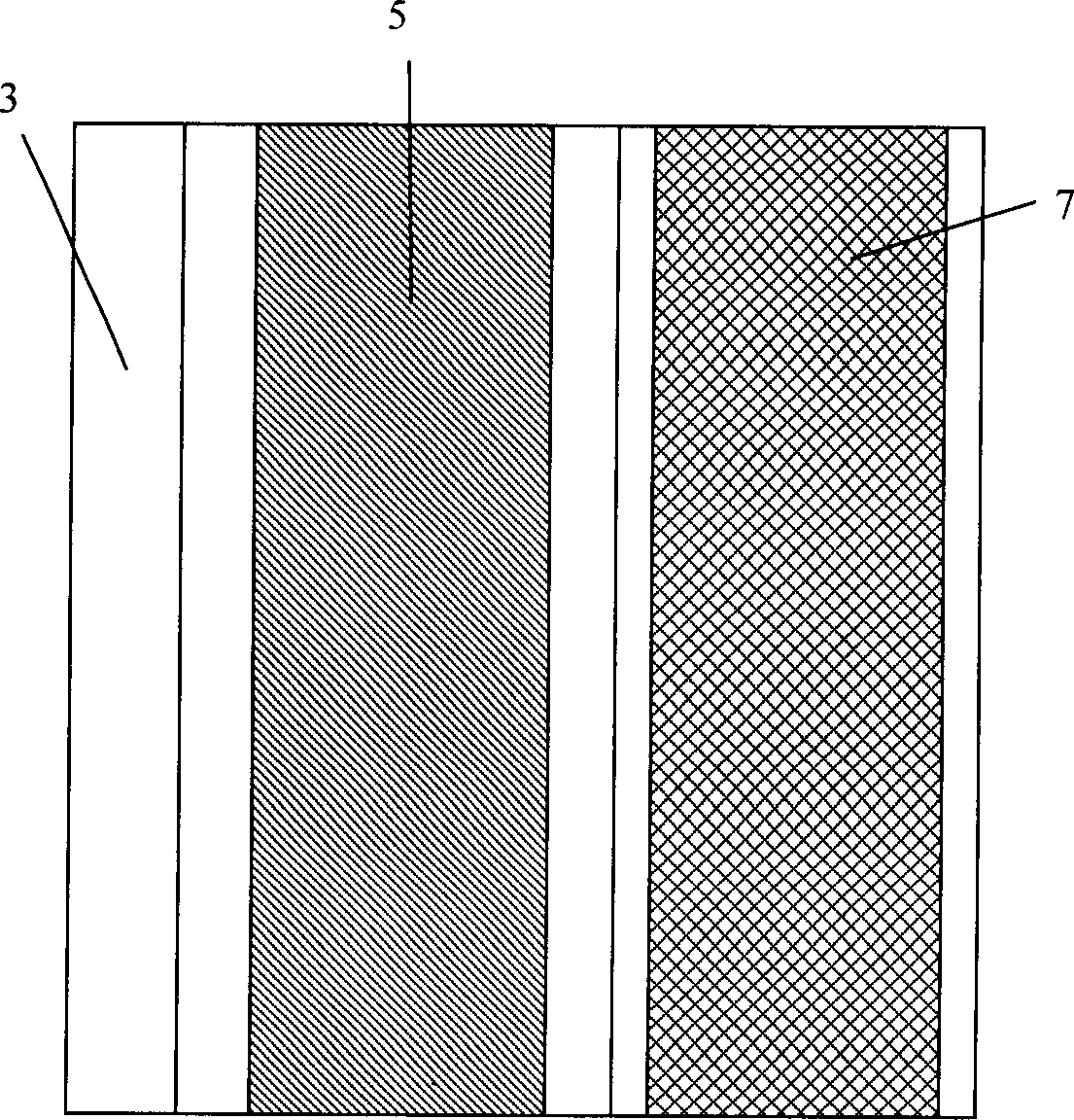

[0027] (a) On the GaN-based LD epitaxial wafer of the sapphire substrate, first etch a P-type mesa 1 with a height of 1.5 μm-2.5 μm; then etch a ridge-shaped waveguide region 2 on the P-type mesa 1 with a height of 0.2 μm-0.8 μm, deposit an oxide insulating layer 3 on the P-type mesa, and deposit a Ni / Au (20nm / 20nm) P-type ohmic contact layer 4 in it after corroding the P-type electrode window. Deposition of Au (30nm / 400nm) 5, then etch the electrode window on N-type GaN 7 and deposit N-type electrode Ti / Al / Ti / Au (30nm / 150nm / 30nm / 400nm) layer 6, 400°C under nitrogen atmosphere After one minute the alloy forms the basic structure of the laser diode, as Figure 1a and 1b ;

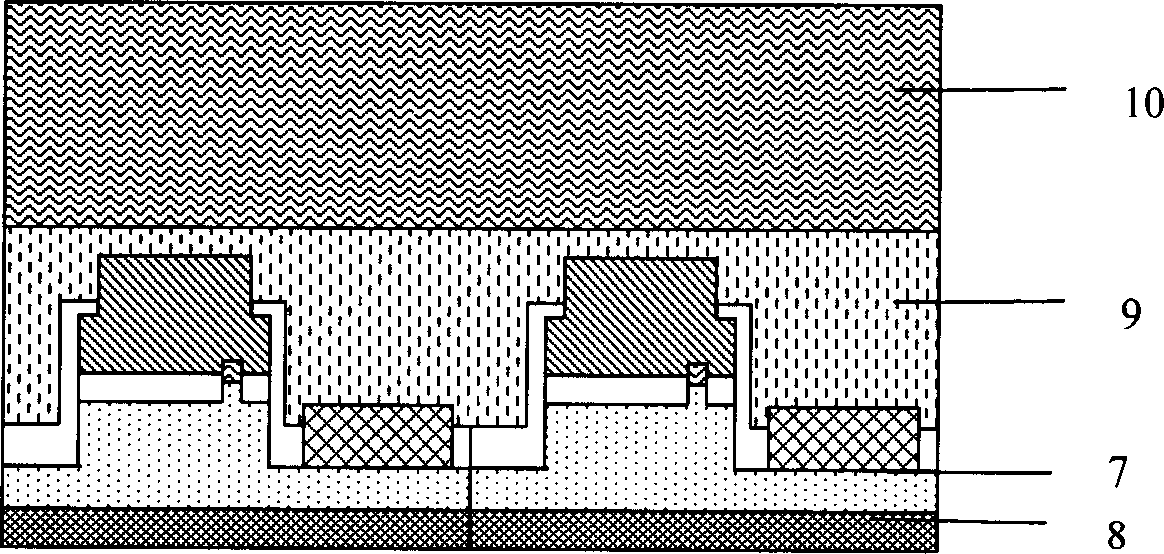

[0028] (b) Apply organic glue 9 on one side of the P-type metal thickened electrode and adhere to the cleaned Si substrate 10, then put it into a vacuum chamber to evacuate, remove air bubbles to ensure the uniformity and smoothness of bonding, as shown in F...

Embodiment approach 2

[0036] Embodiment two of the present invention are as follows (concrete steps are as Fig. 3):

[0037] (a) On the GaN-based LD epitaxial wafer of the sapphire substrate, first etch a P-type mesa 1 with a height of 1.5 μm-2.5 μm; then etch a ridge-shaped waveguide region 2 on the P-type mesa 1 with a height of 0.2 μm-0.8 μm, deposit an oxide insulating layer 3 on the P-type mesa, and deposit a Ni / Au (20nm / 20nm) P-type ohmic contact layer 4 in it after corroding the P-type electrode window. Deposition of Au (30nm / 400nm) 5, followed by alloying at 400°C for one minute under nitrogen atmosphere, as Figure 3a ;

[0038] (b) Apply organic glue 9 on one side of the P-type metal thickened electrode and adhere to the cleaned Si substrate 10, then put it into a vacuum chamber to evacuate to ensure the uniformity and firmness of the bonding, such as Figure 3b

[0039] (c) After the LD epitaxial wafer bonded to the Si wafer is irradiated by the KrF excimer laser 11, the sapphire subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com