Semiconductor laser

A laser and semiconductor technology, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve problems such as technical issues are not very clear, and achieve the effects of suppressing light absorption loss, reducing Auger loss, and decreasing threshold current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

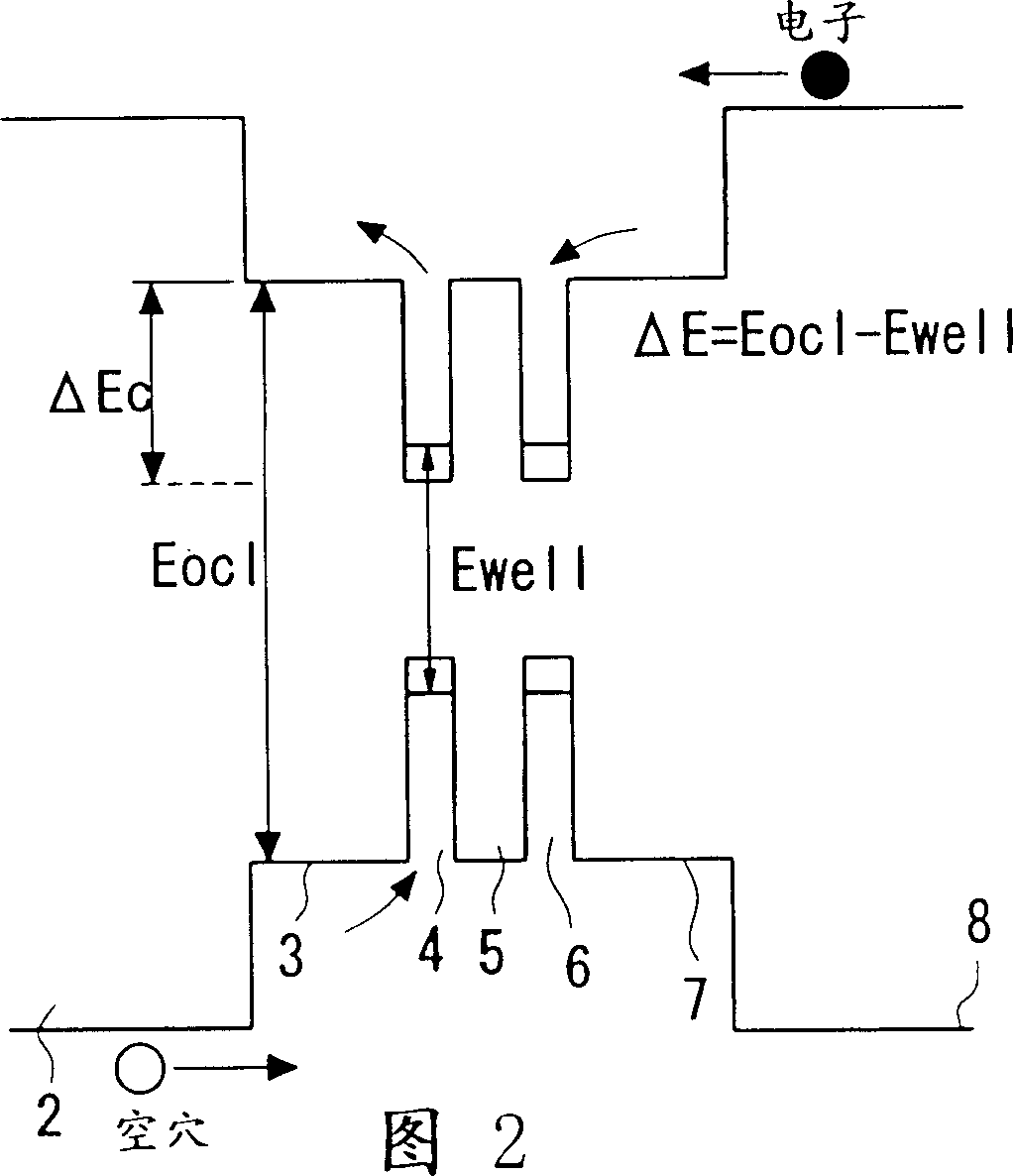

[0041] Sample B with ΔE set at 278meV has an external differential efficiency of 34.5% and a characteristic temperature of 43°K. Good laser characteristics can be obtained.

Embodiment 2

[0043] Set ΔE as sample C of 299meV, due to the large amount of strain, the film thickness of the strained quantum well is close to the critical film thickness, and the external differential efficiency is 27%. Compared with Example 1, the external differential efficiency is low, but the characteristic temperature Roughly equal. In addition, the operating temperature has less influence on the external differential efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com