AZO-coated lithium manganate cathode material for secondary lithium battery and preparation method of same

A technology for secondary batteries and cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as adverse environmental impact, price reduction, poor cycle performance, etc., to improve high-current discharge characteristics, improve high-temperature characteristics, good The effect of crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

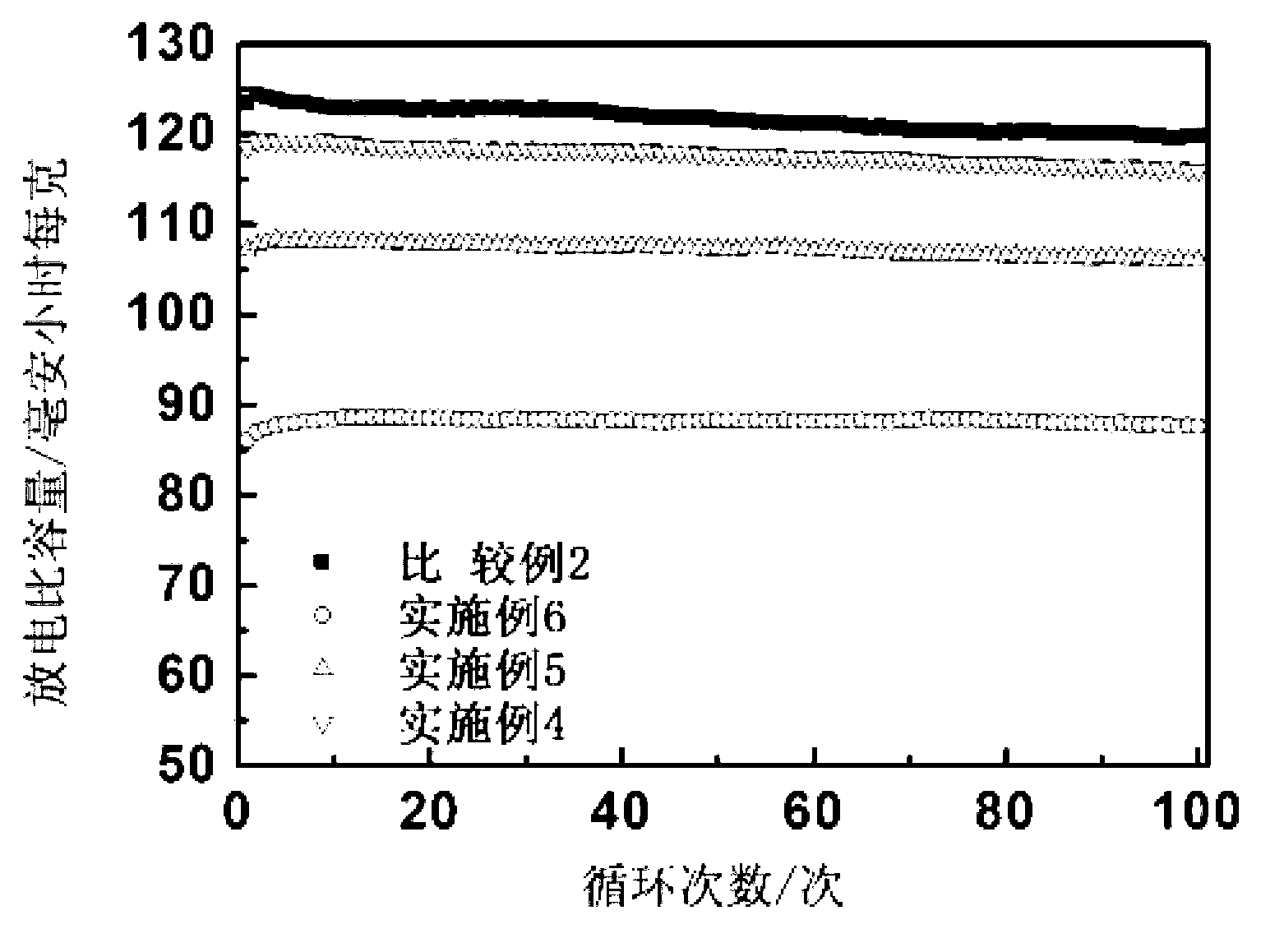

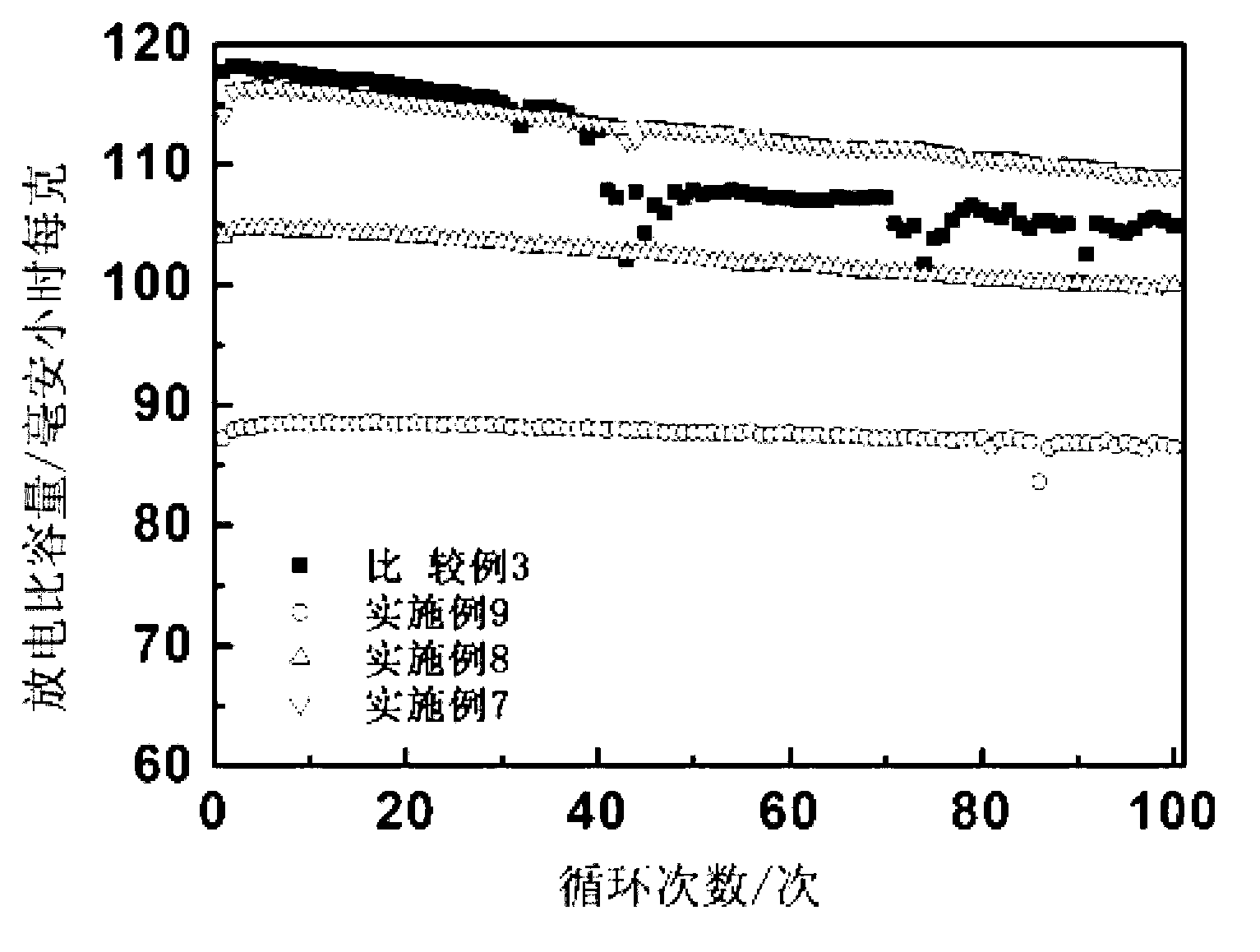

Embodiment 1

[0047] With Zn(CH 3 COO) 2 2H 2 O:LiMn 2 o 4 The mass ratio is that 0.015:1 weighs the LiMn that zinc acetate and comparative example 1 make 2 o 4 , weigh aluminum nitrate with the molar ratio of Al:Zn being 0.015:1, add zinc acetate and aluminum nitrate to a certain amount of distilled water to dissolve, add a certain amount of citric acid solution dropwise to the above solution, stir for 30min, and then add Add weighed LiMn to the above solution 2 o 4 , the mixed solution was stirred in a 70°C constant temperature water bath for 5h to obtain a precursor, the obtained precursor was dried at a constant temperature of 100°C in an air atmosphere for 12h, and the obtained powder was sintered at a constant temperature of 600°C in an air atmosphere for 8h to obtain 1.5 wt%AZO coated LiMn 2 o 4 .

Embodiment 2

[0049] With Zn(CH 3 COO) 2 2H 2 O:LiMn 2 o 4 The mass ratio is that 0.015:1 weighs the LiMn that zinc acetate and comparative example 1 make 2 o 4 , weigh aluminum nitrate with the molar ratio of Al:Zn being 0.03:1, add zinc acetate and aluminum nitrate to a certain amount of distilled water to dissolve, add a certain amount of citric acid solution dropwise to the above solution, stir for 45min, and then add Add weighed LiMn to the above solution 2 o 4 , the mixed solution was stirred in a constant temperature water bath at 80°C for 4h to obtain a precursor, the obtained precursor was dried at a constant temperature of 110°C in an air atmosphere for 12h, and the obtained powder was sintered at a constant temperature of 750°C in an air atmosphere for 7h to obtain 3.0 wt%AZO coated LiMn 2 o 4 .

Embodiment 3

[0051] With Zn(CH 3 COO) 2 2H 2 O:LiMn 2 o 4 The mass ratio is that 0.015:1 weighs the LiMn that zinc acetate and comparative example 1 make 2 o 4 , weigh aluminum nitrate with the molar ratio of Al:Zn being 0.045:1, add zinc acetate and aluminum nitrate to a certain amount of distilled water to dissolve, add a certain amount of citric acid solution dropwise to the above solution, stir for 60min, and then add Add weighed LiMn to the above solution 2 o 4 , the mixed solution was stirred in a 90°C constant temperature water bath for 3h to obtain a precursor, the obtained precursor was dried at a constant temperature of 120°C in an air atmosphere for 12h, and the obtained powder was sintered at a constant temperature of 900°C in an air atmosphere for 6h to obtain 4.5 wt%AZO coated LiMn 2 o 4 .

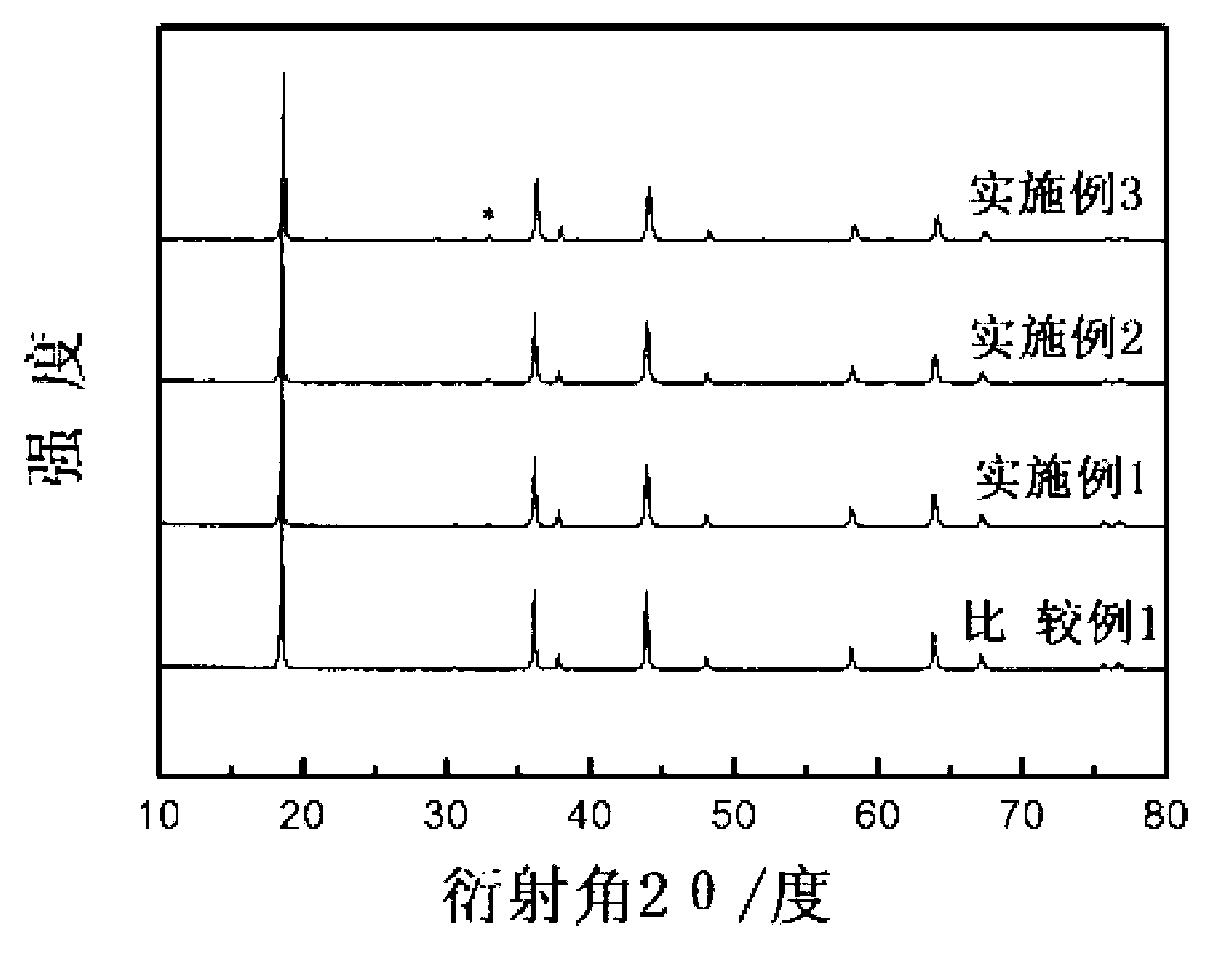

[0052] From figure 1 It can be seen that no matter it is Comparative Example 1 or Examples 1-3, the samples obtained according to our designed experimental route do not see the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com