Positive material of AZO-coated lithium nickel manganese oxide secondary lithium battery and preparation method of positive pole material

A technology for secondary batteries and positive electrode materials, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as difficulty in preparing high-purity samples, improvement of high-current cycle characteristics, etc., to improve electronic conductivity and improve high-current discharge. characteristics, the effect of improving high temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

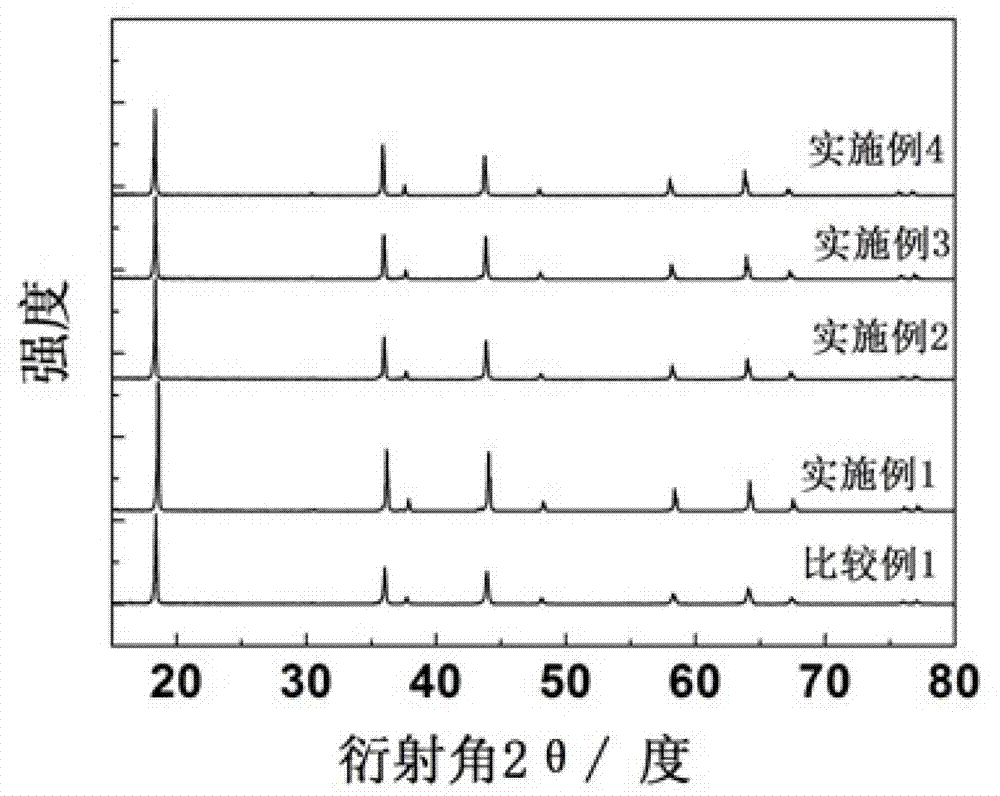

Embodiment 1

[0046] With Zn(CH 3 COO) 2 2H 2 O:LiNi 0.5 mn 1.5 o 4 The mass ratio of 0.015:1 weighs the LiNi that zinc acetate and comparative example 1 make 0.5 mn 1.5 o 4 , add zinc acetate to a certain amount of distilled water to dissolve, add a certain amount of citric acid solution dropwise to the above solution, stir for 30min, and then add weighed LiNi to the above solution 0.5 mn 1.5 o 4 , Stir the mixed solution in a constant temperature water bath at 60°C for 5h to obtain a precursor, dry the obtained precursor at a constant temperature of 100°C in an air atmosphere for 12h, pre-fire the obtained powder at a constant temperature of 500°C in an air atmosphere for 6h, and naturally After cooling, the coated LiNi 0.5 mn 1.5 o 4 , the above compound was sintered at a constant temperature of 700 °C for 10 h in an air atmosphere to obtain LiNi coated with 1.5 wt% ZnO 0.5 mn 1.5 o 4 .

Embodiment 2

[0048] With Zn(CH 3 COO) 2 2H 2 O:LiNi 0.5 mn 1.5 o 4 The mass ratio of 0.015:1 weighs the LiNi that zinc acetate and comparative example 1 make 0.5 mn 1.5 o 4 , weigh aluminum nitrate with the molar ratio of Al:Zn being 0.015:1, add zinc acetate and aluminum nitrate to a certain amount of distilled water to dissolve, add a certain amount of citric acid solution dropwise to the above solution, stir for 30min, and then add Add weighed LiNi to the above solution 0.5 mn 1.5 o 4 , the mixed solution was stirred in a 70°C constant temperature water bath for 5h to obtain a precursor, the obtained precursor was dried at a constant temperature of 100°C in an air atmosphere for 12h, and the obtained powder was pre-fired at a constant temperature of 500°C in an air atmosphere for 6h, naturally After cooling, the coated LiNi 0.5 mn 1.5 o 4 , the above compound was sintered at a constant temperature of 700 °C for 10 h in an air atmosphere to obtain LiNi coated with 1.5 wt% AZ...

Embodiment 3

[0050] With Zn(CH 3 COO) 2 2H 2 O:LiNi 0.5 mn 1.5 o 4 The mass ratio of 0.03:1 weighs the LiNi that zinc acetate and comparative example 1 make 0.5 mn 1.5 o 4 , weigh aluminum nitrate with the molar ratio of Al:Zn being 0.015:1, add zinc acetate and aluminum nitrate to a certain amount of distilled water to dissolve, add a certain amount of citric acid solution dropwise to the above solution, stir for 45min, and then add Add weighed LiNi to the above solution 0.5 mn 1.5 o 4 , Stir the mixed solution in a constant temperature water bath at 80°C for 4h to obtain a precursor, dry the obtained precursor at a constant temperature of 110°C in an air atmosphere for 12h, pre-fire the obtained powder at a constant temperature of 600°C in an air atmosphere for 5h, and naturally After cooling, the coated LiNi 0.5 mn 1.5 o 4 , the above compound was sintered at a constant temperature of 800 °C for 9 h in an air atmosphere to obtain 3wt% AZO-coated LiNi 0.5 mn 1.5 o 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com