Heat resistant steel for exhaust valve

A technology of heat-resistant steel and exhaust valve, applied in the field of heat-resistant steel, can solve the problems of poor hot workability, difficult to control texture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

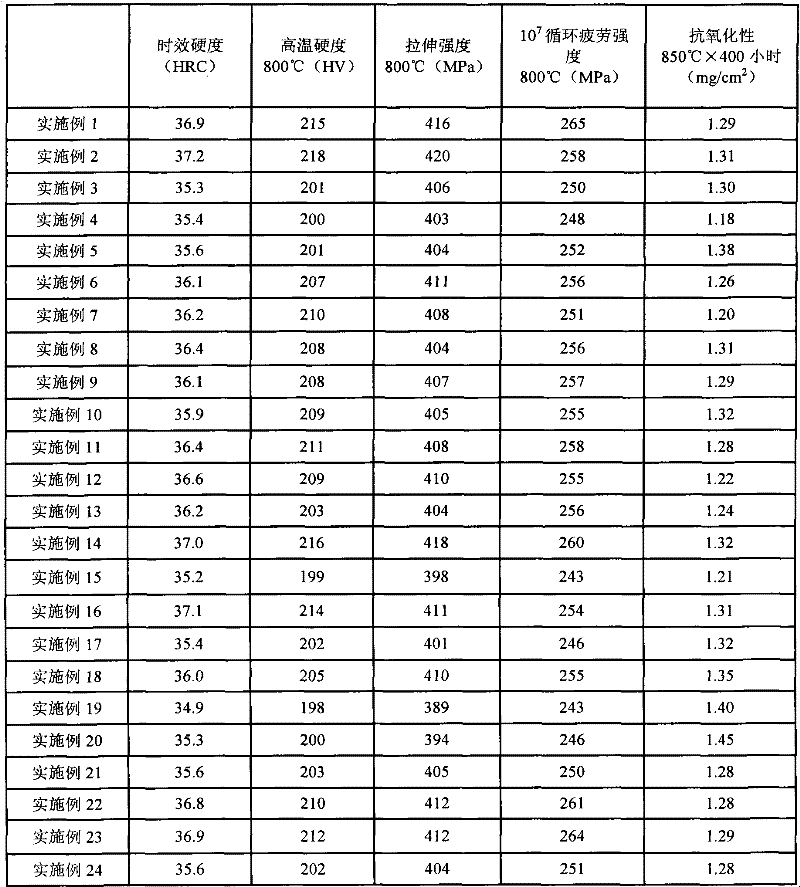

Examples

Embodiment 1 to 24 and comparative example 1 to 16

[0110] [Preparation of samples]

[0111] Each alloy having the composition shown in Tables 1 and 2 was melted in a high-frequency induction furnace to obtain a 50 kg ingot. Each ingot prepared by melting was subjected to a homogenization heat treatment at 1,180° C. for 16 hours. Then, the ingot was forged into a rod stock having a diameter of 18 mm. The forged material is further subjected to solution treatment (ST). Solution treatment at 1,050°C for 30 minutes followed by oil cooling (Examples 1 to 24), or solution treatment at 1,050°C for 30 minutes followed by oil cooling (Comparative Examples 1 to 24) 16). In addition, the material after solution treatment (ST) was subjected to aging treatment (AG) at 750° C. for 4 hours, and then air-cooled.

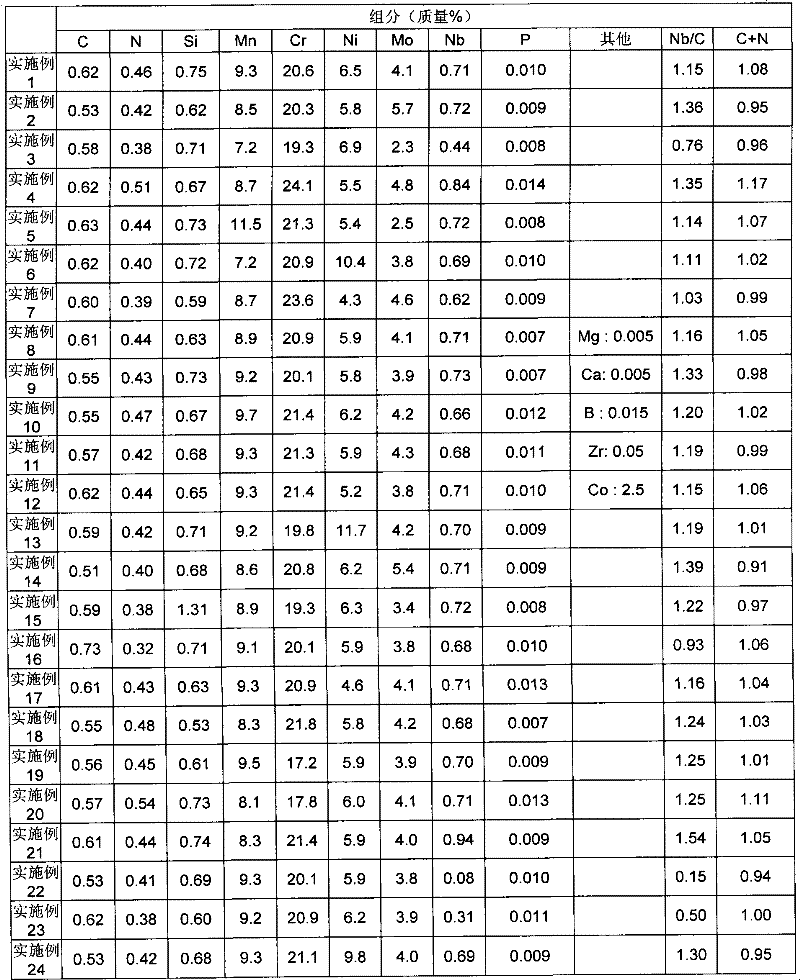

[0112] Table 1

[0113]

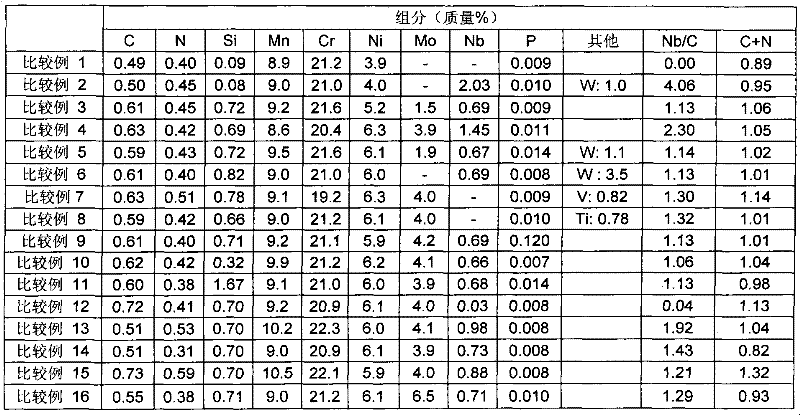

[0114] Table 2

[0115]

[0116] [2. Test method]

[0117] [2.1. Hardness]

[0118] The hardness at normal temperature was measured using the C grade of the Rockwell hardness tester. In addit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com