Super junction device and manufacturing method thereof

A super-junction device and manufacturing method technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of increasing the difficulty of process control, large deviation of breakdown voltage, and increase of filling impurity concentration, etc., to achieve Effects of improving switch and body diode characteristics, increasing N impurity concentration, and increasing N-type doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0098] The first embodiment of the present invention can obtain the following beneficial technical effects:

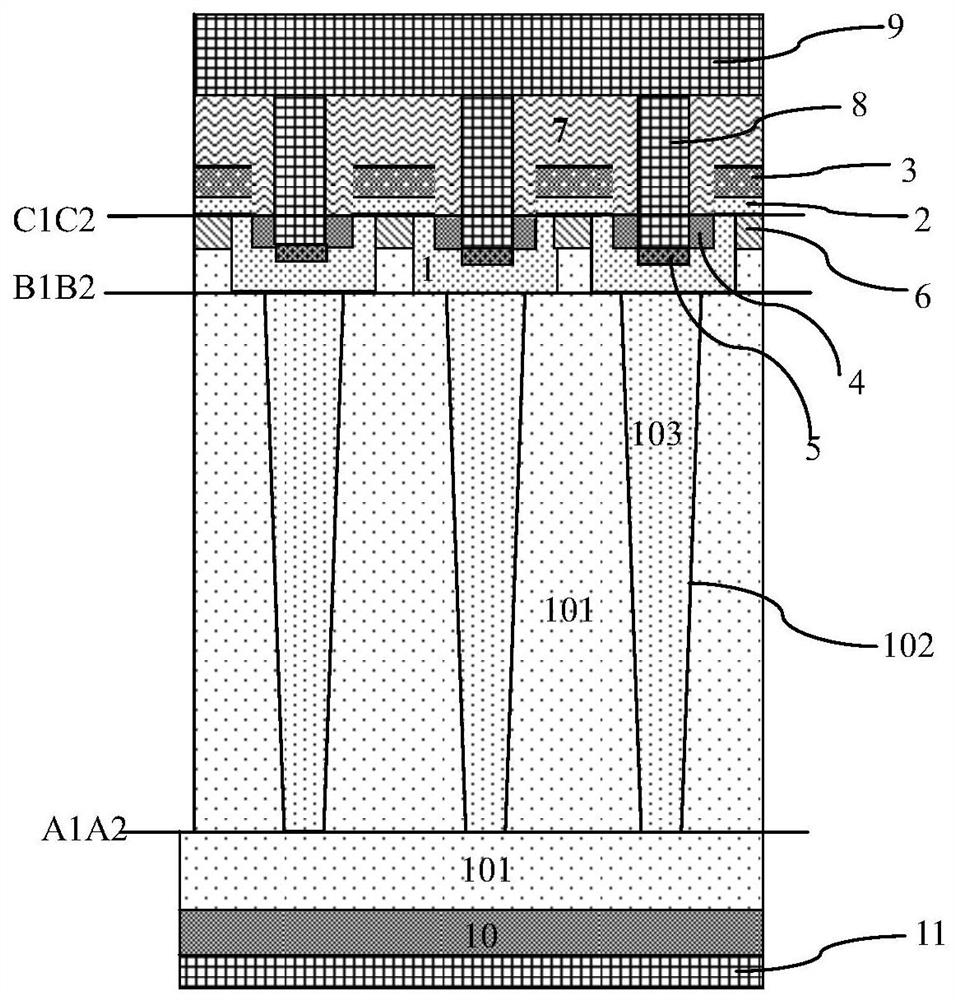

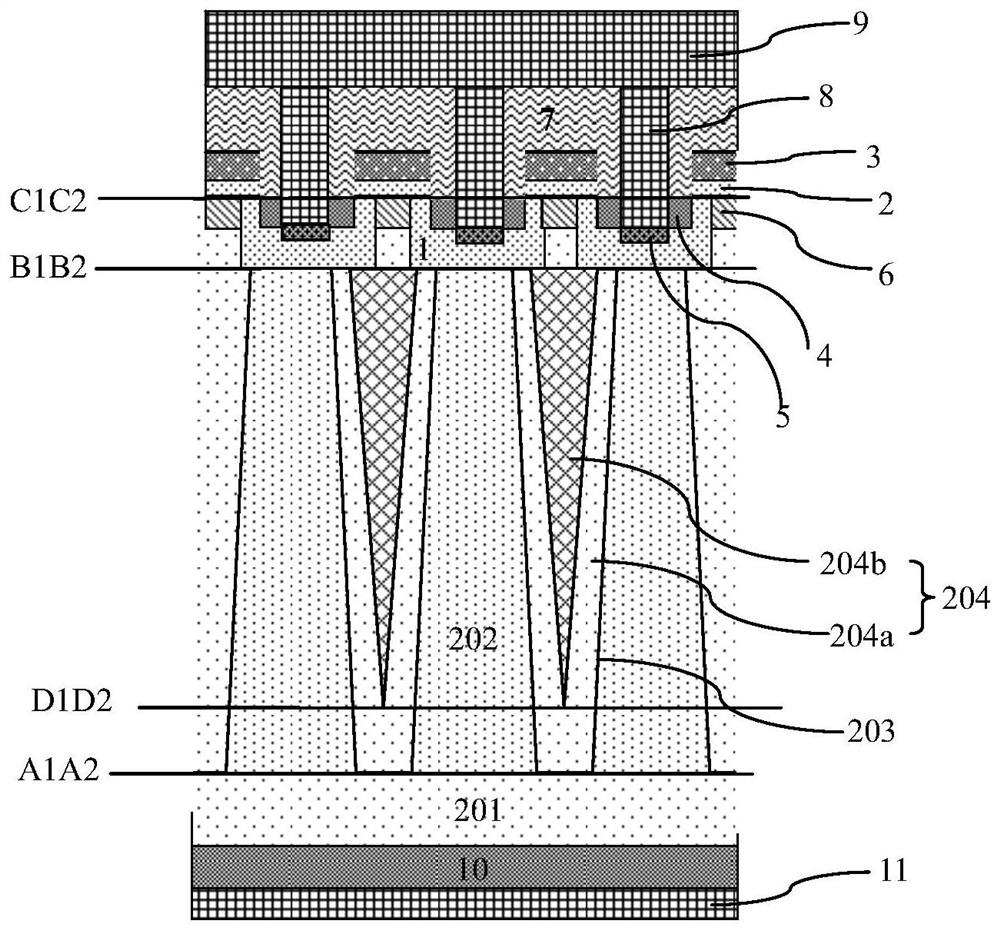

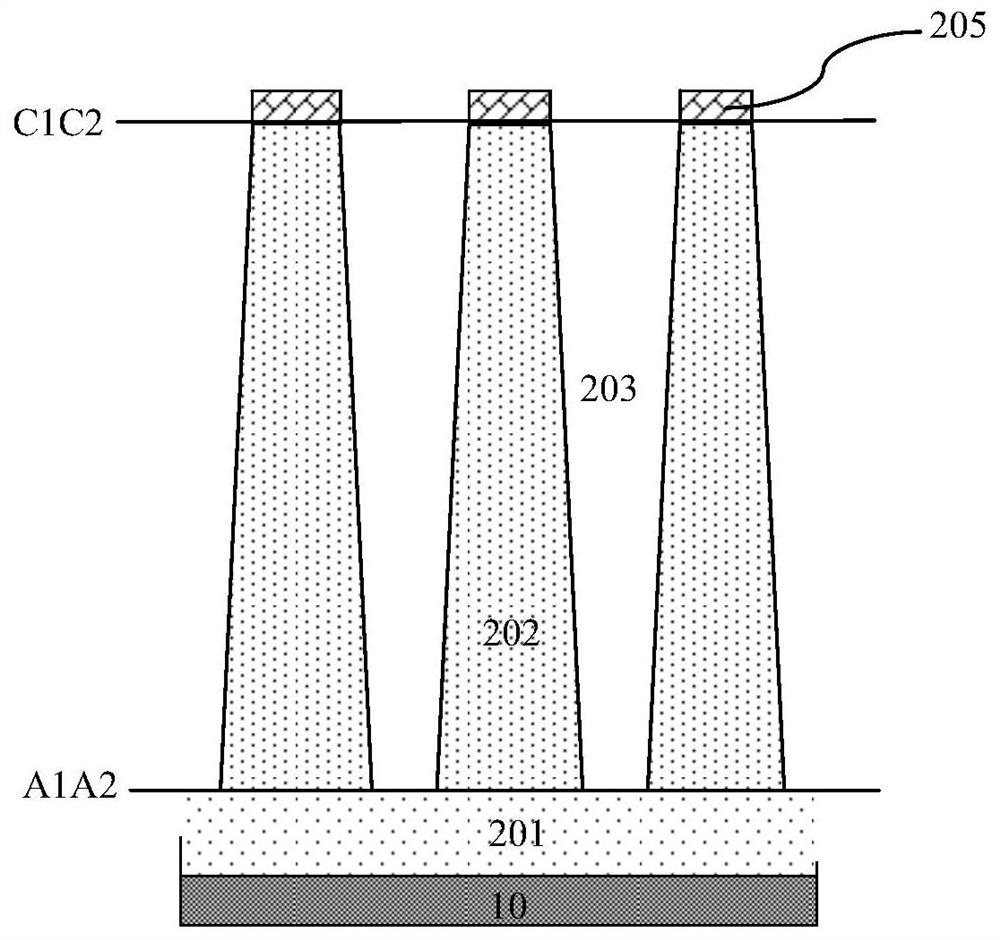

[0099] 1. In the first embodiment of the present invention, the super-junction structure is specially set from the overall structure of the super-junction device. The width of the N-type column 204 and the volume of the N-type column 204 are increased under the condition of keeping the same to reduce the specific on-resistance of the super junction device; on this basis, the first embodiment of the present invention selects the N-type with a larger width The top width of the column 204 is used as the top opening width of the trench 203, and the N-type column 204 is set to be composed of the N-type epitaxial layer filled in the trench 203, that is, the second N-type epitaxial layer, and the trench 203 is formed The epitaxial layer is a P-type epitaxial layer, that is, the first P-type epitaxial layer. Since the width of the top opening of the trench 203 is increased, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com